Food & Beverage

Hygienic Applications

With IP69 rated and 3-A approved guard locking solutions for washdown environments or for close contact with food.

Stainless Steel Interlocks

Where resistance to corrosion and regular washing is required.

Advanced Safety Features

Coded actuators, safety monitoring, and guard locking to prevent defeat, enhance safety and ensure compliance with standards.

Fully Configurable Products

Design tailored safety solutions to meet the specific requirements of any application.

Minimise Downtime and Replacements

Robust products built to last for decades, even in the most challenging applications and harshest environments.

Global Reach

With offices around the world and a large network of trusted partners, Fortress offers support globally.

Hygienic Applications

With IP69 rated and 3-A approved guard locking solutions for washdown environments or for close contact with food.

Stainless Steel Interlocks

Where resistance to corrosion and regular washing is required.

Advanced Safety Features

Coded actuators, monitoring, and guard locking to minimise the possibility of defeat, reduce risk and ensure compliance with standards.

Fully Configurable Products

Design tailored safety solutions to meet the specific requirements of any application.

Minimise Downtime and Replacements

Robust products built to last for decades, even in the most challenging applications and environments.

Global Reach

With offices around the world and a large network of trusted partners, Fortress offers support globally.

Applications -

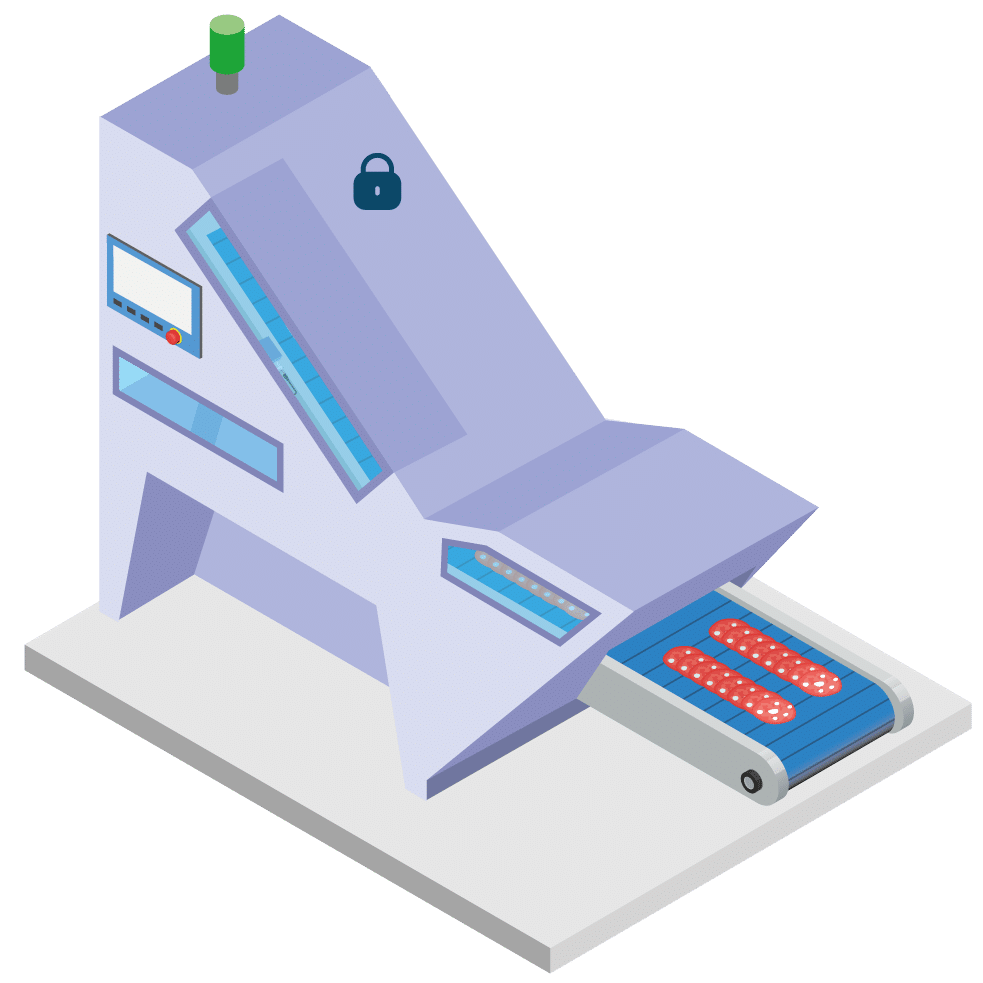

Food Slicer

Hygienic Guard Lock on an Automatic Food Slicer

In the food processing industry, machines like automatic food slicers are commonly used to slice a wide variety of products, including meat and cheese. Such machines have hatches that need to stay closed during the process but may need to be opened periodically for scheduled cleaning and maintenance. The Challenge The machine has blades that […]

