Aliments et boissons

Applications hygiéniques

Avec des solutions IP69 et 3-A approuvé interverrouillage pour les environnements projections d’eau ou pour un contact étroit avec les aliments.

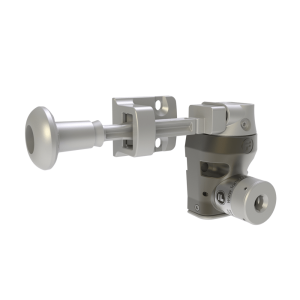

Verrous en acier inoxydable

Lorsque la résistance à la corrosion et le lavage régulier sont nécessaires.

Fonctions de sécurité avancées

Actionneurs codés, contrôle de la sécurité et interverrouillage pour éviter les pannes, améliorer la sécurité et garantir la conformité aux normes.

Produits entièrement configurables

Concevoir des solutions de sécurité sur mesure pour répondre aux exigences spécifiques de toute application.

Minimiser les temps d’arrêt et les remplacements

Des produits robustes conçus pour durer des décennies, même dans les applications les plus exigeantes et les environnements les plus difficiles.

Portée mondiale

Avec des bureaux dans le monde entier et un vaste réseau de partenaires de confiance, Fortress offre une assistance à l'échelle mondiale.

Applications hygiéniques

Avec des solutions IP69 et 3-A approuvé interverrouillage pour les environnements projections d’eau ou pour un contact étroit avec les aliments.

Verrous en acier inoxydable

Lorsque la résistance à la corrosion et le lavage régulier sont nécessaires.

Fonctions de sécurité avancées

Coded actuators, monitoring, and guard locking to minimise the possibility of defeat, reduce risk and ensure compliance with standards.

Produits entièrement configurables

Concevoir des solutions de sécurité sur mesure pour répondre aux exigences spécifiques de toute application.

Minimiser les temps d’arrêt et les remplacements

Robust products built to last for decades, even in the most challenging applications.

Portée mondiale

Avec des bureaux dans le monde entier et un vaste réseau de partenaires de confiance, Fortress offre une assistance à l'échelle mondiale.

