Electrolyte Filling Machine in Battery Manufacturing

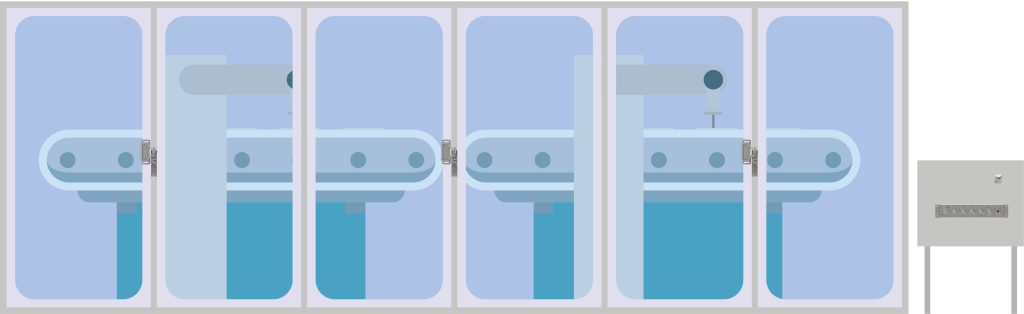

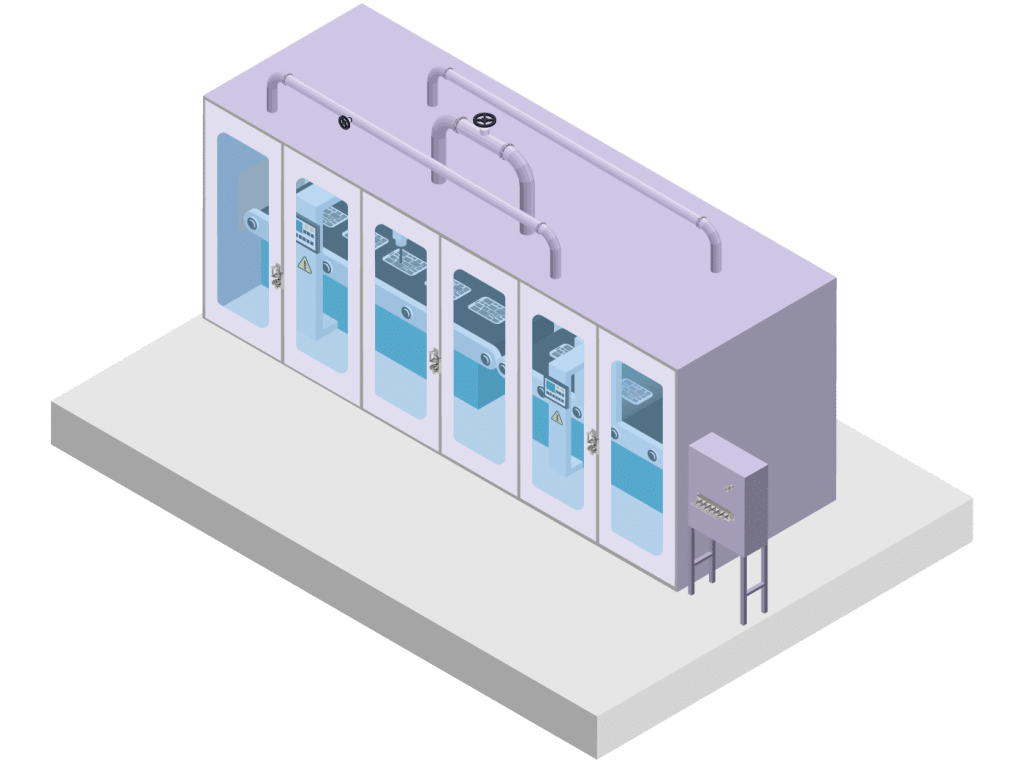

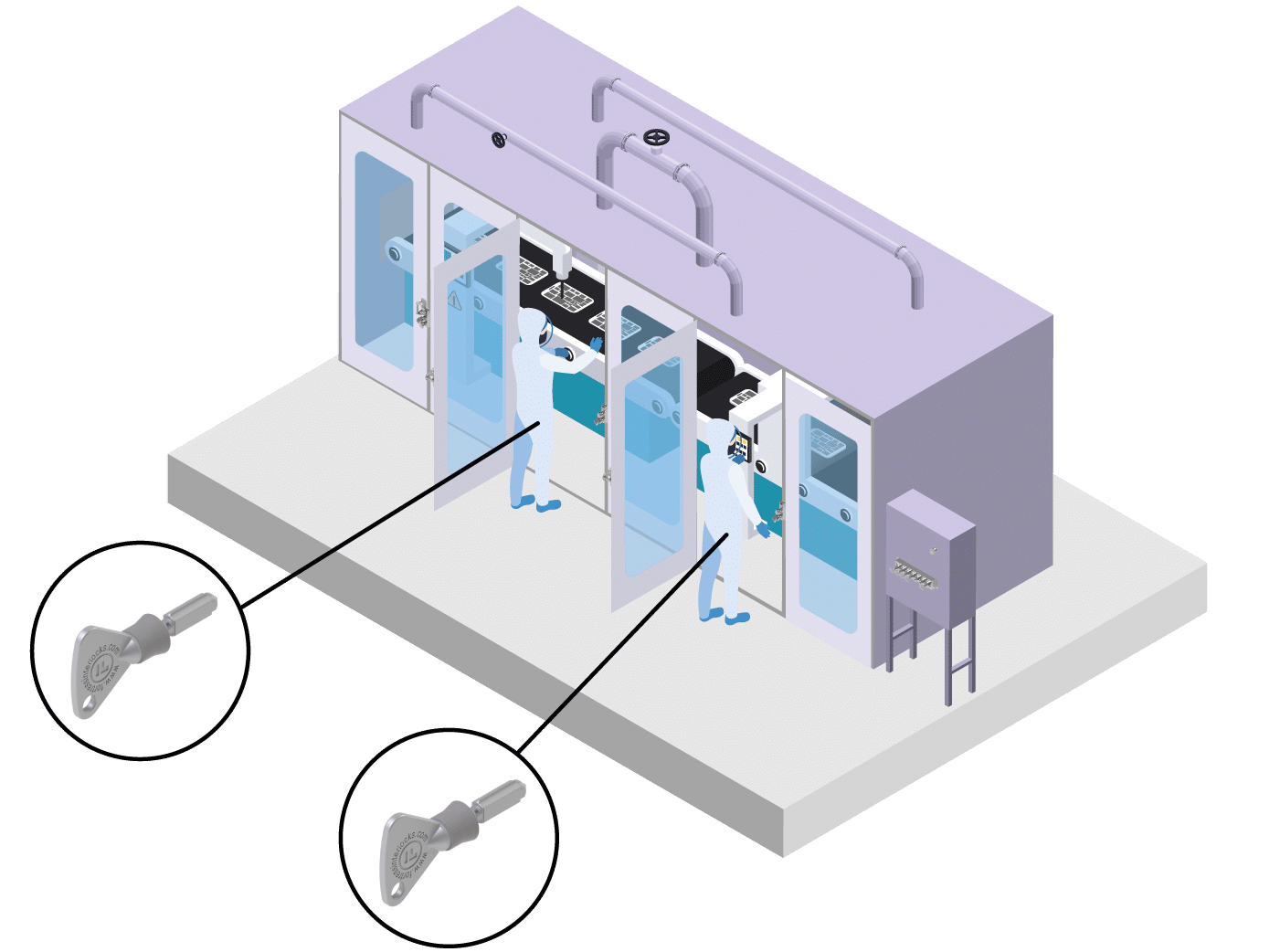

Electrolyte filling is a crucial stage in the EV battery manufacturing process. During this phase, battery cells are filled with electrolyte under vacuum using a high-precision dosing needle. Since the electrolyte can react with moisture to form corrosive by-products, it is essential to maintain dry ambient air during the filling process. The machine itself is large and includes several movable guards that provide access to its different sections.

