Mechanical Trapped Key Interlocks

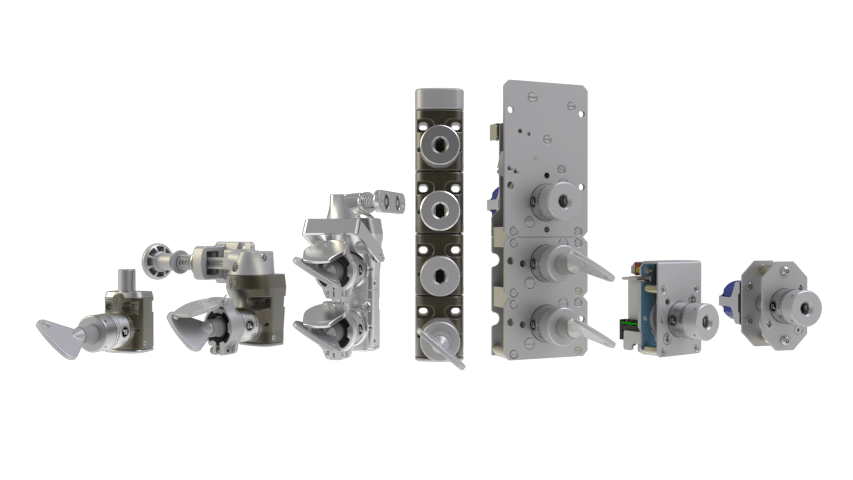

A range of mechanical trapped key interlocks designed to enforce processes without the need for electrical wiring. Cost-effective, easy to install and maintain, and ideal for areas difficult to reach with cables. mGard can enforce specific key sequences, particularly in applications involving multiple energy sources.

Benefits of mGard

Control Hazardous Energy

Mechanical interlocking can be used to control hazardous energy sources (e.g., electrical, pneumatic, hydraulic).

Enforce Sequences

Trapped key systems can be used to enforce a predetermined sequence of events according to the application requirements.

A Cost-Effective Solution

Fully mechanical units are easy to maintain and do not require wiring, with reduced installation cost and time.

Minimise Machine Downtime

Designed for long-term durability reducing the need for repairs and maintenance. Also available in stainless steel for harsh environments.

Enhance Safety and Compliance

Used to meet the requirement of ISO 14119 and ISO 14118. Suitable for use up to PLe/Cat. 4.

Cover Vast Areas

Enforce processes across multiple levels and long distances. Fully mechanical units are ideal for areas difficult to reach with cables.

Control Hazardous Energy

Mechanical interlocking can be used to control hazardous energy sources (e.g., electrical, pneumatic, hydraulic).

Enforce Sequences

Trapped key systems can be used to enforce a predetermined sequence of events according to the application requirements.

A Cost-Effective Solution

Fully mechanical units are easy to maintain and do not require wiring, with reduced installation cost and time.

Minimise Machine Downtime

Designed for long-term durability reducing the need for repairs and maintenance. Also available in stainless steel for harsh environments.

Enhance Safety and Compliance

Used to meet the requirement of ISO 14119 and ISO 14118. Suitable for use up to PLe/Cat. 4.

Cover Vast Areas

Enforce processes across multiple levels and long distances. Fully mechanical units are ideal for areas difficult to reach with cables.

