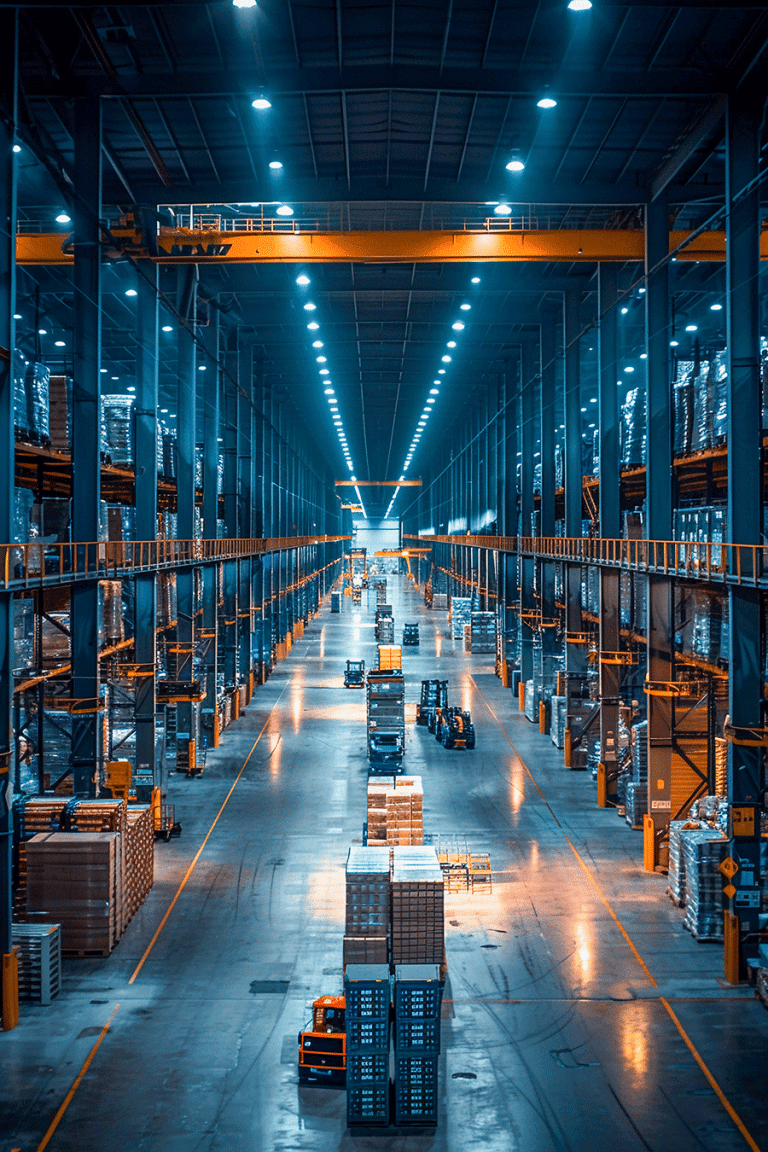

Automated Warehousing

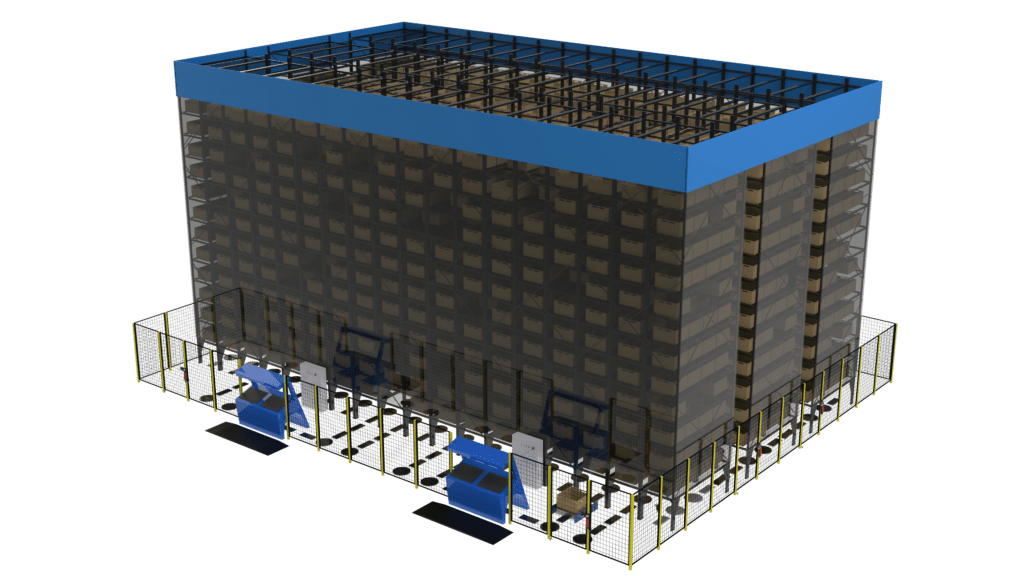

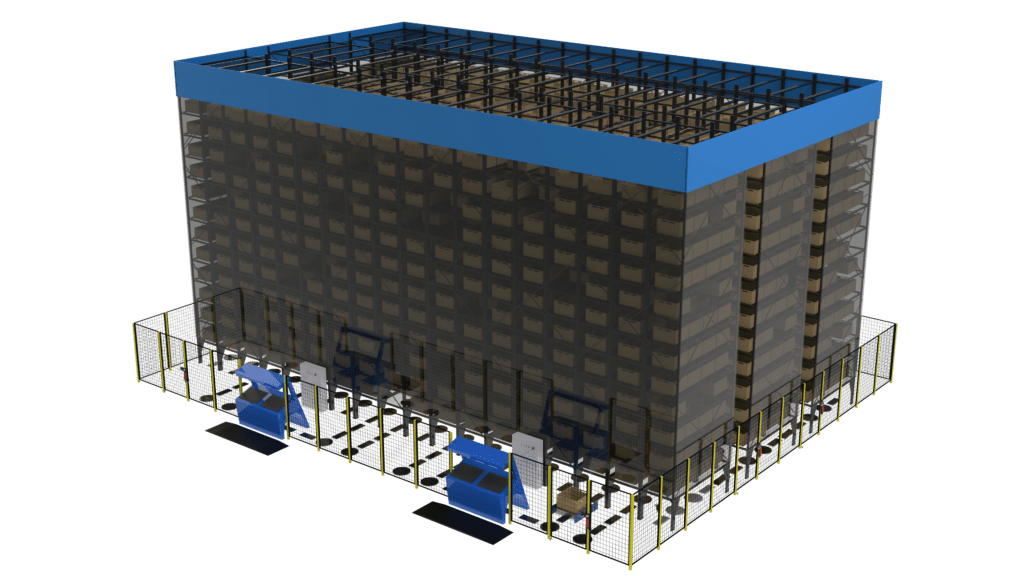

Automated Warehousing presents distinct safety challenges, particularly in protecting operators within large facilities with automated storage and retrieval systems (ASRS) and numerous access points. Limited visibility of personnel, along with the presence of conveyor systems and robotic handling equipment, are just some of the challenges.

Appropriate safeguarding and access control measures are essential to prevent injuries. Fortress offers solutions that meet the highest standards while offering flexibility to adapt to your operations. With expert guidance, technical support, and training, Fortress ensure seamless integration prioritising safety and efficiency.

Functionality & Conformity

Configurable products designed to perform and to meet standards internationally. All the necessary functions combined into one solution.

Scalable Design

Easily scalable and customisable solutions for expanding operations, allowing seamless integration of additional safety systems as needed.

Network Connectivity

Fast to deploy solutions, available on multiple network protocols for rapid installation, integration and commissioning.

Durable Solutions

Minimise downtime and replacements with robust products, built to last for decades even in the most challenging environments.

Operational Efficiency

Intuitive systems, easy to operate, with convenient operator access and controls at the movable guard.

Fully Configurable Products

Design tailored safety solutions to meet the specific requirements of any application.

Functionality & Conformity

Configurable products designed to perform and to meet standards internationally. All the necessary functions combined into one solution.

Scalable Design

Easily scalable and customisable solutions for expanding operations, allowing seamless integration of additional safety systems as needed.

Network Connectivity

Fast to deploy solutions, available on multiple network protocols for rapid installation, integration and commissioning.

Durable Solutions

Minimise downtime and replacements with robust products, built to last for decades even in the most challenging environments.

