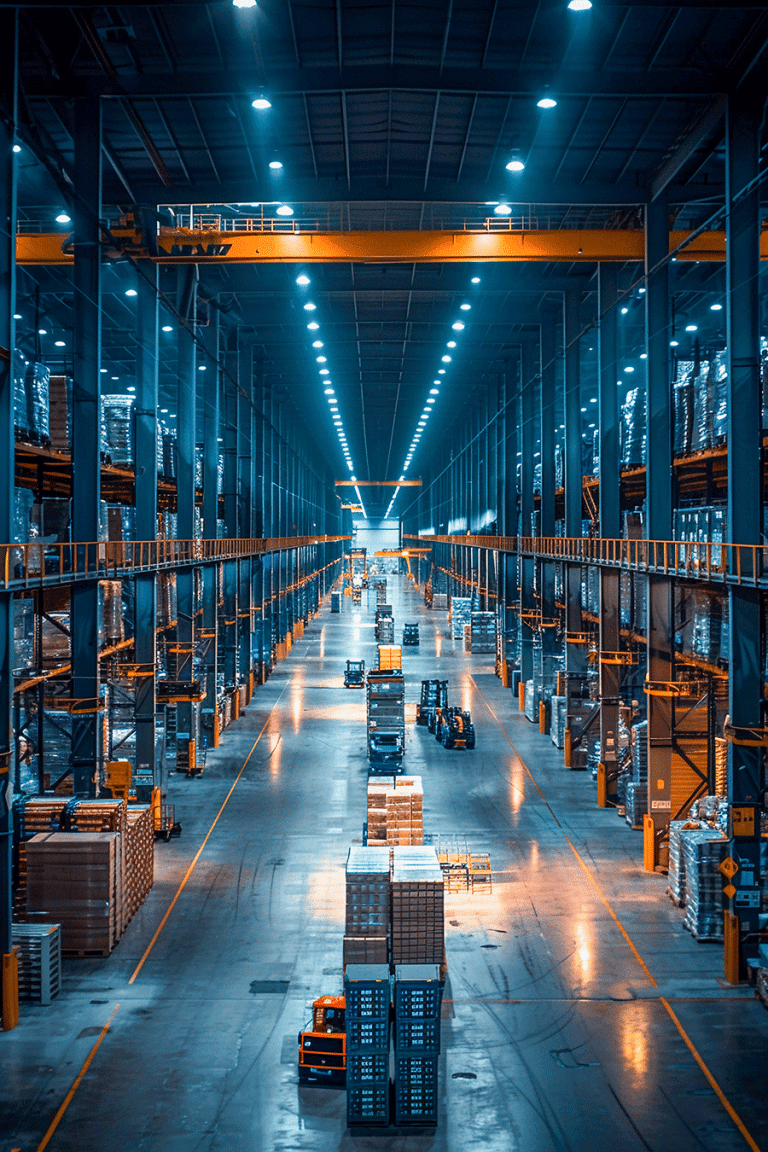

Automatisierte Lagerhaltung

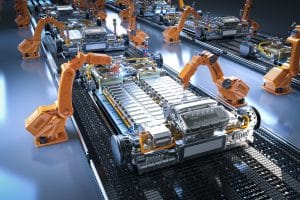

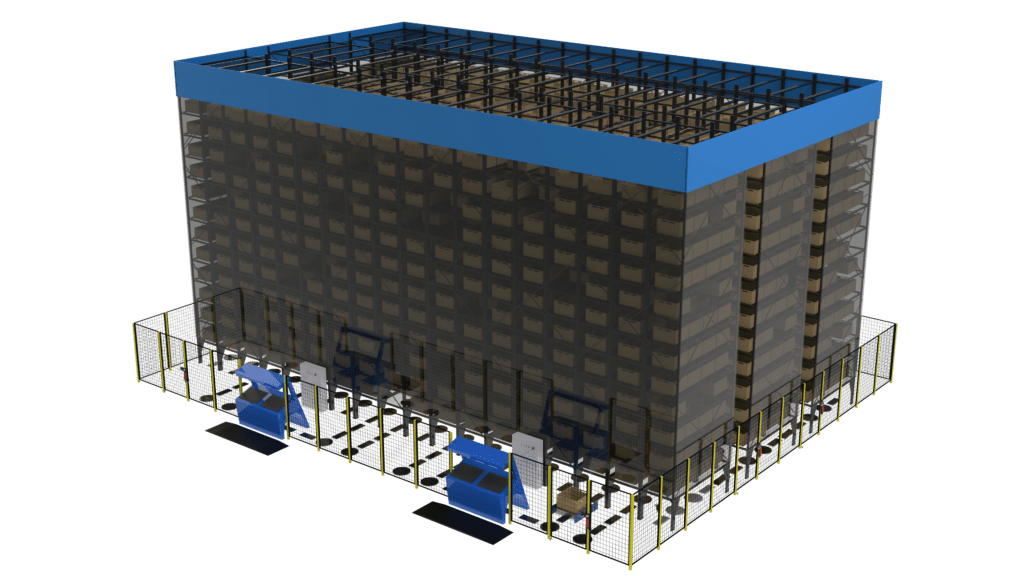

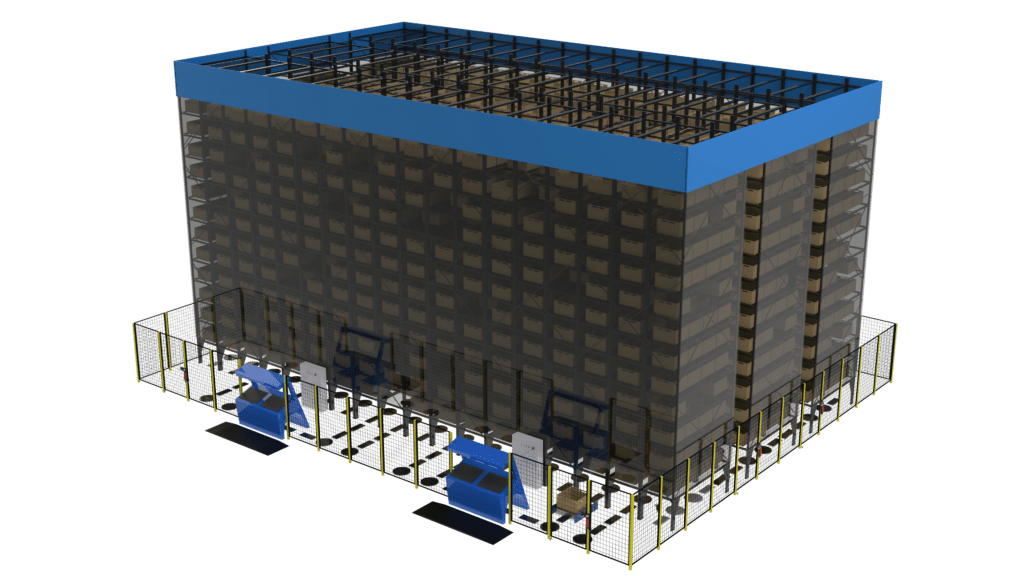

Die automatisierte Lagerhaltung stellt besondere Anforderungen an die Sicherheit, insbesondere an den Schutz des Personals in großen Einrichtungen mit automatisierten Regalbediengeräten (RBG) und zahlreichen Zugangspunkte. Die eingeschränkte Sichtbarkeit des Personals sowie das Vorhandensein von Förderband Systemen und Roboterhandhabungsgeräten sind nur einige der Herausforderungen.

Geeignete Maßnahmen zur Absicherung und Zutrittskontrolle sind unerlässlich, um Verletzungen zu vermeiden. Fortress bietet Lösungen, die den höchsten Standards entsprechen und sich gleichzeitig flexibel an Ihren Betrieb anpassen lassen. Mit fachkundiger Anleitung, technischem Support und Schulungen gewährleistet Fortress eine nahtlose Integration, bei der Sicherheit und Effizienz im Vordergrund stehen.

Funktionalität und Konformität

Konfigurierbare Produkte, die auf Leistung und die Einhaltung internationaler Normen ausgelegt sind. Alle notwendigen Funktionen in einer Lösung vereint.