Applications -

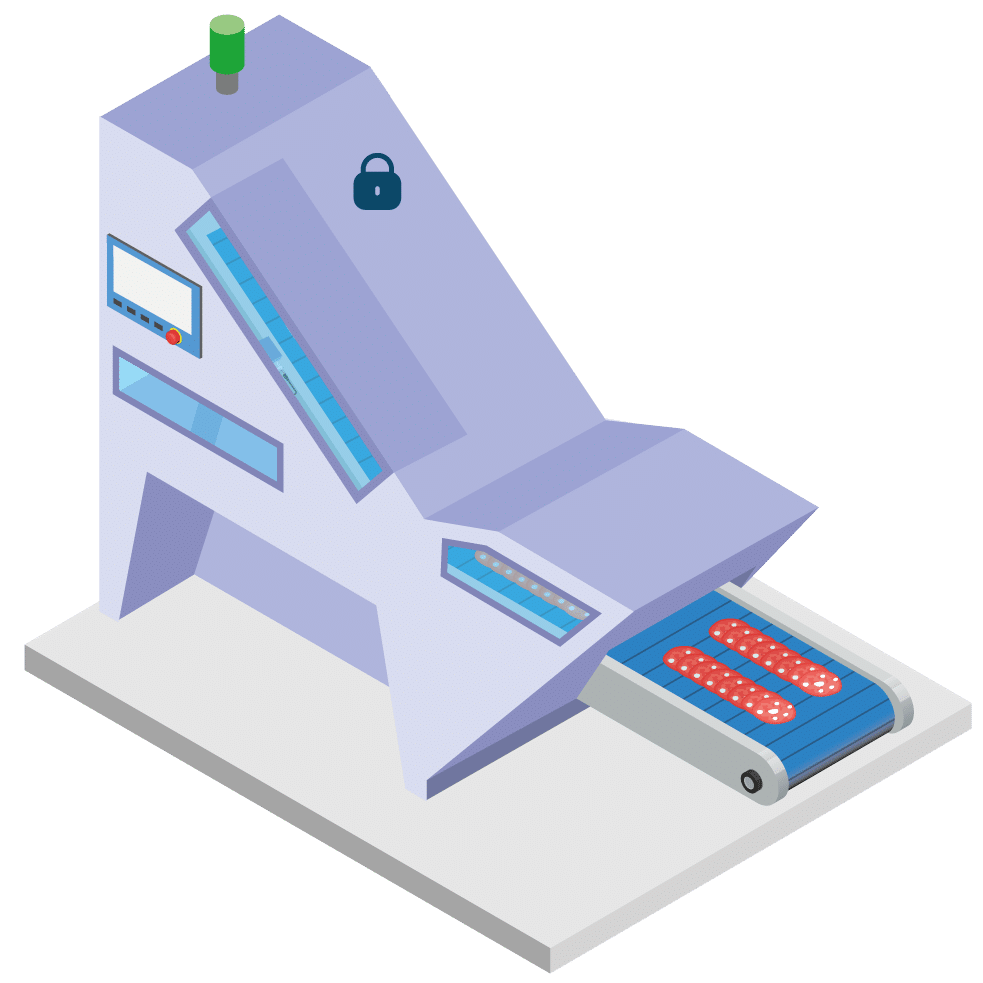

Trancheur d'aliments

protecteur hygiénique sur une trancheuse automatique

Dans l'industrie alimentaire, des machines telles que les trancheuses automatiques sont couramment utilisées pour trancher une grande variété de produits, y compris la viande et le fromage. Ces machines ont des trappes qui doivent rester fermées pendant le processus, mais qui peuvent avoir besoin d'être ouvertes périodiquement pour le nettoyage et la maintenance. Le défi La machine est équipée de lames qui [...]