mGard Features

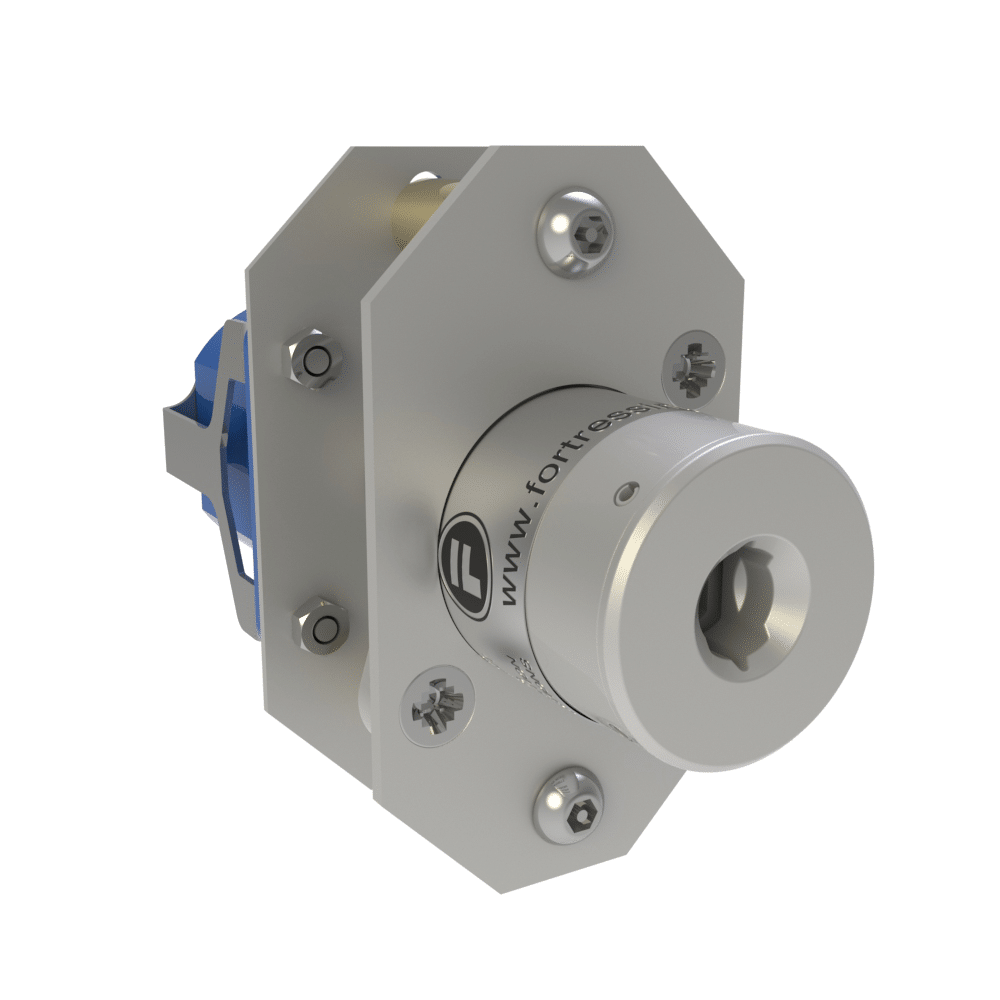

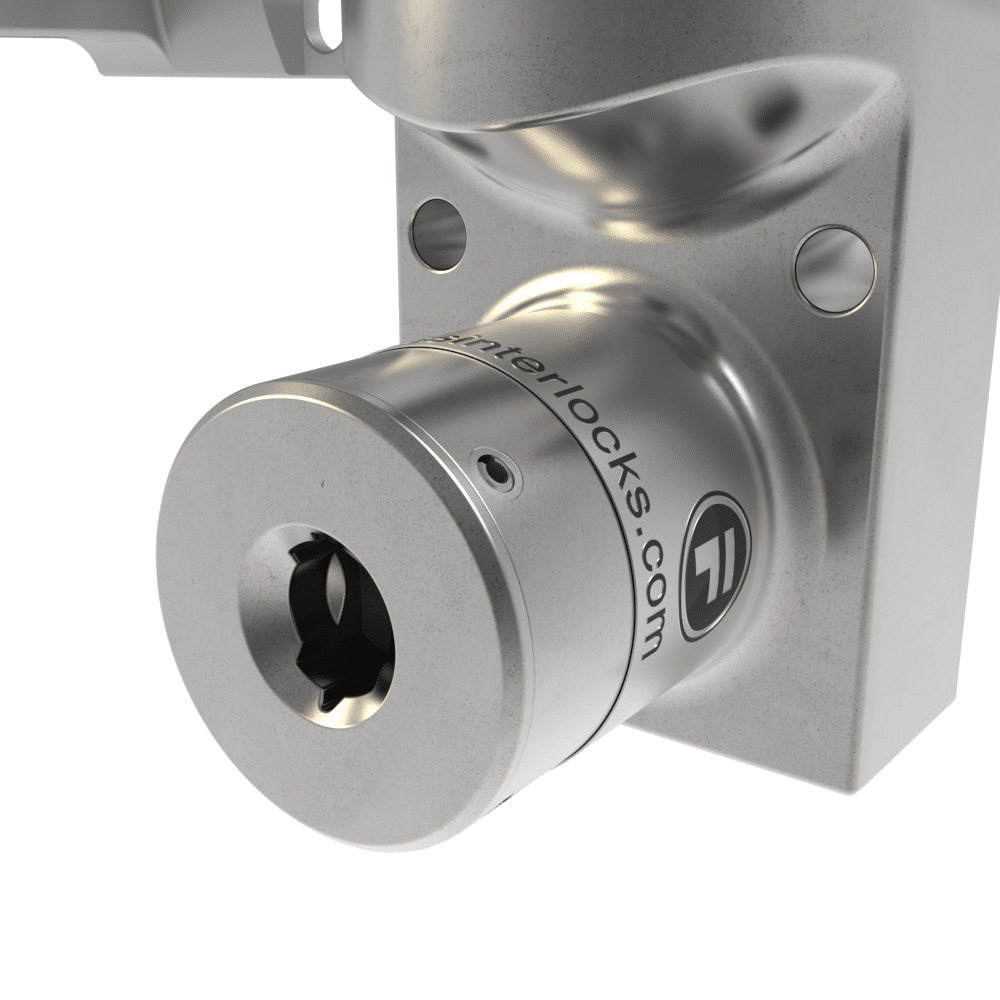

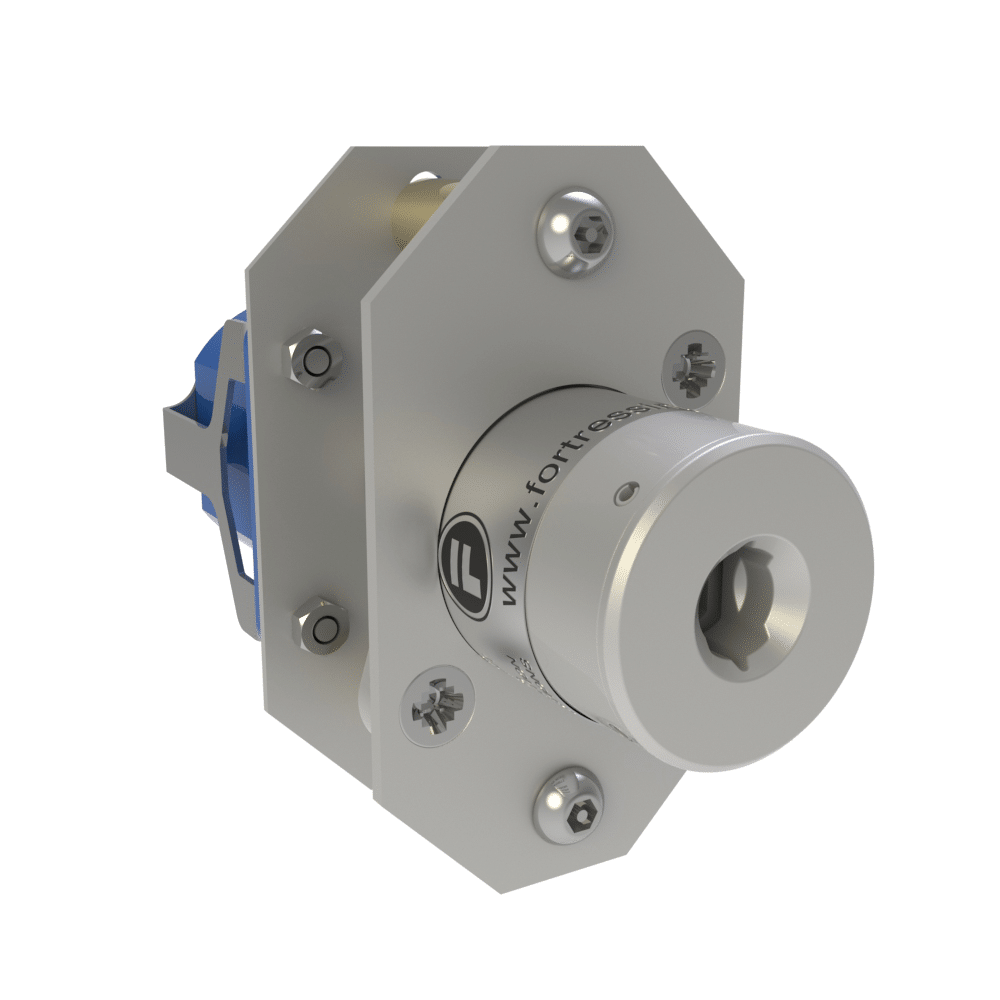

Control Interlocking

Key operated switches for electrical isolation. Time delay and voltage sensing devices to delay access until desired system conditions are met are also available.

