Enhancing Safety and Efficiency at Ibstock Brick Manufacturing Plant

Networked interlocks enhanced safety and efficiency in a brick manufacturing plant, optimising automation and operator protection.

Industry

Building Materials

Products Used

Partners Involved

Underwoods, United Kingdom

Company

The Challenge

Improving the Dehacking Line with Advanced Technology

Meeting growing market demand by improving the Dehacking line with advanced technology while prioritising operator safety.

Safety-Centric Approach: Advancing Functionality

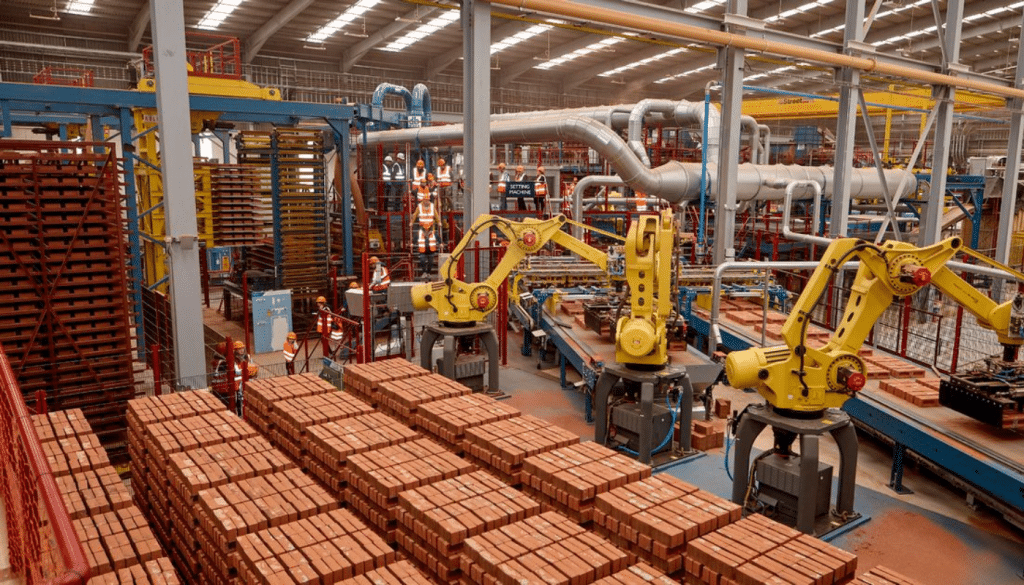

The Ibstock Brick Ravenhead plant embarked on a strategic journey to optimise their Dehacking line. With a strong focus on safety and efficiency, they integrated a new robot palletising system and an automated stretch wrapper. These enhancements aimed to bolster the capacity for processing and packaging bricks, while ensuring top-tier safety standards.

