Access Control Solutions for AIC’s Robot Applications

For over a decade, AIC has relied on Fortress products to control access to robot machines

Industry

Products Used

Partner Involved

Company

General Hazards for Operators Working with Robot Cells

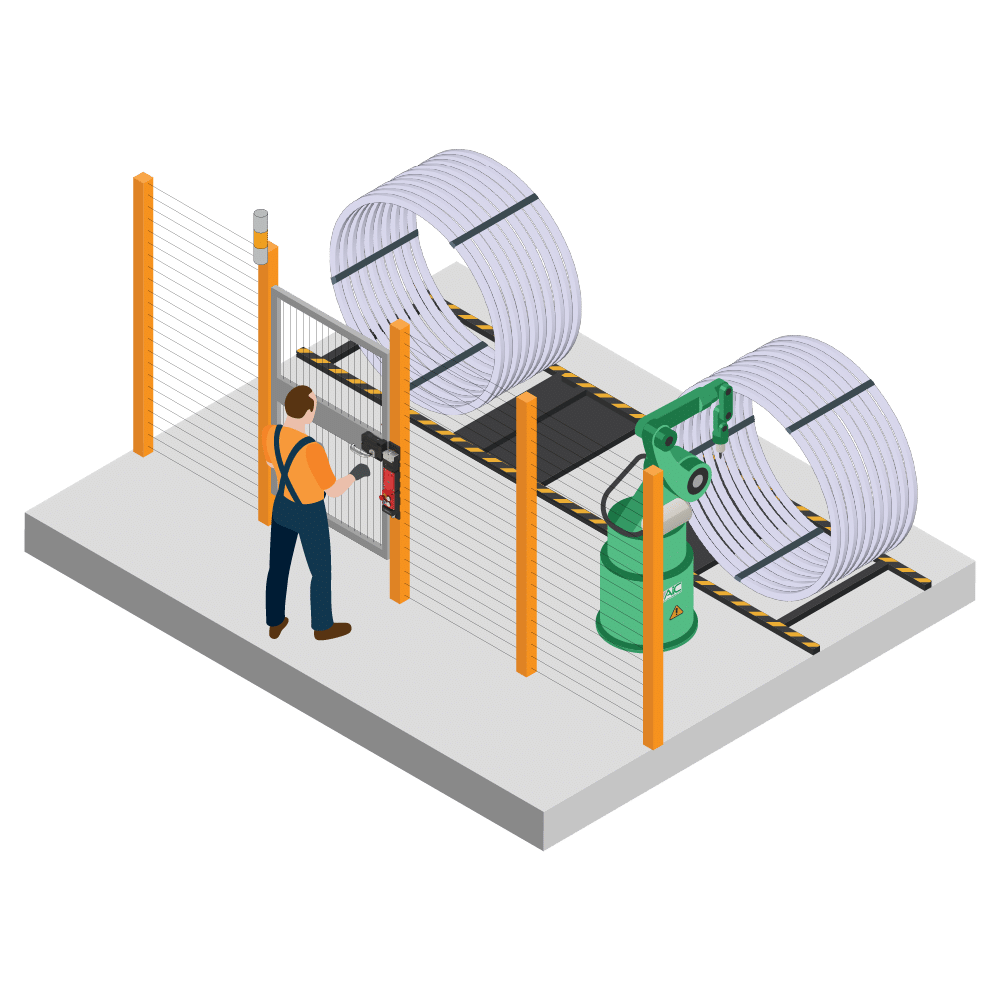

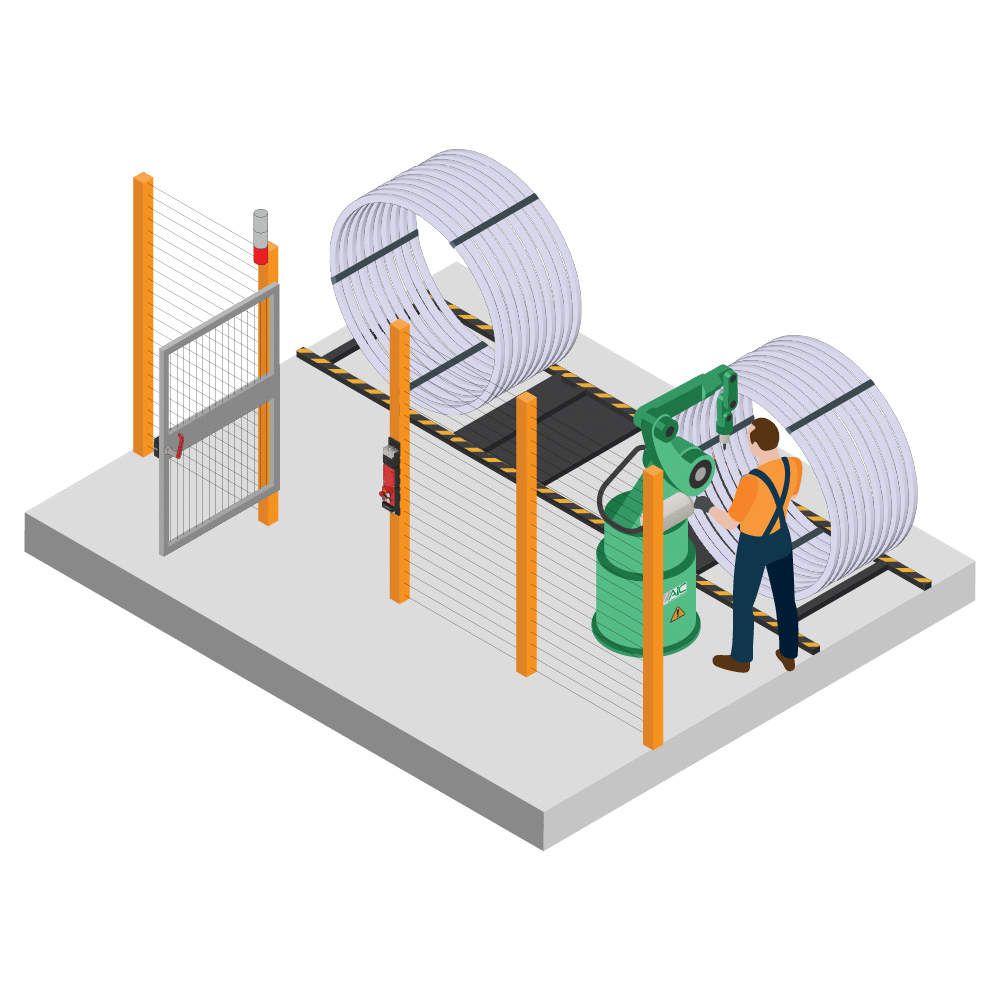

In the demanding environment of steel production and processing, automation plays an important role in certain tasks, which are often performed by robots. Industrial robots can handle large and heavy components and speed up processes, although there are instances where personnel may need to access the areas where they operate.

Unrestricted or unauthorised access exposes operators to crushing and impact hazards, potentially leading to severe or fatal injuries. To mitigate these hazards, safeguarding solutions like interlocked guards are essential. Operators should only enter the safeguarded space once the hazards have reached a safe state.

Automazioni Industriali Capitanio (AIC) – a provider of automation systems and mechatronic solutions for the steel industry – has partnered with Fortress Safety to help protect operators during the tagging of semi-finished or finished metal products (e.g., bars and coils) when access to the machines is required.