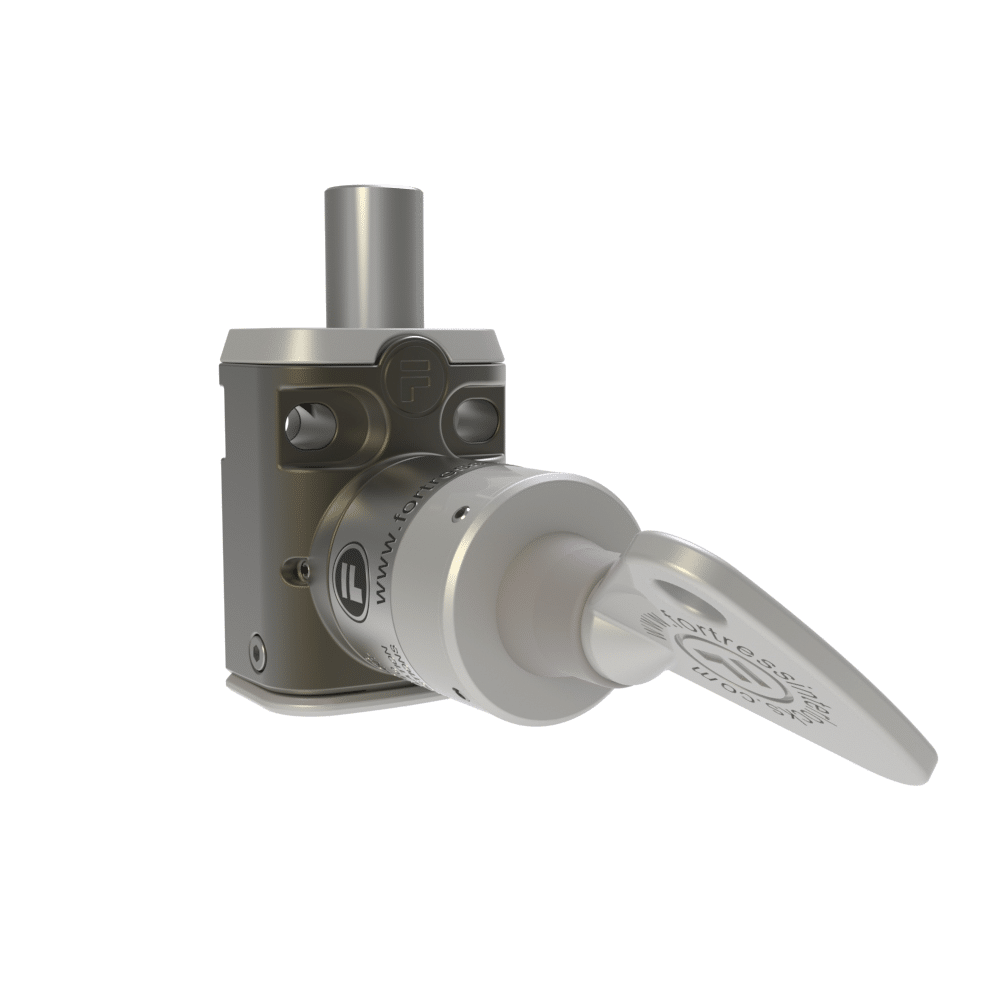

Power Interlocking

Mechanically secure energy sources (circuit breakers, valves, earth switches, etc.) with bolt module units. Valve interlocks for pneumatic and hydraulic isolation also available.

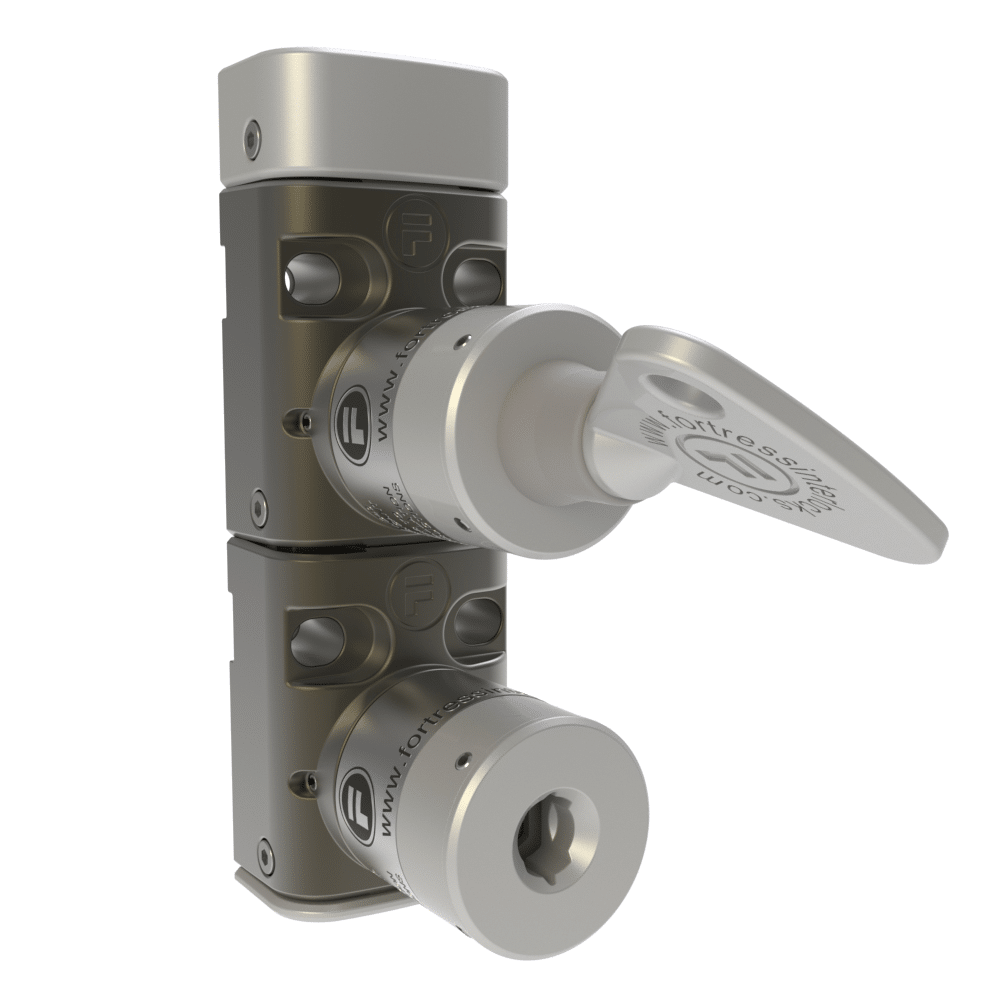

Intermediate Transfer

Key exchange devices to enforce a predetermined sequence of events. Trap or release one or multiple keys. Custom devices for specific applications can be designed.