Skalierbares Design

Leicht skalierbare und anpassbare Lösungen für expandierende Betriebe, die bei Bedarf eine nahtlose Integration zusätzlicher Sicherheitssysteme ermöglichen.

Netzwerk-Konnektivität

Schnell einsetzbare Lösungen, verfügbar für mehrere Netzwerkprotokolle zur schnellen Installation, Integration und Inbetriebsetzung.

Dauerhafte Lösungen

Minimieren Sie Ausfallzeit und Ersatzbeschaffungen mit robusten Produkten, die selbst in den schwierigsten Umgebungen jahrzehntelang halten.

Operative Effizienz

Intuitive, leicht zu bedienende Systeme mit bequemem Zugang für den Bediener und Bedienelementen an der beweglichen Schutzeinrichtung.

Vollständig konfigurierbare Produkte

Entwerfen Sie maßgeschneiderte Sicherheitslösungen, die den spezifischen Anforderungen jeder Anwendung gerecht werden.

Funktionalität und Konformität

Konfigurierbare Produkte, die auf Leistung und die Einhaltung internationaler Normen ausgelegt sind. Alle notwendigen Funktionen in einer Lösung vereint.

Skalierbares Design

Leicht skalierbare und anpassbare Lösungen für expandierende Betriebe, die bei Bedarf eine nahtlose Integration zusätzlicher Sicherheitssysteme ermöglichen.

Netzwerk-Konnektivität

Schnell einsetzbare Lösungen, verfügbar für mehrere Netzwerkprotokolle zur schnellen Installation, Integration und Inbetriebsetzung.

Dauerhafte Lösungen

Minimieren Sie Ausfallzeit und Ersatzbeschaffungen mit robusten Produkten, die selbst in den schwierigsten Umgebungen jahrzehntelang halten.

Operative Effizienz

Intuitive, leicht zu bedienende Systeme mit bequemem Zugang für den Bediener und Bedienelementen an der beweglichen Schutzeinrichtung.

Vollständig konfigurierbare Produkte

Entwerfen Sie maßgeschneiderte Sicherheitslösungen, die den spezifischen Anforderungen jeder Anwendung gerecht werden.

