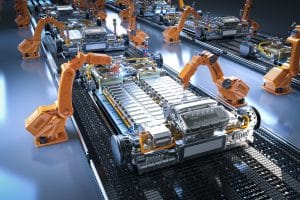

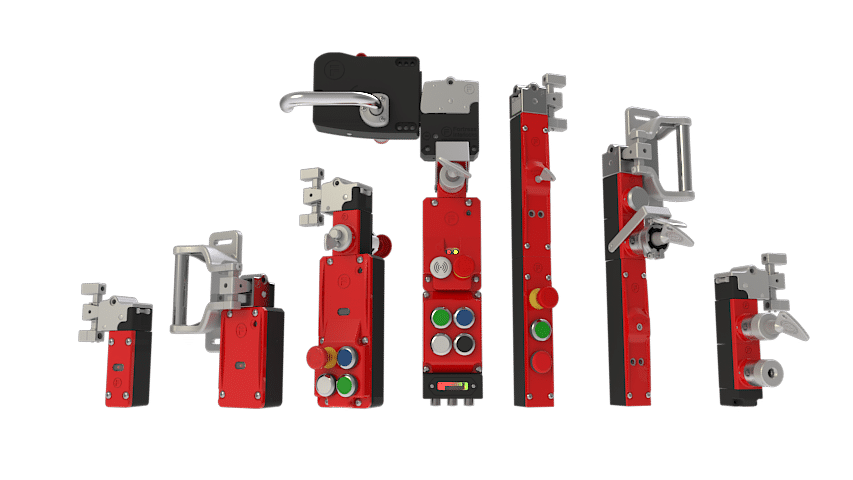

Networked interlocks and control pods

Configurable interlocks and control pods for heavy-duty applications across all industries. Pushbutton controls and trapped key options can be combined into a single unit. Certified for use up to PLe/Cat. 4. Connectivity over EtherNet/IP, PROFINET and EtherCAT is enabled by the proNet communication module.

Benefits of amGardpro

Highly Configurable

Completely configurable, with a variety of features to choose from. Create tailored safety solutions to meet specific application requirements.

Reduce Replacements and Downtime

Made of metal alloy and stainless steel, amGardpro is extremely durable, reducing wear and tear, thus minimising the need for replacements and machine downtime.

All the Controls in One Place

Pushbuttons, lamps, emergency stops, and keys can be incorporated into a single device, providing an all-round and cost-effective solution.

Network Connectivity

The proNet communication module allows amGardpro to communicate with the major industrial network protocols: EtherNet/IP, PROFINET and EtherCAT.

Integration Made Easy

Several types of quick disconnects make the installation process quicker and more efficient. Optional mounting plates are also available.

Enhanced Safety

Designed for high reliability. Tested and third-party certified for use up to PLe/Cat. 4 or SIL 3.

Highly Configurable

Completely configurable, with a variety of features to choose from. Create tailored safety solutions to meet specific application requirements.

Reduce Replacements and Downtime

Made of metal alloy and stainless steel, amGardpro is extremely durable, reducing wear and tear, thus minimising the need for replacements and machine downtime.

All the Controls in One Place

Pushbuttons, lamps, emergency stops, and keys can be incorporated into a single device, providing an all-round and cost-effective solution.

Network Connectivity

The proNet communication module allows amGardpro to communicate with the major industrial network protocols: EtherNet/IP, PROFINET and EtherCAT.

Integration Made Easy

Several types of quick disconnects make the installation process quicker and more efficient. Optional mounting plates are also available.

Enhanced Safety

Designed for high reliability. Tested and third-party certified for use up to PLe/Cat. 4 or SIL 3.

amGardpro Features

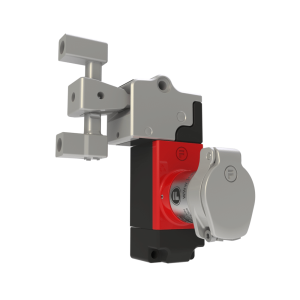

Monitored and Controlled Access

Interlock monitoring to detect guard opening. Interlocks can also include a solenoid controlled locking functionality for guard locking or locking for the protection of process.

