Monitored Access to Detect Guard Opening

The Heavy Duty switch is a robust solution for safe access and control of machinery.

The monitored access device is able to accept a variety of modules from the heavy duty range, enabling it to be used in many applications.

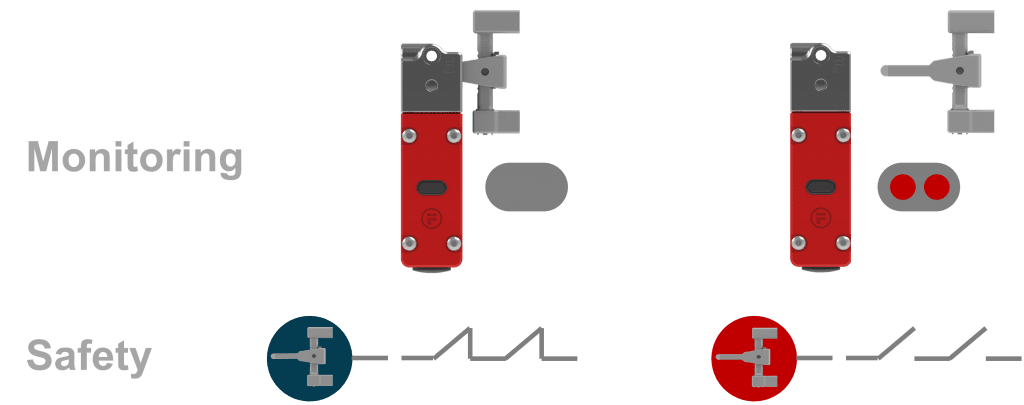

Depressing the internal plunger of the switch breaks the dual safety circuits and closes a monitoring circuit.

Dual Channel Safety on Guard – Monitored Access only Switch

- Gate Shut – monitoring switches have one pair of normally closed safety circuits and one normally open monitoring circuits. In this state the guard is shut, and contacts are closed.

- Gate Unlocked – Opening of the guard causes a machine stop command, opening the dual safety contacts. Instant indication of this state is visible via two red LEDs on the front of the product.

ST401

Non-safe Monitoring of this device is achieved with one Normally Open switch which is linked to LED illumination.

The Red LED indicates when the monitoring circuit for the Guard Opening is Closed (when accessing the safeguarded space).

Dual Channel Safety on Guard – Monitored Access with Personnel Protection

In whole body access applications, a proactive inhibit function such as a safety key can protect operators from unexpected restart. When entering the safeguarded space, the operator removes the key and pockets it, ensuring safety contacts remain open during their access.

In the operation diagram below, the dual safety contacts are broken when the key is removed from the safety lock. A forced extraction lock forces the user to physically remove the key and pull down a band to get access to the safeguarded space. Only when this band is lowered can the actuator be removed from the interlock.

Personnel Protection and the Safety Key