How it works

Step-By-Step Process

The Evolution from Hardwired to Networked Solutions

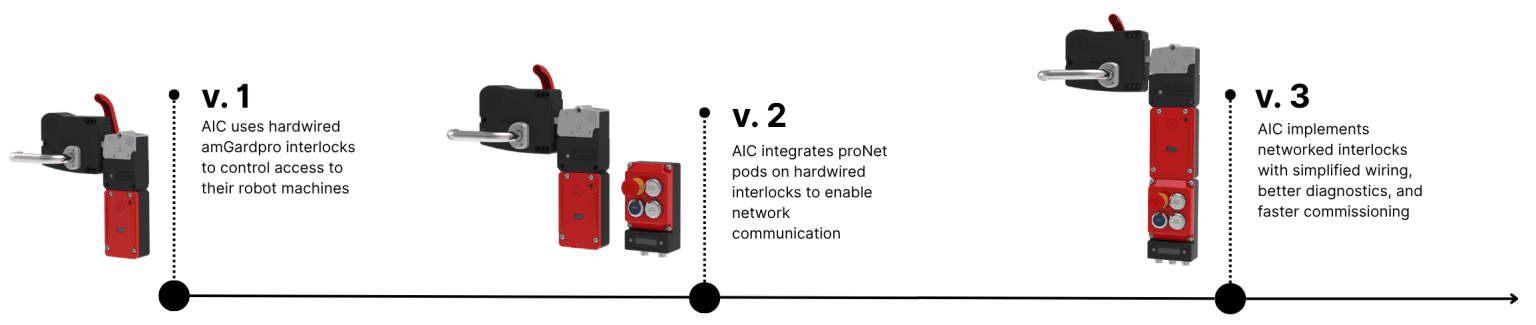

Supported by LAS (Fortress Safety’s Channel Partner for the Italian market), AIC has been using amGardpro products from Fortress to control access to their robot machines for over a decade. Engineered for robustness and certified for use in applications up to PLe, the amGardpro range is ideally suited to the demanding conditions of the steel industry.