Operational Efficiency

Intuitive systems, easy to operate, with convenient operator access and controls at the movable guard.

Fully Configurable Products

Design tailored safety solutions to meet the specific requirements of any application.

Applications -

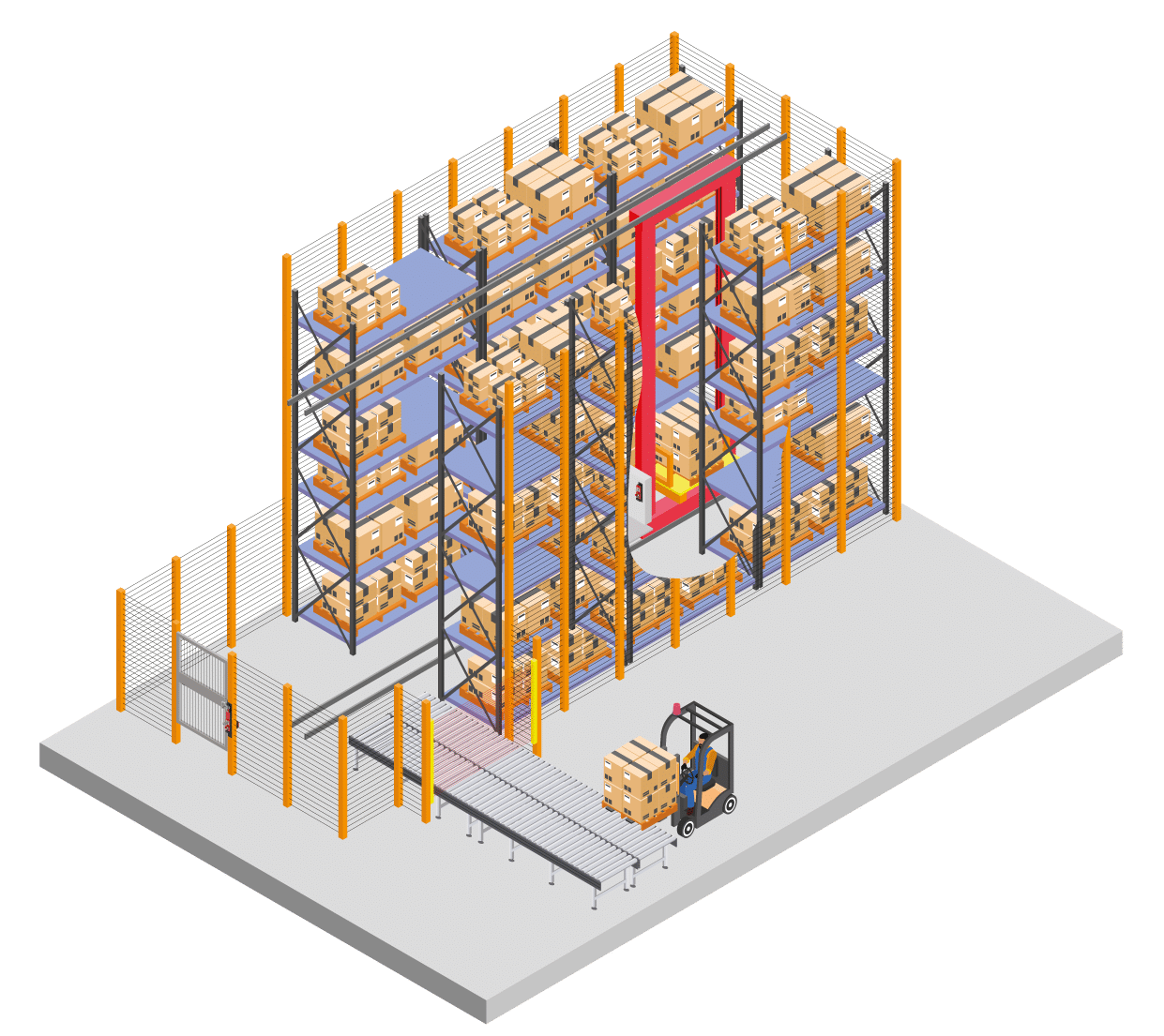

ASRS

Aisle Access in Automated Storage and Retrieval Systems

Automated storage and retrieval systems (ASRS) often span across many aisles, have multiple access points, and are likely to have cranes to retrieve and store products. In some regions, such systems need to conform with EN 528, a safety standard for rail dependent storage and retrieval equipment, which includes a range of requirements with respect […]

