Metals Production

The metal production industry involves diverse machinery applications and challenging conditions, from high-temperature transformations to rolling mills and complex processing equipment. Common hazards include exposure to molten metal, heavy-duty machinery, and harsh environments that can lead to corrosion and structural integrity issues. Protecting personnel from these hazards is crucial.

At Fortress, we leverage our extensive expertise in machinery safety and product offerings to provide safety solutions tailored to metal production applications, helping leading manufacturers meet their specific requirements and protect their personnel with products that can withstand the industry’s demanding conditions.

Large Area Coverage

Enforce sequences over large distances and in areas where wiring is impractical and visibility is limited.

Metal and Stainless Steel Solutions

Ideal for extreme environments where resistance to high temperatures and corrosion is required.

Networked Solutions

Communicate standard and safety I/O via industrial networks, manage access permissions and prevent unauthorized access.

Fully Configurable Products

Design tailored safety solutions to meet the specific requirements of any application.

Minimise Downtime and Replacements

Robust products built to last for decades, even in the most challenging applications and harshest environments.

Global Reach

With offices around the world and a large network of trusted partners, Fortress offers support globally.

Large Area Coverage

Enforce sequences over large distances and in areas where wiring is impractical and visibility is limited.

Metal and Stainless Steel Solutions

Ideal for extreme environments where resistance to high temperatures and corrosion is required.

Networked Solutions

Communicate standard and safety I/O via industrial networks, manage access permissions and prevent unauthorized access.

Fully Configurable Products

Configure safety solutions to meet the specific requirements of any application.

Minimise Downtime and Replacements

Robust products built to last for decades, even in the most challenging applications and environments.

Global Reach

With offices around the world and a large network of trusted partners, Fortress offers support globally.

Get started on your custom solution

Case Study-

Tata Steel

Twenty Years of Protecting People at Tata Steel Llanwern

For over two decades, Fortress Safety has been working closely with Tata Steel to protect the personnel at their sites. Tata Steel is among the top global steel producers and is the largest steelmaker in the United Kingdom.

Products Used

mGard, amGardpro, FRANK

Industry

Metals Production

Who are Duferco?

Duferco Group are a global leader in steel production, energy,

shipping and innovation.

Case Study-

Tata Steel

Twenty Years of Protecting People at Tata Steel Llanwern

For over two decades, Fortress Safety has been working closely with Tata Steel to protect the personnel at their sites. Tata Steel is among the top global steel producers and is the largest steelmaker in the United Kingdom.

Products Used

mGard, amGardpro, FRANK

Industry

Metals Production

Who are Tata Steel?

Tata Steel are a leading global steel manufacturer known for its integrated operations, sustainable practices, and a strong presence in automotive, construction, and infrastructure.

Recommended Product Range

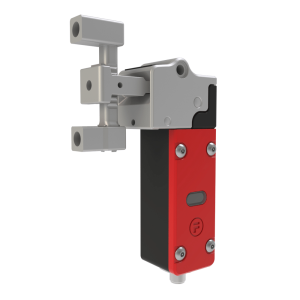

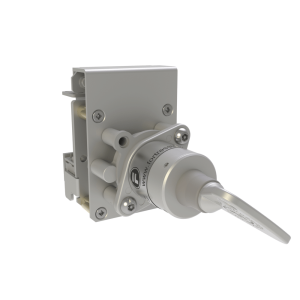

amGardpro

Pushbutton controls, trapped key options, and network connectivity can be combined into a single unit.

Highly configurable

Reduce replacements and downtime

All the controls in one place

Network connectivity

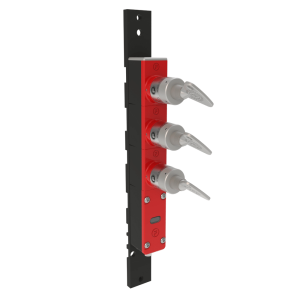

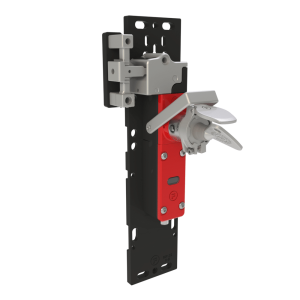

Recommended Product Range

mGard

Mechanical trapped key interlocks designed to enforce specific key sequences, particularly in applications involving multiple energy sources. Cost-effective, easy to install and maintain, and ideal for areas difficult to reach with cables.

Enforce sequences

Control hazardous energy

Minimise machine downtime

No need for wiring

News & Insights

Other Industries

Not sure where to start? We’re here to help

Our dedicated team of experts are here to help create the right solution for you. They can analyse your industry and specific application needs to offer recommendations on how Fortress products could benefit your setup.