Applications -

Robot Stacking

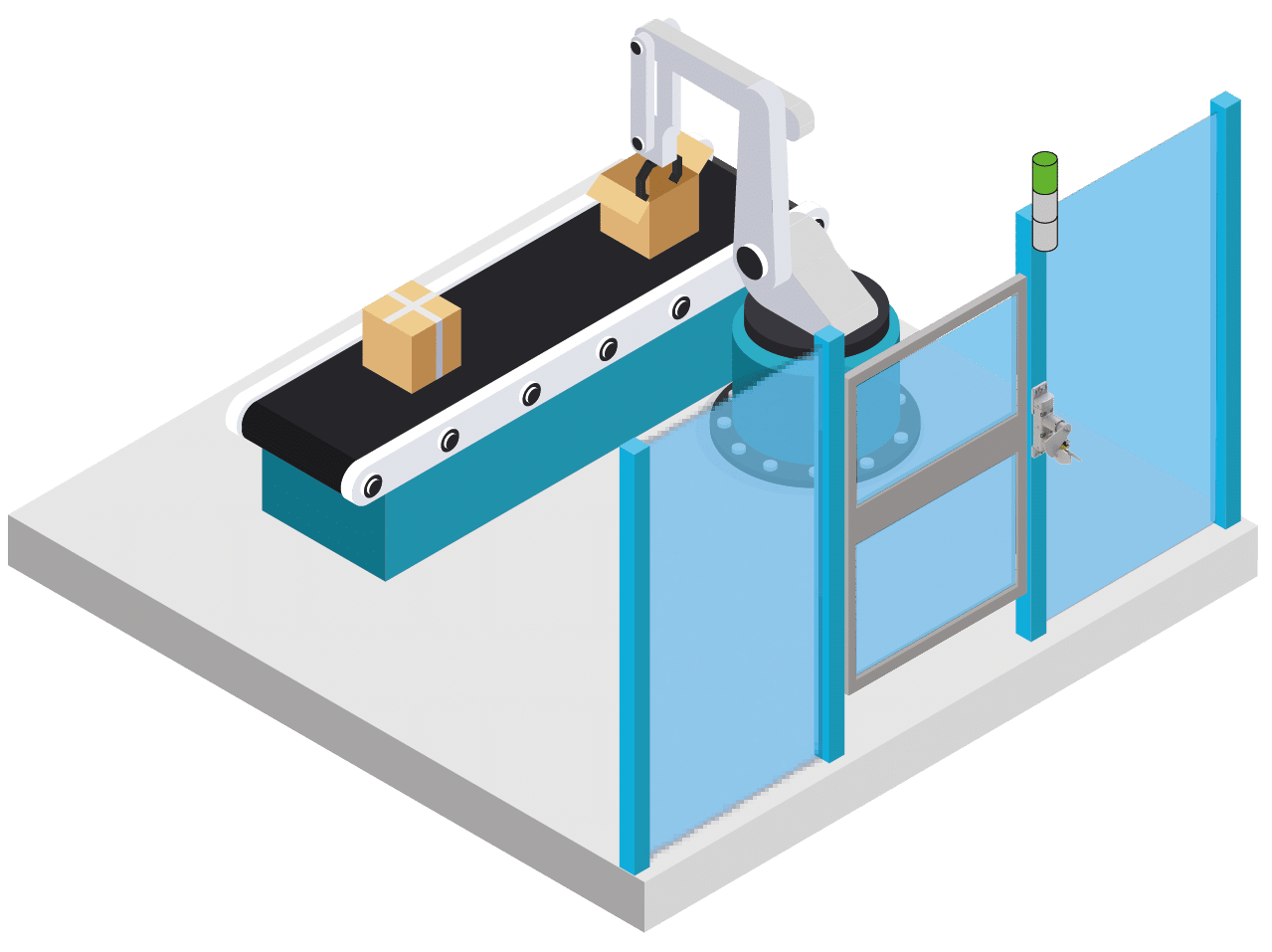

Interlock Blocking for a Robotic Stacking Cell

The customer is a global leader in contact lenses. As part of the production process, robots pick and stack boxes containing contact lenses before they are sent off for packaging. The Challenge The guard that allows access to the area where the robot operates features a sensor that indicates whether it is open or closed. […]