Applications -

Mixer

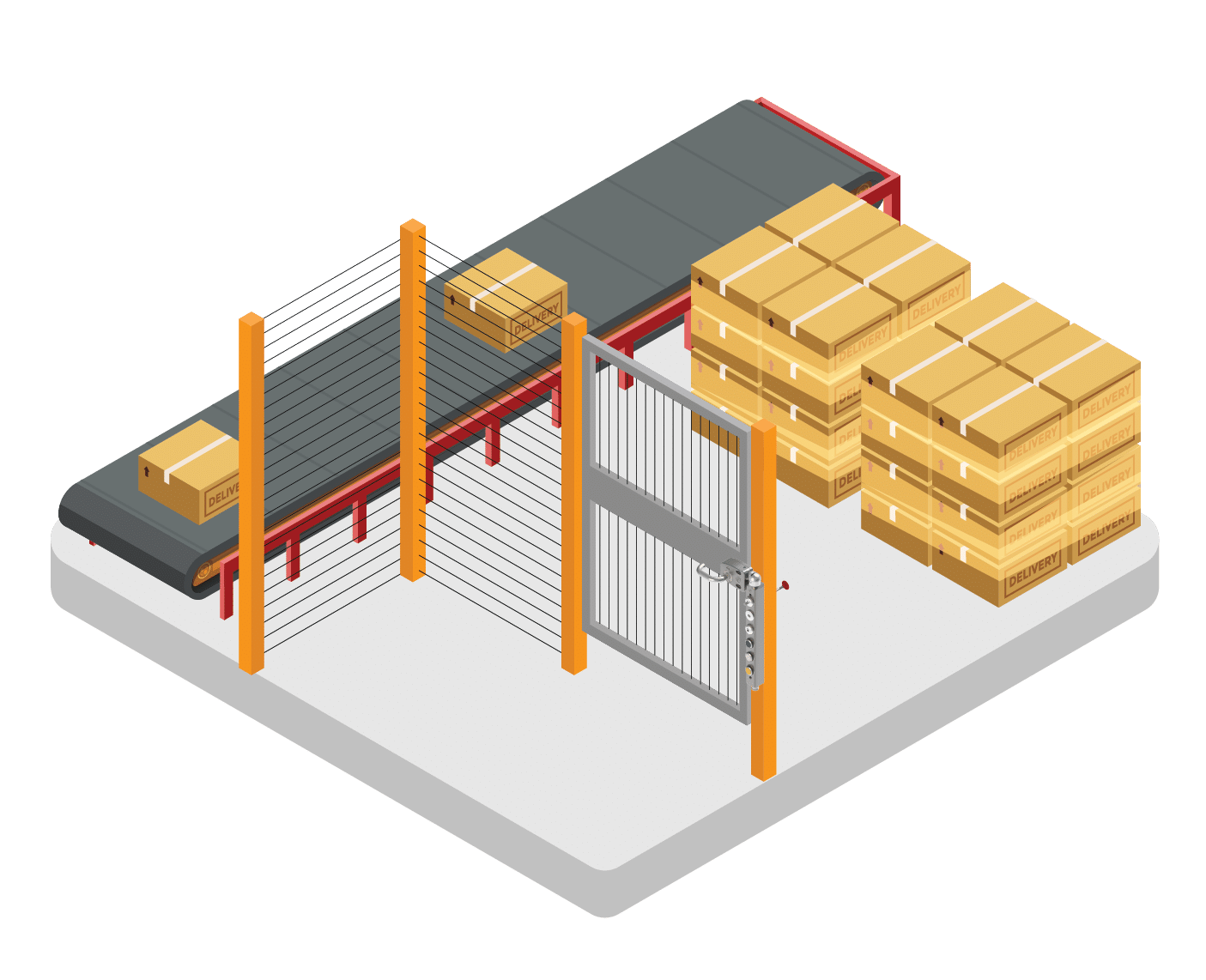

Conveyor System

Conveyor systems in automated warehouses efficiently transport goods throughout the facility, reducing manual labour and increasing speed. They often integrate with other automation technologies to streamline operations from receiving to order fulfilment. In some circumstances, conveyor systems may be safeguarded by interlocked guards to prevent personnel exposure to potential hazards. The Challenge Personnel may need […]