Anwendungen -

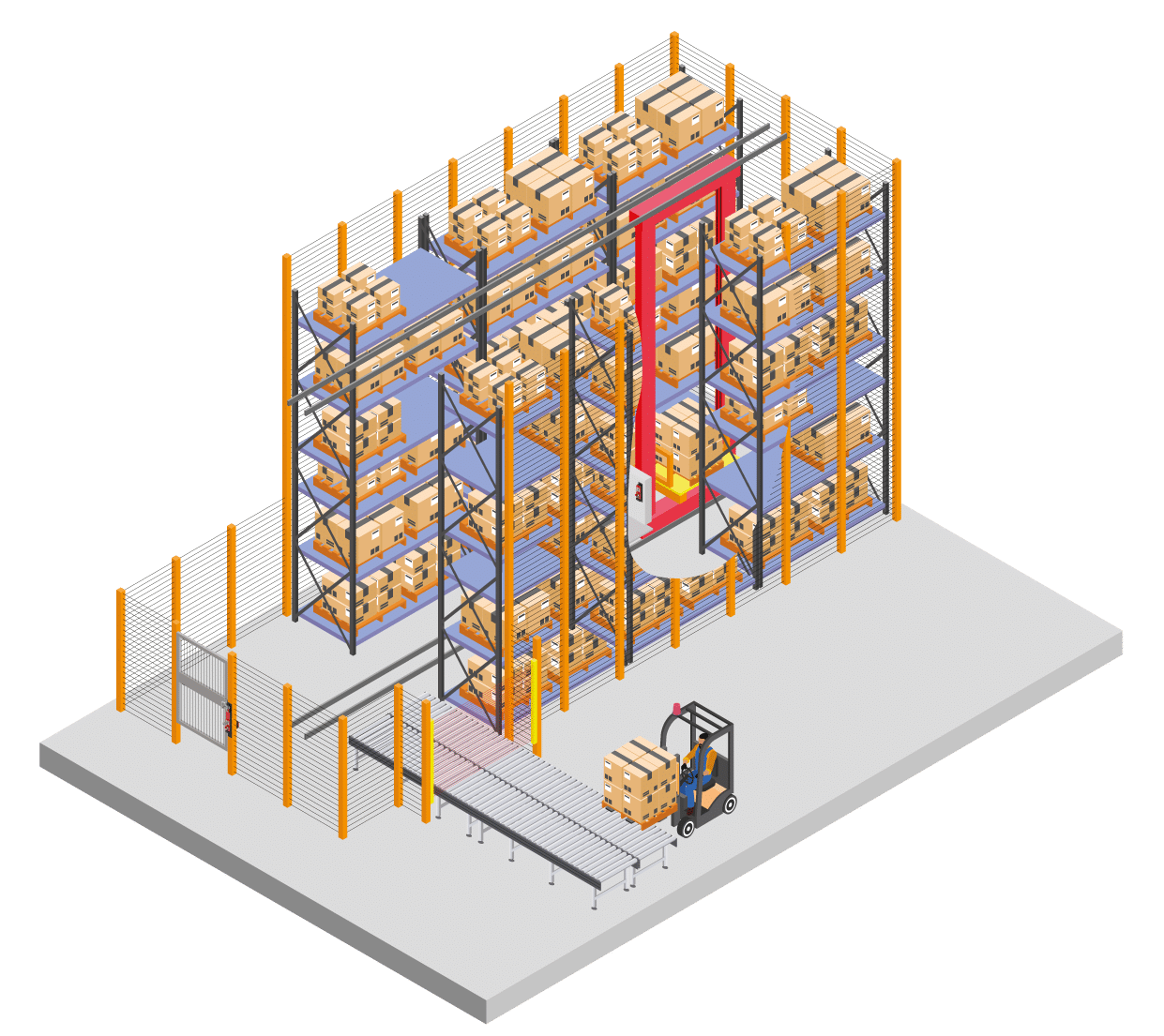

ASRS

Gang Zugang in automatisierten Lager- und Bereitstellungssystemen

Automatische Regalbediengeräte (RBG) erstrecken sich oft über viele Gänge, haben mehrere Zugangspunkte und verfügen wahrscheinlich über Kräne zur Entnahme und Einlagerung von Produkten. In einigen Regionen müssen solche Systeme der EN 528 entsprechen, einer Sicherheitsnorm für schienengebundene Regalbediengeräte, die eine Reihe von Anforderungen in Bezug auf [...]

