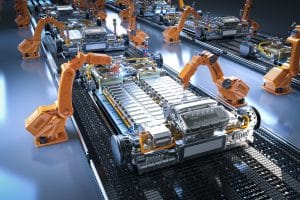

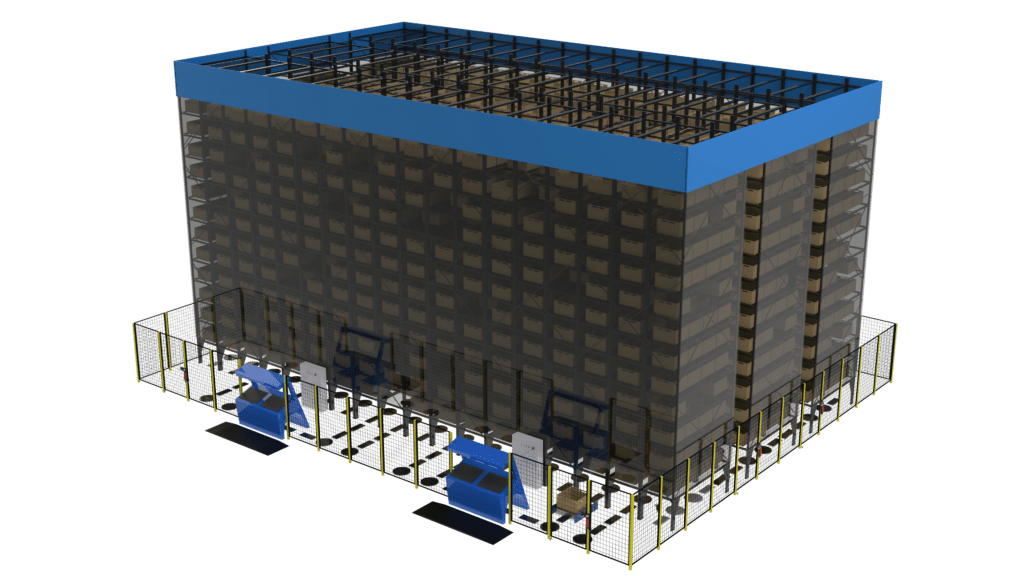

Almacenamiento automatizado

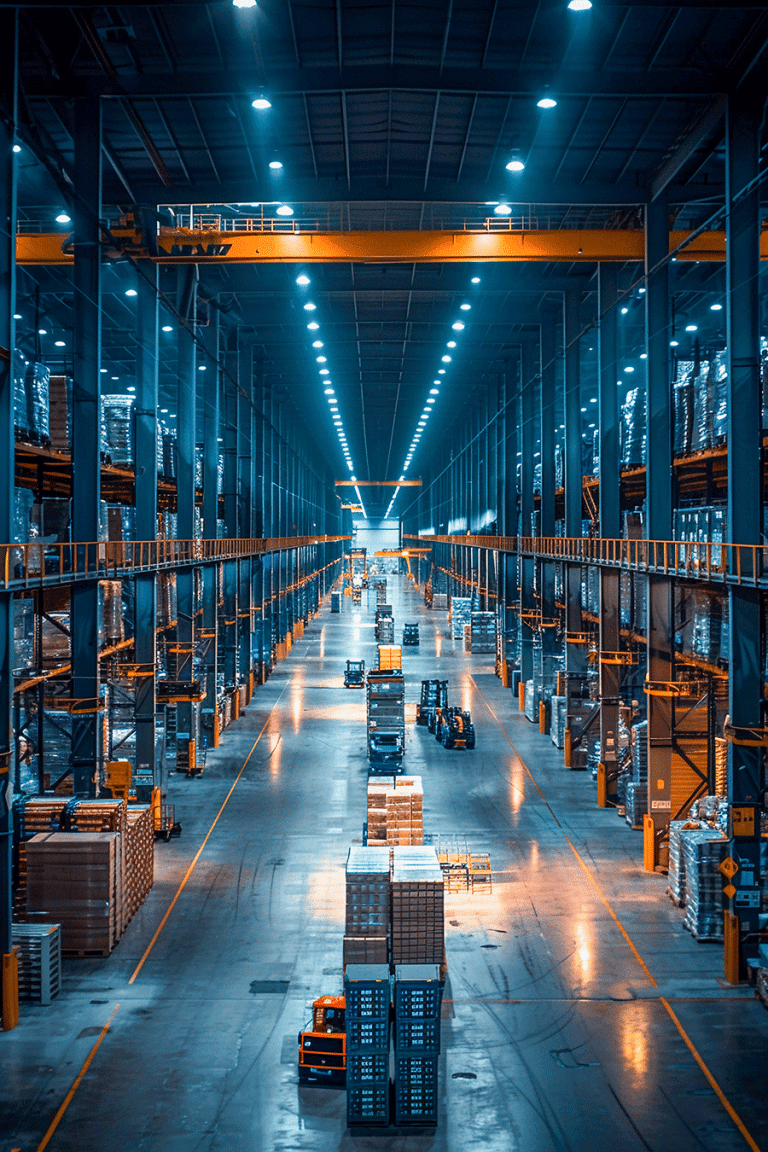

El almacenamiento automatizado presenta retos de seguridad específicos, sobre todo en lo que se refiere a la protección de los operarios en grandes instalaciones con sistemas de almacenamiento y recuperación automatizados (ASRS) y numerosos puntos de acceso. La visibilidad limitada del personal, junto con la presencia de sistemas transportadores y equipos de manipulación robotizados, son solo algunos de los retos.

Unas medidas adecuadas de protección y control de acceso son esenciales para evitar lesiones. Fortress ofrece soluciones que cumplen las normas más estrictas, al tiempo que ofrecen flexibilidad para adaptarse a sus operaciones. Con orientación experta, soporte técnico y formación, Fortress garantiza una integración perfecta priorizando la seguridad y la eficiencia.

Funcionalidad y conformidad

Productos configurables diseñados para rendir y cumplir las normas a escala internacional. Todas las funciones necesarias combinadas en una solución.

Diseño escalable

Soluciones fácilmente escalables y personalizables para operaciones en expansión, que permiten la integración sin fisuras de sistemas de seguridad adicionales según sea necesario.

Conectividad de red

Soluciones rápidas de implantar, disponibles en múltiples protocolos de red para una rápida instalación, integración y puesta en servicio.