Applications -

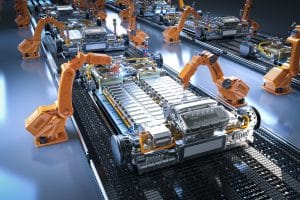

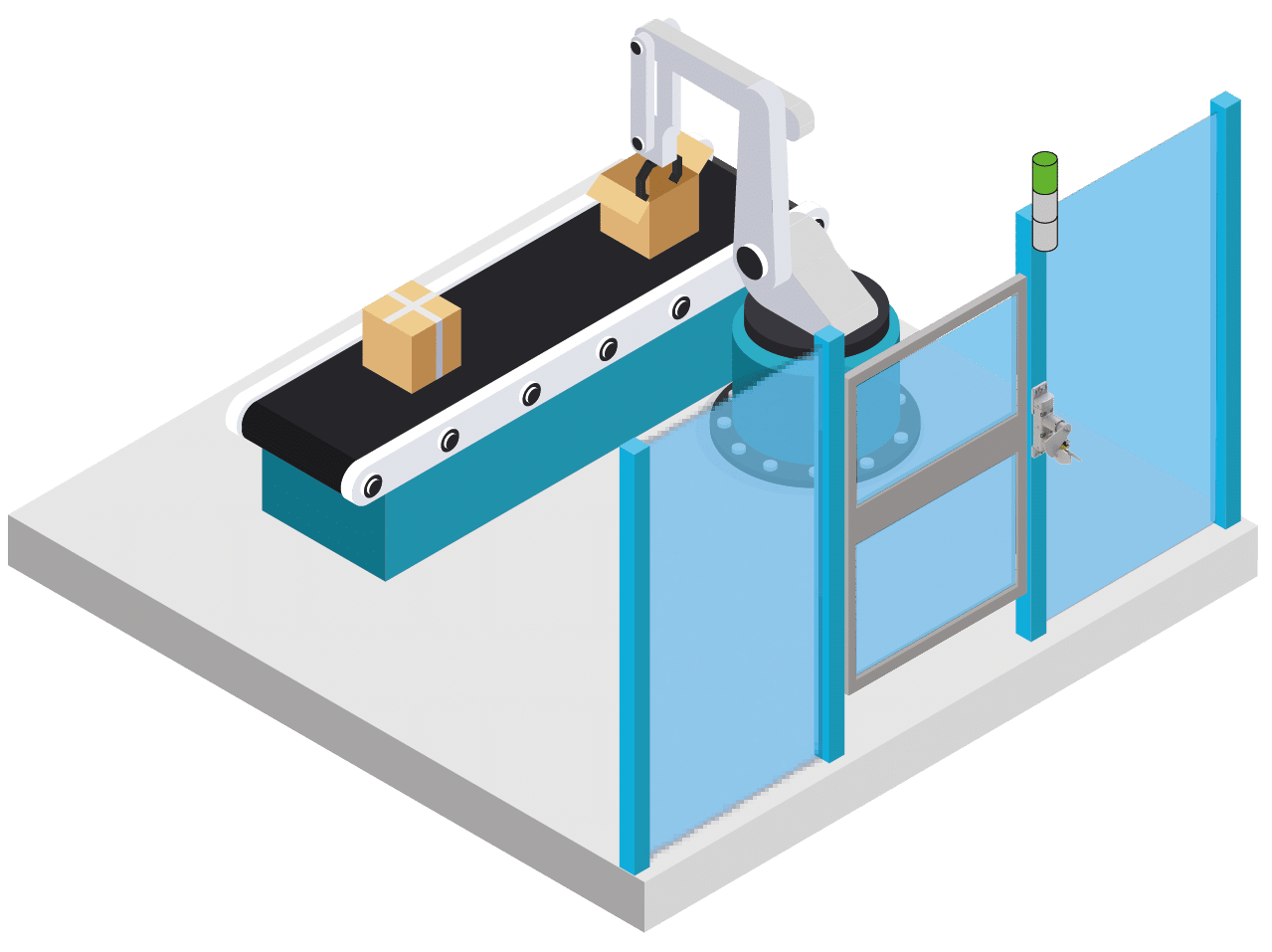

Robot Stacking

Interlock Blocking for a Robotic Stacking Cell

The customer is a global leader in contact lenses. As part of the production process, robots pick and stack boxes containing contact lenses before they are sent off for packaging. The Challenge The guard that allows access to the area where the robot operates features a sensor that indicates whether it is open or closed. […]

