News & Insights

Read the latest articles, news, and company updates from Fortress. Explore our insights on industry trends, product launches, and upcoming events to keep you connected and informed.

We are proud to be featured in leading industry publications – check out where we have been published here.

//

Featured

Webinar Recap: Interlocking in Machinery Safety

Missed our recent webinar on “Interlocking in Machinery Safety”? The

- Event

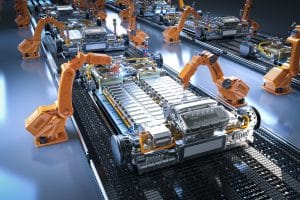

Webinar Recap: Enhancing Safety in Automated Storage and Retrieval Systems (ASRS)

- Article

Building a Safer Workplace – The First Six Months of Remlive with Fortress Safety

Get started on your custom solution

Our sales team are on hand to help provide the perfect interlock solution for your industry; or, with our product configurator, you fill in a quick form outlining your specific needs, to generate a custom configuration part number.