Configurable Access & Control Solutions

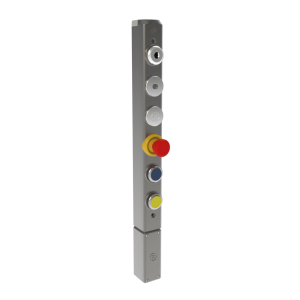

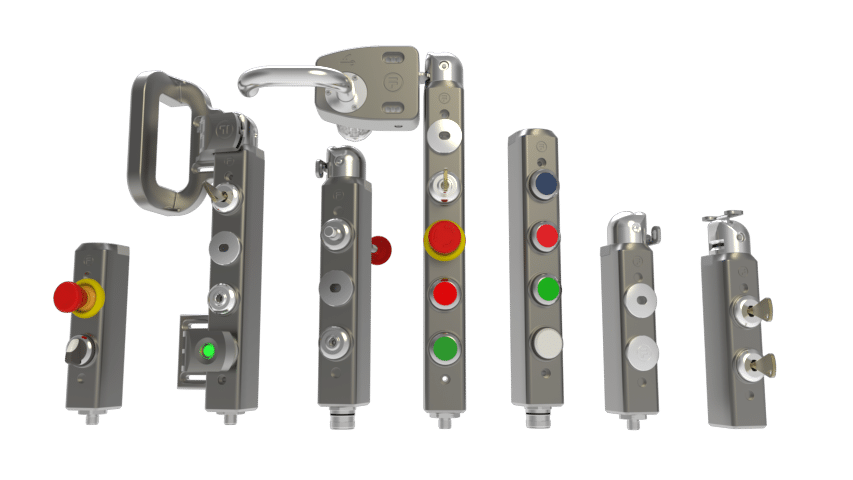

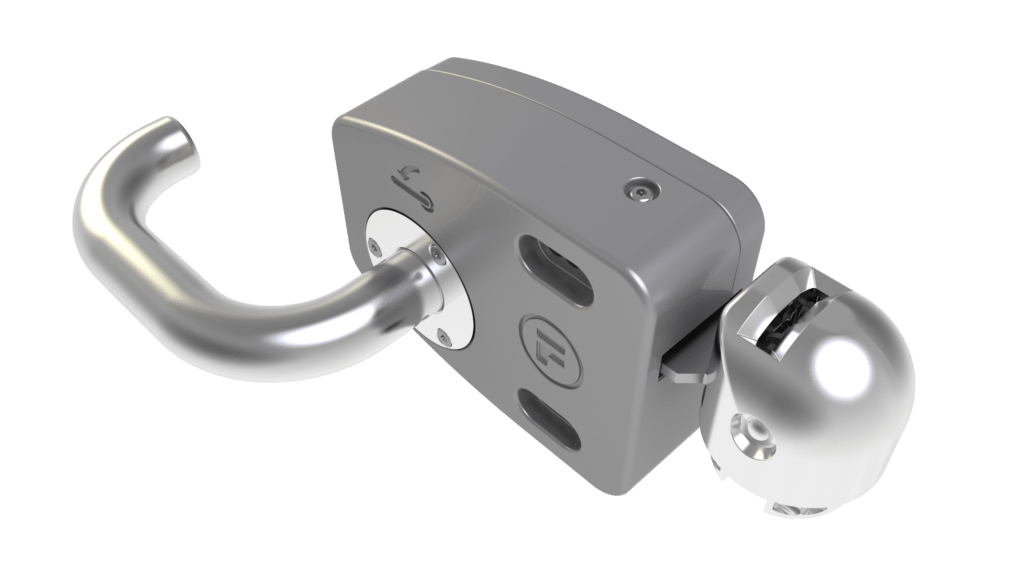

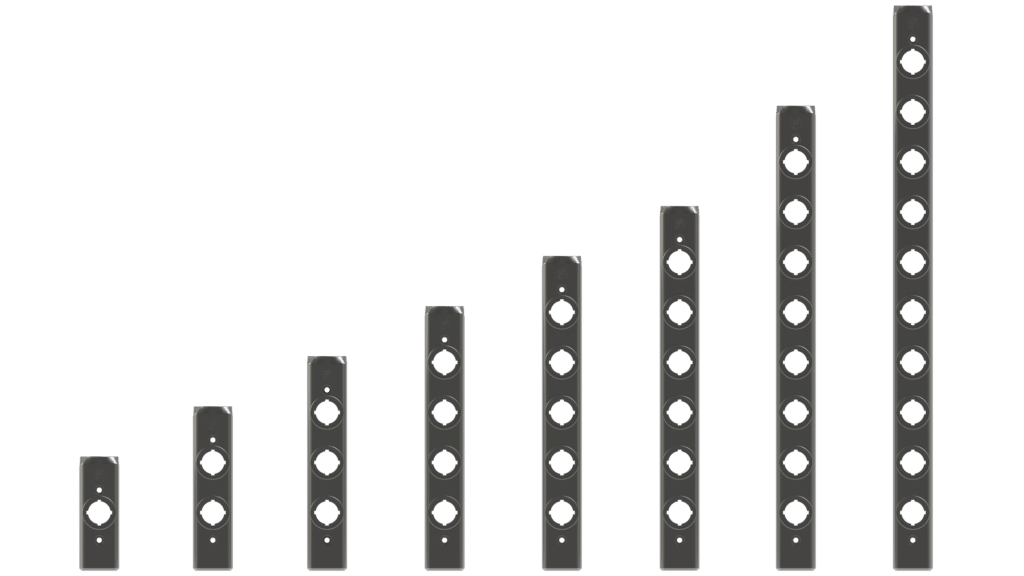

A versatile range of interlocks and control stations. tGard can accommodate up to ten modules, including trapped keys and operator controls. Each unit is housed in a robust 40mm metal body, making them suitable for various manufacturing and industrial automation applications.

Benefits of tGard

Tailored To Your Requirements

With eight body types and up to ten features per unit, tGard can be configured to meet your specific needs.

Efficient Integrated Solution

Combine multiple operator controls into a single device. Available as part of an interlock or control station.

Designed for High Reliability

Third party certified for use up to PLd/Cat. 3, or PLe/Cat. 4 where the High Level Coded element is used.

Installation Made Easy

With just two mounting points, QD connectors options, and a compact 40mm housing, tGard can be installed easily.

Resistant and Durable

Compact metal body for long-lasting operations in a variety of manufacturing and industrial automation settings.

Safety Data Communications

tGard can communicate directly with an IO-Link Safety master and provide important status information. AS-I safe solutions are also available.

Tailored to Your Requirements

With eight body types and up to ten features per unit, tGard can be configured to meet your specific needs.

Efficient Integrated Solution

Combine multiple operator controls into a single device. Available as part of an interlock or control station.

Designed for High Reliability

Third party certified for use up to PLd/Cat. 3, or PLe/Cat. 4 where the High Level Coded element is used.

Installation Made Easy

With just two mounting points, QD connectors options, and a compact 40mm housing, tGard can be installed easily.

Resistant and Durable

Compact metal body for long-lasting operations in a variety of manufacturing and industrial automation settings.

Safety Data Communications

tGard can communicate directly with an IO-Link Safety master and provide important status information. AS-I safe solutions are also available.

