Construction Materials – Clay Extrusion Silo Safety- Whole Body Access & The Escape Release

This case study looks at a Clay Extrusion Silo safety and how the right interlocking solution was chosen. When designing a safeguarding solution, the best risk reduction measure is to design out risk. Whole body access is where an operator can be completely inside the safeguarded space, this can be incredibly dangerous. If there is risk of an operator becoming trapped inside a safeguarded space, make sure the space has good visibility from the point of manual reset. If this isn’t possible, mechanical measures can be considered to prevent operators becoming trapped and hazards unexpectedly restarting.

In this case study we take a look at a safeguarded entry with good visibility and how the solution is designed with ‘what if’ in mind.

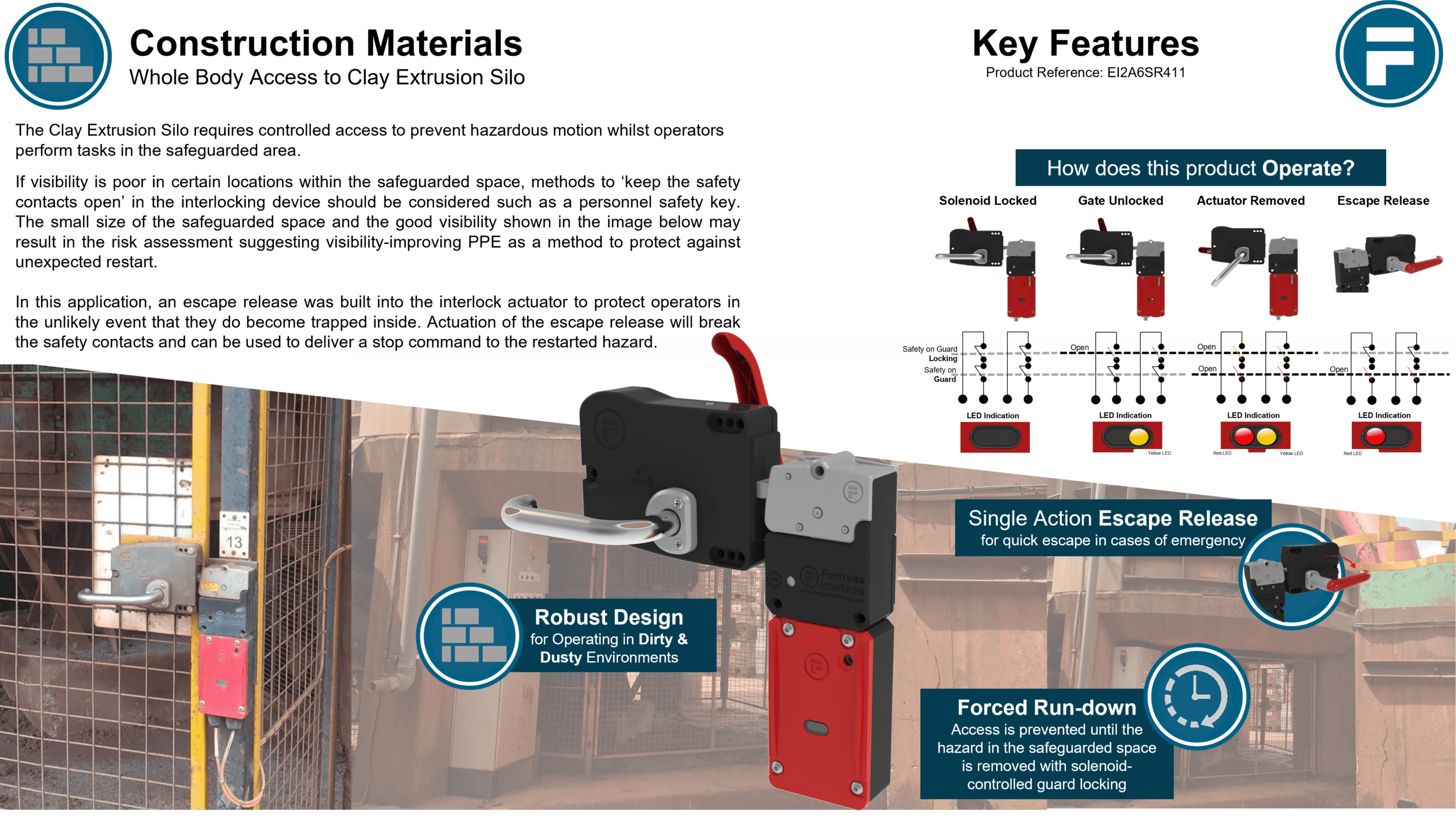

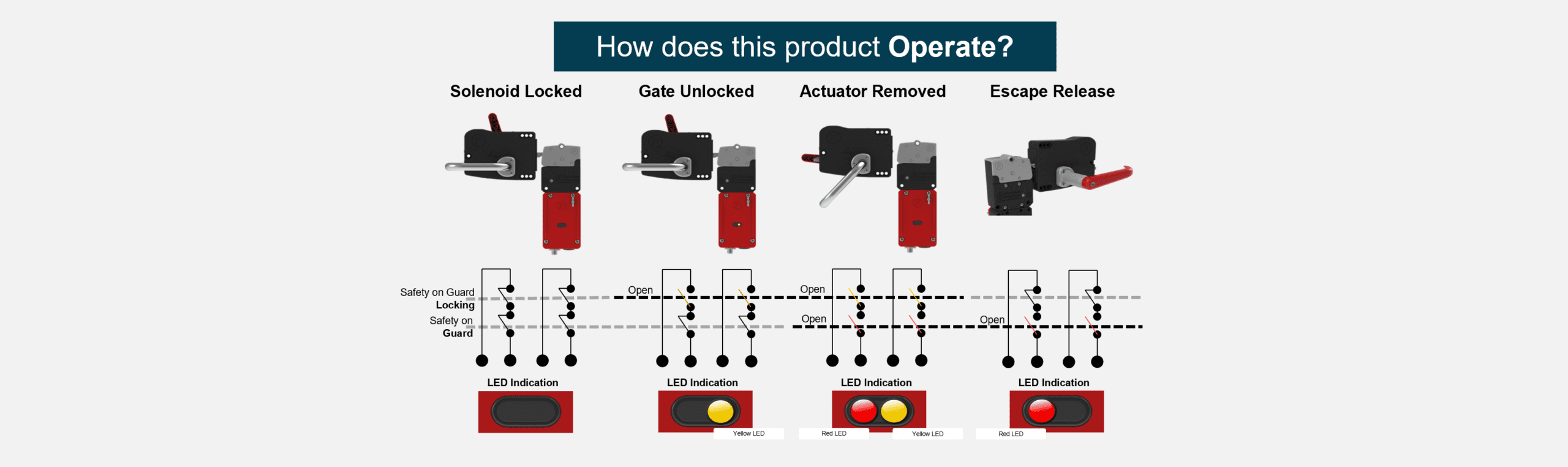

Access to The Clay Extrusion Silo is protected with an interlock with guard locking. The interlock has a solenoid which forces a run-down time before entry is allowed. When the run-down time is complete, the locking mechanism within the interlock can be ‘unlocked’ and the entry to the safeguarded space can be opened.

