Pharmaceutical Rapid Mixer Granulator

Rapid mixer granulator (RMG) machines are used for tablet manufacturing in the pharmaceutical industry. Such machines have hatches that need to stay closed during the rotation process but may need to be opened periodically for scheduled cleaning.

The Challenge

Operators working with RMG machines are exposed to a rotating hazard. Access should only be allowed once the power to the mixer has been isolated and mechanically secured. While the hatch is open, there is also a risk of unexpected start-up.

The Solution

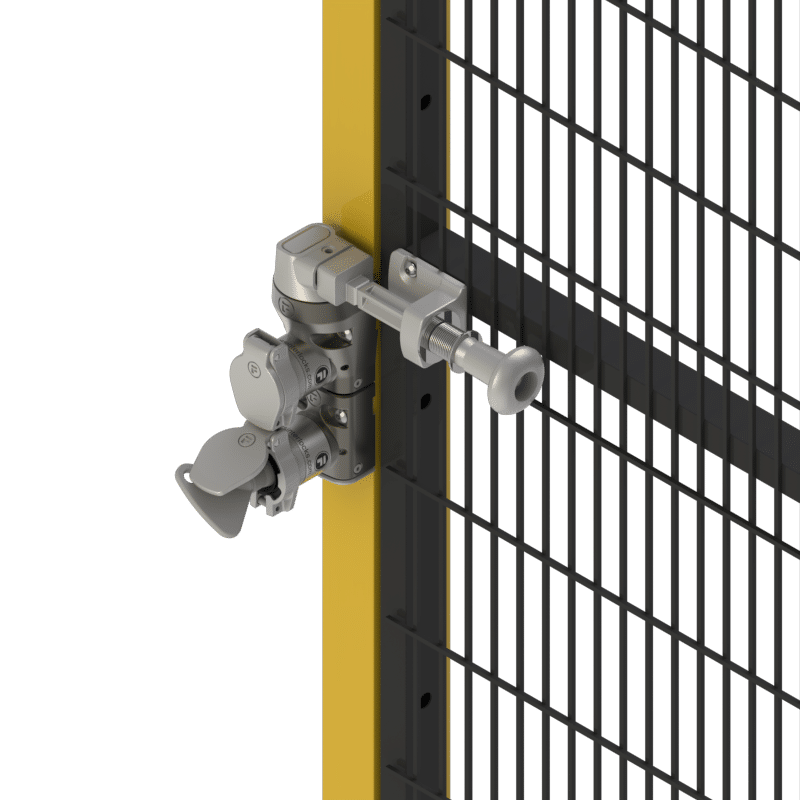

mGard

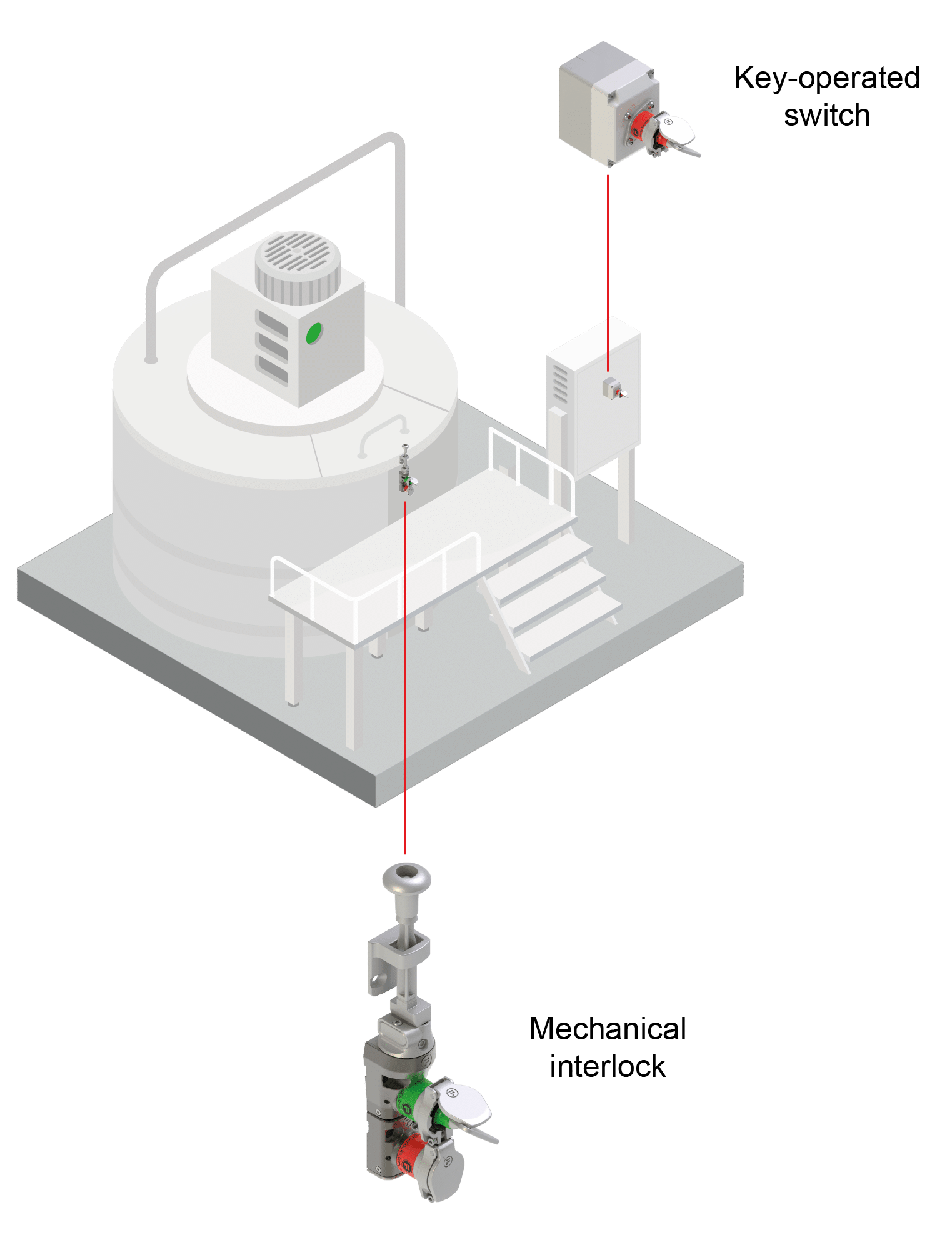

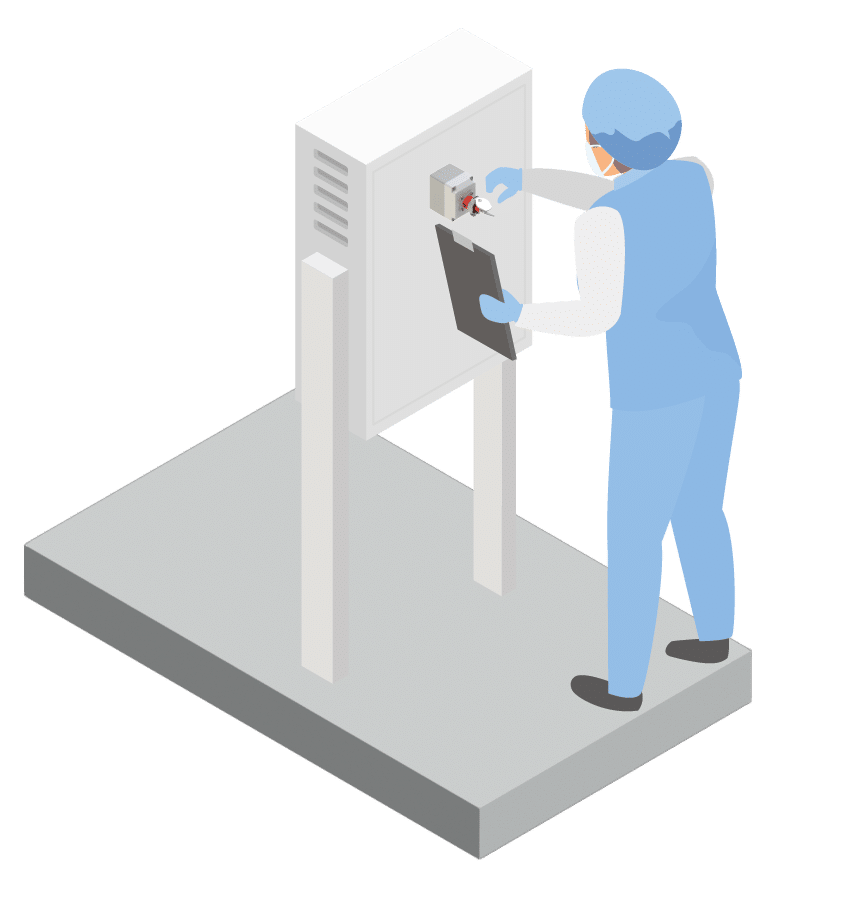

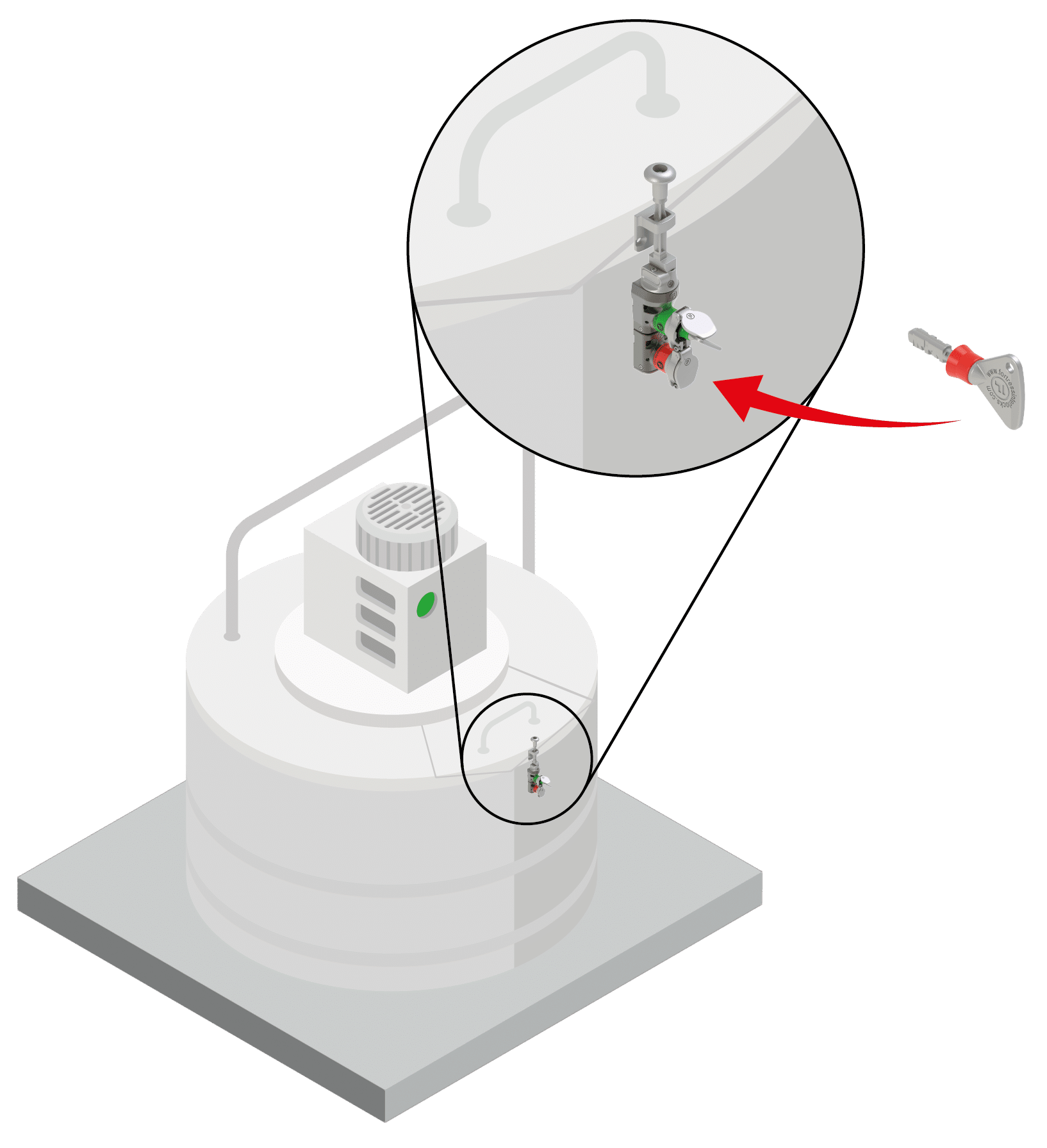

