EtherCAT-Enabled Interlocks for OPEX’s Automated Warehouse

EtherCAT-enabled interlocks for access to multiple aisles, tailored to specific needs in a New Jersey ASRS.

Industry

Automated Warehousing

Products Used

Partners Involved

Country

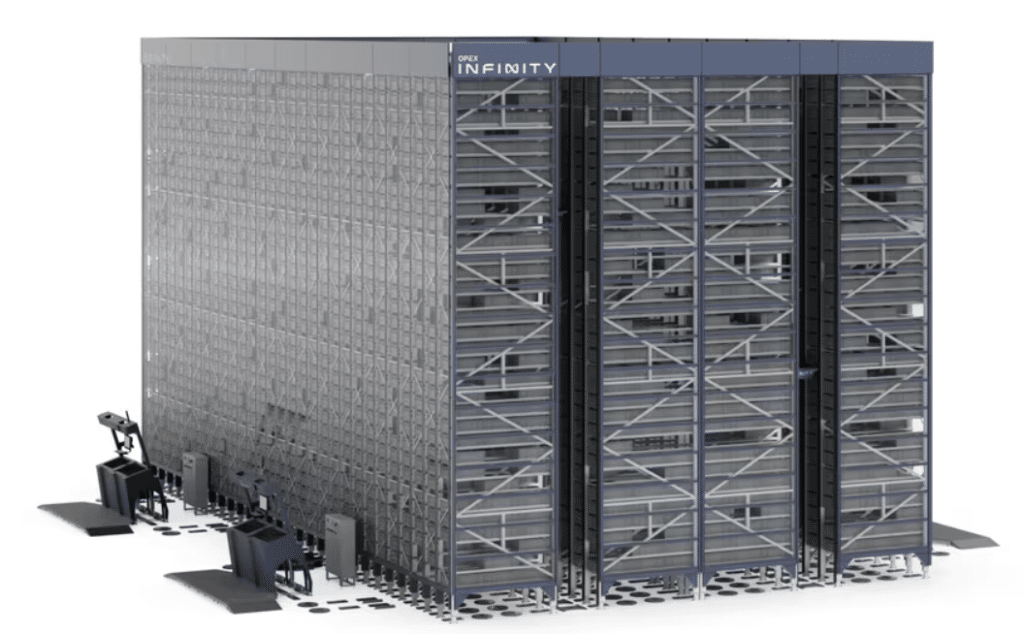

Overview of Automated Storage and Retrieval Systems

Automated Storage and Retrieval Systems (ASRS or AS/RS) are computer- and robot-aided systems that can retrieve or store items in specific locations. ASRS may consist of aisles with shuttles, crane, carousels, vertical lifts, etc., and are widely used in manufacturing, distribution facilities, and other settings.

ASRS offer high-density storage (providing considerable space savings), contribute to optimising operations, and help reduce the costs of manual labour. However, they are vulnerable to power outages, subject to breakdowns, and require maintenance.

There may be situations where personnel need to access the aisles. Since ASRS involve moving parts, conveyors, and possibly robotic arms, operators can be exposed to hazards, getting caught in moving machinery with the risk of body parts being trapped or crushed.

The Challenge

Fortress Safety worked with a global technology leader in high-speed automation and material handling, to design and provide safety solutions for an innovative ASRS in New Jersey, USA. The system consists of multiple aisles, with guards at each end to allow access, as well as side access guards.

The customer identified the need for safety solutions in the form of interlocks to address situations where access to the aisles is required. They were also looking for a solution that could be easily scalable to adapt to changing business needs and growth (i.e., to accommodate future expansion or shifts in operational strategy). Moreover, since other devices on site communicate over EtherCAT, the customer required a solution that could be easily integrated into their existing network.