Soluciones duraderas

Minimice inactividad y las sustituciones con productos robustos, fabricados para durar décadas incluso en los entornos más exigentes.

Eficiencia operativa

Sistemas intuitivos, fáciles de manejar, con cómodo acceso para el operador y controles en la protección móvil.

Productos totalmente configurables

Diseñe soluciones de seguridad a medida para satisfacer los requisitos específicos de cualquier aplicación.

Funcionalidad y conformidad

Productos configurables diseñados para rendir y cumplir las normas a escala internacional. Todas las funciones necesarias combinadas en una solución.

Diseño escalable

Soluciones fácilmente escalables y personalizables para operaciones en expansión, que permiten la integración sin fisuras de sistemas de seguridad adicionales según sea necesario.

Conectividad de red

Soluciones rápidas de implantar, disponibles en múltiples protocolos de red para una rápida instalación, integración y puesta en servicio.

Soluciones duraderas

Minimice inactividad y las sustituciones con productos robustos, fabricados para durar décadas incluso en los entornos más exigentes.

Eficiencia operativa

Sistemas intuitivos, fáciles de manejar, con cómodo acceso para el operador y controles en la protección móvil.

Productos totalmente configurables

Diseñe soluciones de seguridad a medida para satisfacer los requisitos específicos de cualquier aplicación.

