Building Materials

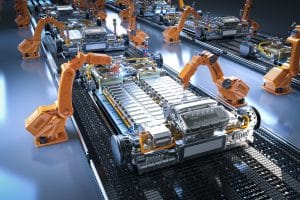

When manufacturing building materials such as glass, concrete, and clay, handling heavy materials and high-temperature processes presents significant hazards. Key challenges include preventing injuries from moving parts and reducing risks associated with high-pressure systems, dust, and fumes.

Fortress Safety helps to tackle these challenges with robust solutions designed for heavy-duty environments. Our products are well-suited for demanding conditions and limited visibility scenarios and can withstand high levels of dust and dirt. This durability helps reduce component failures, protect operators, and minimize machine downtime.

| Advanced Safety Features |

Coded actuators, safety monitoring, and guard locking to prevent defeat, enhance safety and ensure compliance with standards.

Dust and Dirt Resistance

IP67 and IP69 rated solutions for environments where dust and dirt residues can cause blockages or damage mechanical parts.

Unexpected Start-Up Prevention

Multiple options available to give operators control to prevent a machine being reset while they are inside the safeguarded space.

Fully Configurable Products

Design tailored safety solutions to meet the specific requirements of any application.

Minimise Downtime and Replacements

Robust products built to last for decades, even in the most challenging applications and harshest environments.

| Global Reach |

With offices around the world and a large network of trusted partners, Fortress offers support globally.

Advanced Safety Features

Coded actuators, safety monitoring, and guard locking to prevent defeat, enhance safety and ensure compliance with standards.

Dust and Dirt Resistance

IP67 and IP69 rated solutions for environments where dust and dirt residues can cause blockages or damage mechanical parts.

Unexpected Start-Up Prevention

Multiple options available to give operators control to prevent a machine being reset while they are inside the safeguarded space.

Fully Configurable Products

Design tailored safety solutions to meet the specific requirements of any application.

Minimise Downtime and Replacements

Robust products built to last for decades, even in the most challenging applications and harshest environments.

Global Reach

With offices around the world and a large network of trusted partners, Fortress offers support globally.

Get started on your custom solution

Recommended Product Range

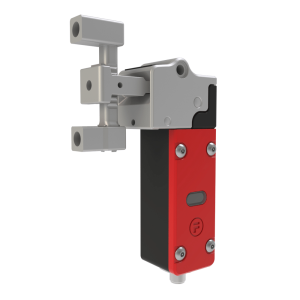

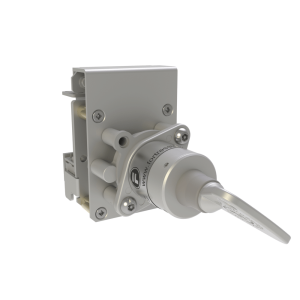

amGardpro

Configurable interlocks and control pods for heavy-duty applications certified for use up to PLe/Cat. 4. Pushbutton controls, trapped key options, and network connectivity can be combined into a single unit.

Highly configurable

Reduce replacements and downtime

All the controls in one place

Network connectivity

Recommended Product Range

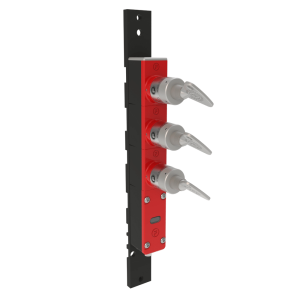

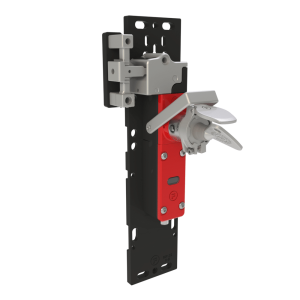

mGard

Mechanical trapped key interlocks designed to enforce specific key sequences, particularly in applications involving multiple energy sources. Cost-effective, easy to install and maintain, and ideal for areas difficult to reach with cables.

Enforce sequences

Control hazardous energy

Minimise machine downtime

No need for wiring

News & Insights

Other Industries

Not sure where to start? We’re here to help

Our dedicated team of experts are here to help create the right solution for you. They can analyse your industry and specific application needs to offer recommendations on how Fortress products could benefit your setup.