Monitored safety valves for fluid power

Monitored safety valves primarily designed as an interface between the fluid power operation of a machine and the electrical safety circuits monitoring gates, guards, and emergency stop circuits.

Benefits of Fluidsentry

Reduce Risk with Control of Fluid Power

The valves are designed to prevent unexpected start-up or movement of machinery by controlling the pneumatic or hydraulic energy.

Safety Redundancy

Devices offered with dual channel safety and dual channel exhausts (pneumatic) and tank outlets (hydraulic).

Safety Up Time

The Fluidsentry range has been designed with ‘up time’ in mind, that’s why Fluidsentry products all proudly boast ‘ single tool swap out’.

Robust and Durable

Fortress Fluidsentry products are built for longevity to guarantee a long operational lifetime.

Fully Serviceable

Perform a ‘single tool swap’ and send the affected unit to us. We can rectify, re-certify, and return the unit to you.

Retrofittable

Easily integrate Fluidsentry into your system. Installation is quick and easy with four pre-threaded holes on the base of the unit.

Reduce Risk with Control of Fluid Power

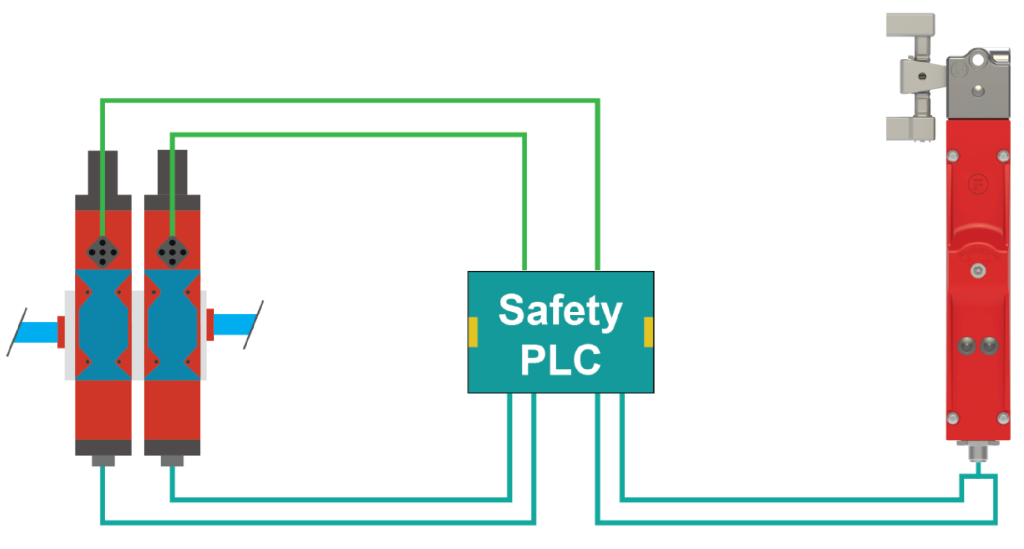

Valves can be interfaced with guard locking interlocks, ensuring power is in the off state before enabling access.

Safety Redundancy

Devices offered with dual channel safety and dual channel exhausts (pneumatic) and tank outlets (hydraulic).

Safety Up Time

The Fluidsentry range has been designed with ‘up time’ in mind, that’s why Fluidsentry products all proudly boast ‘ single tool swap out’.

Robust and Durable

Fortress Fluidsentry products are built for longevity to guarantee a long operational lifetime.

Fully Serviceable

Perform a ‘single tool swap’ and send the affected unit to us. We can rectify, re-certify, and return the unit to you.

Retrofittable

Easily integrate Fluidsentry into your system. Installation is quick and easy with four pre-threaded holes on the base of the unit.

Fluidsentry Features

Network Communications Model

Fortress offers an add on module to enable safety information to be communicated on ethernet networks.