In this scenario, the clay extrusion silo is surrounded by a mesh fence, from which a relatively good view of inside the safeguarded space can be achieved. As the chance of being trapped inside this safeguarded space cannot be guaranteed, an escape release has been designed into the interlock actuator for quick escape in an emergency.

The Clay Extrusion Silo Safety Solution

Key Features

- Robust by Design – we design our solutions to operate and remain operable in the dirtiest & dustiest environments

- Built-in Misalignment – Fortress devices are designed with in-build misalignment to ensure they continue operating even when their mounting locations may become distorted or deformed under normal operation.

- Maximise Safety Performance – the heavy duty solution from Fortress is TUV approved for use in up to Cat. 4, SIL 3, PLe Applications.

- Single Action Escape Release – the ergonomic handle with escape release offers and easy to operated quick release method to escape safeguarded spaces in emergencies

“How could this installation have been quicker and easier?”

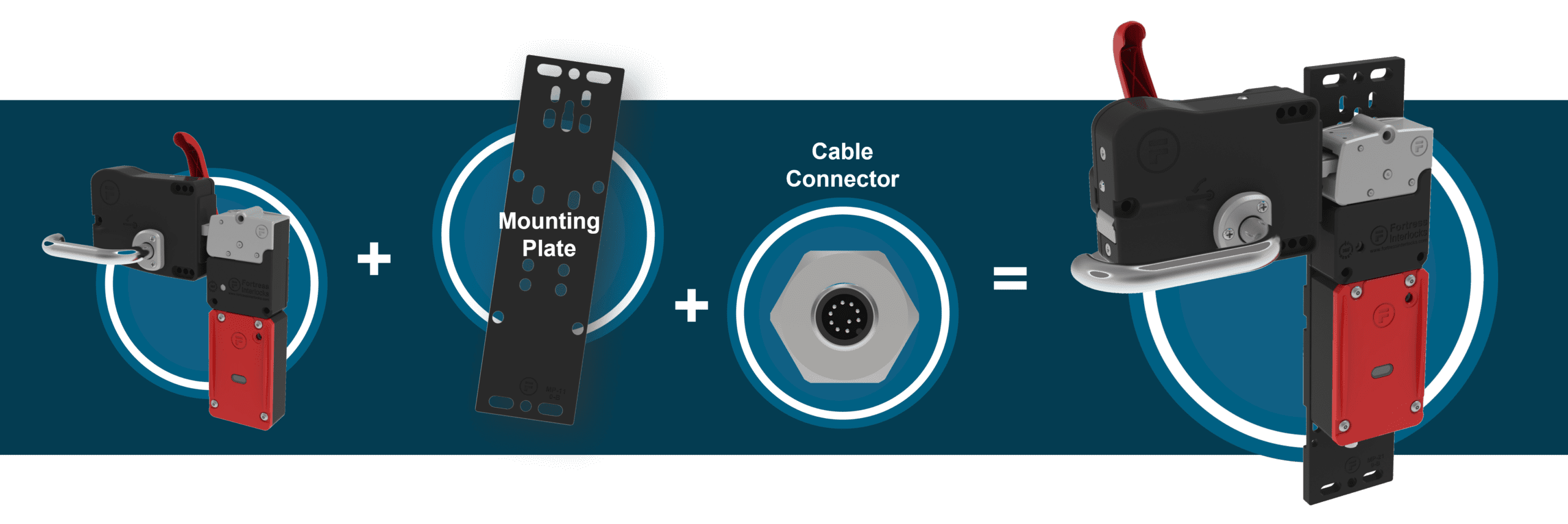

Did you know… Fortress offer standard or bespoke wiring options & mounting solutions to make your installation even easier.

Click here for more details on our entire amGardpro range of robust interlocks

Use the button below to download a PDF of this case study.