Applications -

Mixer

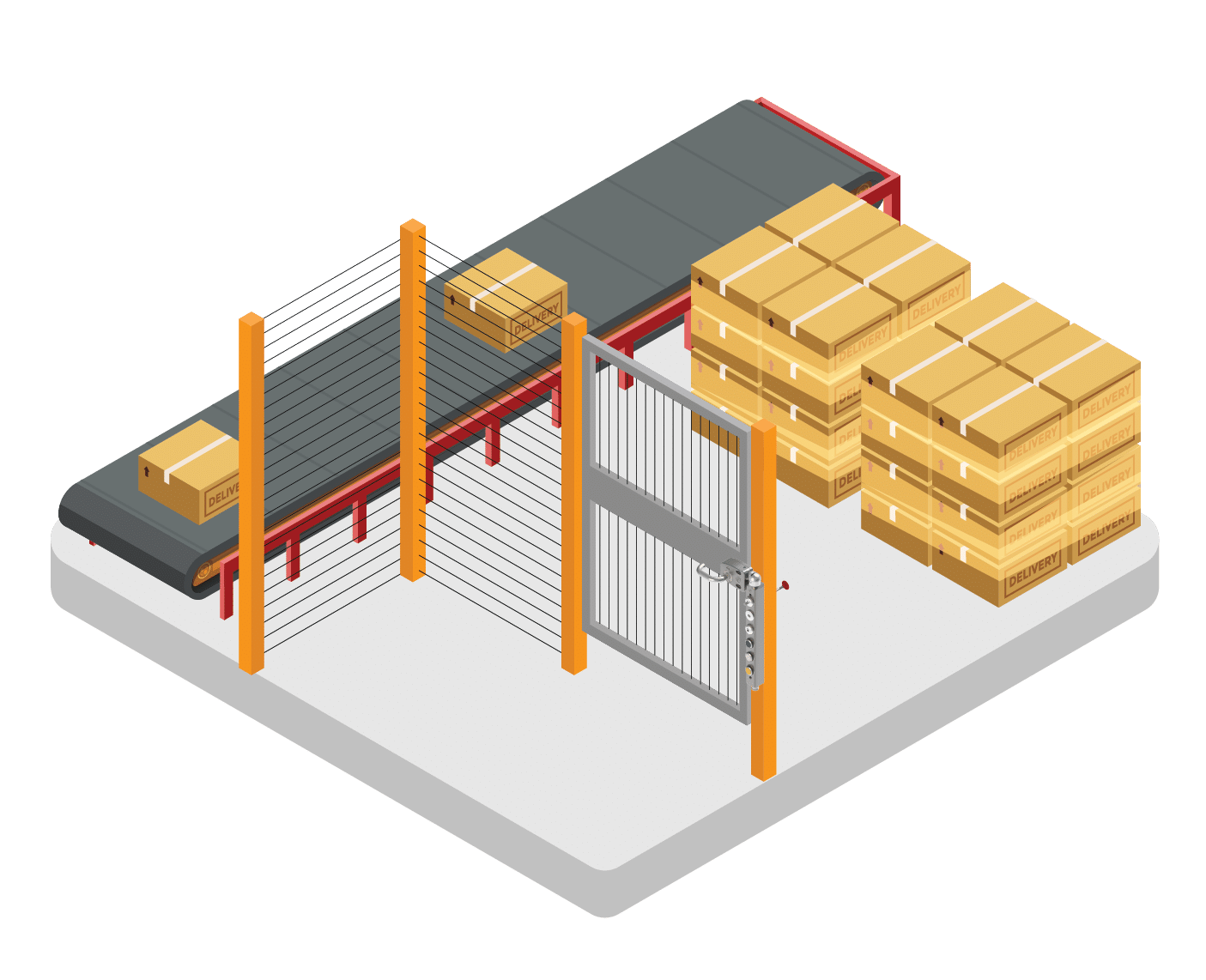

Conveyor System

Conveyor systems in automated warehouses efficiently transport goods throughout the facility, reducing manual labour and increasing speed. They often integrate with other automation technologies to streamline operations from receiving to order fulfilment. In some circumstances, conveyor systems may be safeguarded by interlocked guards to prevent personnel exposure to potential hazards. The Challenge Personnel may need […]

Get started on your custom solution

Case Study-

Tata Steel

Twenty Years of Protecting People at Tata Steel Llanwern

For over two decades, Fortress Safety has been working closely with Tata Steel to protect the personnel at their sites. Tata Steel is among the top global steel producers and is the largest steelmaker in the United Kingdom.

Products Used

mGard, amGardpro, FRANK

Industry

Metals Production

Who are Coca-Cola?

The Coca-Cola Company is a multinational corporation that manufactures and sells beverages.

Case Study - Coca Cola

Enhancing machinery safety at bottling sites

The beverage production industry faces intricate safety challenges, with machinery safety being one of the critical aspects. Several machinery-related injuries in drink production factories are caused by applications involving conveyors, bottling machines, packaging machines, and palletisers.

