Entry Looper in Steel Processing

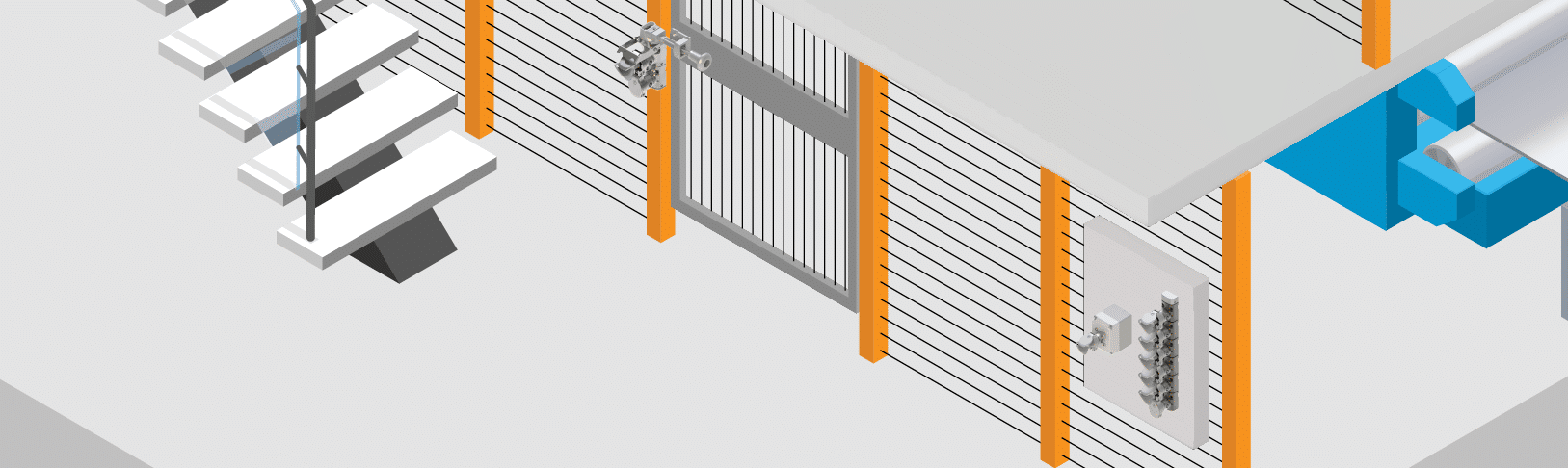

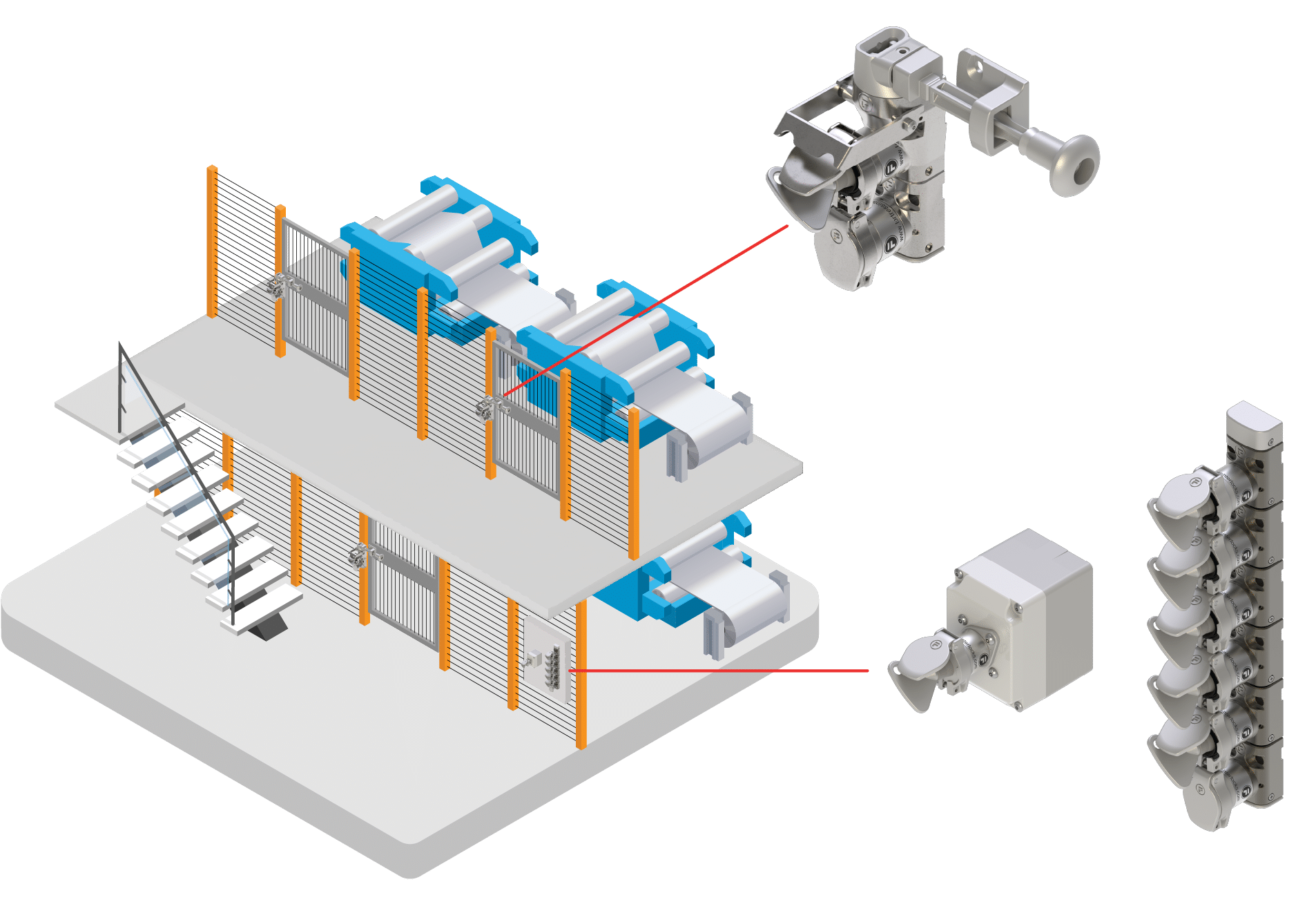

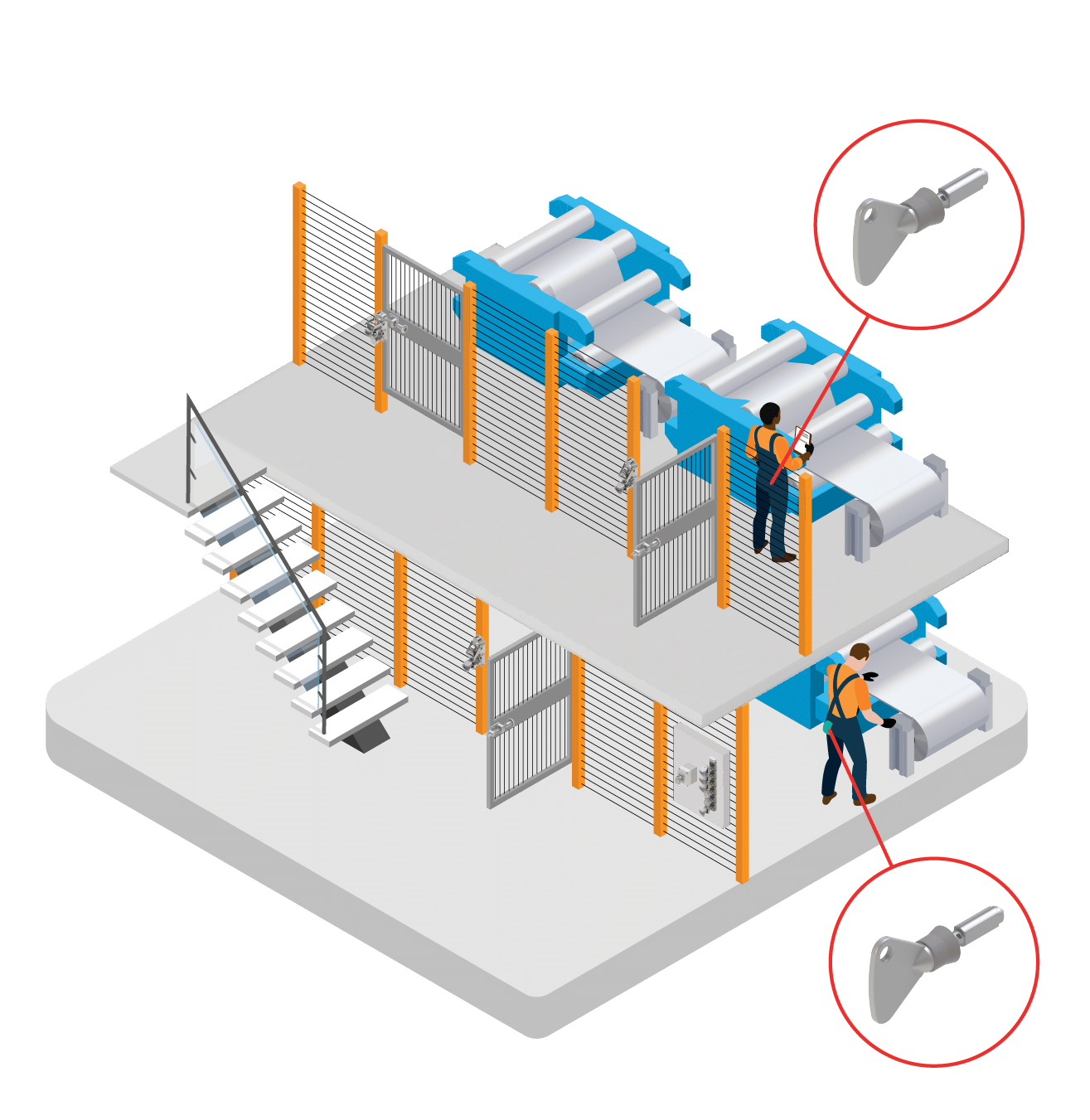

During the galvanization process of steel, metal rolls pass through the accumulator (entry looper). This section spans multiple levels and regulates the flow and tension of the steel strips, ensuring a continuous and controlled feed. Personnel regularly need access to this area for specific tasks.

挑戦

Previously, fixed guards were used, which operators would remove when access was required. This practice often resulted in damaged guards and exposed operators to hazards if the guards were not re-bolted properly. Hence, the customer upgraded to movable guards that require interlocks. In addition, due to the vast size of the area, running cables across multiple levels also presents challenges.