Anwendungen -

Mischpult

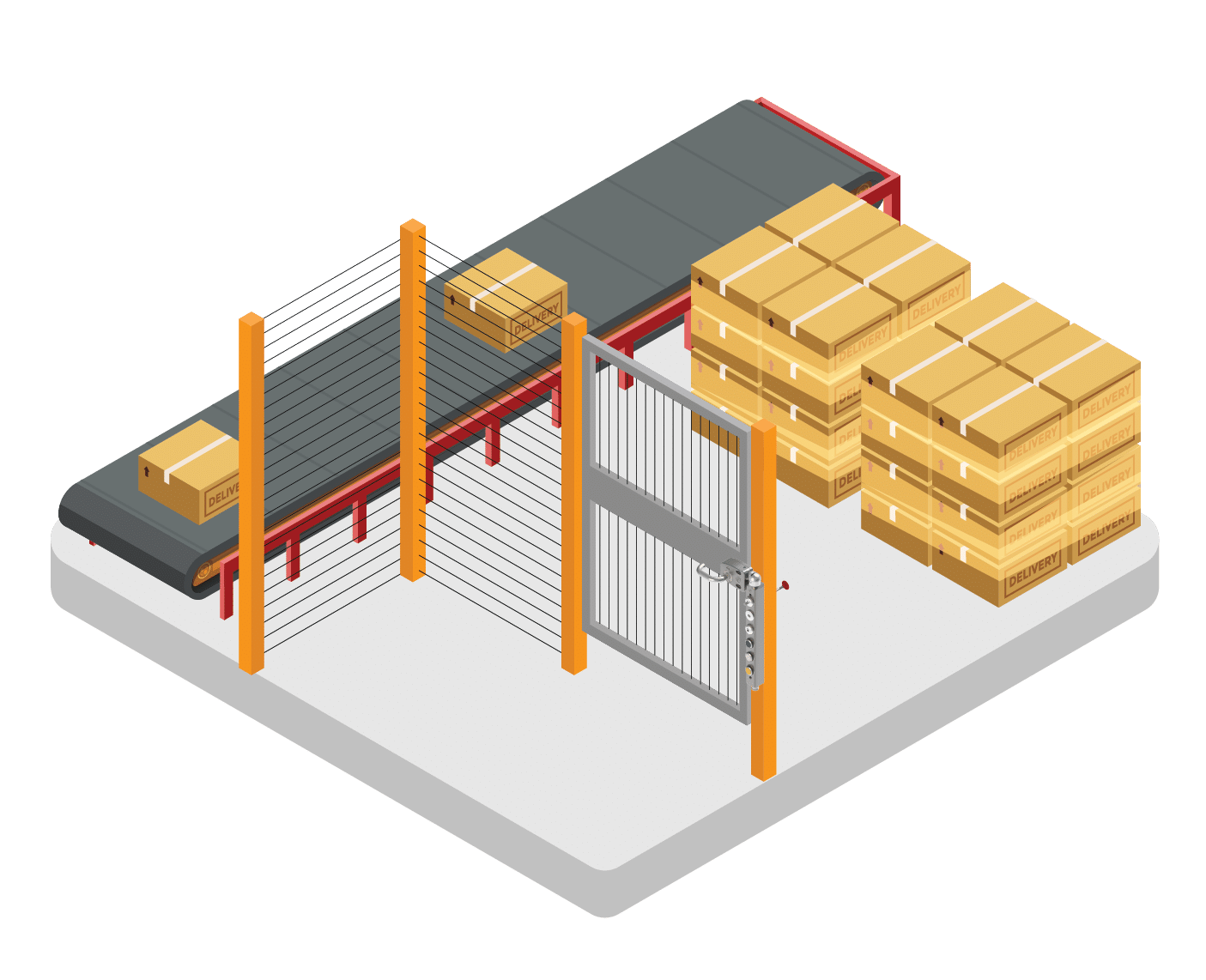

Förderband System

Förderband in automatisierten Lagern transportieren die Waren effizient durch die Einrichtung, verringern die manuelle Arbeit und erhöhen die Geschwindigkeit. Häufig werden sie mit anderen Automatisierungstechnologien kombiniert, um die Abläufe vom Wareneingang bis zur Auftragsabwicklung zu optimieren. Unter bestimmten Umständen können Förderband durch verriegelte Schutzvorrichtungen gesichert werden, um zu verhindern, dass das Personal potenziellen Gefahren ausgesetzt wird. Die Herausforderung Das Personal muss unter Umständen [...]