Applications -

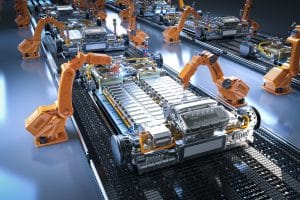

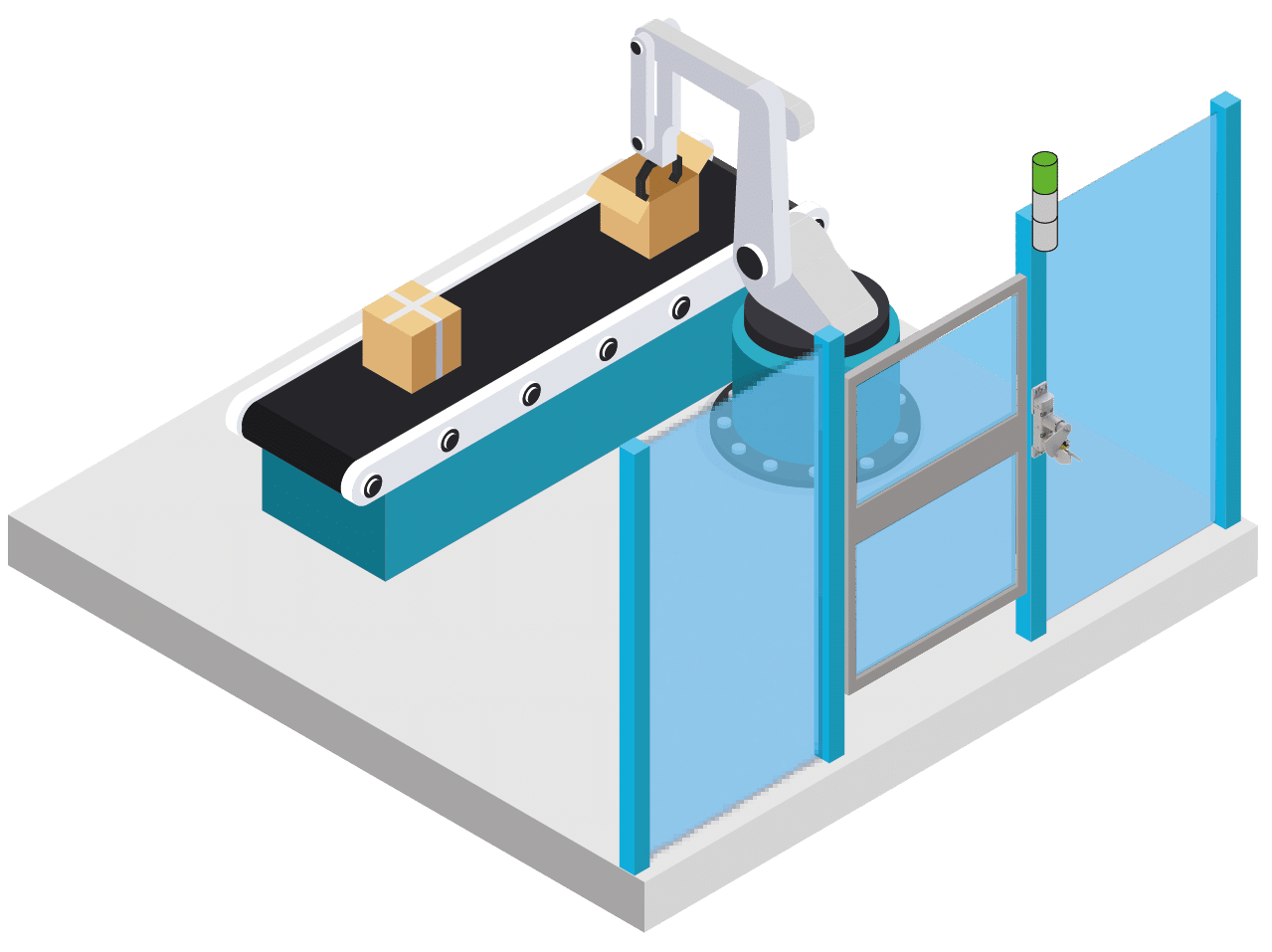

Empilage de robots

Blocage d'interverrouillage pour une cellule d'empilage robotisée

Le client est un leader mondial dans le domaine des lentilles de contact. Dans le cadre du processus de production, les robots prélèvent et empilent des boîtes contenant des lentilles de contact avant de les envoyer à l'emballage. Le défi Le dispositif de protection qui permet d'accéder à la zone où opère le robot est doté d'un capteur qui indique s'il est ouvert ou fermé. [...]