ソリューション

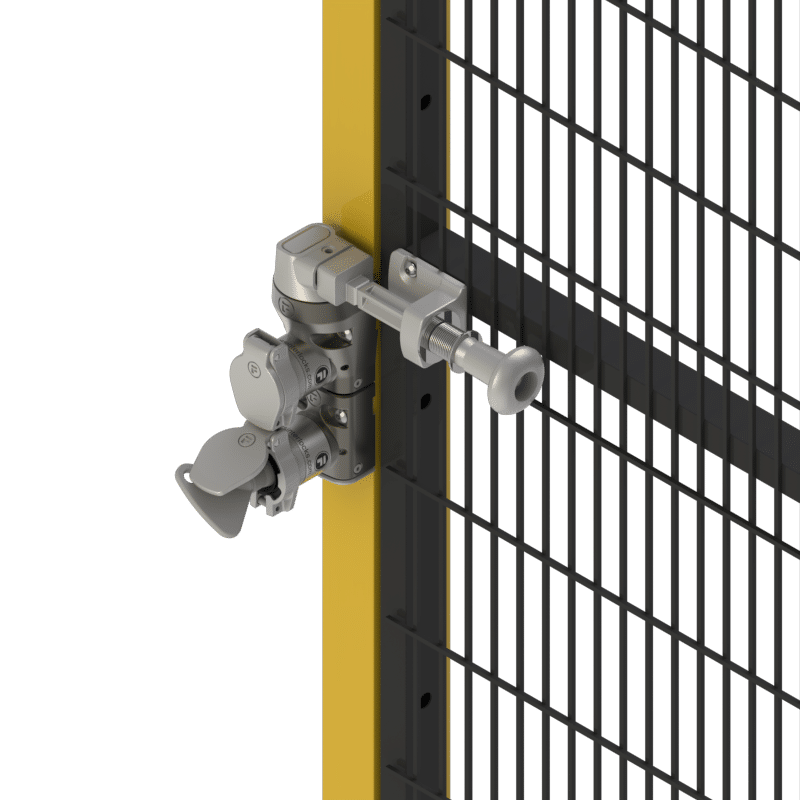

mGard

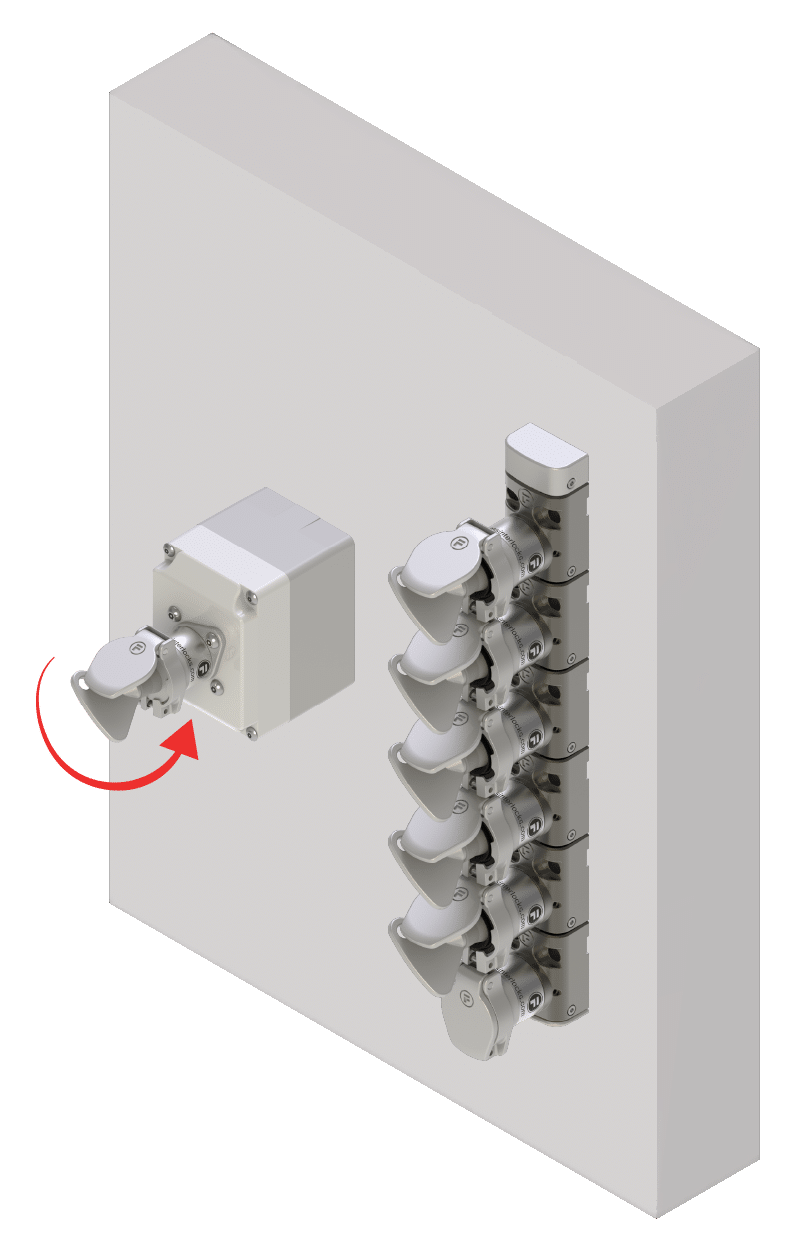

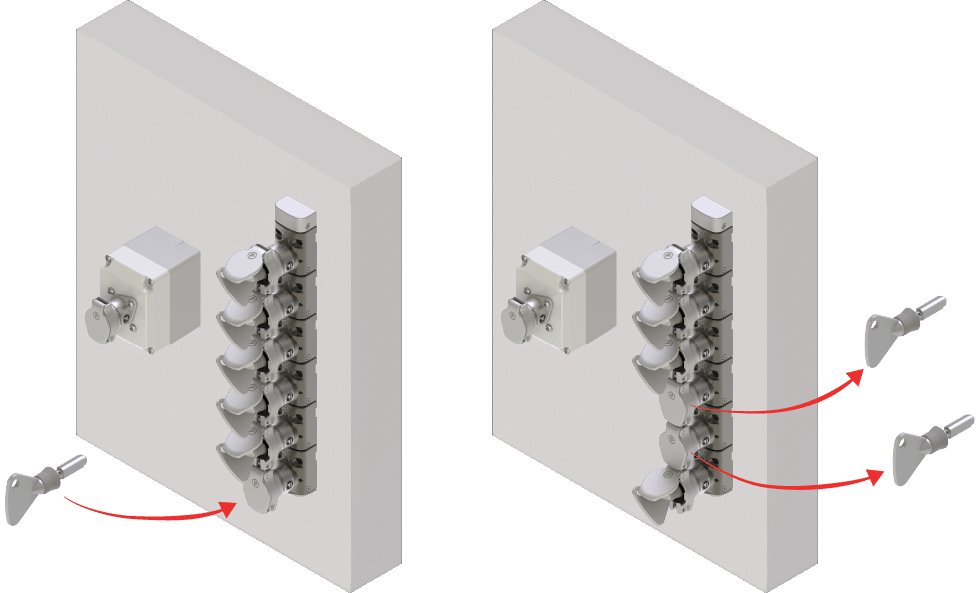

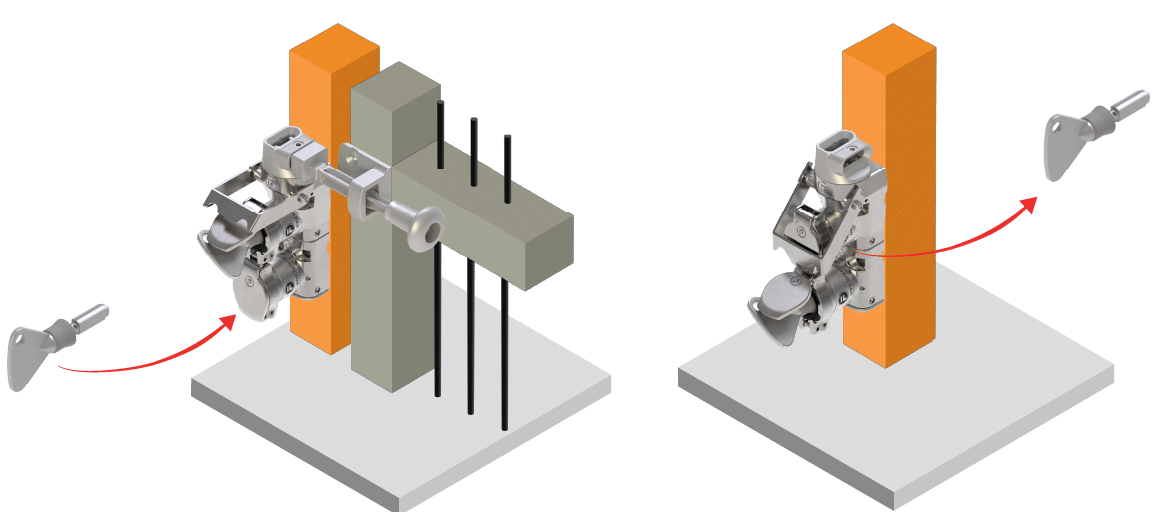

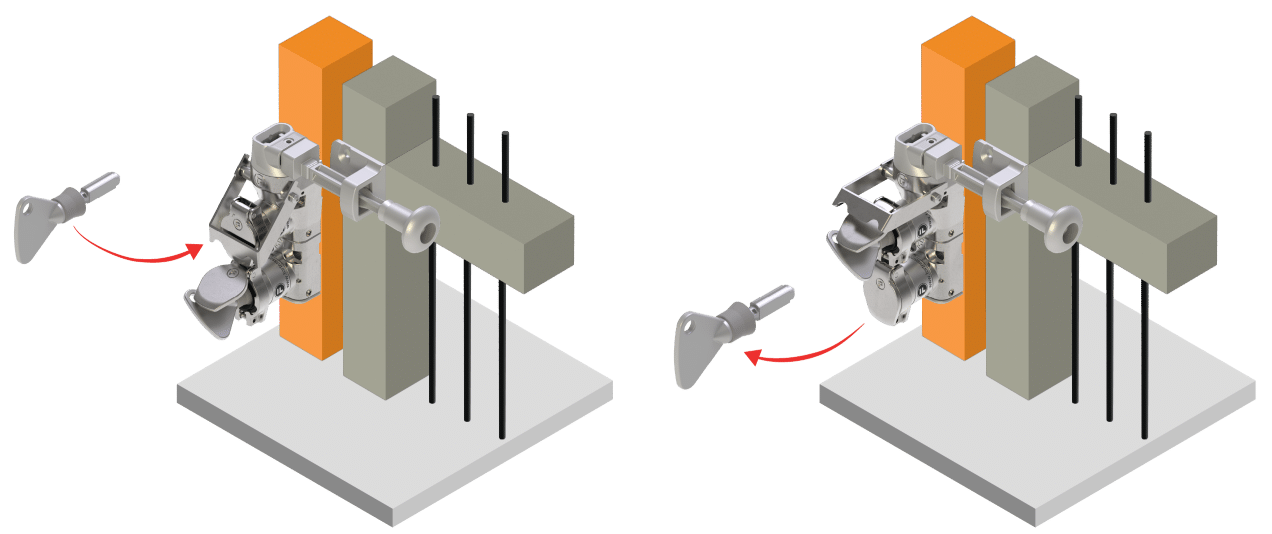

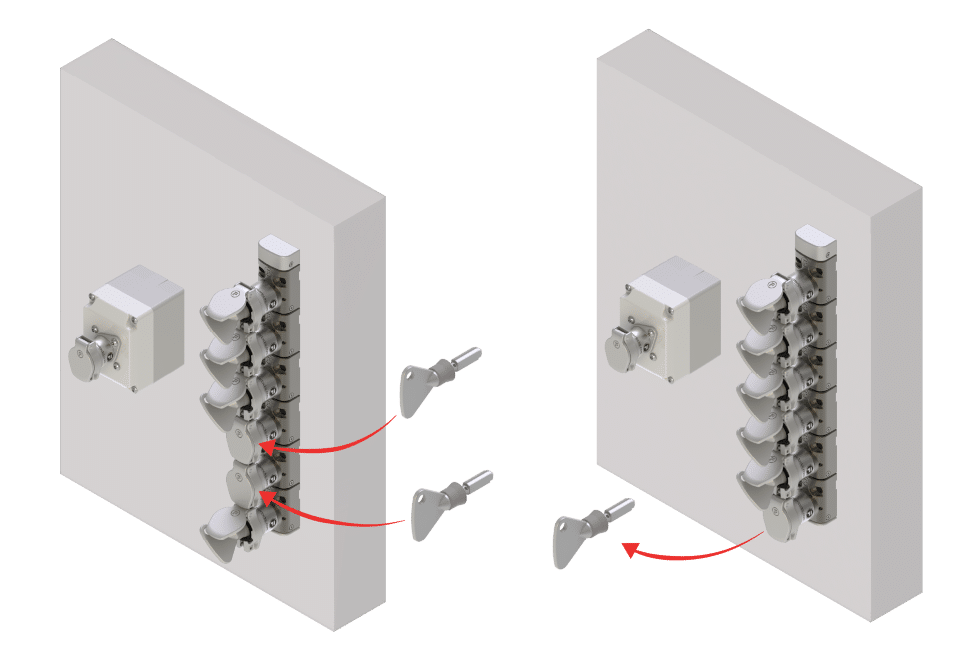

Fortress proposed a trapped key system with mGard mechanical interlocks. A key-operated switch is used to isolate power to the machine. The transfer of the key to the key exchange device releases the access keys that allow opening the respective interlocks on the upper levels. The machine can restart only when the sequence is reversed.

仕組み

ステップ・バイ・ステップ・プロセス

このソリューションは、特定のお客様の課題を解決することに成功しました。Fortress 、別のセットアップやマルチレンジオプションにも対応できます。お客様のニーズを満たすオーダーメイド・ソリューションを設計いたしますので、アプリケーションの詳細をお知らせください。

推奨製品

Why Mechanical Trapped Key?

In this application, a mechanical trapped key system based on the mGard range was chosen for a few reasons:

It enforces a sequence of events

While the key is removed, the energy source is prevented from being accidently turned on

It ensures that guards are closed before operations are allowed to resume

Another advantage of this solution is that by using mechanical interlocks it is possible to reach areas where wiring is impractical.