Smarter Safety at the University of Nottingham

Discover why Omnifactory (University of Nottingham) chose to work with Fortress Safety on their innovative project.

Industry

Research / Education

Products Used

Company

Country

The Challenge

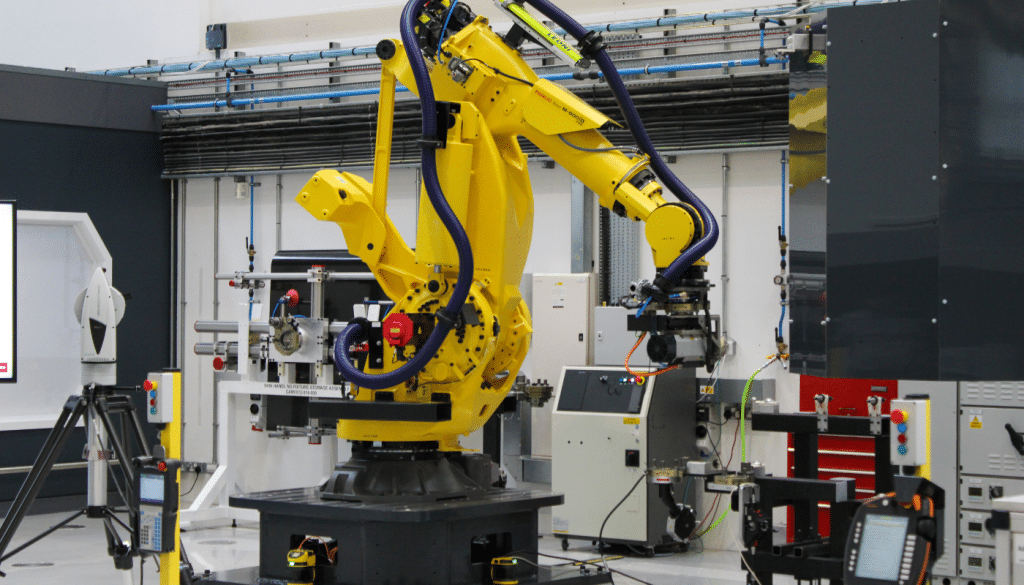

Ensuring Safety in a Reconfigurable Manufacturing Environment

Omnifactory at the University of Nottingham is a reconfigurable manufacturing cell that supports local partners and aerospace companies in advanced manufacturing projects, integrating digital technologies to enhance traditional manufacturing practices. Given its dynamic environment, protecting personnel working at Omnifactory while maintaining flexibility was a key priority. They needed to secure the perimeter of the manufacturing cell, preventing staff from being inside during operations.

The Solution

Implementing Fortress Safety’s Innovative Interlocking Solutions

To address these challenges, the Omnifactory team collaborated with Fortress Safety to implement interlocking solutions that secure the perimeter of the manufacturing cell, ensuring that no one is inside when operations are active. The approach included:

- Power over Ethernet (PoE) for simplified installation: Using PoE allowed for a simplified installation with just a single cable, reducing costs, lead times, and installation complexity

- Control Pods for Safety Walk Process: Fortress integrated control pods within the network, enabling an safety walk process. An authorised operator starts the safety walk at one module, verifies that the area is clear, and then confirms at a second module in the control room before operations move into full-speed mode

- Seamless Integration with Siemens Orchestration: The Fortress safety solution integrated effortlessly with Omnifactory’s existing Siemens orchestration framework, streamlining operations

The Omnifactory

Measurable Benefits of the Collaboration

By working closely with Omnifactory from the beginning, Fortress Safety was able to provide a tailored safety approach that met the needs of a dynamic, advanced manufacturing environment. The collaboration between Fortress Safety and the University of Nottingham’s Omnifactory resulted in:

Enhanced Safety

through a safeguarded perimeter and safety walk verification

Simplified Installation and Reduced Costs

due to the use of PoE technology

Seamless Integration

with existing control frameworks, improving operational efficiency

More Case Studies

Fortress supplied interlocks for 100+ access points at Duferco’s new Smart Beam Manufacturing mill in Italy.

Discover why Omnifactory (University of Nottingham) chose to work with Fortress Safety on their innovative project.

Fortress Safety has worked closely with Coca-Cola India to enhance personnel protection across nearly forty sites.