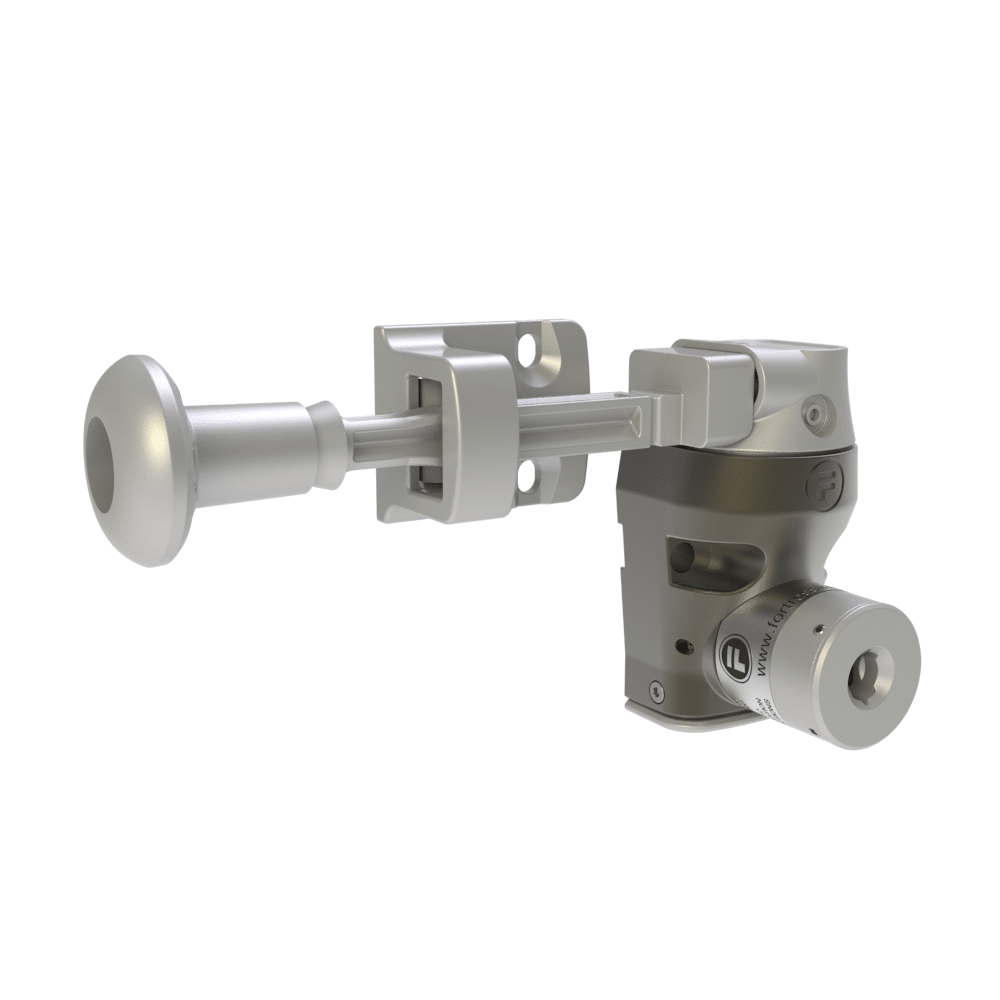

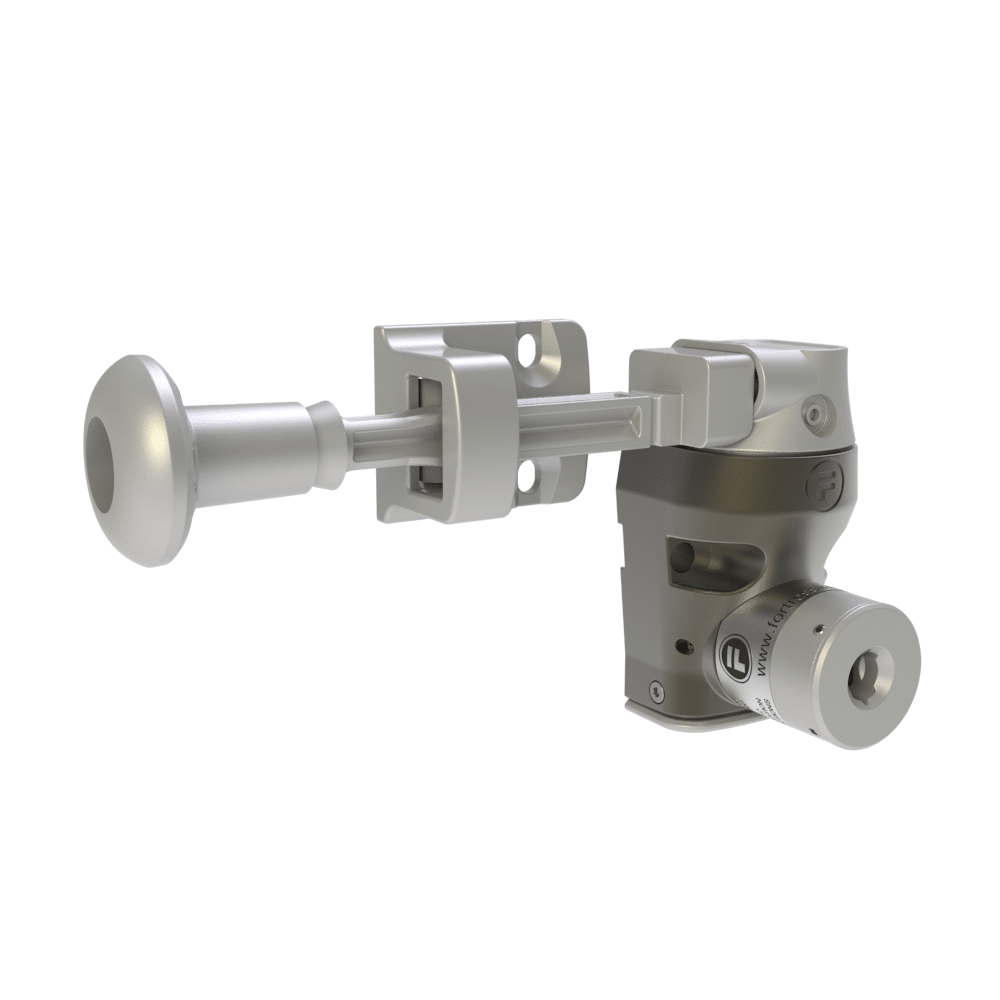

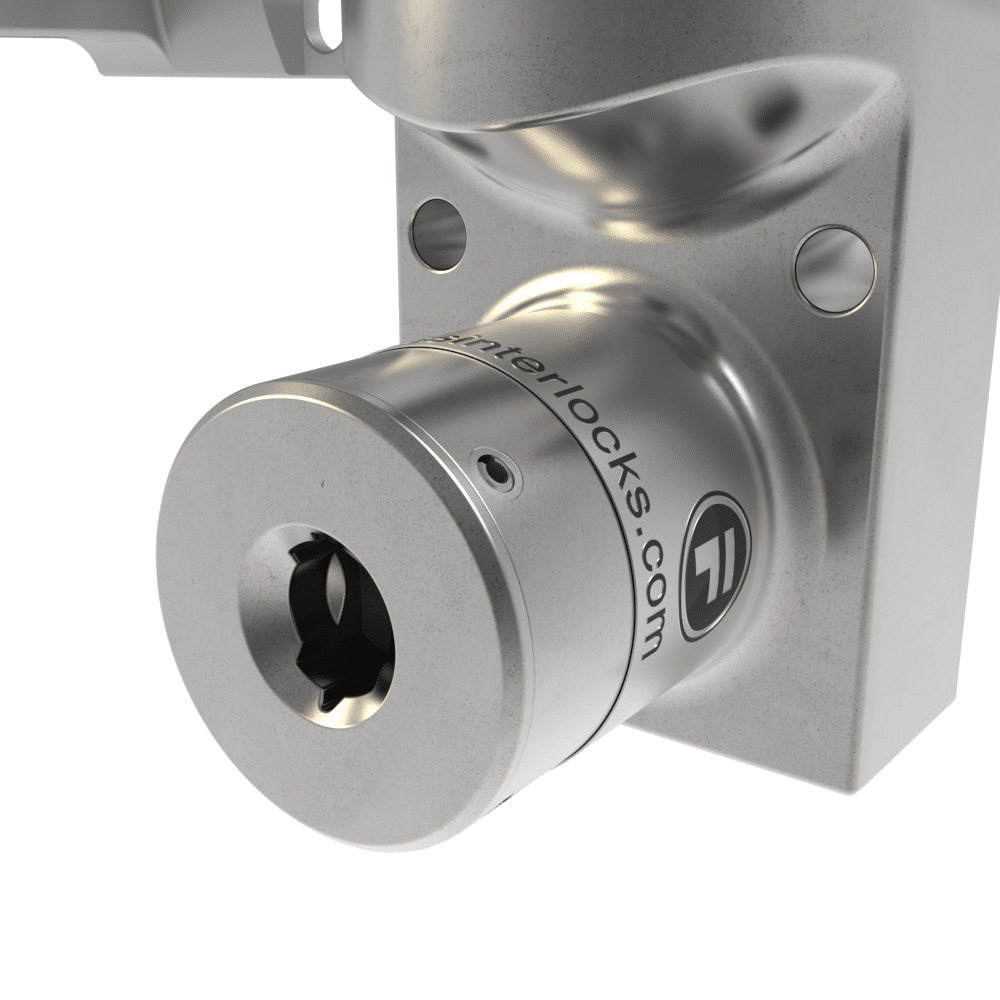

Access Control

Multiple options for access locks and actuators. No wiring required at the access point. Actuators remain closed until the correct key is inserted and rotated.

