Safeguarding the Roller Coaster UNTAMED with a Trapped Key System

Discover how Fortress’s mechanical interlocks were implemented to enhance operator safety at Walibi Holland amusement park.

Industry

Other

Products Used

Partners Involved

Company

The Challenge

Protecting People in Amusement Parks During Maintenance and Inspections

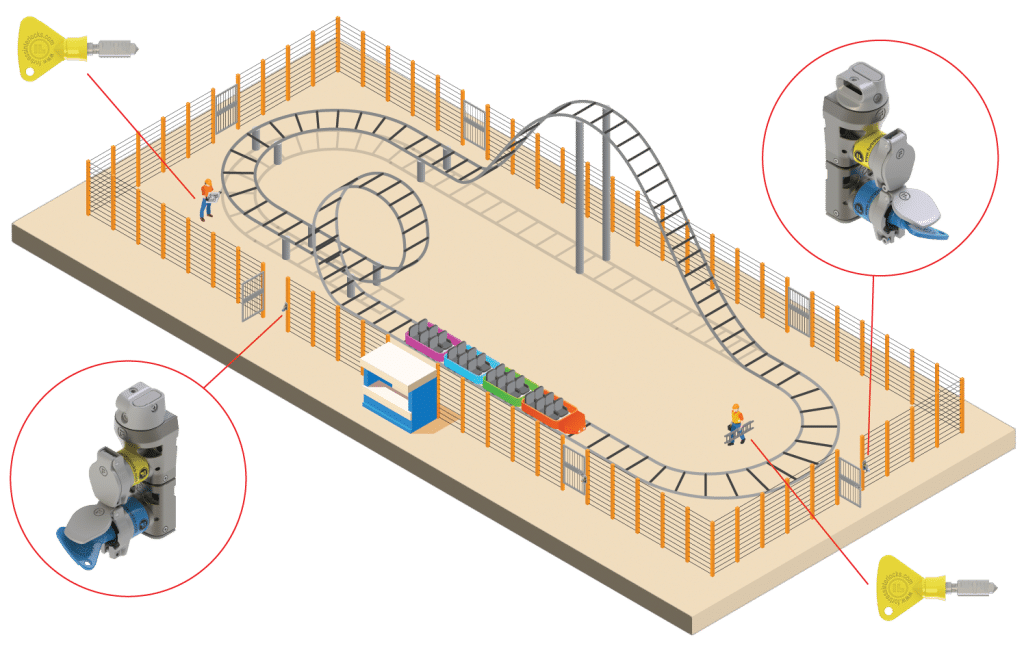

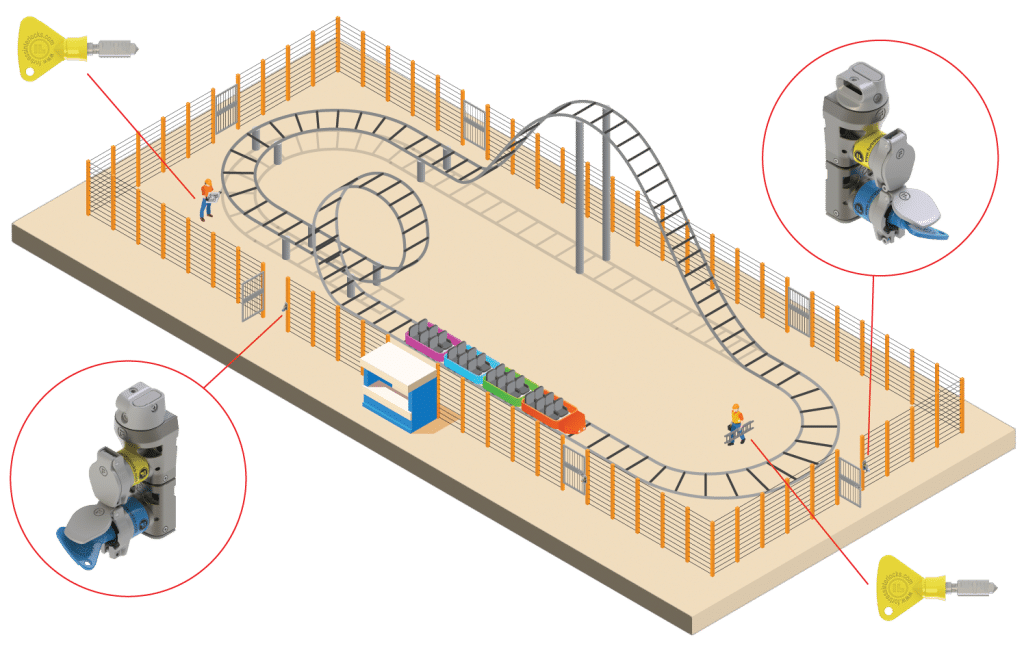

Ensuring the safety of both guests and employees in amusement parks, especially for roller coasters, is critical. Roller coasters undergo frequent inspections and maintenance to identify and address potential hazards. This may include daily checks before the park opens and more comprehensive inspections at regular intervals. Fortress Safety and Unique Safety Products (USP) were asked to safeguard UNTAMED, a steel hybrid roller coaster located at Walibi Holland theme park (Biddinghuizen, Flevoland, Netherlands) that can reach a speed of 92 kilometres per hour and a height of 35.4 meters.

The Solution

Using Mechanical Interlocks to Enforce a Process

USP proposed the use of mGard mechanical trapped key interlocks from Fortress Safety. Trapped key systems are used to enforce a sequence of operations in a predetermined order through the transfer of keys that are either trapped or released before access is permitted. With no need for wiring, mechanical interlocks from the mGard range are ideal for vast areas that might be difficult to reach with cables, like the one safeguarding the roller coaster.

In this specific case, the solution provided consisted of:

• A key-operated switch in the control station

• A key exchange device

• Six access locks with personnel keys

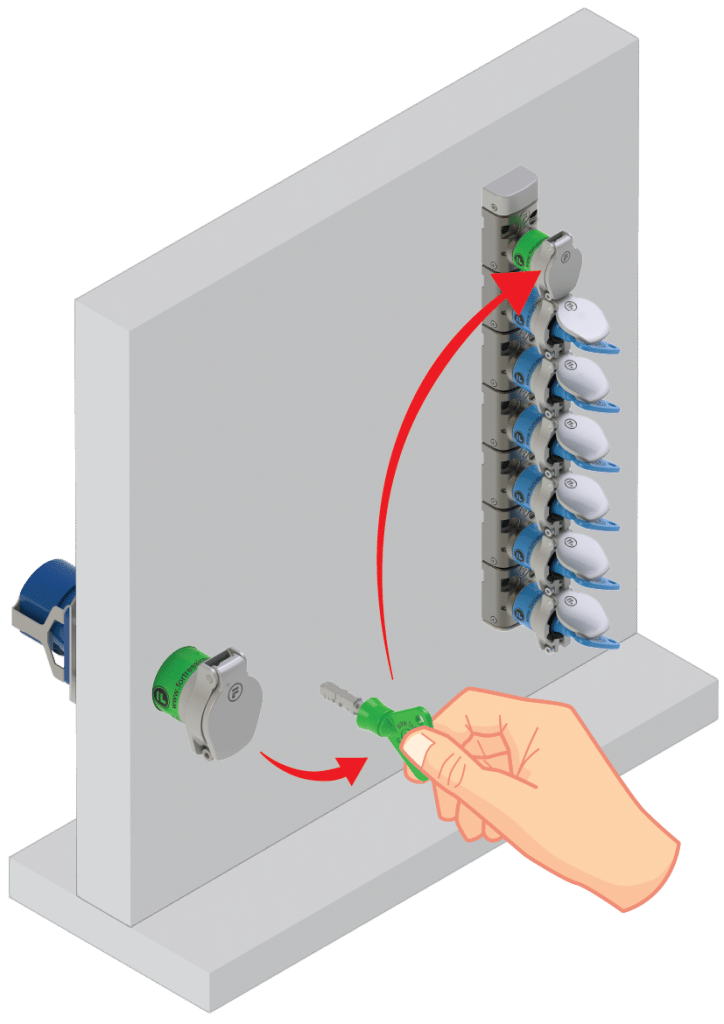

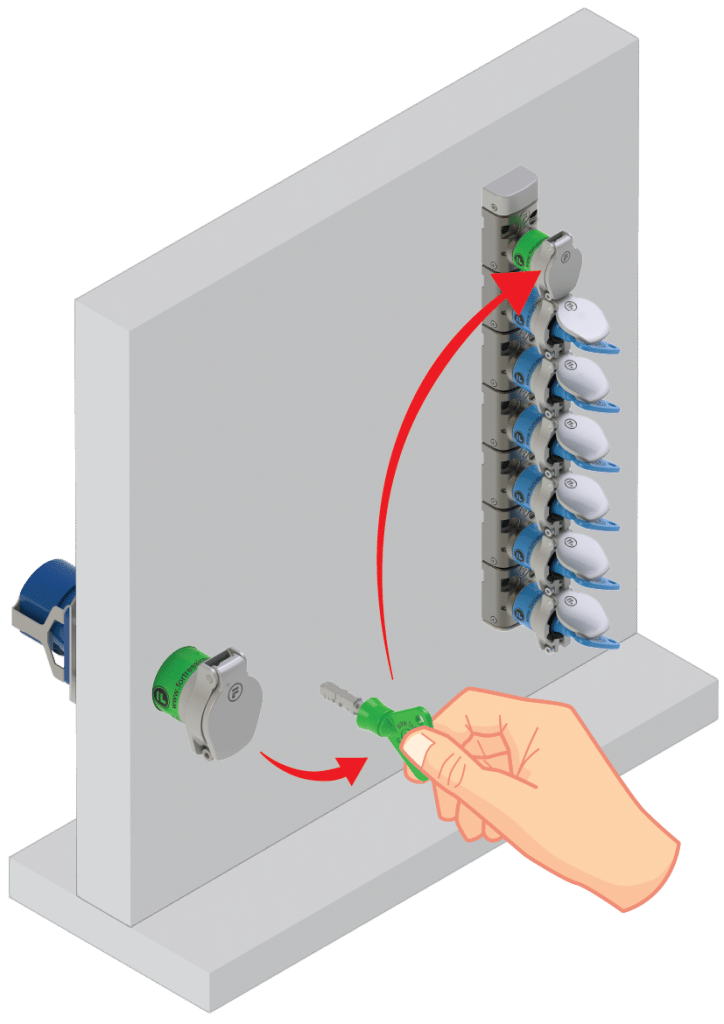

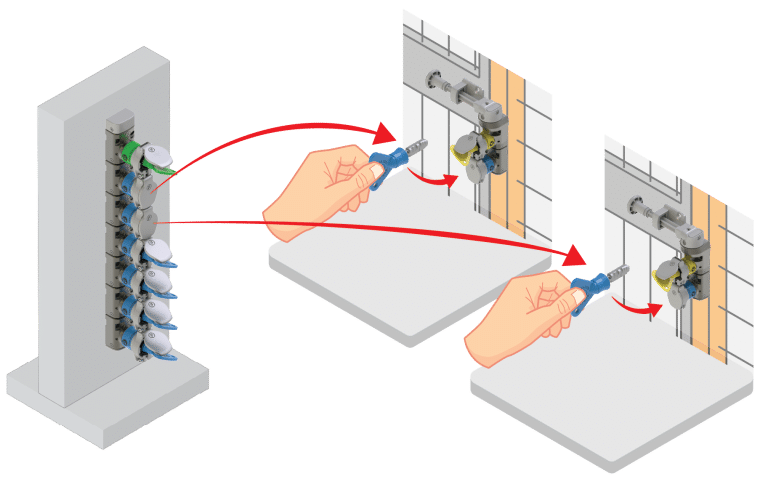

Before the area safeguarding the roller coaster can be entered, power must be turned off using the key-operated switch, bringing the roller coaster into a secured position. The key is then removed and inserted into the key exchange device, which releases up to six access keys, one for each access point.