Aplicaciones -

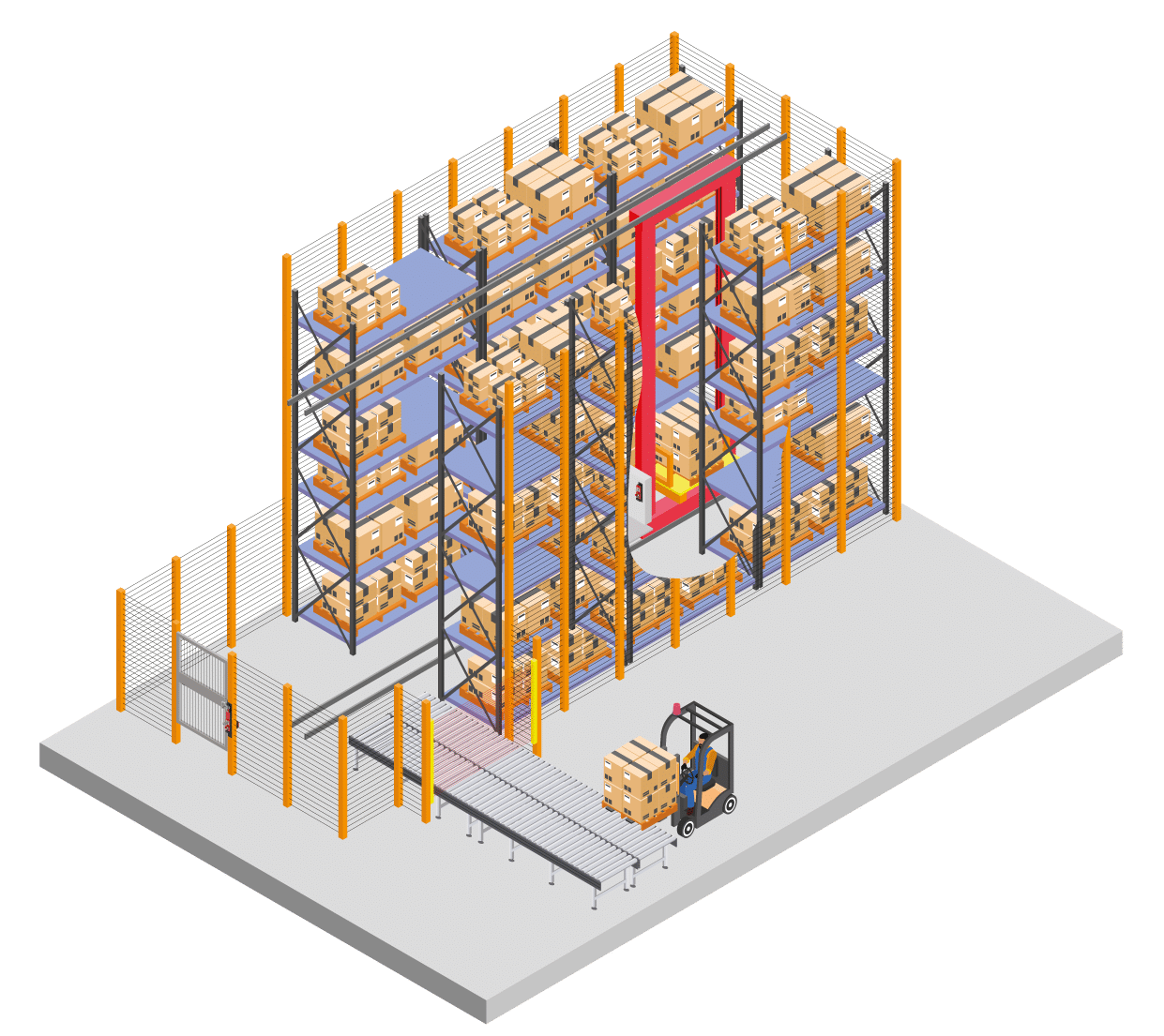

ASRS

Acceso a pasillos en sistemas de almacenamiento y recuperación automatizados

Los sistemas de almacenamiento y recuperación automatizados (ASRS) suelen abarcar muchos pasillos, tener múltiples puntos de acceso y es probable que dispongan de grúas para recuperar y almacenar productos. En algunas regiones, estos sistemas deben cumplir la norma EN 528 de seguridad para equipos de almacenamiento y recuperación sobre raíles, que incluye una serie de requisitos [...].