tGard Features

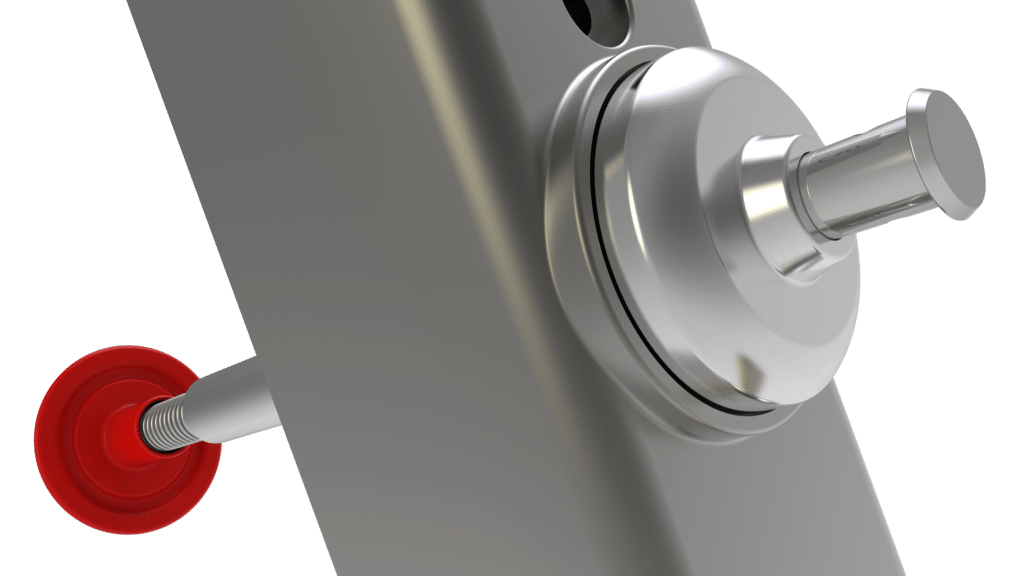

Integrated Machine Controls

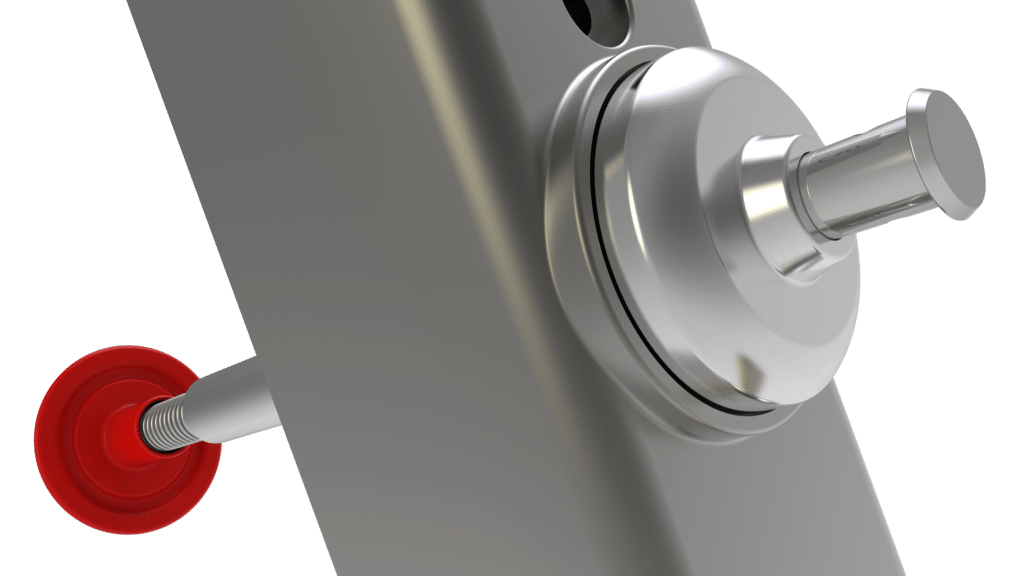

Configure interlocks and control stations with a combination of custom engraved pushbuttons, lamps, switches and emergency stop elements.

Keys and Escape Release

Include access keys, personnel keys, and escape release functionality to enforce processes and protect personnel against unexpected start-up.

Monitored and Controlled Access

tGard interlocks feature guard monitoring, with options for solenoid controlled locking with guard locking for applications with a rundown time.

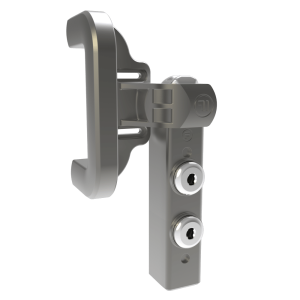

Heads and Actuators

A variety of actuators for hinged and sliding guards. The head can be easily rotated onsite depending on the desired orientation.