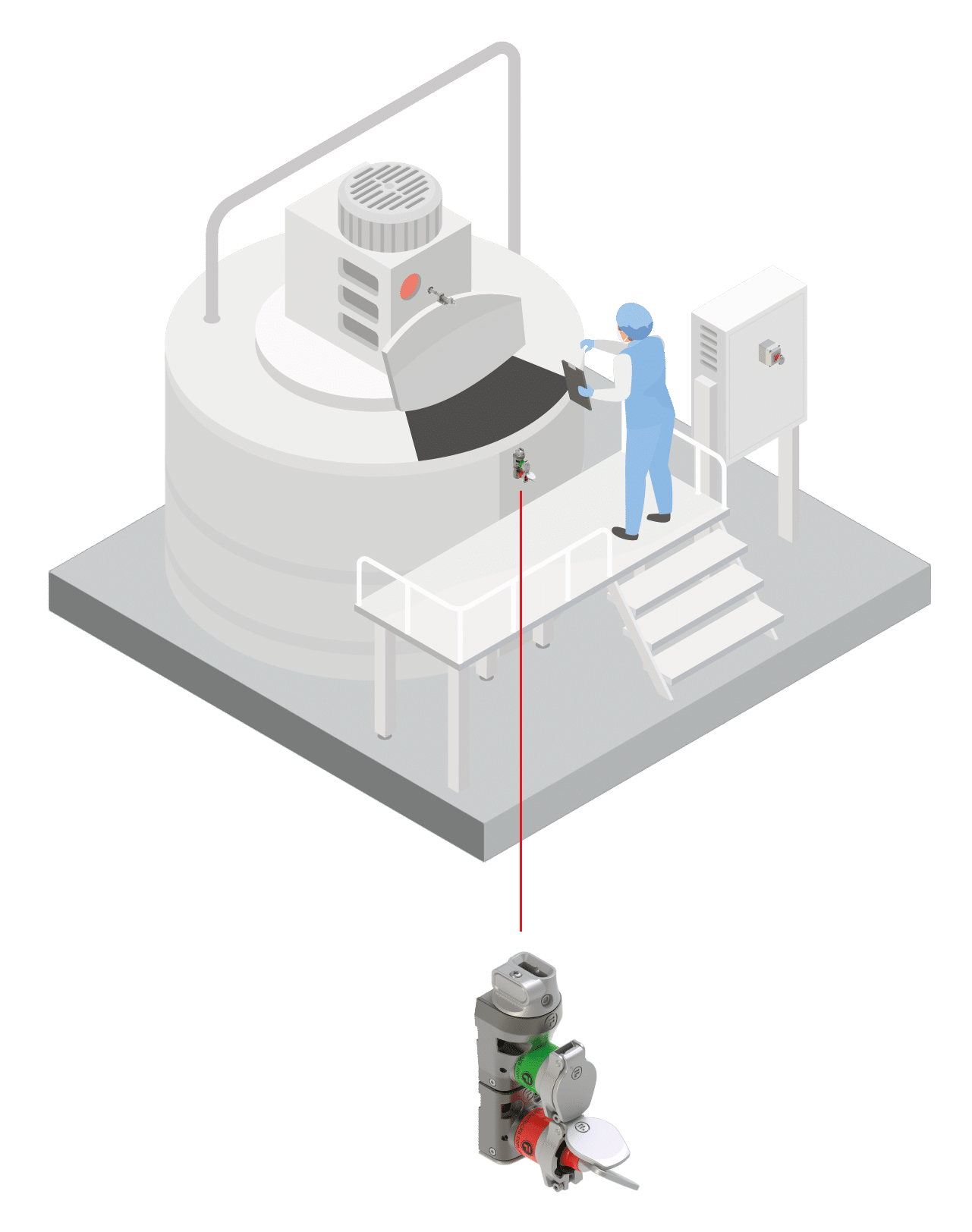

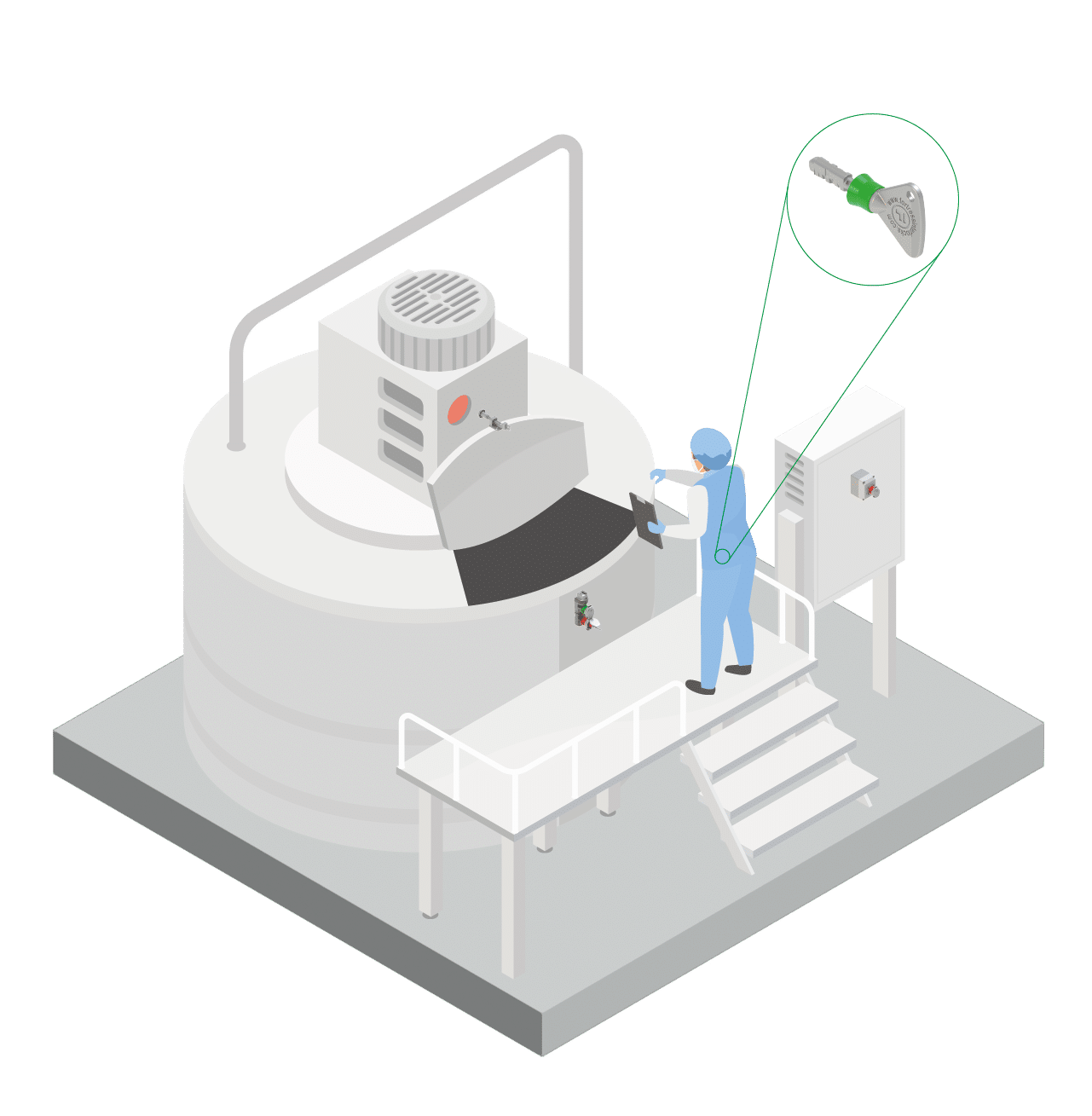

Fortress proposed the mGard trapped key solution with a key-operated switch and an access lock. The key-operated switch is used to isolate power to the machine. The key is released and can be removed. Insertion of the key in the access lock allows the release of a personnel key and the opening of the hatch. The mixer cannot restart until all the keys are returned and the power restored.

How it works

Step-By-Step Process

This solution successfully resolved a challenge for a specific customer. Fortress can accommodate alternative setups and/or multi-range options. Share your application details with us so we can design a bespoke solution to meet your needs.

Recommended Product Range

Why mGard?

In this application, mGard was chosen because:

Mechanical interlocks eliminate the need for wiring, with considerable savings in installation costs

While the key is removed, the energy source is prevented from being accidentally turned on

The personnel key, acting as a proactive inhibit function, provides protection against unexpected start-up