Hygienic Guard Lock on an Automatic Food Slicer

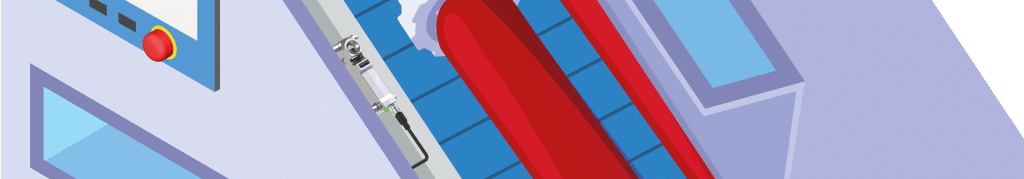

In the food processing industry, machines like automatic food slicers are commonly used to slice a wide variety of products, including meat and cheese. Such machines have hatches that need to stay closed during the process but may need to be opened periodically for scheduled cleaning and maintenance.

The Challenge

The machine has blades that rotate at high speed, exposing operators to hazards. Food slicers can in fact cause serious injuries such as cuts and amputations when workers operate, perform maintenance, or clean the machines.

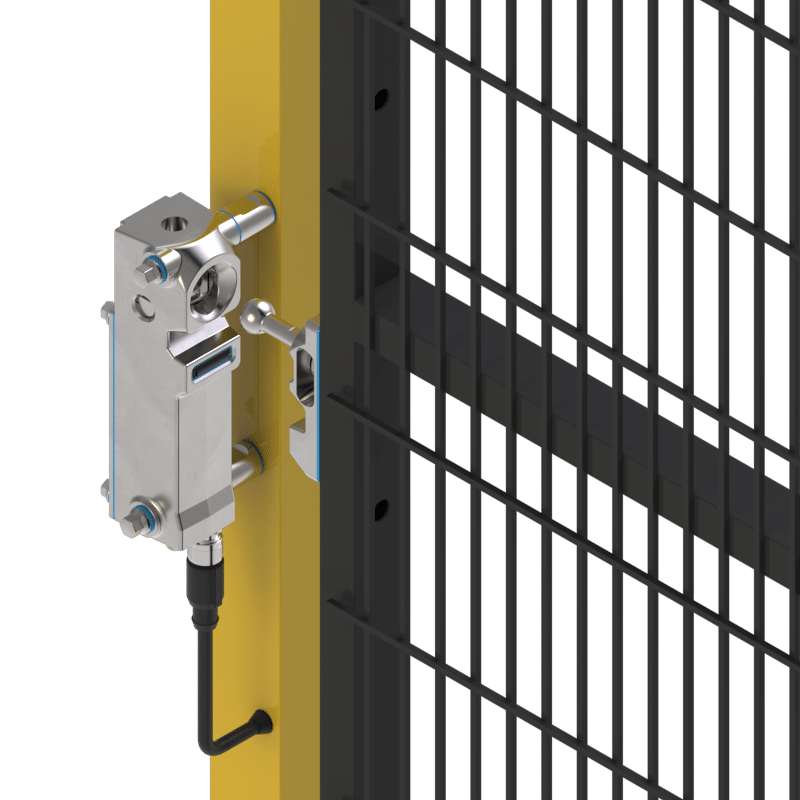

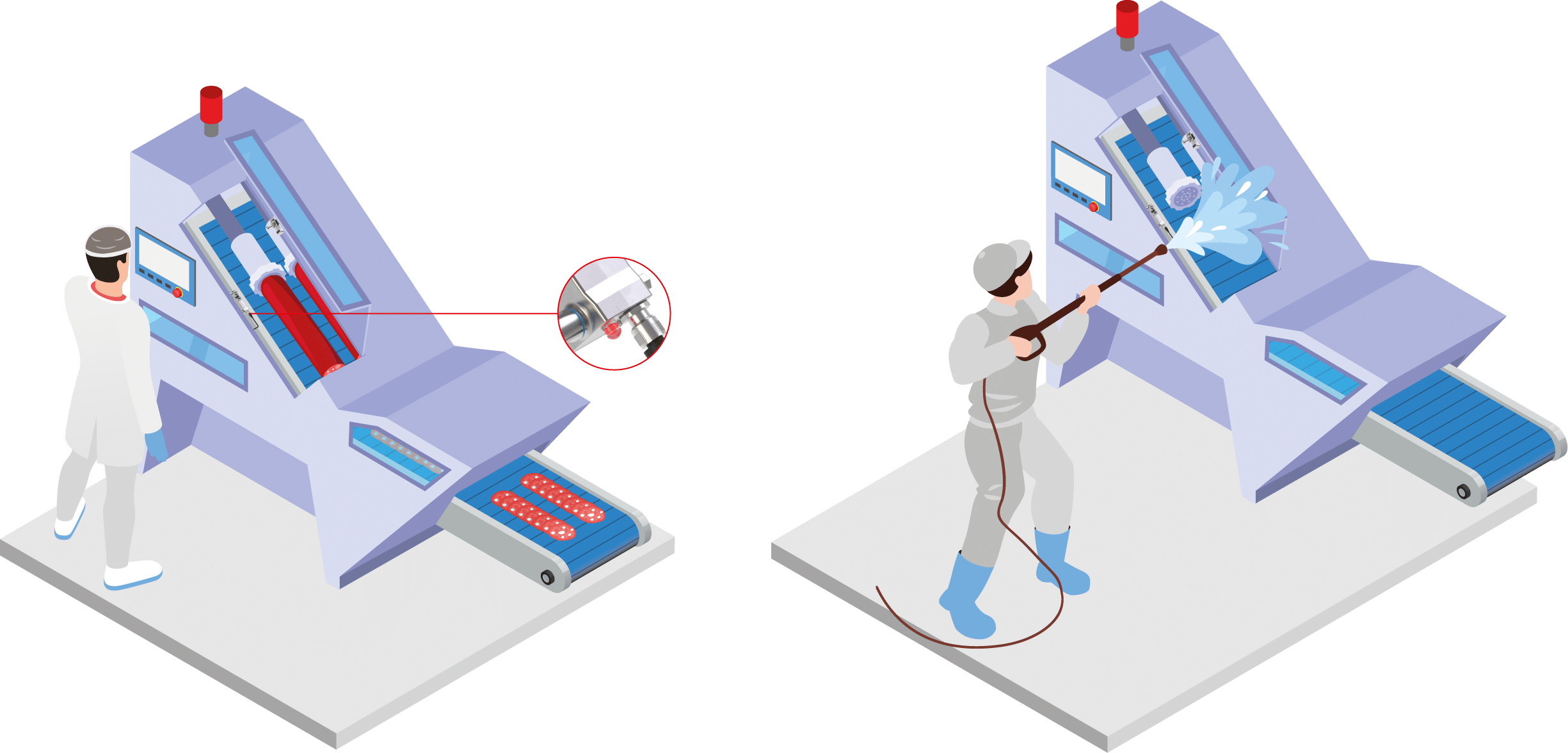

In this case the customer also needs to incorporate guard locking on the machines. Units are mounted inside the guarding and constantly exposed to the product, therefore frequent washdown is needed.

The Solution

Hygienic Guard Lock (HGL)