Get started on your custom solution

Case Study -

Opex

EtherCAT-Enabled Safety Solutions in Warehouse Automation

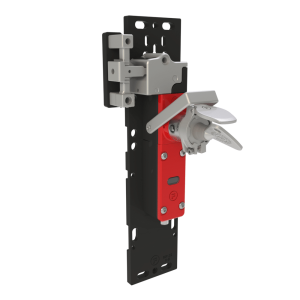

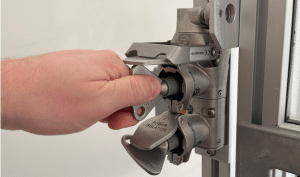

Fortress offered devices for aisle access and remote safety I/O capability through devices able to communicate over EtherCAT. Three types of units from the amGardpro range were provided, allowing for aisle access, side access, and remote I/O respectively.

Products Used

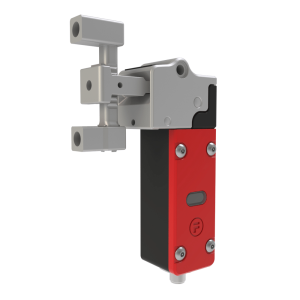

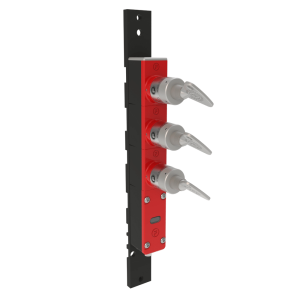

amGardpro

The Outcome

Tailored ASRS safety with EtherCAT integration—fast to deploy, easy to operate, and built to scale.

Who are OPEX?

OPEX offers scalable warehouse and document & mail automation solutions to drive efficiencies in infrastructure.

Case Study - OPEX

EtherCAT-Enabled Safety Solutions in Warehouse Automation

Fortress offered devices for aisle access and remote safety I/O capability through devices able to communicate over EtherCAT. Three types of units from the amGardpro range were provided, allowing for aisle access, side access, and remote I/O respectively.

Products Used

amGardpro

Partners Involved

Shingle & Gibb Automation, East Coast Automation

Who are OPEX?

OPEX offers scalable warehouse and document & mail automation solutions to drive efficiencies in infrastructure.

Recommended Product Range

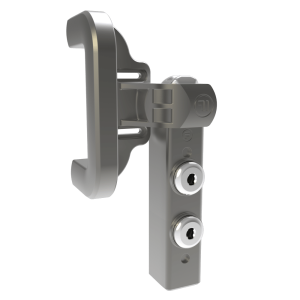

amGardpro

Configurable interlocks and control pods for heavy-duty applications certified for use up to PLe/Cat. 4. Pushbutton controls, trapped key options, and network connectivity can be combined into a single unit.

Highly configurable

Reduce replacements and downtime

All the controls in one place

Network connectivity

Recommended Product Range

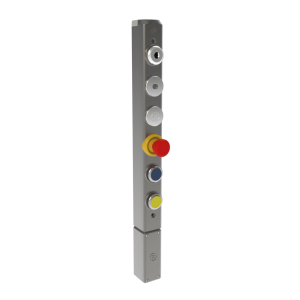

tGard

A versatile range of interlocks and control stations that can accommodate up to ten modules, including trapped keys and operator controls. Housed in a robust 40mm metal body, suitable for various manufacturing and industrial automation applications.

Tailored to your requirements

Efficient integrated solution

Installation made easy

Resistant and durable

News & Insights

- Event

Not sure where to start? We’re here to help

Our dedicated team of experts are here to help create the right solution for you. They can analyse your industry and specific application needs to offer recommendations on how Fortress products could benefit your setup.