The Challenge

There is a risk of electrolyte leakage, and operators might need to inspect and maintain the machine. It is important to prevent anyone from getting trapped, either by preventing the movable guard(s) from closing or by having an escape release. However, in this case drilling a hole through the guard could potentially lead to leakage of flammable gases.

The Solution

Trapped Keys and Stainless Steel

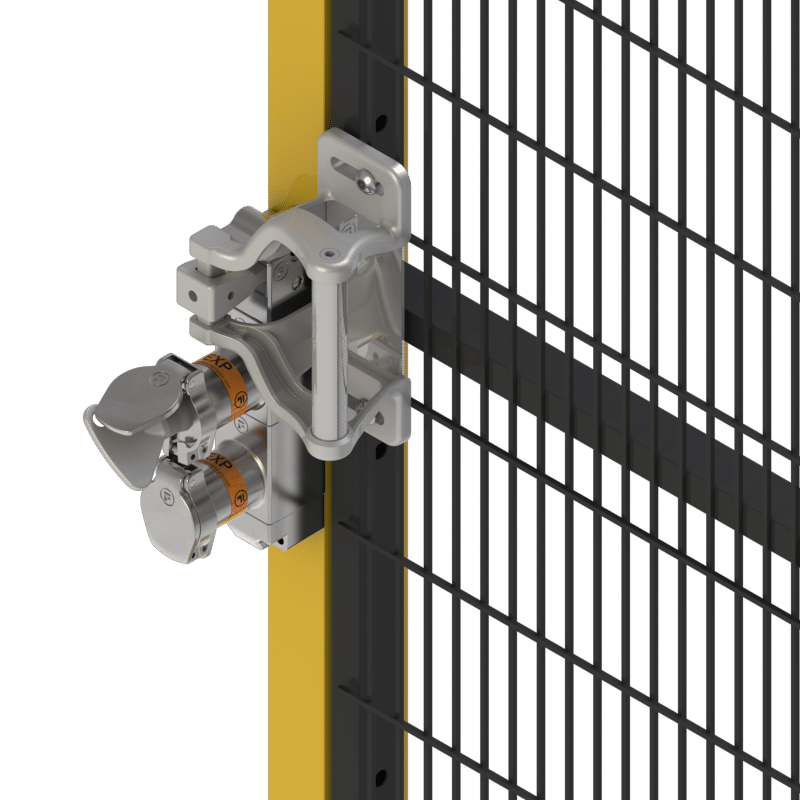

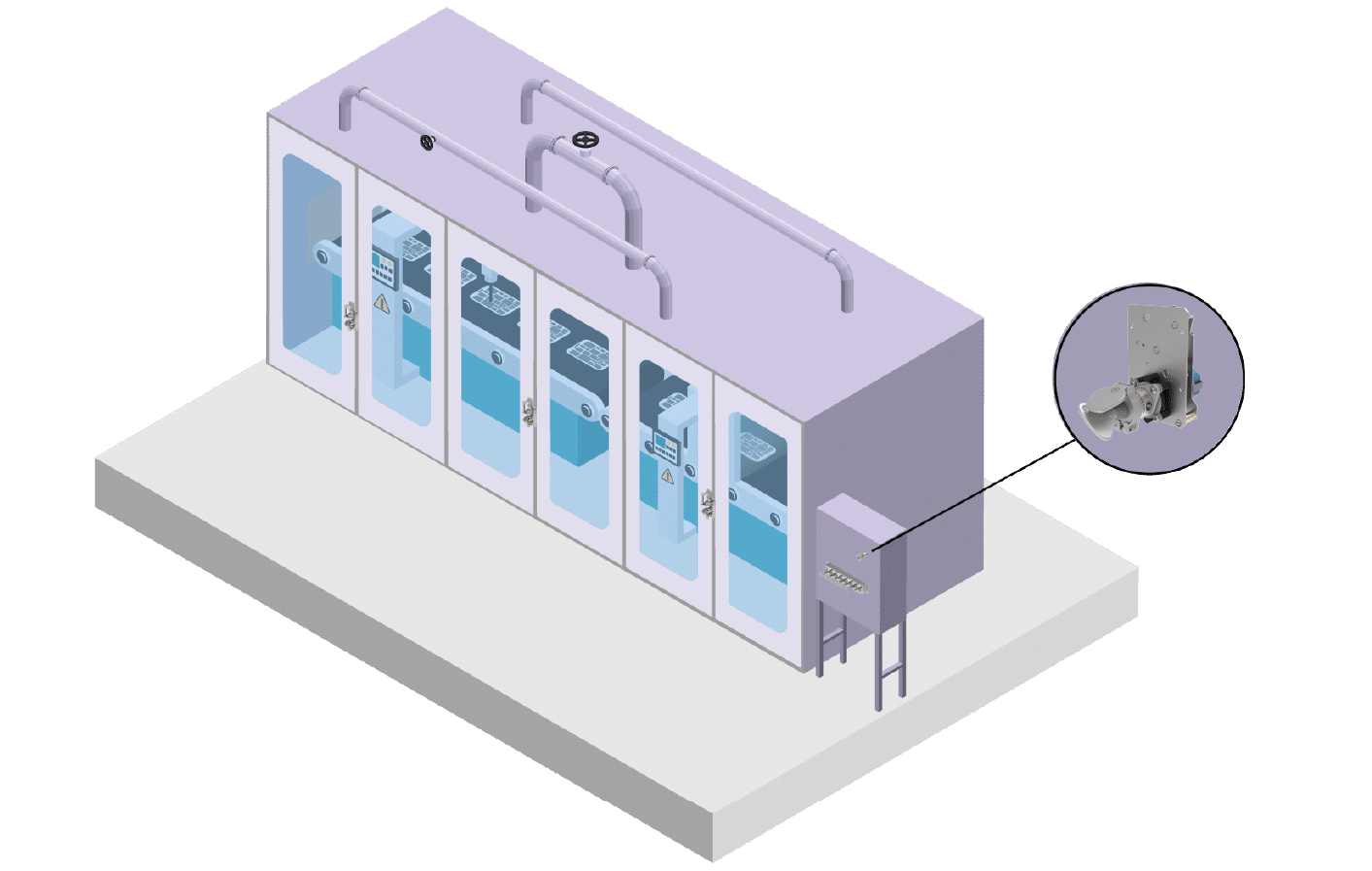

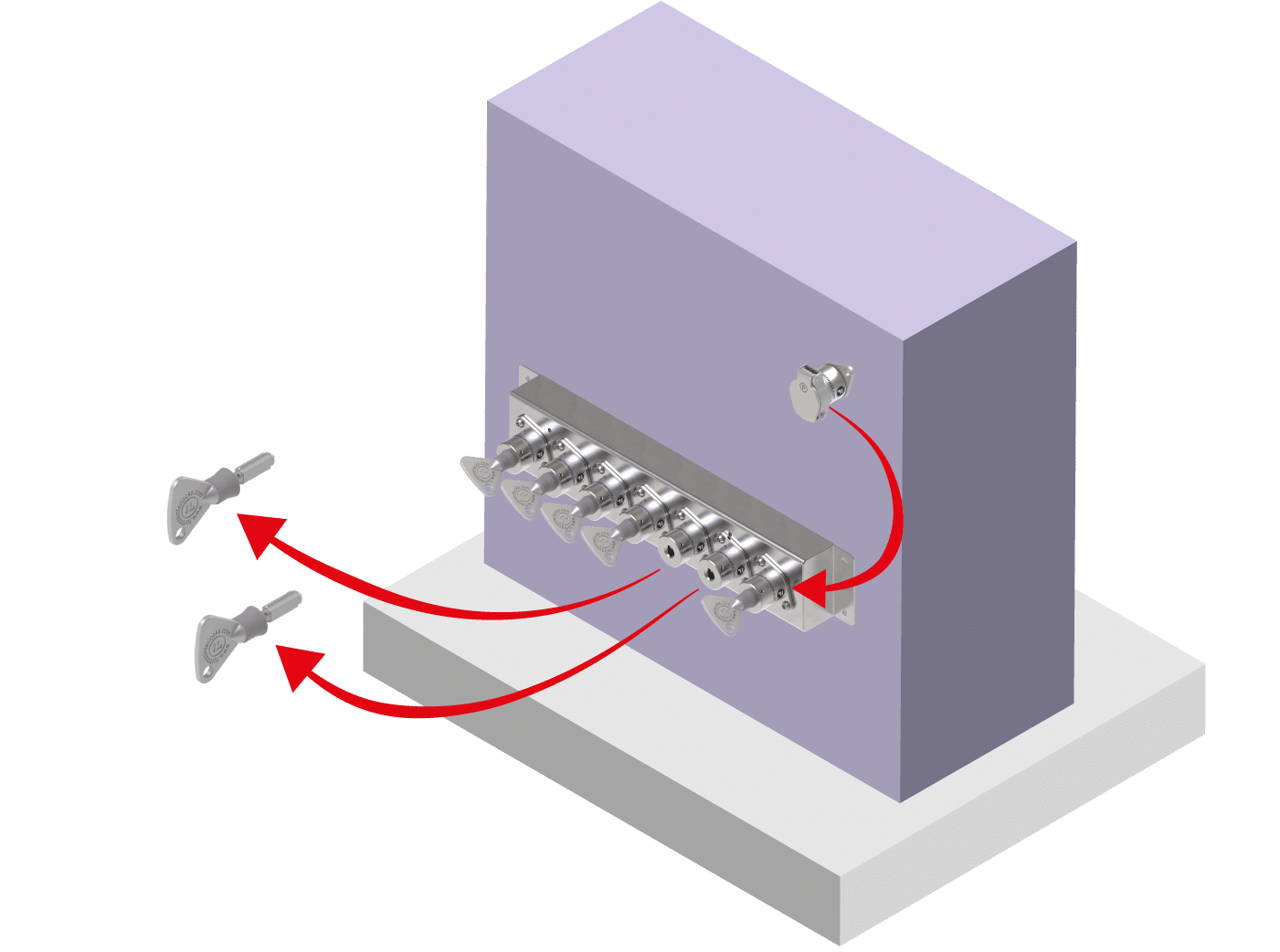