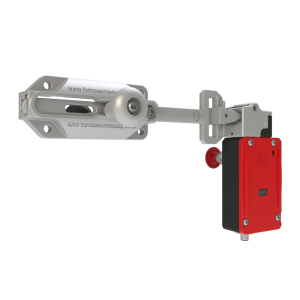

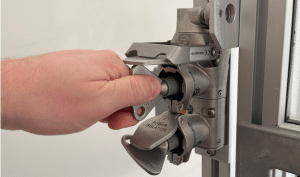

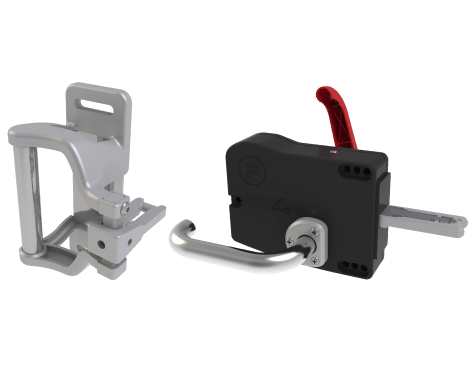

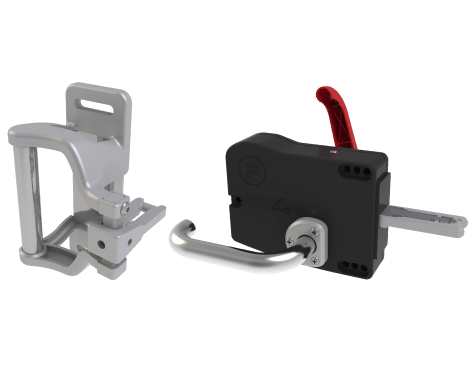

Heads and Actuators

A variety of actuators for hinged and sliding guards. Market leading misalignment capabilities to cope with guards’ movement and variability in machine guarding installation.

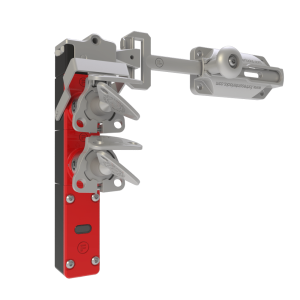

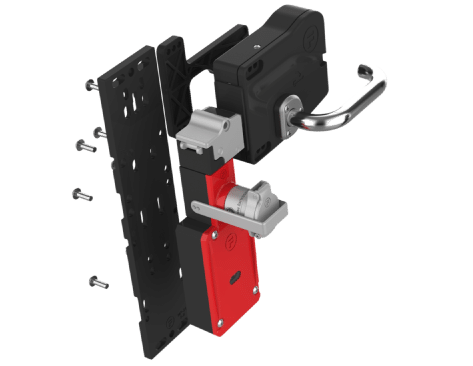

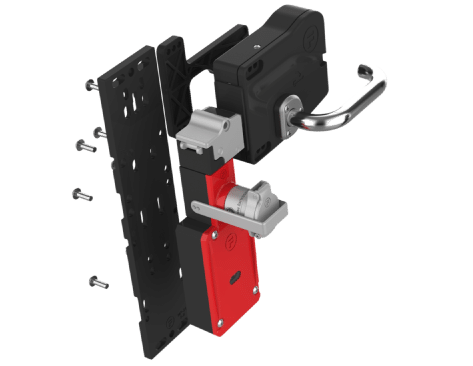

Mounting Plates and Connectors

Devices can be pre-fitted on mounting plates, reducing installation time and costs. Multiple connector configurations are available with the respective mating cables in different lengths.

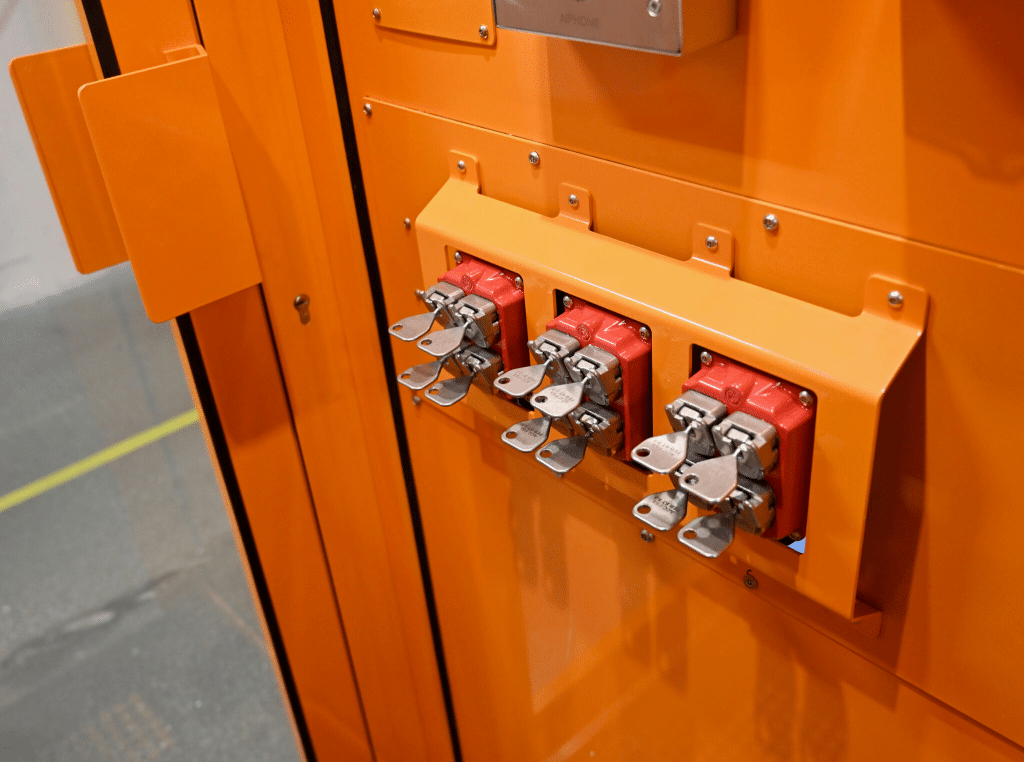

Trapped Key Adaptors

Trapped keys can be used to control access or as proactive inhibit functions to protect personnel. RFID coded personnel keys are also available.

