Enclavamientos habilitados para EtherCAT para el almacén automatizado de OPEX

Enclavamientos habilitados para EtherCAT para el acceso a varios pasillos, adaptados a las necesidades específicas de una ASRS de Nueva Jersey.

Industria

Almacenamiento automatizado

Productos utilizados

Socios implicados

País

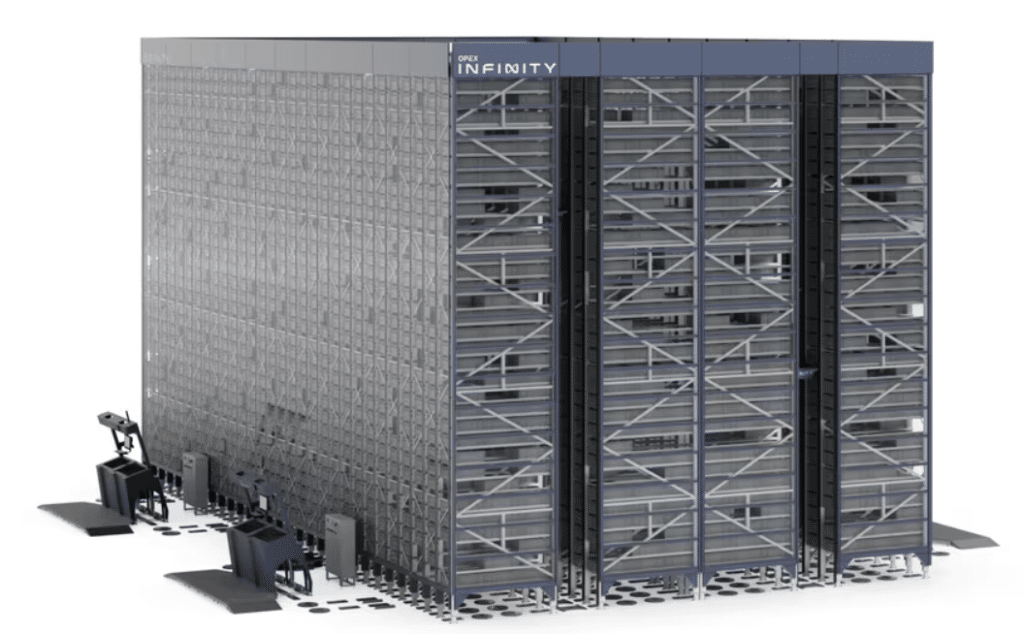

Visión general de los sistemas de almacenamiento y recuperación automatizados

Los sistemas de almacenamiento y recuperación automatizados (ASRS o AS/RS) son sistemas asistidos por ordenador y robot que pueden recuperar o almacenar artículos en ubicaciones específicas. Los ASRS pueden consistir en pasillos con lanzaderas, grúas, carruseles, elevadores verticales, etc., y se utilizan ampliamente en fábricas, instalaciones de distribución y otros entornos.

Los ASRS ofrecen un almacenamiento de alta densidad (lo que supone un considerable ahorro de espacio), contribuyen a optimizar las operaciones y ayudan a reducir los costes de mano de obra. Sin embargo, son vulnerables a los cortes de electricidad, sufren averías y requieren mantenimiento.

Puede haber situaciones en las que el personal necesite acceder a los pasillos. Dado que los ASRS implican piezas móviles, cintas transportadoras y, posiblemente, brazos robóticos, los operarios pueden estar expuestos a peligros, quedando atrapados en la maquinaria en movimiento con el riesgo de que partes del cuerpo queden atrapadas o sean aplastadas.

El desafío

Fortress Safety trabajó con un líder tecnológico mundial en automatización de alta velocidad y manipulación de materiales, para diseñar y proporcionar soluciones de seguridad para un innovador ASRS en Nueva Jersey (EE.UU.). El sistema consta de varios pasillos, con protecciones en cada extremo para permitir el acceso, así como protecciones de acceso lateral.

El cliente identificó la necesidad de soluciones de seguridad en forma de enclavamientos para hacer frente a situaciones en las que fuera necesario acceder a los pasillos. También buscaban una solución que pudiera ampliarse fácilmente para adaptarse a los cambios en las necesidades y el crecimiento de la empresa (es decir, para adaptarse a futuras ampliaciones o cambios en la estrategia operativa). Además, dado que otros dispositivos in situ se comunican a través de EtherCAT, el cliente necesitaba una solución que pudiera integrarse fácilmente en su red existente.