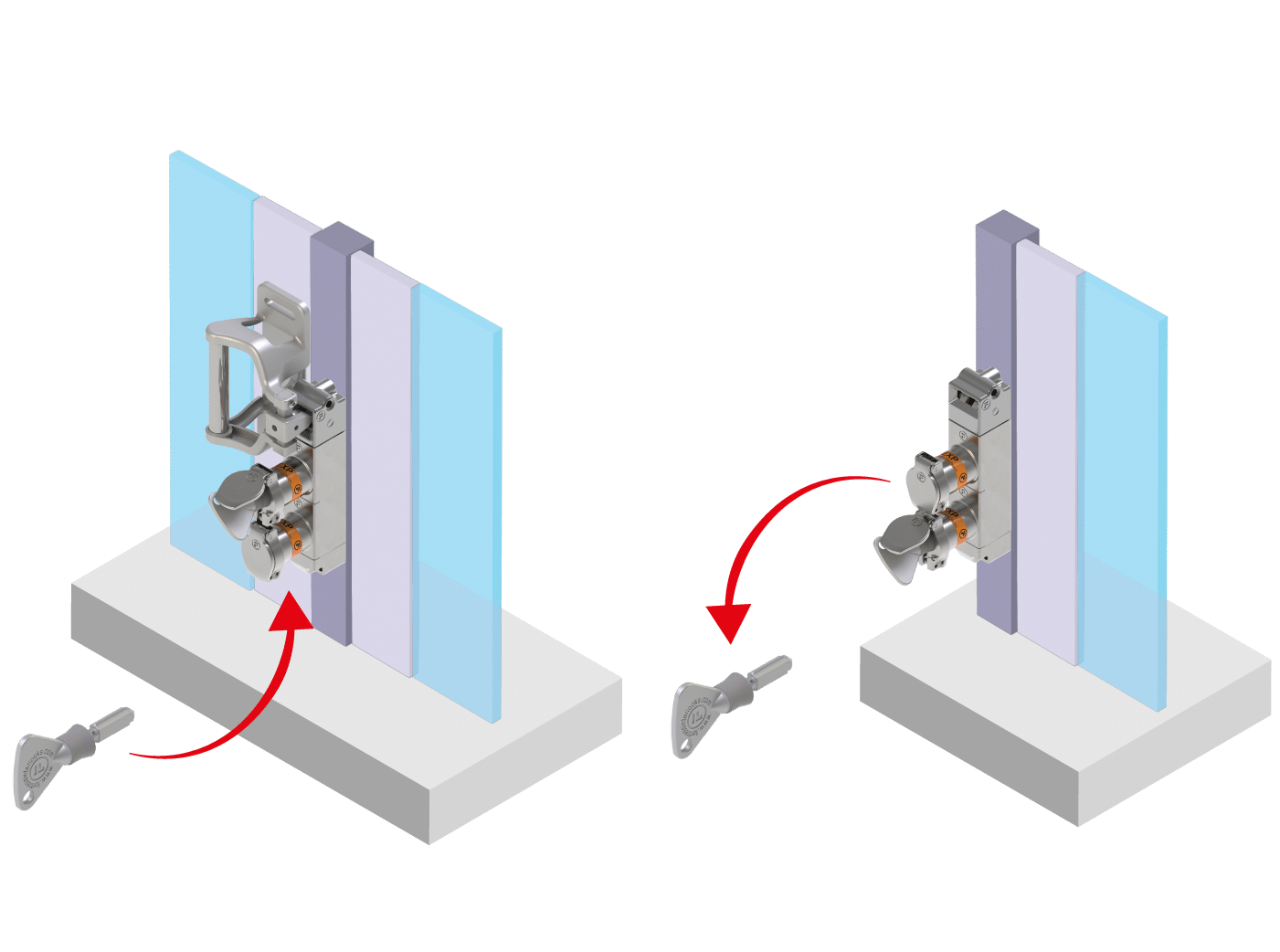

Fortress developed a trapped key system to allow access to 13 sections of the electrolyte filling machine. Enforcing a predetermined sequence of events allows access to personnel only once the machine has come to a controlled stop. Stainless steel interlocks were mounted on each access point. Personnel keys provide an additional level of protection against unexpected start-up.

How it works

Step-By-Step Process

This solution successfully resolved a challenge for a specific customer. Fortress can accommodate alternative setups and/or multi-range options. Share your application details with us so we can design a bespoke solution to meet your needs.

Recommended Product Range

Why Trapped Keys and Stainless Steel?

Trapped key systems are very versatile and are used to enforce a predetermined sequence of events. In this case personnel can only get access once the machine has stopped. Until all the keys are returned, power cannot be restored, and the machine cannot restart.

The stainless steel interlocks used:

Are compatible with the harsh environment of battery manufacturing applications

Can be used in the presence of flammable chemicals

Are mechanical and do not require wiring, simplifying installation

In addition, personnel keys provide an additional level of protection preventing movable guards from locking when personnel are performing tasks. Since in this case drilling is not feasible and an escape release is not a viable option, the solution provided meets the customer’s needs.