Reducing Risk in Duferco’s Innovative Rolling Mill

Fortress supplied interlocks for 100+ access points at Duferco’s new Smart Beam Manufacturing mill in Italy.

Industry

Metals Production

Products Used

mGard, tGard

Partners Involved

LAS Automation & Safety Solutions, Italy

Company

Reducing Risk in the Steel Industry

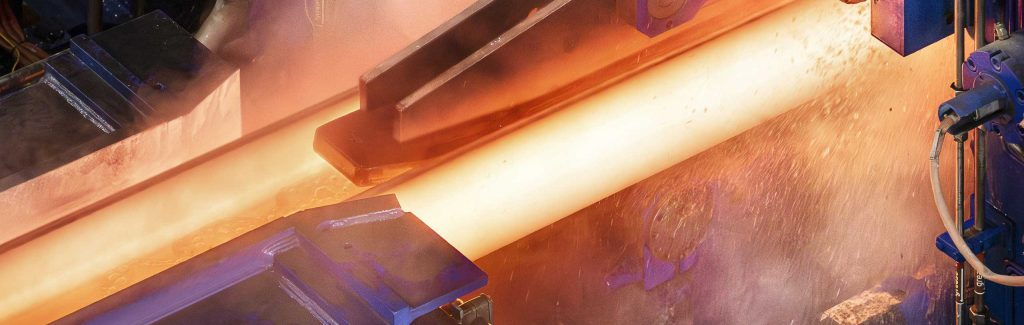

The steel industry heavily relies on high-temperature transformations to achieve the final product. Components are susceptible to corrosion, wear and tear, and structural integrity issues. In addition, the harsh environment poses significant risks, making it challenging to ensure the safety of personnel.

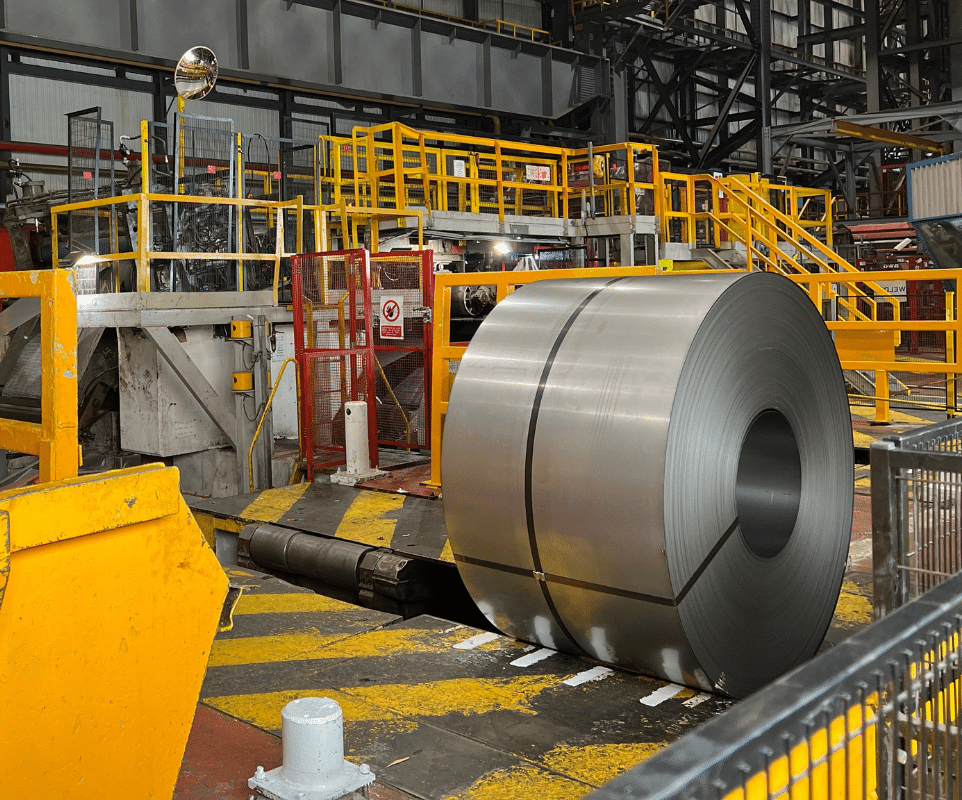

In October 2023, Duferco Travi e Profilati launched a new rolling mill called Smart Beam Manufacturing (SBM) in San Zeno Naviglio, Brescia, Italy. With a length of 500 m and a surface of over 78,000 m2 it is the biggest rolling mill in Italy, with a total rolling capacity of 700 K tons of long products. Designed to be at the forefront in terms of sustainability, technology, and innovation, the plant is powered entirely by renewable energy.