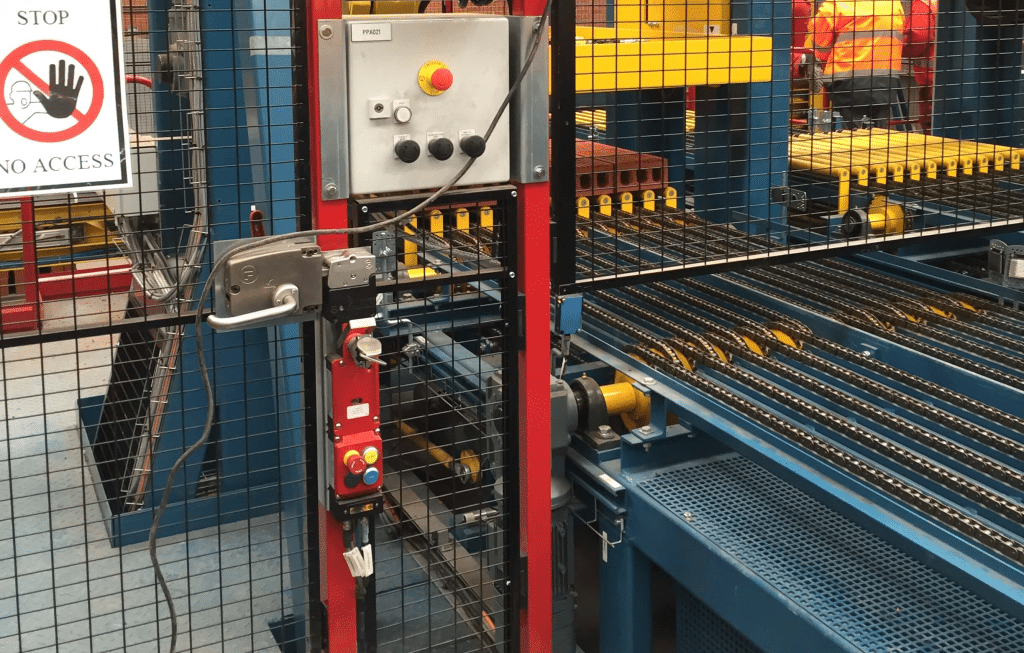

The Safety Imperative: Shielding Plant Operators

The robotic palletising systems, while enhancing efficiency, posed challenges for plant operators working within these systems, often out of direct sight. During the upgrade, the plant’s key concern was to enhance functional safety. This was particularly crucial due to multiple access points along the Dehacking line frequently used by authorised operators and maintenance personnel.

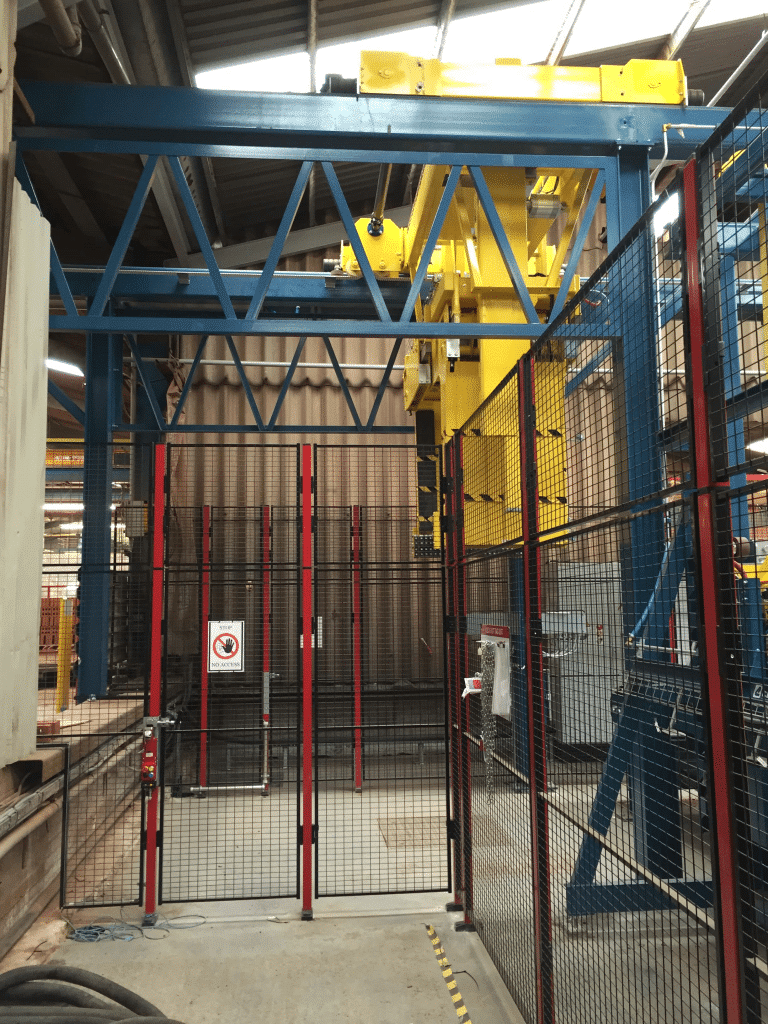

The comprehensive risk assessment highlighted an important issue: the potential for unexpected start-up. This scenario, as defined in ISO 14118:2017 – Prevention of unexpected start-up, posed the risk of serious injuries or even fatalities if an operator inadvertently restarted the machine while a colleague was within the safeguarded space.