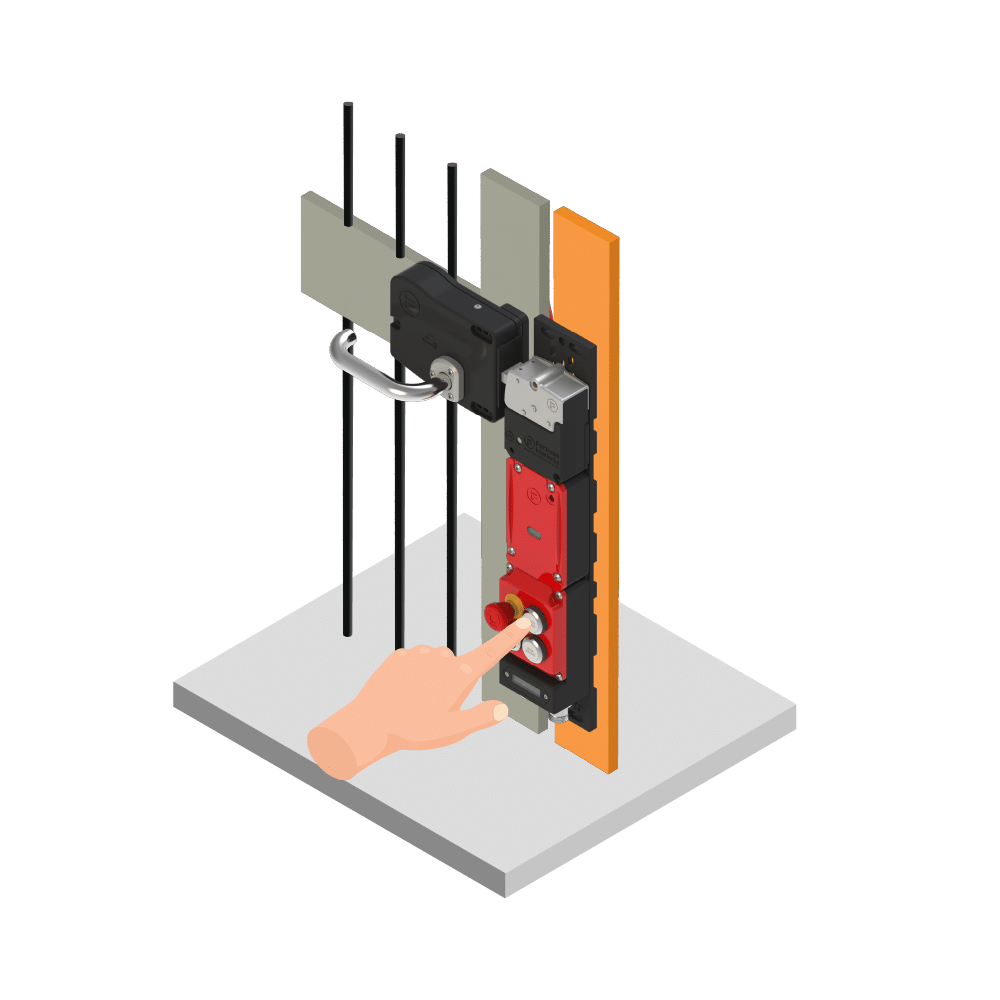

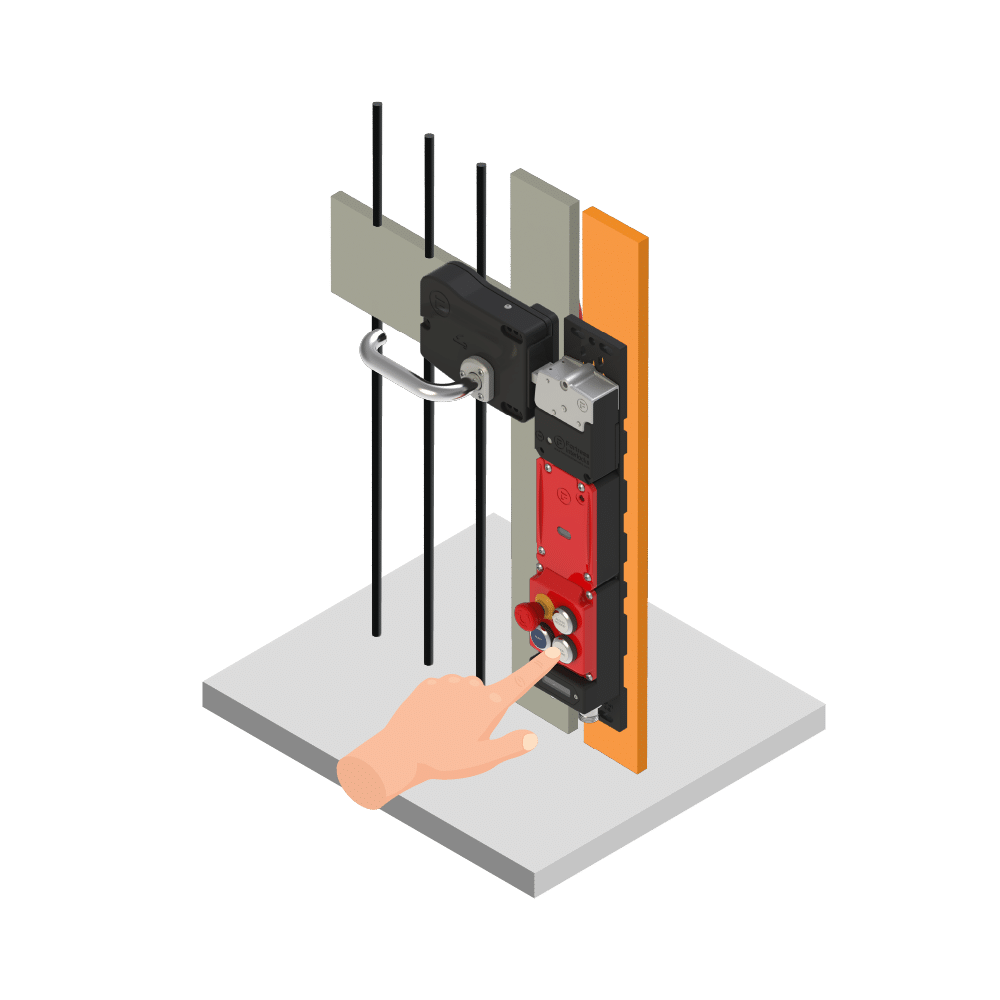

In a typical configuration within AIC’s tagging applications, access to the areas containing the robot is allowed only after it has reached a controlled stop. The process involves halting the robot’s activity after its cycle is complete and confirming the safety status before access is permitted. The interlock’s solenoid locking mechanism holds the movable guard in a locked state. When required, operators can request to enter, and once the robot is in a safe state, the interlock is unlocked, allowing access to the cell.

Initially relying on hardwired interlocks, AIC has progressively evolved its approach and started to integrate networked solutions that communicate with PROFINET and EtherNet/IP protocols. There has been significant benefits to the shift made to networked interlocks

- Simplified wiring

- Better diagnostics

- Faster commissioning

These all come without compromising on the robustness required in steel plant environments.

AIC also chooses to integrate additional features into the interlocks, such as pushbuttons, emergency stops, and escape releases to allow operators to exit in case they inadvertently become trapped inside. With the help of amGardpro, AIC now safeguards multiple robot applications installed across the world.

We started with the hardwired solution […] Then over the years we evolved, and we tested the first networked interlocks, and lately we’ve been using almost exclusively those because they greatly simplify wiring and improve diagnostics, still maintaining the robustness and reliability proven over the years

Michele Serlini, Technical Director – Mechatronics Unit AIC

The Keys to Success: Strong Partnership and Proven Performance

AIC’s long-standing partnership with Fortress Safety and LAS has been integral to the success of their automation solutions. Fortress interlocks are part of AIC’s offering from the moment the robot applications are designed. Given the complexity of the automation tasks and the very demanding environment the machines operate in, AIC needs the top-tier technology and robust components that only Fortress can provide.