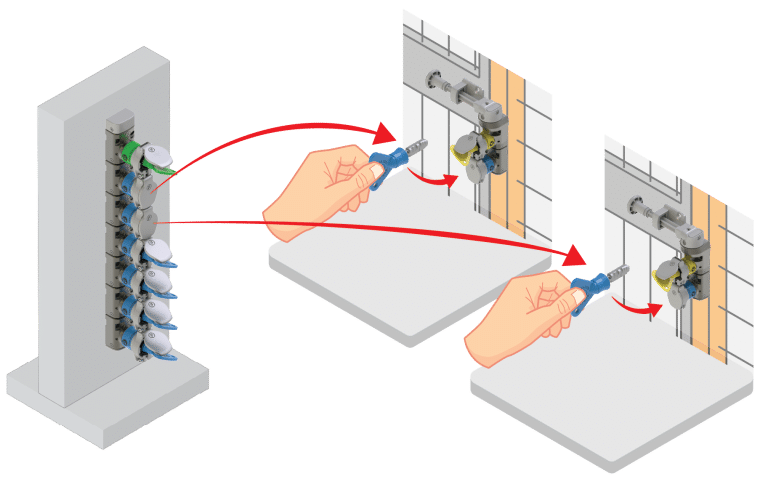

The access keys can be taken by operators, inserted into the respective access locks, and rotated to release the personnel keys. This allows operators to open the interlocks and access the area through the respective movable guard.

While the personnel key is removed, the access key is trapped and the interlock cannot be closed, preventing personnel from being trapped. Once operations are completed and personnel have left the area, reversing the process allows the movable guards to be to closed and the roller coaster to be restarted.

Before the area safeguarding the roller coaster can be entered, power must be turned off using the key-operated switch, bringing the roller coaster into a secured position. The key is then removed and inserted into the key exchange device, which releases up to six access keys, one for each access point.

The access keys can be taken by operators, inserted into the respective access locks, and rotated to release the personnel keys. This allows operators to open the interlocks and access the area through the respective movable guard.

While the personnel key is removed, the access key is trapped and the interlock cannot be closed, preventing personnel from being trapped. Once operations are completed and personnel have left the area, reversing the process allows the movable guards to be to closed and the roller coaster to be restarted.

The Key to Success

The use of mechanical interlocks eliminates most of the electrical wiring associated with other types of interlocks, making mGard cost-effective and easy to install and maintain. Keys and lock covers can be engraved and customised with different colour variations for easy identification.

Wiebe Damstra – Project Manager at Walibi Holland who worked with USP to implement this solution and enhance the safety of the inspection and maintenance tasks – was impressed by the ease of operation and reliability of Fortress trapped key systems. They are also planning to use this solution for more attractions in the future.

Working Closely with USP

As our channel partner, Unique Safety Products (USP) is a leading supplier of high-quality machine safety solutions tailored for various industries. Creating a safe and efficient work environment by meeting the strictest safety requirements through premium products and support is their priority.

With a long-standing relationship, Fortress Safety and USP have been working together for over 15 years to provide the best safety solutions to customers in the Netherlands and regions of Germany, exceeding their expectations.

For any safety related questions, please get in touch with Fortress or USP.

More Case Studies

Fortress Safety has worked closely with Coca-Cola India to enhance personnel protection across nearly forty sites.

Networked interlocks enhanced safety and efficiency in a brick manufacturing plant, optimising automation and operator protection.

Discover how Fortress’s mechanical interlocks were implemented to enhance operator safety at Walibi Holland amusement park.