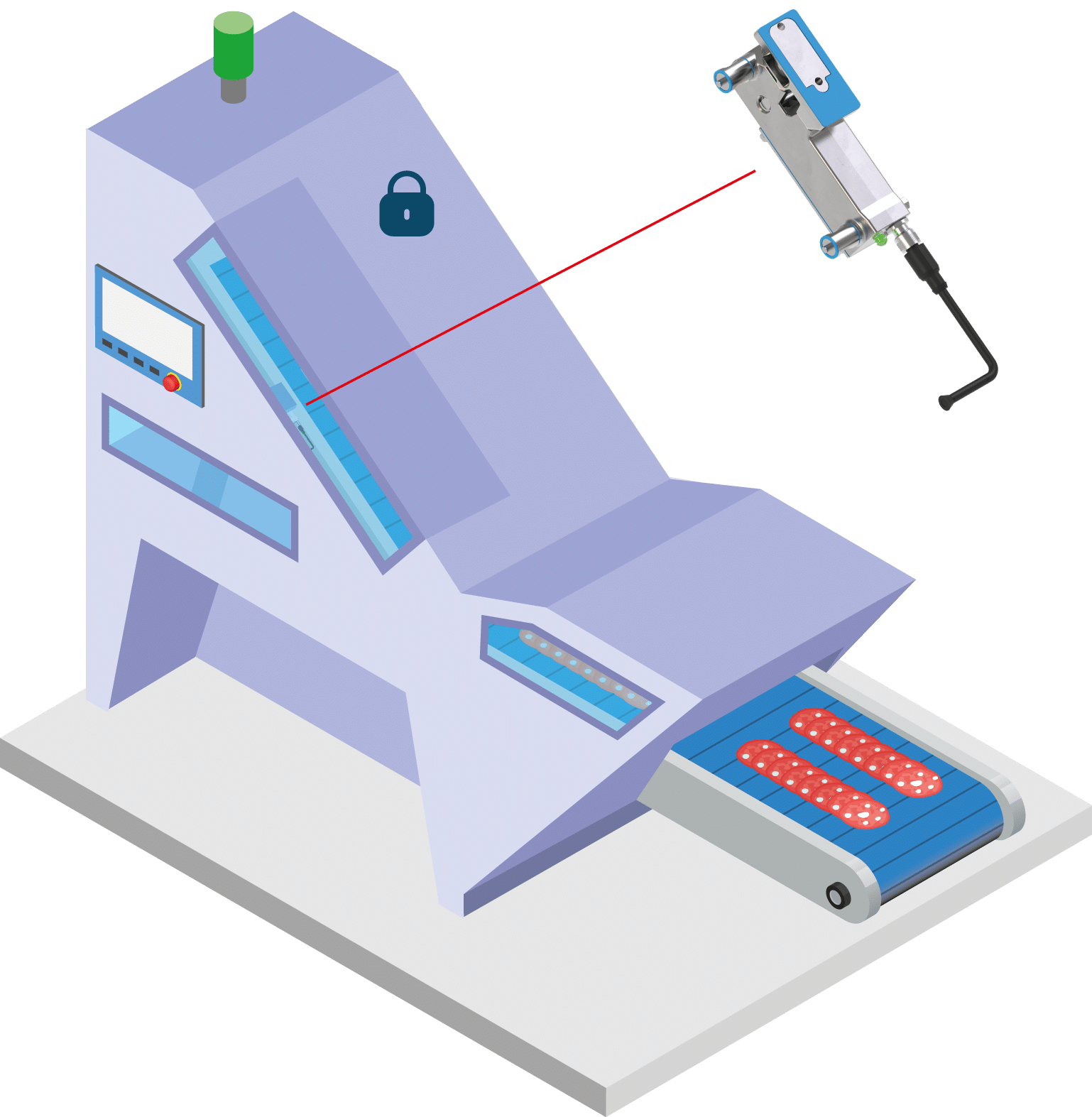

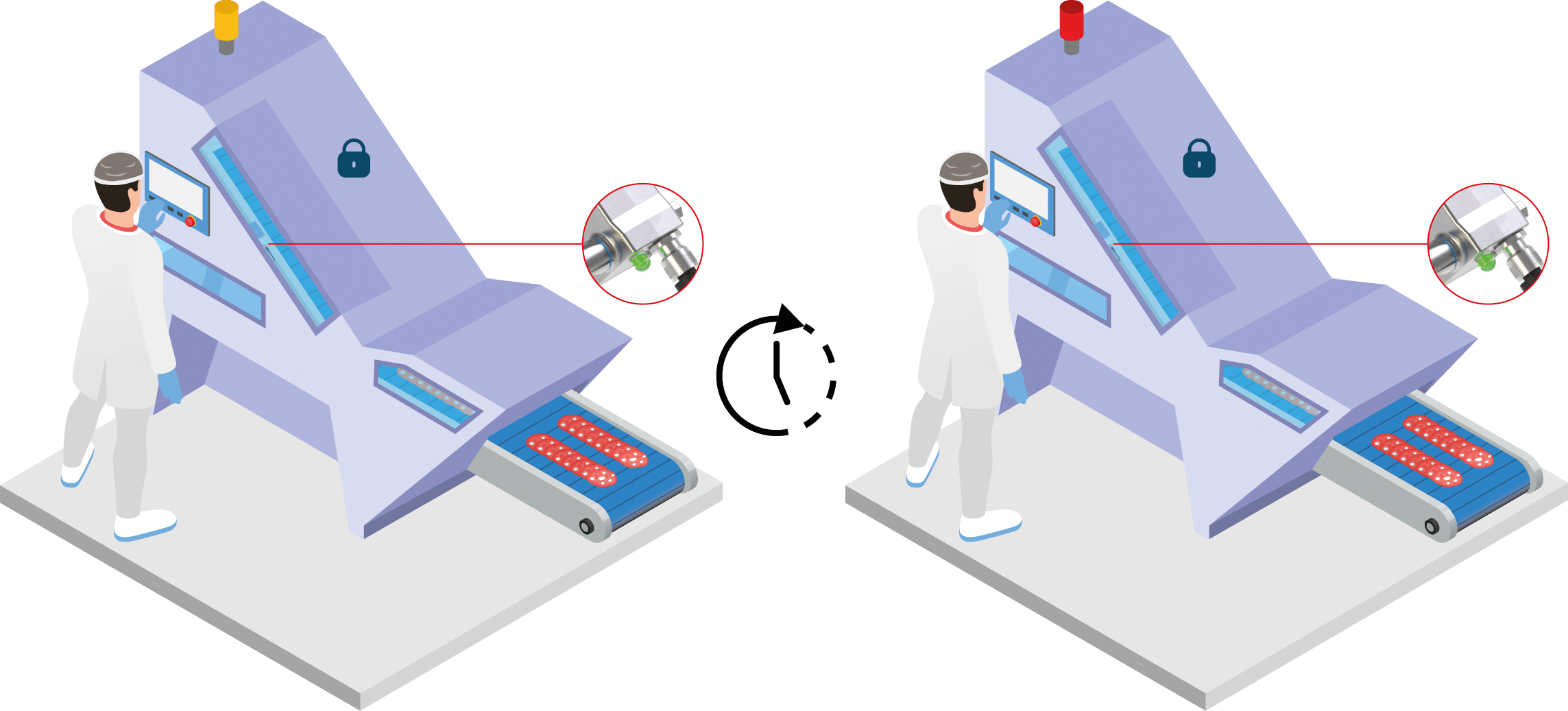

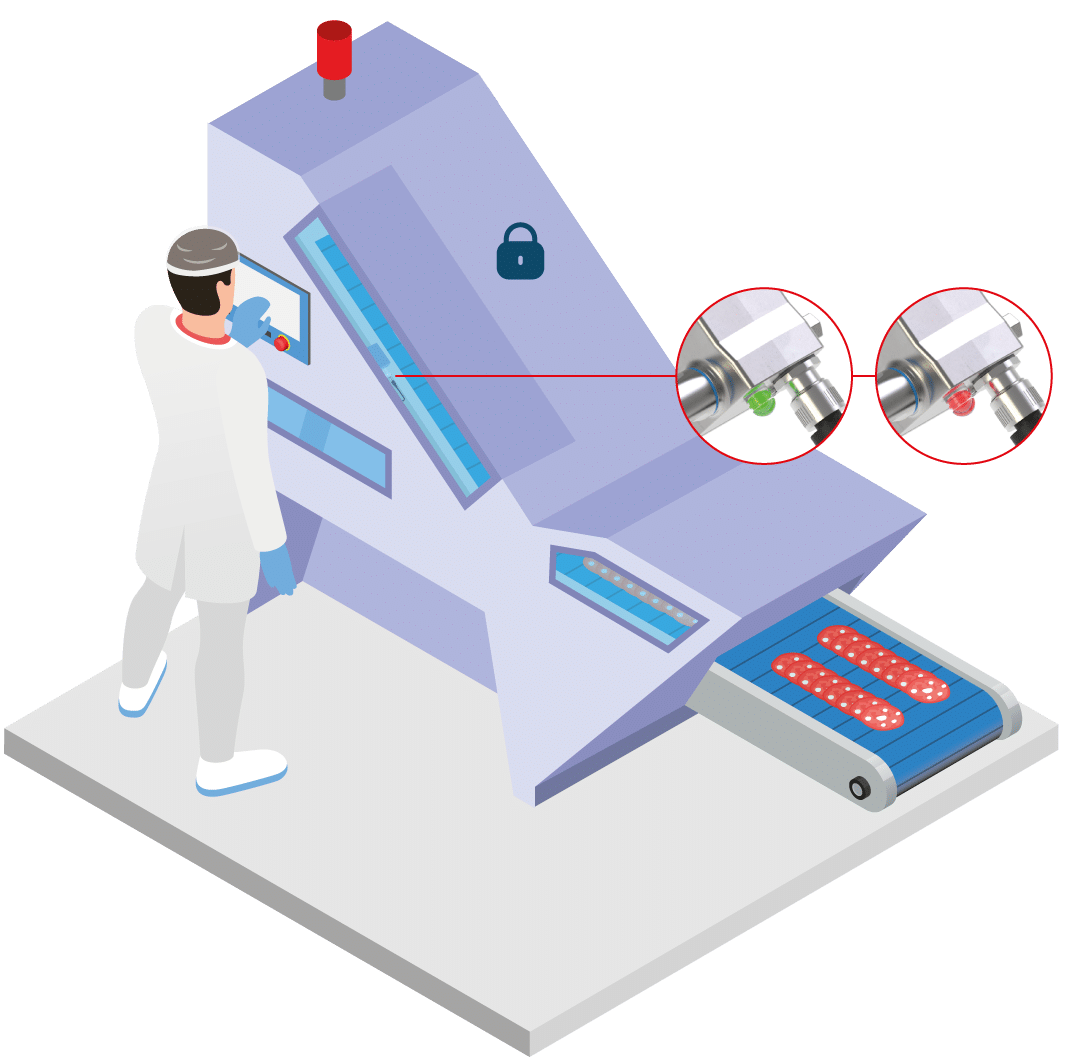

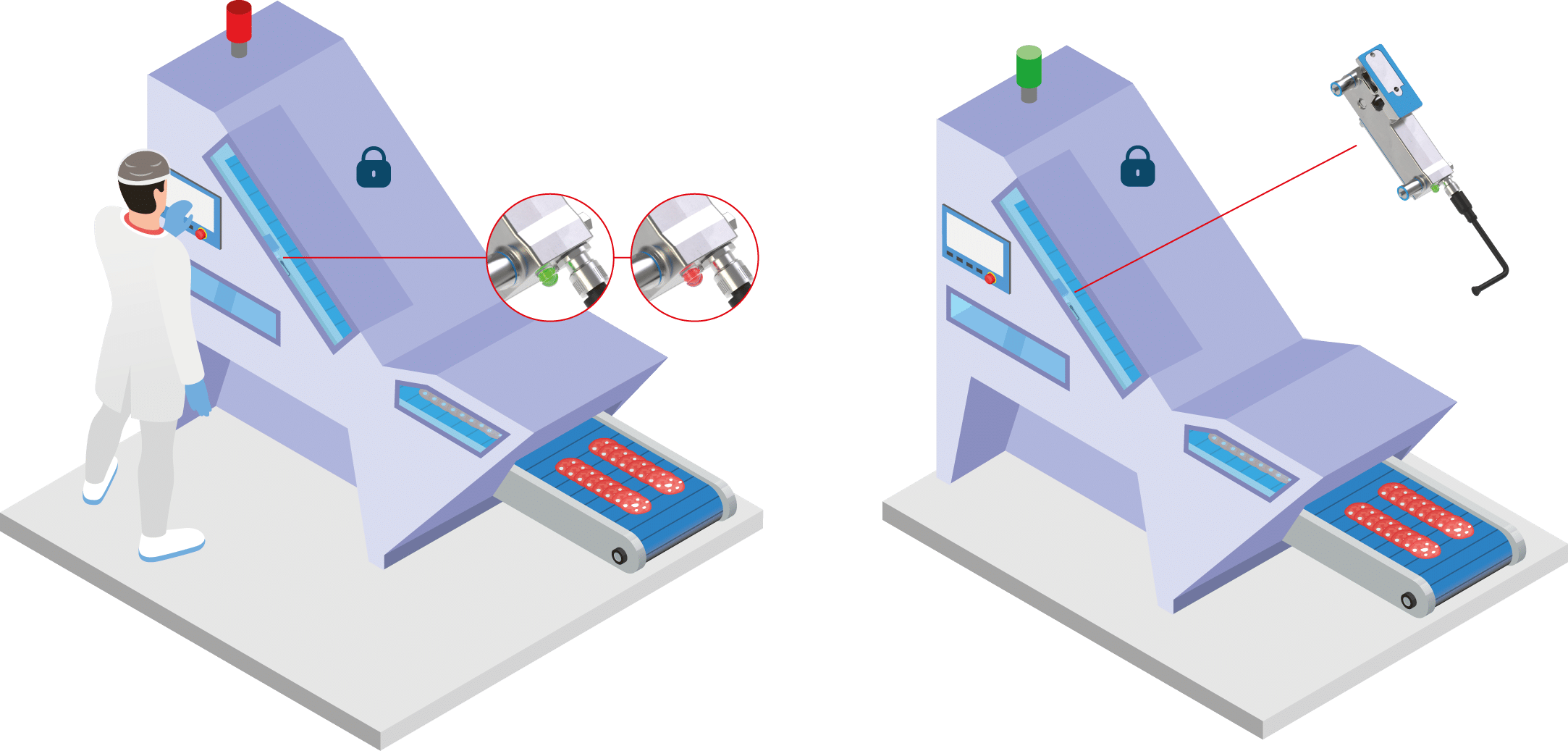

The Hygienic Guard Lock (HGL) is a compact stainless steel interlock that prevents the guard from opening whilst the machine is running. When the machine reaches a safe state (i.e., following a request to stop and run down time), HGL can be unlocked and the guard can be opened. Once the cleaning is complete and the guard is closed, it is possible to lock the HGL and then restart the machine.

How it works

Step-By-Step Process

This solution successfully resolved a challenge for a specific customer. Fortress can accommodate alternative setups and/or multi-range options. Share your application details with us so we can design a bespoke solution to meet your needs.

Recommended Product Range

Why HGL?

The Hygienic Guard Lock is an interlocking solution designed for the harshest cleaning and washdown applications.

Its features include:

3rd party hygienic certification, with 3-A approval for use in sanitary and food-safe applications

Corrosion-resistant 316 stainless steel, suitable for washdown

IP67 and IP69 rating

Open design prevents dirt and dust build-up

Dual channel safety circuits

In addition, with its compact design HGL is perfect for small guards.