Safety and Control Connectors

Pre-wired units with a variety of quick disconnect options. Also available with AS-Interface and IO-Link Safety.

40mm Aluminium Body

Suitable for a variety of manufacturing and industrial automation applications. Eight body types available.

Integrated Machine Controls

Configure interlocks and control stations with a combination of custom engraved pushbuttons, lamps, switches and emergency stop elements.

Keys and Escape Release

Include access keys, personnel keys, and escape release functionality to enforce processes and protect personnel against unexpected start-up.

Monitored and Controlled Access

tGard interlocks feature guard monitoring, with options for solenoid controlled locking with guard locking for applications with a rundown time.

Heads and Actuators

A variety of actuators for hinged and sliding guards. The head can be easily rotated onsite depending on the desired orientation.

Safety and Control Connectors

Pre-wired units with a variety of quick disconnect options. Also available with AS-Interface and IO-Link Safety.

40mm Aluminium Body

Suitable for a variety of manufacturing and industrial automation applications. Eight body types available.

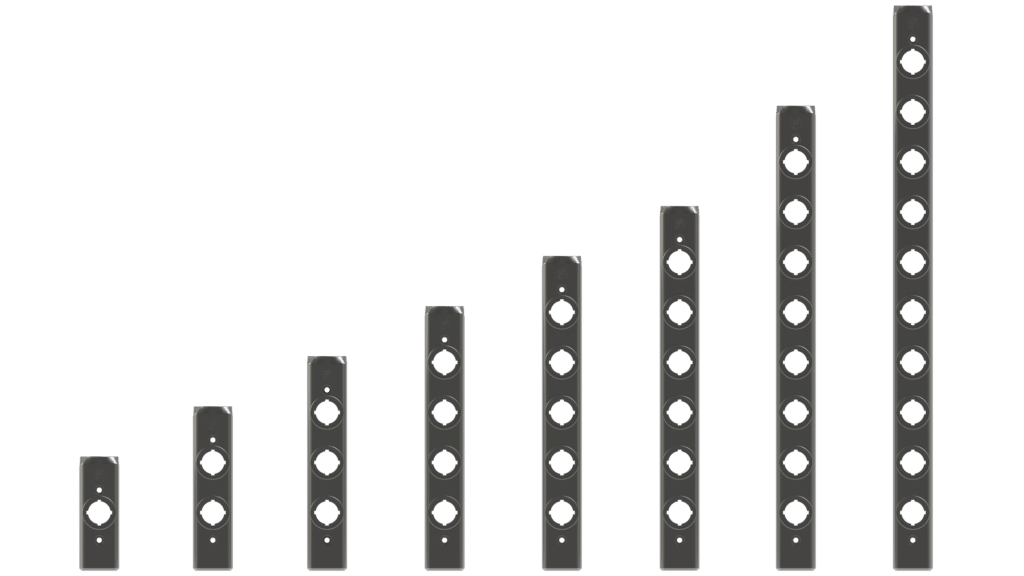

Up to 10 modules per unit

With 8 different body types, tGard can accommodate up to 10 modules.

A range of hinging, sliding and ergonomic actuators, customisable operator controls, and escape release option are available.

IO-Link Safety

tGard can be integrated into an IO-Link system with safe point-to-point communication, with increased productivity and increased data availability and accuracy.

The single 5-pin connector helps reduce cabling costs and simplifies installation, maintenance and replacement processes. A valuable and cost-effective solution for small/medium sized spaces.

High Level Coded Element

Speak to an expert about your access, Control and control needs

Contact our expert sales team to discuss the best solution for your application needs, or use our custom configurator to build the right solution for you.

tGard compatible parts

Document Downloads

Brochures

Log in to access all documents

Access additional technical files related to this product range by signing up to MyFortress

News & Insights

Not sure where to start? We’re here to help

Our dedicated team of experts are here to help create the right solution for you. They can analyse your industry and specific application needs to offer recommendations on how Fortress products could benefit your setup.