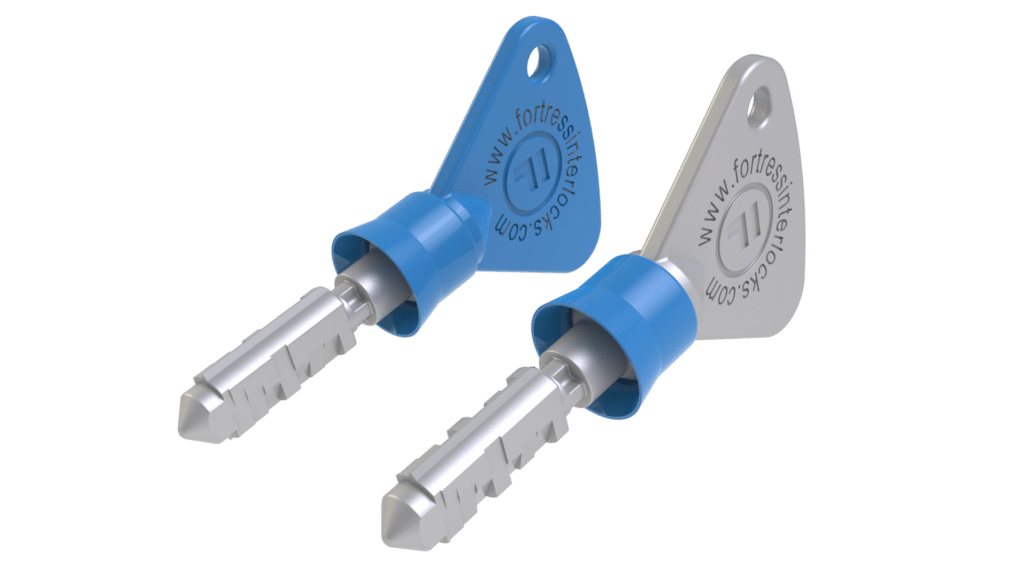

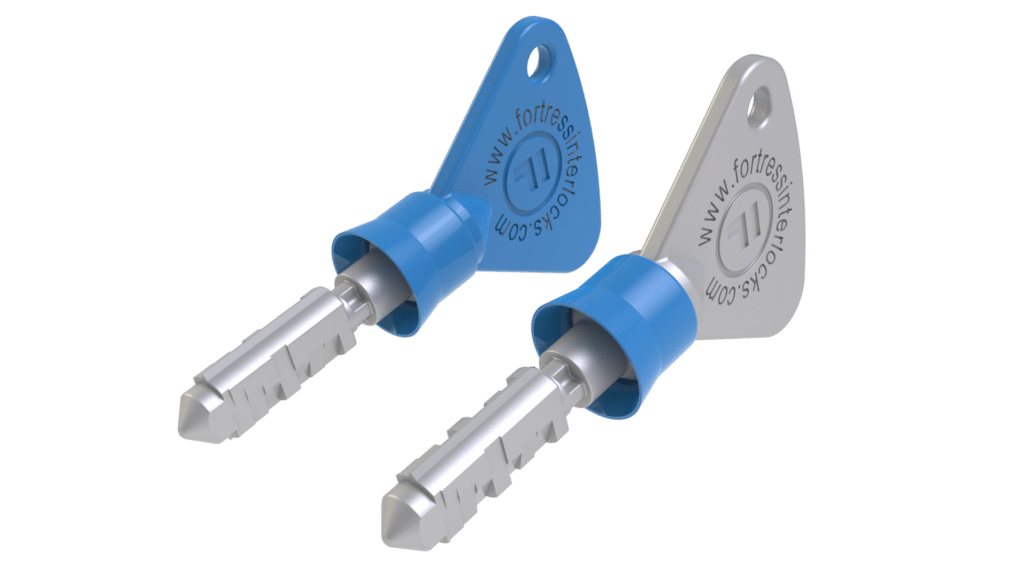

Keys and Accessories

With over 200,000 ‘cut’ combinations, keys can be engraved and customised with different colours. Standard or padlockable dustcovers and hasps are also available.

Resistance to Harsh Conditions

A robust product made of metal alloy but also available in stainless steel for the most demanding environments.

Control Interlocking

Key operated switches for electrical isolation. Time delay and voltage sensing devices to delay access until desired system conditions are met are also available.