Option Pods

Available as a standalone product or as part of an amGardpro interlock, option pods allow the incorporation of pushbuttons, selector switches, lamps, and emergency stops.

Escape Release

Escape release options to allow personnel to leave the safeguarded space should they become trapped. Single action, push reset, or key reset variants available.

Monitored and Controlled Access

Interlock monitoring to detect guard opening. Interlocks can also include a solenoid controlled locking functionality for guard locking or locking for the protection of process.

Heads and Actuators

A variety of actuators for hinged and sliding guards. Market leading misalignment capabilities to cope with guards’ movement and variability in machine guarding installation.

Mounting Plates and Connectors

Devices can be pre-fitted on mounting plates, reducing installation time and costs. Multiple connector configurations are available with the respective mating cables in different lengths.

Trapped Key Adaptors

Trapped keys can be used to control access or as proactive inhibit functions to protect personnel. RFID coded personnel keys are also available.

Option Pods

Available as a standalone product or as part of an amGardpro interlock, option pods allow the incorporation of pushbuttons, selector switches, lamps, and emergency stops.

Escape Release

Escape release options to allow personnel to leave the safeguarded space should they become trapped. Single action, push reset, or key reset variants available.

Network Connectivity with proNet

Enabling Communication with Industrial Network Protocols. A proNet option pod can be configured as part of an amGardpro interlock, but also as standalone control station and connected to external devices.

Installation and validation can be performed at reduced time and cost compared to hardwired connections.

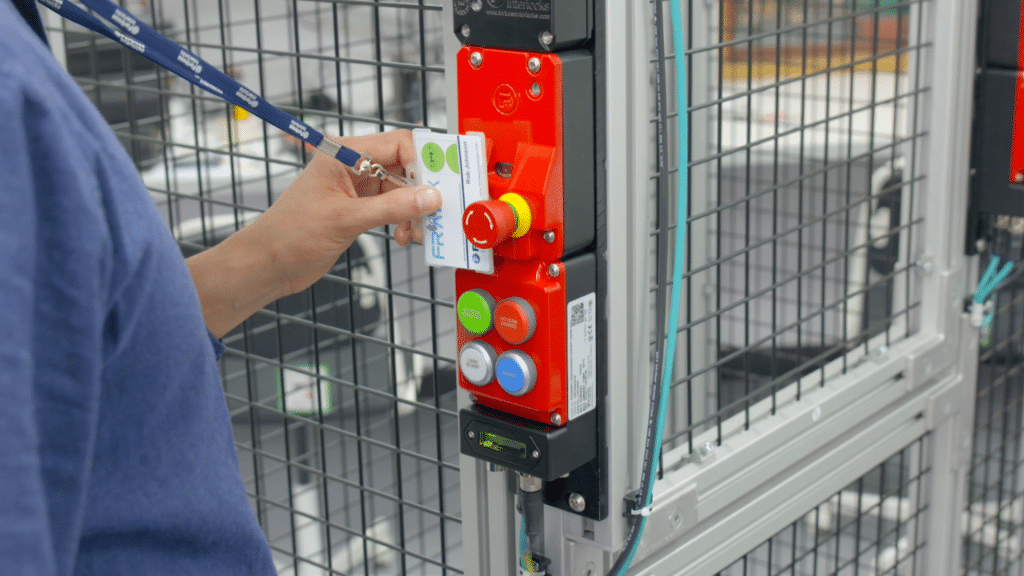

Managing Permissions over Industrial Networks

Fortress has developed Fortress RFID Access Network Keys (FRANK). Using the employees’ existing RFID cards, the FRANK system allows the assignment of employee permissions, which can then be used to enforce conditions for machine operation or access.

Designed to work with proNet devices, FRANK can be integrated into automation systems using network protocols to manage access control permissions.

RFID Safety Keys (RSK)

Speak to an expert about your access, control and safety needs

Contact our expert sales team to discuss the best solution for your application needs, or use our custom configurator to build the right solution for you.

amGardpro Product Catalogue

amGardpro Videos

Playlist

Document Downloads

Brochures

Log in to access all documents

Access additional technical files related to this product range by signing up to MyFortress

Support Tools

news & Insights

- Event

Not sure where to start? We’re here to help

Our dedicated team of experts are here to help create the right solution for you. They can analyse your industry and specific application needs to offer recommendations on how Fortress products could benefit your setup.