Anwendungen -

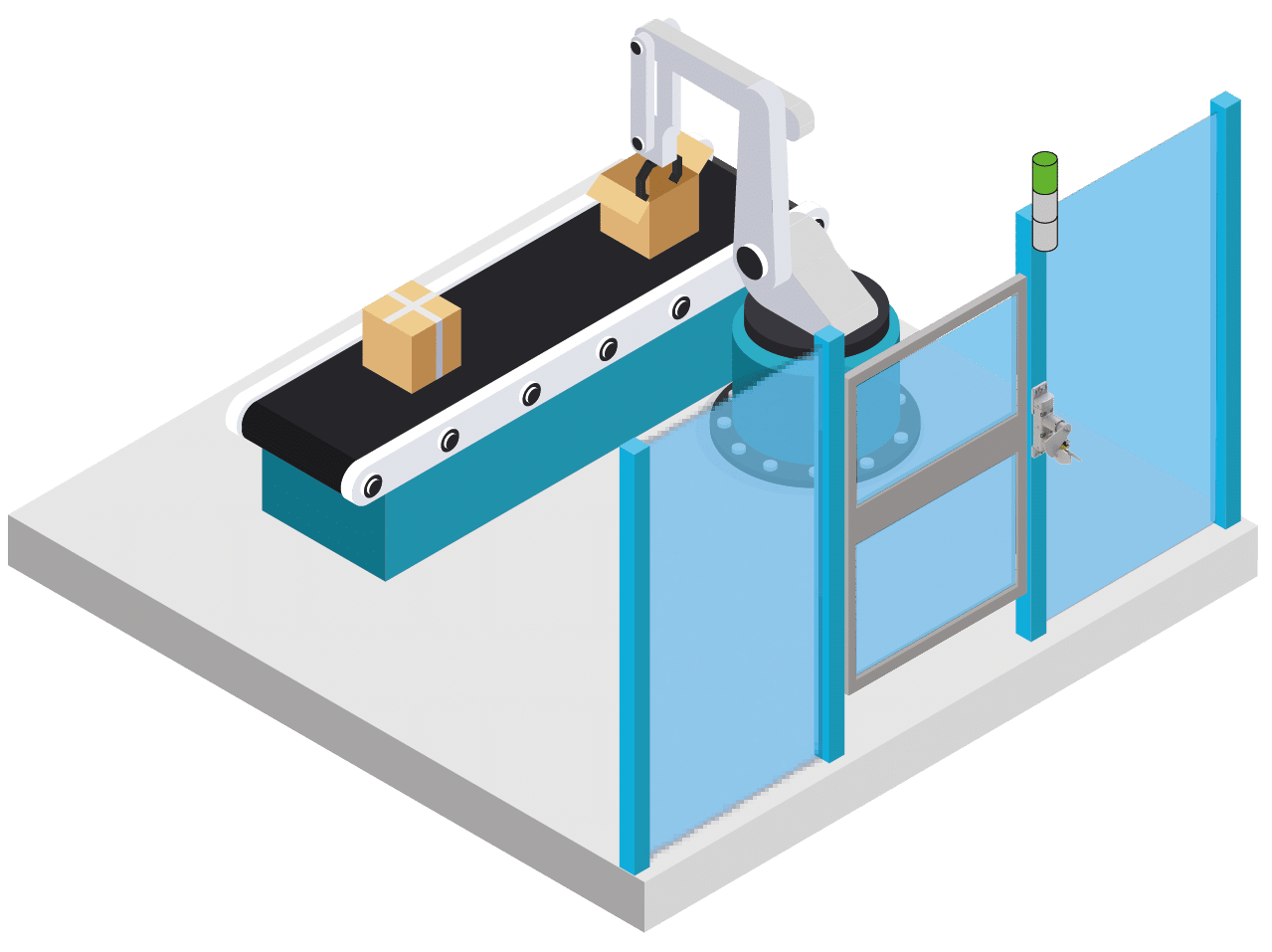

Roboter stapeln

Verriegeln für eine Roboter-Stapelzelle

Der Kunde ist ein weltweit führender Hersteller von Kontaktlinsen. Im Rahmen des Produktionsprozesses nehmen Roboter Schachteln mit Kontaktlinsen auf und Stapel sie, bevor sie zur Verpackung aus werden. Die Herausforderung Die Schutzvorrichtung, die den Zugang zu dem Bereich ermöglicht, in dem der Roboter arbeitet, Eigenschaften über einen Sensor, der anzeigt, ob sie offen oder geschlossen ist. [...]

Beginnen Sie mit Ihrer individuellen Lösung

Fallstudie -

Opex

EtherCAT-fähige Sicherheitslösungen in Lagerautomatisierung

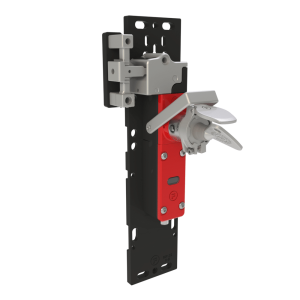

Fortress bot Geräte für den Gang und Remote-Safety-I/O-Fähigkeit durch Geräte, die über EtherCAT kommunizieren können. Es wurden drei Gerätetypen aus der amGardpro angeboten, die jeweils den Gang , den seitlichen Zugang und die dezentrale E/A ermöglichen.