Aplicaciones -

Mezclador

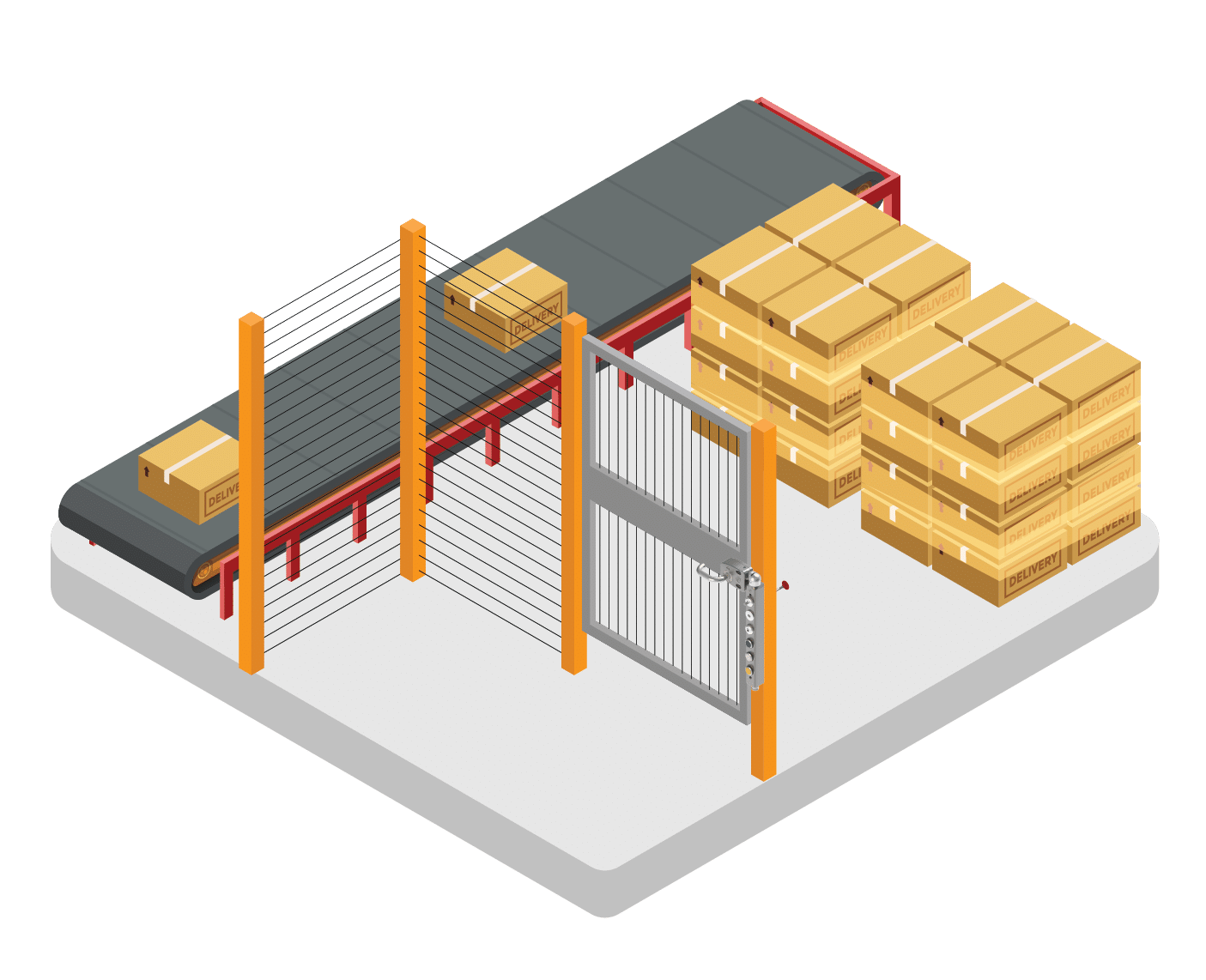

Sistema transportador

Los sistemas transportadores de los almacenes automatizados transportan eficazmente las mercancías por toda la instalación, reduciendo el trabajo manual y aumentando la velocidad. A menudo se integran con otras tecnologías de automatización para agilizar las operaciones, desde la recepción hasta la realización de pedidos. En algunas circunstancias, los sistemas transportadores pueden estar protegidos por protecciones con enclavamiento para evitar la exposición del personal a posibles peligros. El reto El personal puede necesitar [...]