The Solution

Innovative Solution: Smart Interlocking by Fortress Safety and Underwoods

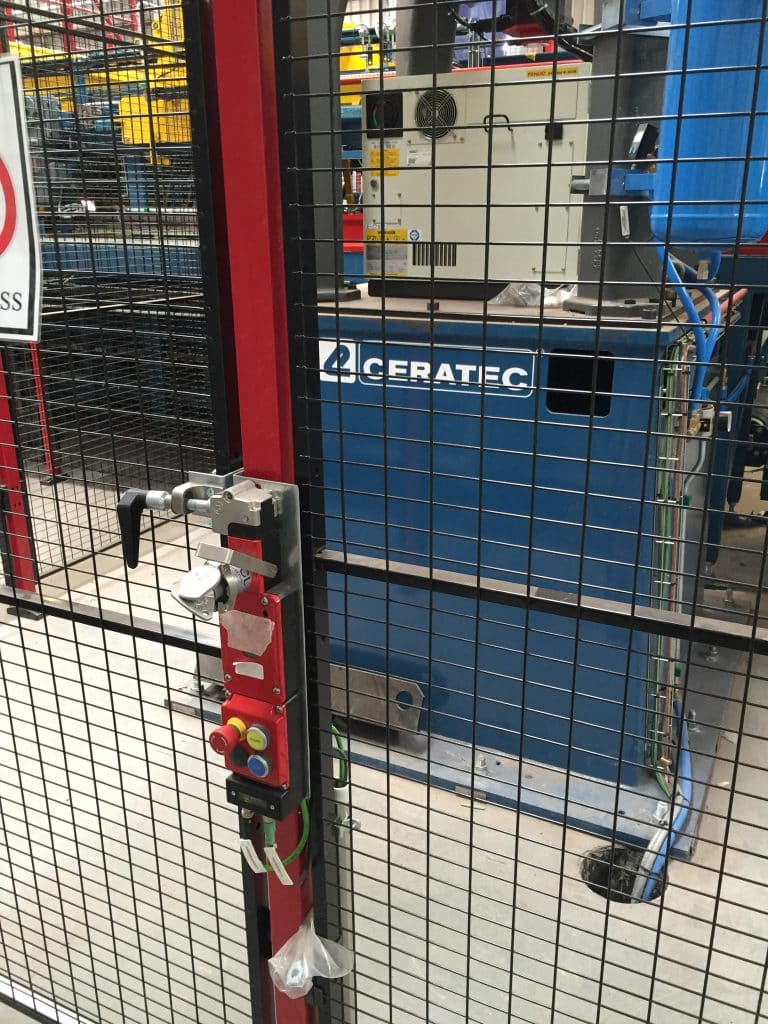

Addressing this concern, Ibstock Brick collaborated with their trusted channel partner Underwoods and integrated PROFI-enabled amGardpro interlocks, a groundbreaking solution from Fortress Safety.

These interlocks introduced personnel keys, held by operators working within the safeguarded space. This ensured personnel protection by preventing machine restart until all personnel keys are returned to the interlock as operators exit the space, and the guard and interlock are then closed.

Moreover, a practical feature was the integration of basic machine control functions into each device. Incorporating restart buttons and emergency stops into the interlock design eliminated the need for additional hardware and associated wiring costs.