The transition to networked interlocks reflects both the technological advancement of AIC’s automation solutions and the ongoing demand for high-performance safety solutions in harsh industrial environments. With installations in Brazil, USA, Oman, Italy, and Germany, AIC continues to lead in combining safety and innovation.

Another key player in this success is LAS, Fortress’ Channel Partner in Italy. LAS brings deep expertise in industrial automation safety and works closely with AIC to design and implement solutions tailored to their needs, ensuring compliance and operational efficiency.

As automation utilising robots becomes more advanced and widespread, there is a need for robust and flexible solutions to help keep operators safe. The combined strengths of AIC’s mechatronic engineering, Fortress’ technologies, and LAS’s local expertise and support, enhance personnel protection across multiple sites globally.

About AIC

Automazioni Industriali Capitanio (AIC) is a global supplier of automation systems, process control, and mechatronic solutions for the steel industry. Focused on both greenfield and revamping projects, AIC serves more than 250 clients across 65 countries, with specialised solutions for rolling mills and long product lines.

65

Countries

250

Customers

2,000

Applications

180

Employees

6,700

sqm of panels and mechanical shops

About LAS

LAS A&S SRL is a leading safety automation partner in Italy, known for delivering customised, innovative systems across various industries. With over 30 years of experience and a strong strategic partnership with Fortress Safety, LAS provides end-to-end support, from consultation to implementation and after-sales service, ensuring reliable safety solutions tailored to every application.

More Case Studies

Discover how Fortress’s mechanical interlocks were implemented to enhance operator safety at Walibi Holland amusement park.

Tata Steel chose FRANK to manage access control permissions and enhance safety on their ZODIAC line.

Discover how a trapped key system was implemented to protect staff while accessing a bear enclosure.