Aplicaciones -

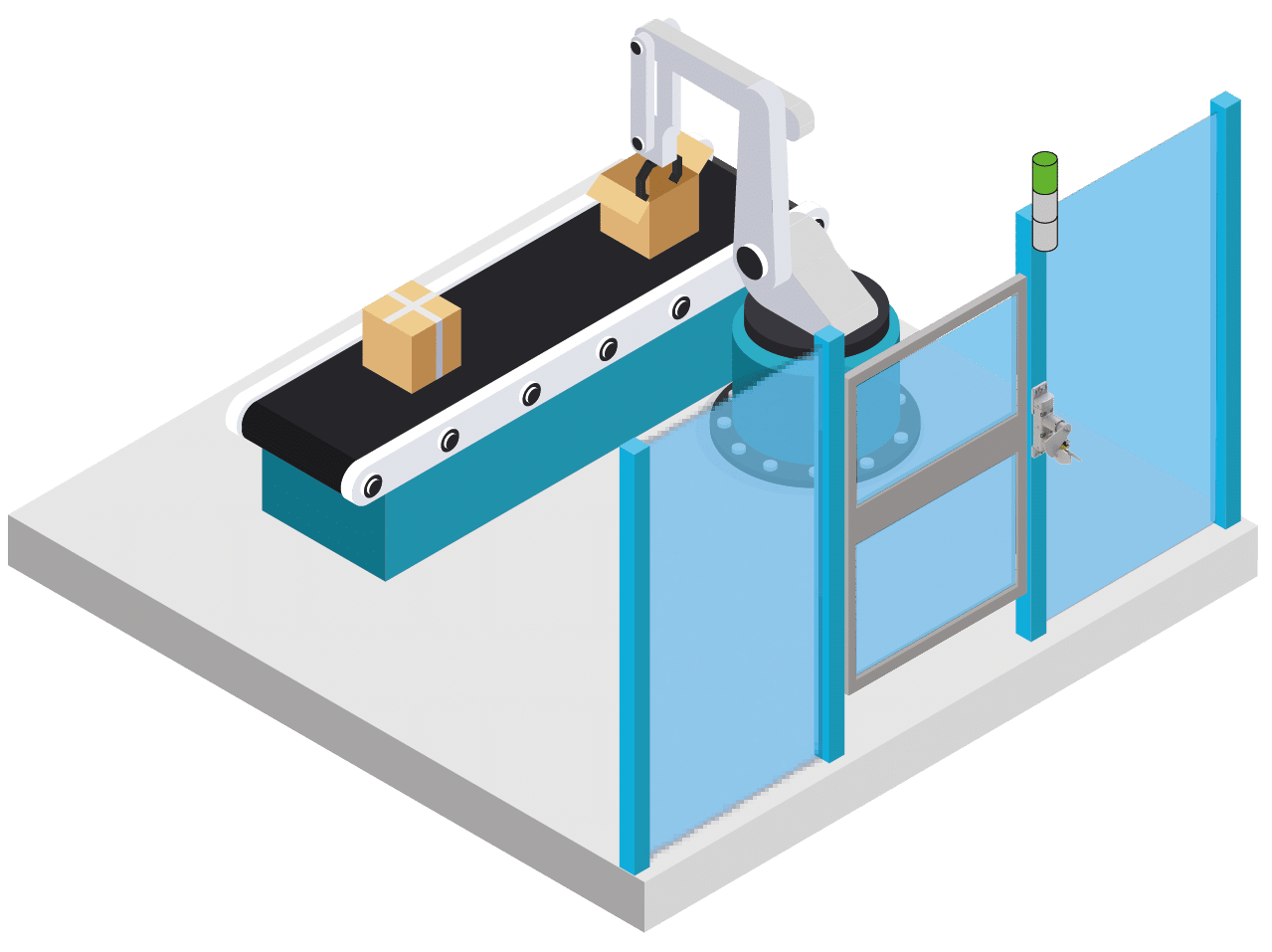

Apilamiento de robots

Bloqueo de enclavamiento para una célula de apilamiento robotizada

El cliente es un líder mundial en lentes de contacto. Como parte del proceso de producción, los robots recogen y apilan cajas que contienen lentes de contacto antes de enviarlas a empaquetar. El reto La protección que permite el acceso a la zona donde opera el robot cuenta con un sensor que indica si está abierta o cerrada. [...]

Empiece a trabajar en su solución personalizada