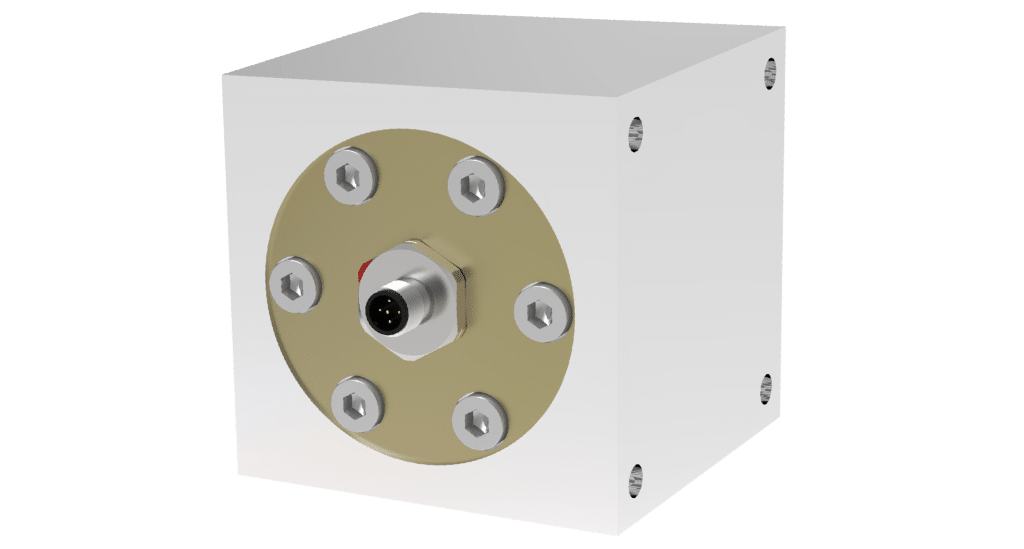

Monitor Pressure in Low Frequency Access Applications

Confirm pressurised systems are in a safe state. Non-adjustable, non-tamperable device to confirm zero pressure in your system.

Highest Safety Level for Access Control

Valves can be interfaced with guard locking interlocks, ensuring power is in the off state before enabling access.

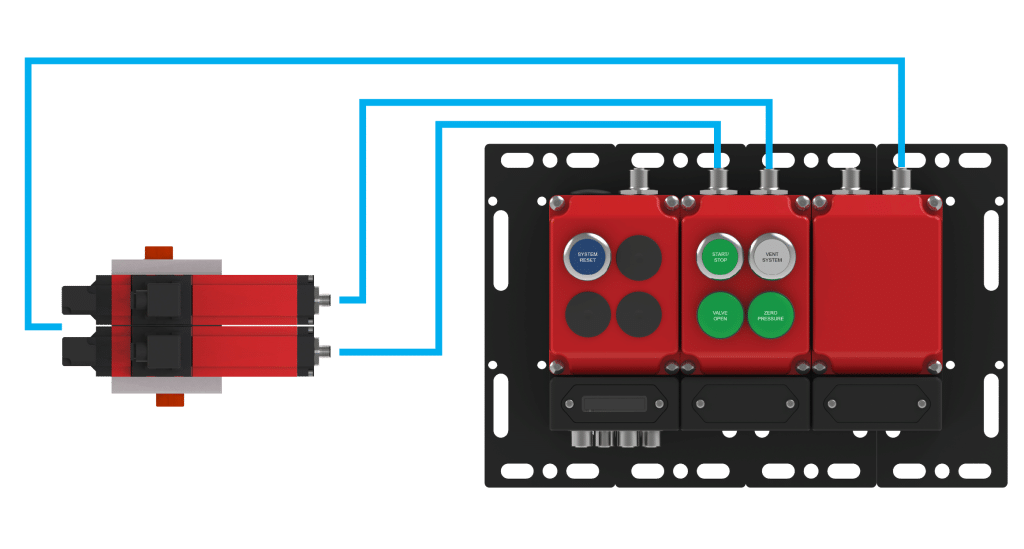

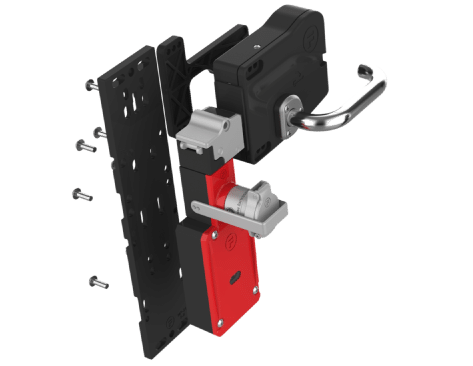

Mounting Plates and Connectors

Devices can be pre-fitted on mounting plates, reducing installation time and costs. Multiple connector configurations are available with the respective mating cables in different lengths.

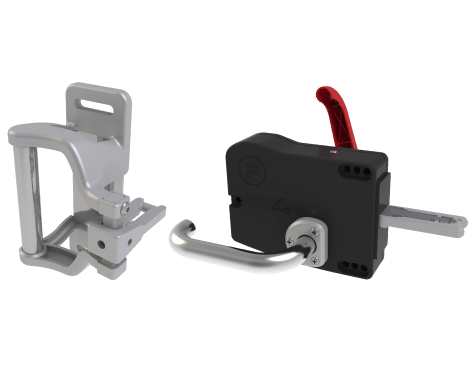

Heads and Actuators

A variety of actuators for hinged and sliding guards. Market leading misalignment capabilities to cope with guards’ movement and variability in machine guarding installation.

Monitored and Controlled Access

Interlock monitoring to detect guard opening. Interlocks can also include a solenoid controlled locking functionality for guard locking or locking for the protection of process.

