Rolling Mills: Hot and Cold Rolling Applications

Click on the highlighted areas below to learn more about safeguarding automated crane systems and how our Heavy-Duty Interlocking solution may benefit you.

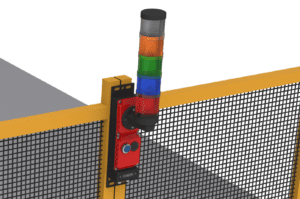

Push Button Control Devices can be configured into a multitude of designs, from vertical stacks which sit inline with upright guarding, or in a configured array which can be installed at a user-convenient location.

Fortress mounting solutions provide the flexibility to install against any flat surface. Push Button Control devices are offered with either PROFINET or EtherNet/IP protocols for non-safe communication and with PROFIsafe and CIP safety available for safety applications.

High-density non-safe I/O can be time consuming to set up and install. Long cable lengths further increase project costs.

Whether I/O is integrated or cabled externally to the I/O module, the flexibility of Fortress solutions makes connecting devices simple. Speak to our team to discuss our solutions.

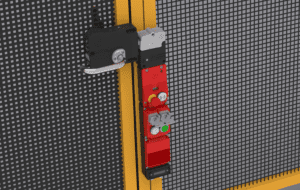

The Networked Interlocks range offers a direct communication to Ethernet/IP & CIP Safety or PROFINET & PROFIsafe based systems for industrial safety and control.

Configurability is at the heart of our solutions, allowing our partners to design solutions to their industrial requirements, from integrating external safe and non-safe I/O such as light curtains, enabling switches, or stack lights, or standard connected interlocks with push button control.

Is instant access to your Rolling Mill safe?

Most likely the answer will be no, and an interlocking solution must prevent access until it is safe to do so. In metal manufacturing environments, ‘any old interlock’ won’t cut it. Fortress design robust solenoid locking interlocks which can withstand operation in harsh industrial environments and prevent entry with up to 10,000N retention force.

Our solutions range from safety PLC controlled with direct communication via EtherNet/IP with CIP safety or PROFINET with PROFIsafe, hardwired solutions with a range of connector options or fully mechanical and sequential systems where wiring direct to the point of entry is not possible.

How do you protect operators performing whole body access in your rolling mills? Mechanical measures to prevent unexpected restart can be easily integrated within our interlocking products to keep your personnel safe at work.

Does your system require complex I/O inside the safeguarded area?

Custom I/O modules can be created bespoke for applications to combine both safe and non-safe elements into a single device.