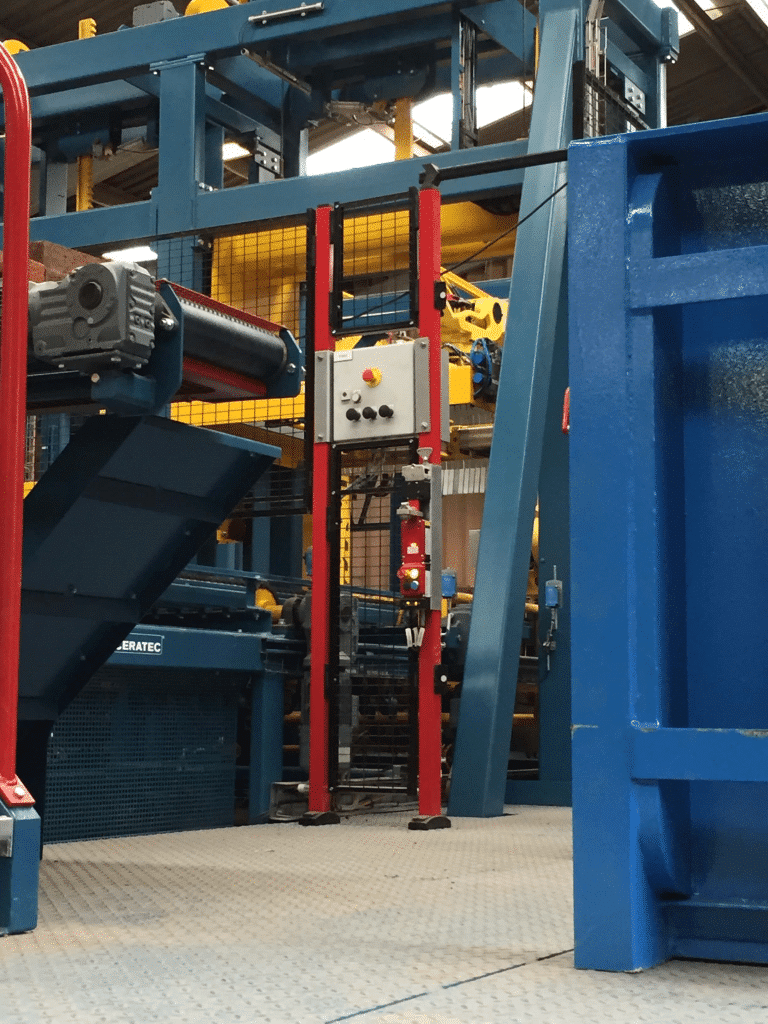

Durability and Reliability: Customised Safety

Interlocks from Fortress Safety were the natural choice due to their exceptional protection for both plant and personnel. Known for being one of the most robust interlocking solutions in the market, they are designed and tested for a wide range of industries and are durable even in harsh industrial conditions. This resilience was especially beneficial for brick plants known for their dusty environments.

Enhanced Efficiency: PROFINET Network Integration

The Ravenhead plant gained further advantages by integrating each interlock into its PROFINET network with PROFIsafe extensions. This innovation streamlined wiring, reduced design-related expenses, and improved diagnostic capabilities.

Enhanced Efficiency: PROFI-Enabled Diagnostic Coverage

The installation of PROFI-enabled interlocks brought about improved diagnostics for the Ravenhead plant. Engineers could now access accurate topology displays via standard internet browsers, facilitating quicker fault detection and minimising production downtime. Remote access to network displays empowered authorised personnel to diagnose system faults without being physically present.

Driving Progress: Transforming Production

The comprehensive PROFINET network enabled swift and secure data exchange, optimising the use of production data for continuous improvement. Through investments in this network and interconnecting field devices like interlocks, Ibstock Brick, Fortress Safety, and Underwoods collectively propelled the Ravenhead plant towards refined control, monitoring, and management. These improvements translated into noticeable advancements in productivity and operational excellence.

More Case Studies

Fortress supplied interlocks for 100+ access points at Duferco’s new Smart Beam Manufacturing mill in Italy.

Discover how Fortress’s mechanical interlocks were implemented to enhance operator safety at Walibi Holland amusement park.

Fortress Safety has worked closely with Coca-Cola India to enhance personnel protection across nearly forty sites.