Applications -

Mélangeur

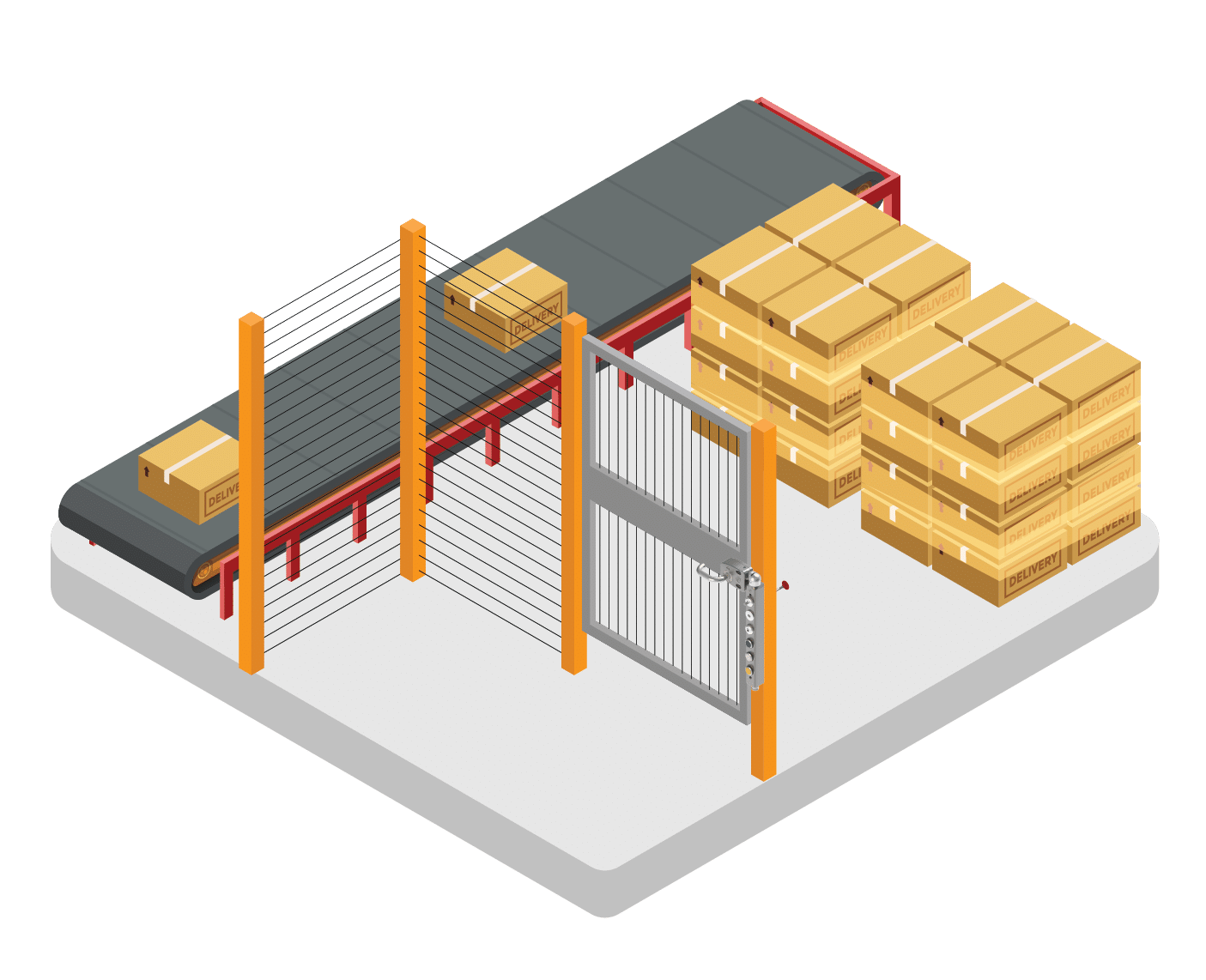

Système de convoyage

Les systèmes de convoyage des entrepôts automatisés transportent efficacement les marchandises dans l'ensemble de l'installation, en réduisant le travail manuel et en augmentant la vitesse. Ils s'intègrent souvent à d'autres technologies d'automatisation pour rationaliser les opérations, de la réception à l'exécution des commandes. Dans certaines circonstances, les systèmes de convoyage peuvent être protégés par des dispositifs de verrouillage afin d'éviter que le personnel ne soit exposé à des risques potentiels. Le défi Le personnel peut avoir besoin [...]

Commencez à élaborer votre solution personnalisée

Étude de cas -

OPEX

Solutions de sécurité basées sur le protocole EtherCAT dans les pays en développement automatisation des entrepôts

Fortress a proposé des dispositifs pour l'accès aux allées et des capacités d'E/S de sécurité à distance grâce à des dispositifs capables de communiquer via EtherCAT. Trois types d'unités de la gamme amGardpro ont été fournis, permettant respectivement l'accès aux allées, l'accès latéral et les E/S à distance.

Produits utilisés

amGardpro

Le résultat

Sécurité ASRS sur mesure avec intégration EtherCAT - rapide à déployer, facile à utiliser et évolutif.

Qui est Coca-Cola ?

La société Coca-Cola est une multinationale qui fabrique et vend des boissons.

Étude de cas - Coca Cola

Améliorer la sécurité des machines sur les sites d'embouteillage

L'industrie de la production de boissons est confrontée à des défis complexes en matière de sécurité, la sécurité des machines étant l'un des aspects critiques. Dans les usines de production de boissons, de nombreuses blessures liées aux machines sont causées par des applications impliquant des convoyeurs, des machines d'embouteillage, des machines d'emballage et des palettiseurs.

Produits utilisés

amGardpro, mGard, Osbourn

Partenaires impliqués

Deebar, Afrique du Sud

Qui est Coca-Cola ?

La société Coca-Cola est une multinationale qui fabrique et vend des boissons.

Gamme de produits recommandés

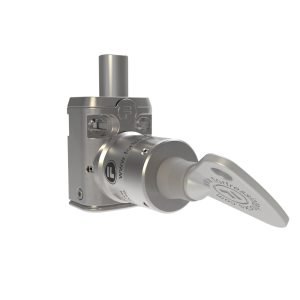

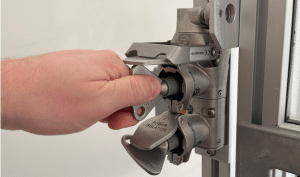

HGL

Le protecteur hygiénique (HGL) est un interverrouillage hygiénique 3-A approuvé avec une construction en acier inoxydable et des joints en silicone conformes aux normes alimentaires de la FDA. Conçu pour projections d’eau et pour les situations où l'hygiène et la salubrité sont essentielles.

Conception certifiée pour la sécurité alimentaire

Acier inoxydable résistant à la corrosion

Le nettoyage en toute simplicité

Convient aux petits points d'accès

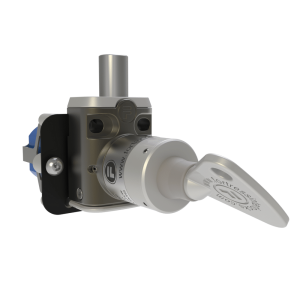

Gamme de produits recommandés

mGard

Verrouillages mécaniques à clé bloquée conçus pour imposer des séquences de clés spécifiques, en particulier dans les applications impliquant des sources d'énergie multiples. Rentables, faciles à installer et à entretenir, des variantes en acier inoxydable sont disponibles.

Options en acier inoxydable

Appliquer les séquences

Minimiser les machines temps d’arrêt

Pas de câblage nécessaire

Actualités et perspectives

- Événement

Vous ne savez pas par où commencer ? Nous sommes là pour vous aider

Notre équipe d'experts est là pour vous aider à créer la bonne solution pour vous. Ils peuvent analyser votre secteur d'activité et vos besoins spécifiques en matière d'application afin de vous proposer des recommandations sur la manière dont les produits Fortress pourraient bénéficier à votre installation.