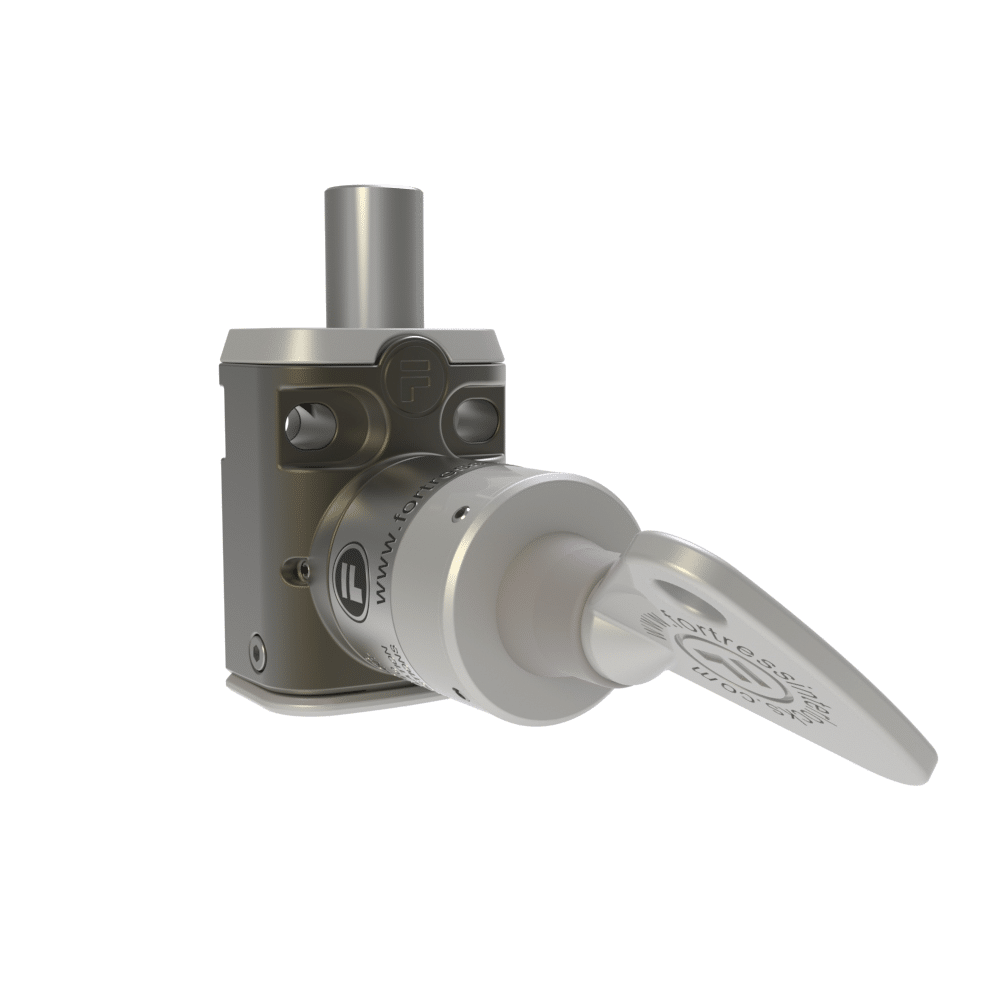

Power Interlocking

Mechanically secure energy sources (circuit breakers, valves, earth switches, etc.) with bolt module units. Valve interlocks for pneumatic and hydraulic isolation also available.

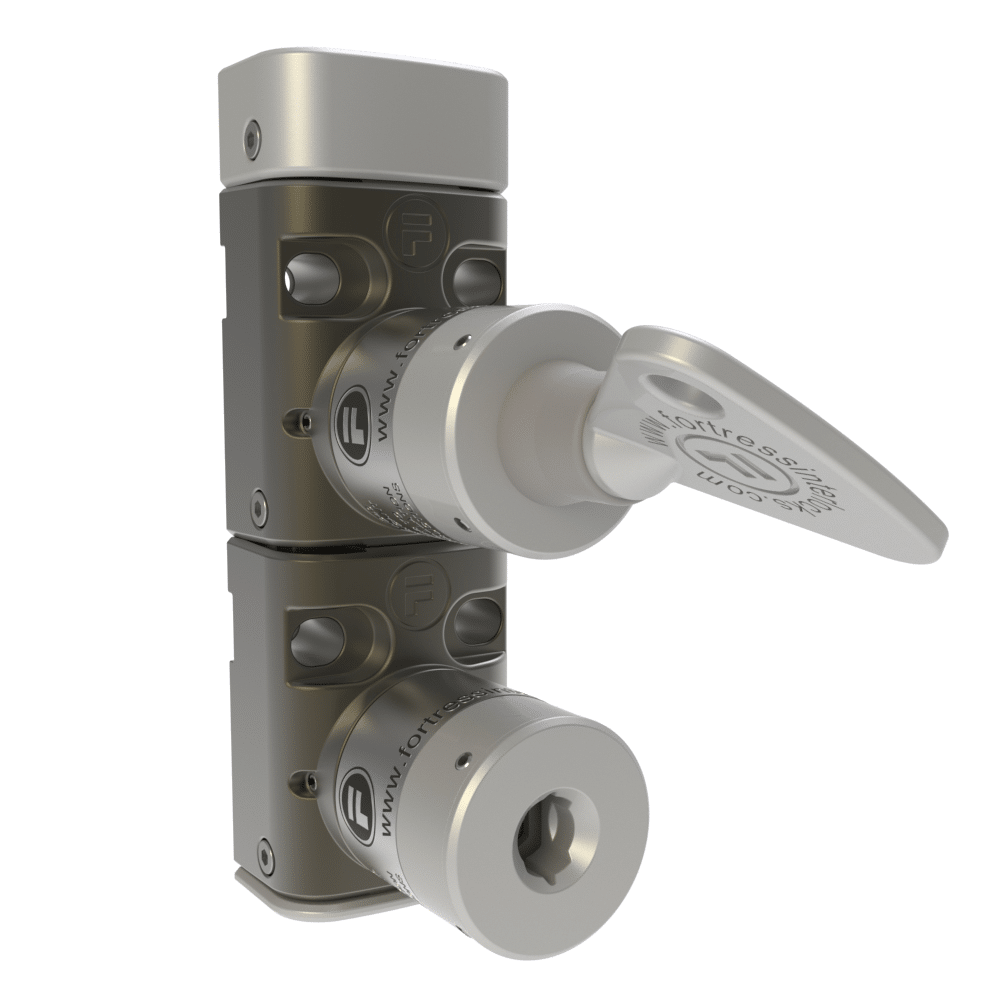

Intermediate Transfer

Key exchange devices to enforce a predetermined sequence of events. Trap or release one or multiple keys. Custom devices for specific applications can be designed.

Access Control

Multiple options for access locks and actuators. No wiring required at the access point. Actuators remain closed until the correct key is inserted and rotated.

Keys and Accessories

With over 200,000 ‘cut’ combinations, keys can be engraved and customised with different colours. Standard or padlockable dustcovers and hasps are also available.

Resistance to Harsh Conditions

A robust product made of metal alloy but also available in stainless steel for the most demanding environments.

No Need for Wiring

Mechanical interlocks eliminate most of the electrical wiring associated with other types of interlocks, making mGard cost effective and easy to install and maintain.

Customisable and Versatile

Speak to an expert about your access, control and safety needs

Contact our expert sales team to discuss the best solution for your application needs, or use our custom configurator to build the right solution for you.

mGard Product Catalogue

Document Downloads

Brochures

Log in to access all documents

Access additional technical files related to this product range by signing up to MyFortress

News & Insights

Not sure where to start? We’re here to help

Our dedicated team of experts are here to help create the right solution for you. They can analyse your industry and specific application needs to offer recommendations on how Fortress products could benefit your setup.