Estudio de caso -

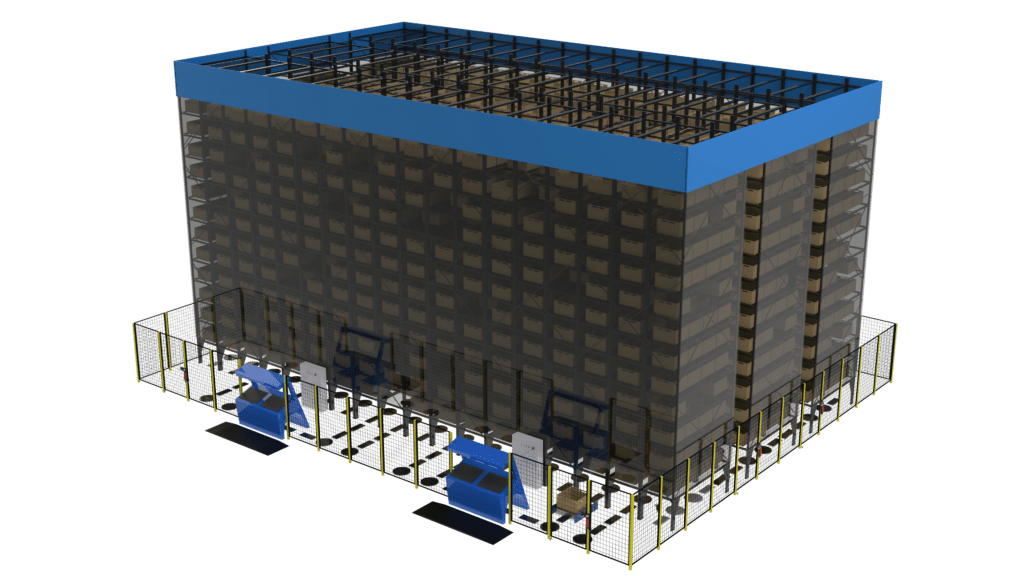

OPEX

Soluciones de seguridad basadas en EtherCAT en automatización de almacenes

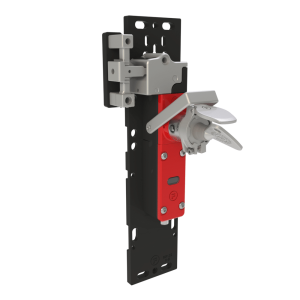

Fortress ofreció dispositivos para acceso a pasillos y E/S de seguridad remotas mediante dispositivos capaces de comunicarse a través de EtherCAT. Se proporcionaron tres tipos de unidades de la gama amGardpro , que permiten el acceso al pasillo, el acceso lateral y la E/S remota, respectivamente.