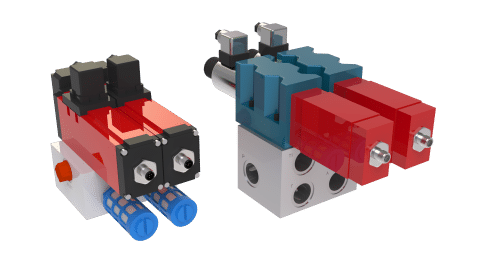

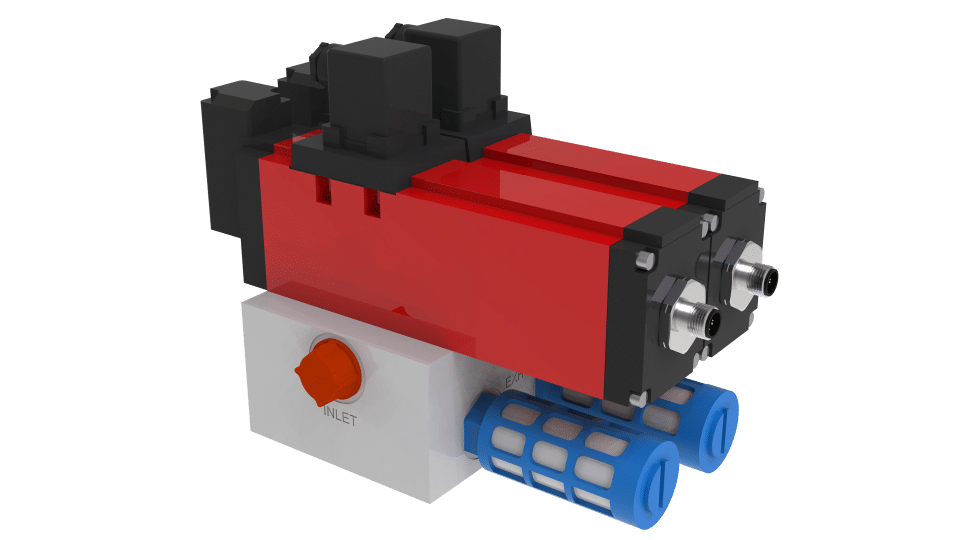

Pneumatic Monitored Safety Valves

Directional control valves for pneumatic safety applications in five port two position sliding spool type with static seals, mounted on a safety manifold configured for three port two position operation.

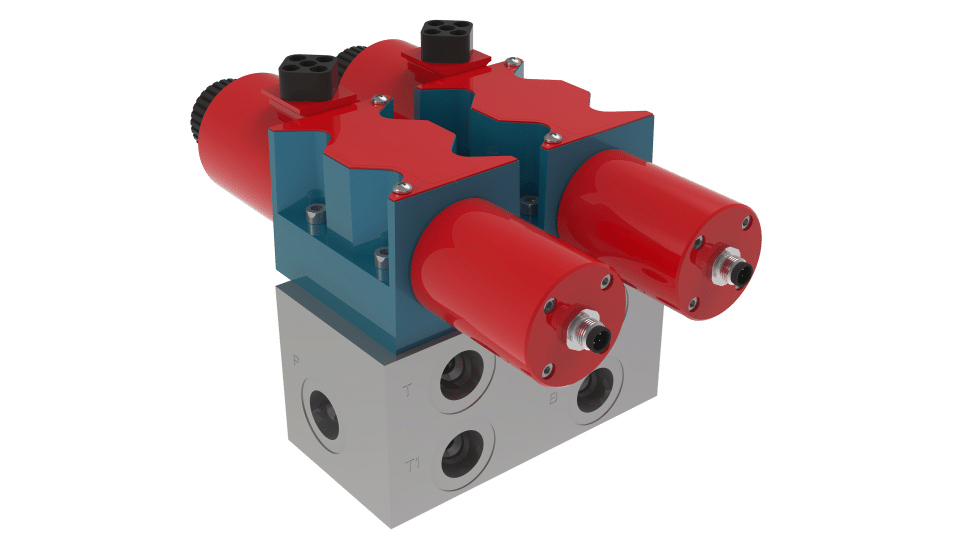

Hydraulic Monitored Safety Valves

Dual directional control valves mounted on a specially manufactured mainfold for hydraulic safety applications.

Speak to an expert about your access, control and safety needs

Contact our expert sales team to discuss the best solution for your application needs, or use our custom configurators to build the right solution for you.

Document Downloads

Operating Instructions

Login to access all documents

Access additional technical files related to this product range by signing up to MyFortress

News & Insights

Not sure where to start? We’re here to help

Our dedicated team of experts are here to help create the right solution for you. They can analyse your industry and specific application needs to offer recommendations on how Fortress products could benefit your setup.