Products Used

amGardpro, mGard, Osbourn

Partners Involved

Deebar, South Africa

Who are Coca-Cola?

The Coca-Cola Company is a multinational corporation that manufactures and sells beverages.

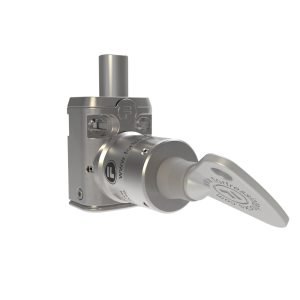

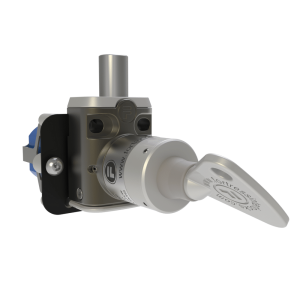

Recommended Product Range

HGL

The Hygienic Guard Lock (HGL) is a 3-A approved hygienic interlock with stainless steel construction and FDA food contact compliant silicon seals. Designed for washdown and for situations where hygiene and good sanitation are critical.

Certified food-safe design

Corrosion-resistant stainless steel

Cleaning made easy

Suitable for small access points

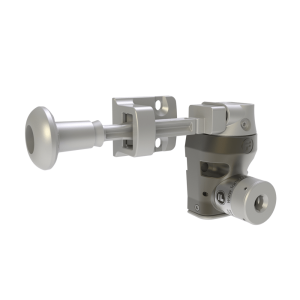

Recommended Product Range

mGard

Mechanical trapped key interlocks designed to enforce specific key sequences, particularly in applications involving multiple energy sources. Cost-effective, easy to install and maintain, with stainless steel variants available

Stainless steel options

Enforce sequences

Minimise machine downtime

No need for wiring

News & Insights

Not sure where to start? We’re here to help

Our dedicated team of experts are here to help create the right solution for you. They can analyse your industry and specific application needs to offer recommendations on how Fortress products could benefit your setup.