The Solution

Our Safety Solutions with EtherCAT

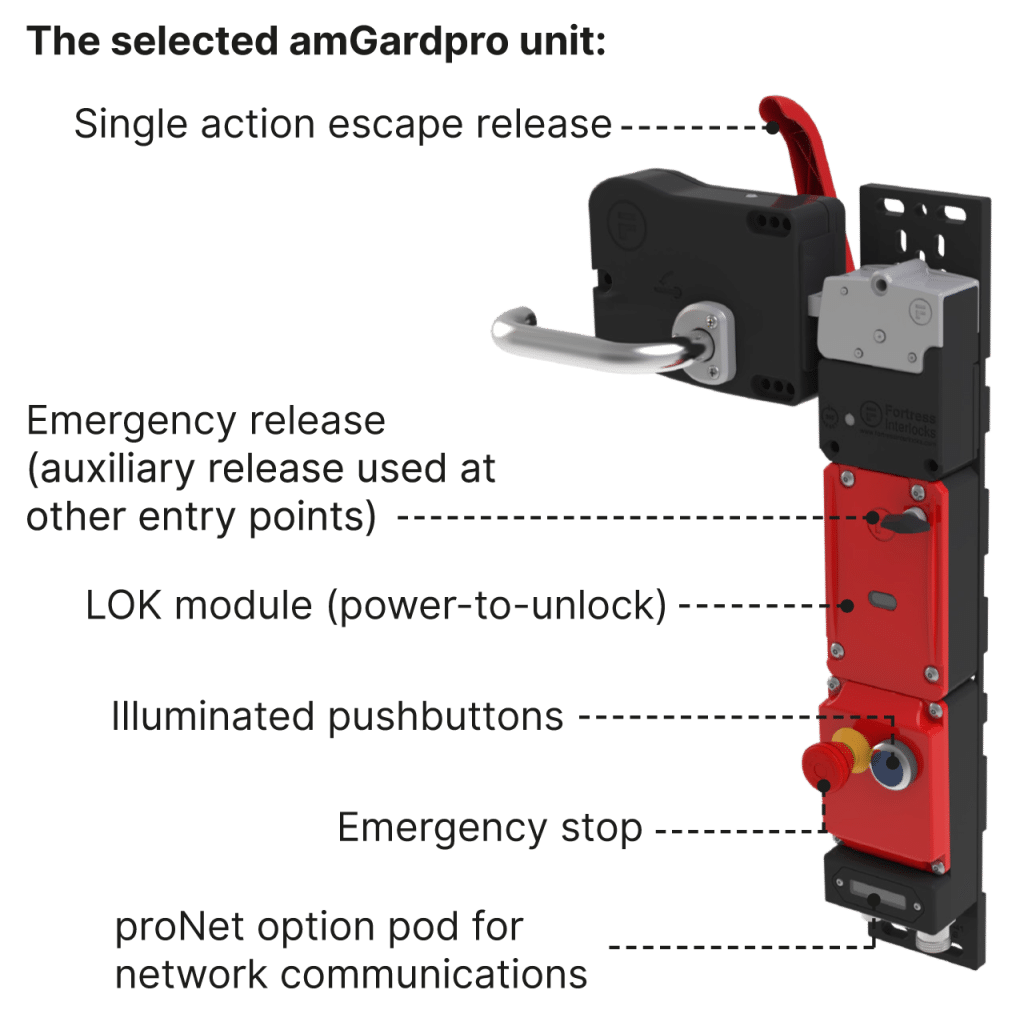

Fortress designed a customised interlocking solution from the amGardpro range. Different interlock configurations for aisle-specific entry (side access and end-of-row access, respectively) and I/O blocks were provided.

In particular, an all-in-one interlocking solution was used at the access points, featuring:

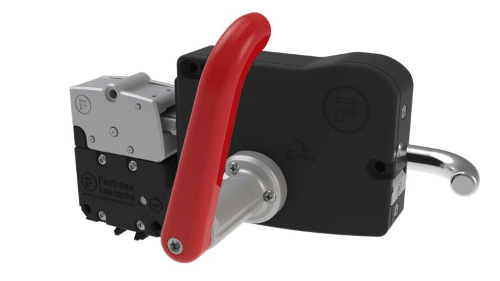

- Single action escape release handle – for enhanced operator safety, enabling quick exit from inside the safeguarded space

- Guard locking functionality (power-to-unlock) – for secure access control

- Manual release functionality – to unlock the device from outside; auxiliary release for the end-of-row access units, and emergency release for the side access units

- Illuminated emergency stop and pushbuttons – for improved usability and efficiency

The configuration for side access was used in four locations, while the one for end-of-row access was used in ten locations. The I/O blocks enabled the connection of e-stops or other safety devices and were installed in eight locations.

All the devices could communicate over the EtherCAT network and were pre-installed on mounting plates for easier and quicker installation. When safety, strength, and reliability are of paramount importance, amGardpro is the optimal solution.

Interlocks with emergency release for side access

Single action escape release

I/O blocks

The Key to Success

We were able to provide a solution tailored to the customer’s needs, addressing the requirements of their specific application. For this partnership we also developed a connector base that utilises L-coded M12 connectors instead of the larger 7/8” variants.

This project was made possible thanks to the cooperation of the various parties involved. Throughout the whole process, experts from Fortress Safety worked closely with OPEX®, offering advice, and ensuring optimal operation, together with Shingle & Gibb Automation (our channel partner), and East Coast Automation (our manufacturing rep).

Shingle & Gibb Automation provide products for industrial automation and networking, motion control, machine safety and power transmission. East Coast Automation is a manufacturers rep firm servicing the mid-Atlantic market.

Fortress Safety and ASRS

The products described in this case study were selected based on the requirements for a specific customer. Fortress offers a variety of safety solutions suitable for the warehouse automation industry and is a trusted partner in creating safer and more efficient ASRS environments. Some of our devices are also designed to conform with EN 528, a European standard that includes a range of requirements for ASRS, including key dependency and mode selection.

More Case Studies

Discover why Omnifactory (University of Nottingham) chose to work with Fortress Safety on their innovative project.

Fortress Safety has worked closely with Coca-Cola India to enhance personnel protection across nearly forty sites.

Fortress supplied interlocks for 100+ access points at Duferco’s new Smart Beam Manufacturing mill in Italy.