Productos utilizados

amGardpro

Resultados

Seguridad ASRS a medida con integración EtherCAT: rápida de implantar, fácil de manejar y diseñada para ampliarse.

¿Quiénes son los OPEX?

OPEX ofrece soluciones escalables de automatización de almacenes, documentos y correo para impulsar la eficiencia de las infraestructuras.

Estudio de caso - OPEX

Soluciones de seguridad basadas en EtherCAT en automatización de almacenes

Fortress ofreció dispositivos para acceso a pasillos y capacidad de E/S de seguridad remota mediante dispositivos capaces de comunicarse a través de EtherCAT. Se ofrecieron tres tipos de unidades de la gama amGard pro, que permiten el acceso al pasillo, el acceso lateral y la E/S remota, respectivamente.

Productos utilizados

amGardpro

Socios implicados

Automatización Shingle & Gibb, Automatización East Coast

¿Quiénes son los OPEX?

OPEX ofrece soluciones escalables de automatización de almacenes, documentos y correo para impulsar la eficiencia de las infraestructuras.

Gama de productos recomendados

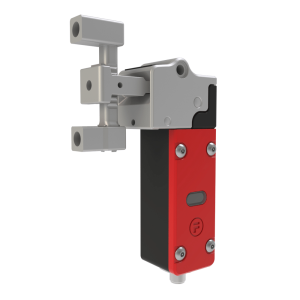

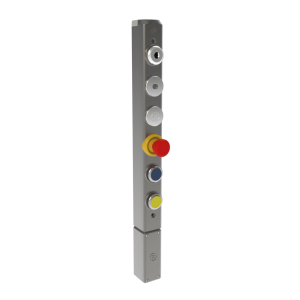

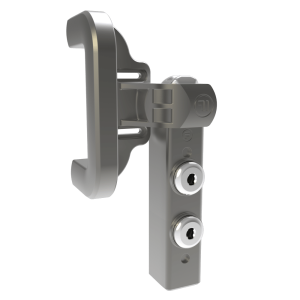

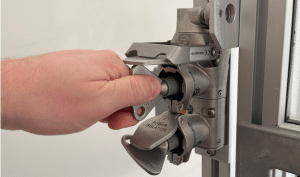

amGardpro

Enclavamientos configurables y vainas de control para aplicaciones pesadas certificadas para su uso hasta PLe/Cat. 4. Los controles de pulsador, las opciones de llave atrapada y la conectividad de red pueden combinarse en una sola unidad.

Altamente configurable

Reducir las sustituciones y inactividad

Todos los controles en un solo lugar

Conectividad de red

Gama de productos recomendados

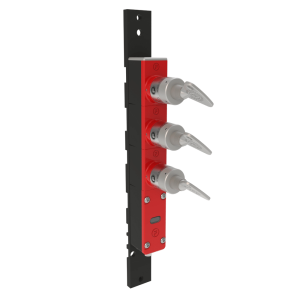

tGard

Una gama versátil de enclavamientos y estaciones de control que puede alojar hasta diez módulos, incluidas llaves atrapadas y controles de operador. Alojados en un robusto cuerpo metálico de 40 mm, son adecuados para diversas aplicaciones de fabricación y automatización industrial.

A la medida de sus necesidades

Solución integrada eficaz

Instalación sencilla

Resistente y duradero

Noticias y datos

- Evento

- Evento

¿No sabe por dónde empezar? Estamos aquí para ayudarle

Nuestro equipo de expertos está aquí para ayudarle a crear la solución adecuada para usted. Pueden analizar su sector y las necesidades específicas de su aplicación para ofrecerle recomendaciones sobre cómo los productos Fortress podrían beneficiar a su instalación.