La solución

Nuestras soluciones de seguridad con EtherCAT

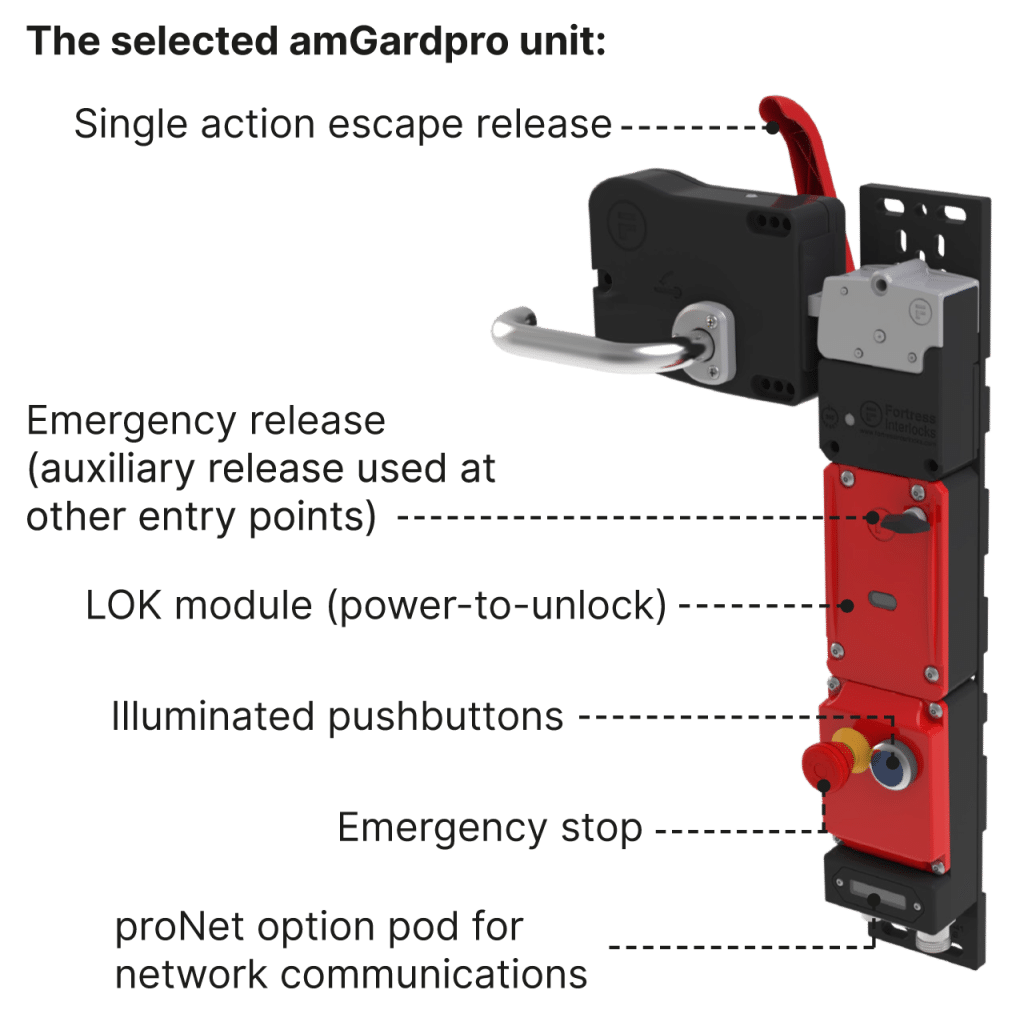

Fortress diseñó una solución de enclavamiento personalizada a partir de la gama amGard. Se proporcionaron diferentes configuraciones de enclavamiento para la entrada específica del pasillo (acceso lateral y acceso al final de la fila, respectivamente) y bloques de E/S.

En concreto, en los puntos de acceso se utilizó una solución de enclavamiento "todo en uno":

- Asa de liberación de escape de acción simple: para mayor seguridad del operario, permite una salida rápida desde el interior del espacio protegido.

- funcionalidadbloqueo de protección (power-to-unlock) - para un control de acceso seguro

- Funcionalidad de desbloqueo manual: para desbloquear el dispositivo desde el exterior; desbloqueo auxiliar para las unidades de acceso de final de fila y desbloqueo de emergencia para las unidades de acceso laterales.

- parada de emergencia y pulsadores iluminados para mayor facilidad de uso y eficacia

La configuración para acceso lateral se utilizó en cuatro ubicaciones, mientras que la de acceso al final de la fila se utilizó en diez ubicaciones. Los bloques de E/S permitían conectar paradas de emergencia u otros dispositivos de seguridad y se instalaron en ocho ubicaciones.

Todos los dispositivos podían comunicarse a través de la red EtherCAT y estaban preinstalados en placas de montaje para facilitar y agilizar la instalación. Cuando la seguridad, la resistencia y la fiabilidad son primordiales, amGardpro es la solución óptima.

Enclavamientos con desbloqueo de emergencia para acceso lateral

Acción simple liberación de escape

Bloques de E/S

La clave del éxito

Pudimos ofrecer una solución adaptada a las necesidades del cliente, atendiendo a los requisitos de su aplicación específica. Para esta colaboraciónTambién desarrollamos una base de conectores que utiliza conectores M12 codificados en L en lugar de las variantes más grandes de 7/8".

Este proyecto fue posible gracias a la cooperación de las distintas partes implicadas. A lo largo de todo el proceso, los expertos de Fortress Safety colaboraron estrechamente con OPEX®, ofreciendo asesoramiento y garantizando un funcionamiento óptimo, junto con Shingle & Gibb Automation (nuestro socio de canal) y East Coast Automation (nuestro representante de fabricación).

Shingle & Gibb Automation ofrecen productos para automatización industrial y redes, control de movimiento, seguridad de máquinas y transmisión de potencia. East Coast Automation es una empresa de representación de fabricantes que da servicio al mercado del Atlántico Medio.

Fortress Safety y ASRS

Los productos descritos en este caso práctico se seleccionaron en función de los requisitos de un cliente específico. Fortress ofrece una variedad de soluciones de seguridad adecuadas para la industria de automatización de almacenes y es un socio de confianza en la creación de entornos ASRS más seguros y eficientes. Algunos de nuestros dispositivos también están diseñados para cumplir con la norma EN 528, una norma europea que incluye una serie de requisitos para ASRS, incluyendo la dependencia clave y la selección de modo.

Más estudios de caso

Descubra por qué Omnifactory (Universidad de Nottingham) eligió trabajar con Fortress Safety en su innovador proyecto.

Tata Steel eligió FRANK para gestionar los permisos control de acceso y mejorar la seguridad en su línea ZODIAC.

Descubra cómo se implementaron los enclavamientos mecánicos de Fortresspara mejorar la seguridad de los operarios en el parque de atracciones Walibi Holland.