Thanks to the great work carried out by LAS, our Channel Partner in Italy, Fortress Safety has been entrusted with the role of protecting personnel working at the brand-new site, providing safety solutions for over 100 access points.

The Challenge

Tackling the Challenges of Extreme Conditions

To be suitable for use in the conditions under which the rolling mill operates (i.e., risk of impact with heavy moving parts, high temperatures that can reach 1250 °C) the safety products had to:

- Be extremely resistant

- Have no wiring near the access points

- Provide protection in vast areas where operators might not always be visible

Due to the risk of personnel being trapped, unexpected start-up had to be addressed. In this specific case, since wiring near the access points was not possible, escape release functions were not viable. In addition, with electric panels controlling specific sections (each with multiple access points), there was the need of a module to enforce a sequence for the release of keys to allow access to the respective entry points upon isolating the power from the panels.

The Solution

Mechanical Trapped Key Interlocks

Fortress had the perfect solution to address all the above-mentioned requirements in the mGard range:

- Fully mechanical, with no need for wires

- Stainless steel interlocks suitable for harsh environments

- Key(s) with forced extraction, so that personnel must take their personnel key with them in the safeguarded area

Using Fortress coded personnel keys mitigated the risk of personnel being locked in the safeguarded area. Padlockable dustcovers provided further protection, giving additional personnel entering the safeguarded area the possibility to apply personal padlocks on the lock, preventing the guard from being closed whilst still inside.

Other important benefits from Fortress were:

- The possibility of engravings and different colour options on keys. This simplified key management and made it easier for the operators to know which key to use

- Master key available to dedicated personnel (i.e., maintenance manager or site manager) in case of emergency or issues

Electromechanical Products for Additional Functionalities

For the access points of a different section of the rolling mill (cool area, with less challenging conditions, compatible with wiring) pushbuttons and functions such as an escape release were needed.

With the tGard range, Fortress was able to offer electromechanical solutions all in one product. tGard products in fact have a 40mm metal body that can accommodate up to 10 modules, with the possibility to include pushbuttons, lamps, emergency stops, etc.

Although it may seem unusual, the tGard units were mounted upside down because of ergonomic factors. The units were quite long, therefore mounting the interlocks upside down not only made it is easier to reach buttons (which would have otherwise been too close to the floor) but also allowed the escape release to be at a suitable height.

The Keys to Success

Our channel partner LAS has been involved since the early stages of the project, working with project managers, engineers, and the line builder, providing recommendations on the Fortress solutions, and designing the access points and the sequences to enforce.

Fortress was able to provide unique products to meet the customer’s demand that no one else could offer. Moreover, the possibility of having a mix of mechanical and electromechanical systems (depending on the area or application) and getting them from the same supplier was a great advantage and one of the keys to success.

The customer was familiar with Fortress since our solutions were already used in other sectors of the steel plant. Knowing the robustness and resistance to harsh conditions, the customer requested Fortress products be installed on the new site to protect 150 workers. For over twenty years Fortress has been the go-to provider for the Italian steel industry and there is no doubt the approach used for this rolling mill could be replicated to other sites.

Who are Duferco?

Duferco Group are a global leader in steel production, energy, shipping and innovation.

The new rolling mill Fortress worked on is integrated with the steel mill, through innovative and sustainable technologies. Echoing our business values of being the innovators and targeting net zero by 2040. Duferco invested €220million and created 150 new job positions with their new Smart Beam Manufacturing rolling mill; which has a potential production capacity of 700,000 tons per year. The plant will have the lowest possible environmental impact, and will be powered by energy from renewable sources.

It’s a fantastic opportunity to elevate steel manufacturing in Italy and Europe to a new sustainable model.

Working Closely with LAS

With over 30 years of experience in the industrial automation and safety market, LAS A&S SRL represent a technical commercial hub in Italy for all safety professionals.

As our Channel Partner, LAS represent Fortress in Italy across all projects and have grown our brand incredibly. LAS support customers starting from the identification of the best solution, to after-sales assistance, through design and implementation of these cutting-edge systems.

For any safety related questions in Italy, please get in touch with Fortress or LAS directly.

More Case Studies

Discover how Fortress’s mechanical interlocks were implemented to enhance operator safety at Walibi Holland amusement park.

Tata Steel chose FRANK to manage access control permissions and enhance safety on their ZODIAC line.

Discover how Fortress has been protecting personnel working at Tata Steel Llanwern for over two decades.