Verwendete Produkte

amGardpro

Das Ergebnis

Maßgeschneiderte ASRS-Sicherheit mit EtherCAT-Integration - schnell zu implementieren, einfach zu bedienen und skalierbar.

Wer sind OPEX?

OPEX bietet skalierbare Lösungen zur Automatisierung von Lagern, Dokumenten und Post, um die Effizienz der Infrastruktur zu steigern.

Fallstudie - OPEX

EtherCAT-fähige Sicherheitslösungen in Lagerautomatisierung

Fortress bot Geräte für den Gang Zugang und die Möglichkeit der Sicherheitsfernsteuerung durch Geräte, die über EtherCAT kommunizieren können. Es wurden drei Gerätetypen aus der Reihe amGardpro angeboten, die jeweils den Zugriff auf Gang , den seitlichen Zugriff und die dezentrale E/A ermöglichen.

Verwendete Produkte

amGardpro

Involvierte Partner

Schindel & Gibb Automation, Ostküste Automation

Wer sind OPEX?

OPEX bietet skalierbare Lösungen zur Automatisierung von Lagern, Dokumenten und Post, um die Effizienz der Infrastruktur zu steigern.

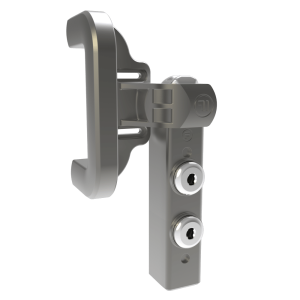

Empfohlener Bereich Produkt

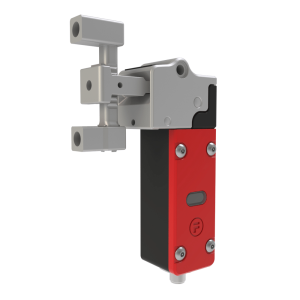

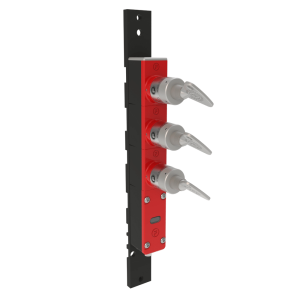

amGardpro

Konfigurierbare Verriegelungen und Steuerkapseln für Schwerlastanwendungen, zertifiziert für den Einsatz bis PLe/Cat. 4. Drucktastensteuerungen, Schlüsseltransfer Optionen und Netzwerkkonnektivität können in einem einzigen Einheit kombiniert werden.

Hochgradig konfigurierbar

Reduzieren Sie Ersatzbeschaffungen und Ausfallzeit

Alle Bedienelemente an einem Ort

Netzwerkkonnektivität

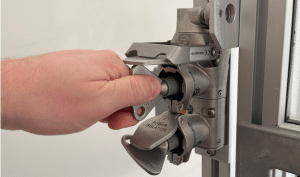

Empfohlener Bereich Produkt

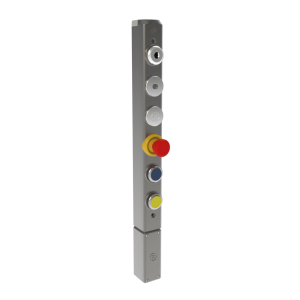

tGard

Eine vielseitige Reihe von Verriegelungen und Kontrollstationen, die aufnehmen bis zu zehn Module, einschließlich eingeklemmter Schlüssel und Bedienelemente, aufnehmen kann. Untergebracht in einem robusten 40-mm-Metallgehäuse, geeignet für verschiedene Anwendungen in der Fertigung und der industriellen Automatisierung.

Maßgeschneidert auf Ihre Anforderungen

Effiziente Lösung integriert

Einbau leicht gemacht

Widerstandsfähig und langlebig

Nachrichten und Einblicke

- Veranstaltung

Sie wissen nicht, wo Sie anfangen sollen? Wir sind hier, um zu helfen

Unser engagiertes Expertenteam hilft Ihnen, die richtige Lösung für Sie zu finden. Sie können Ihre Branche und Ihre spezifischen Anwendungsbedürfnisse analysieren und Ihnen Empfehlungen geben, wie Ihre Einrichtung von Fortress profitieren kann.