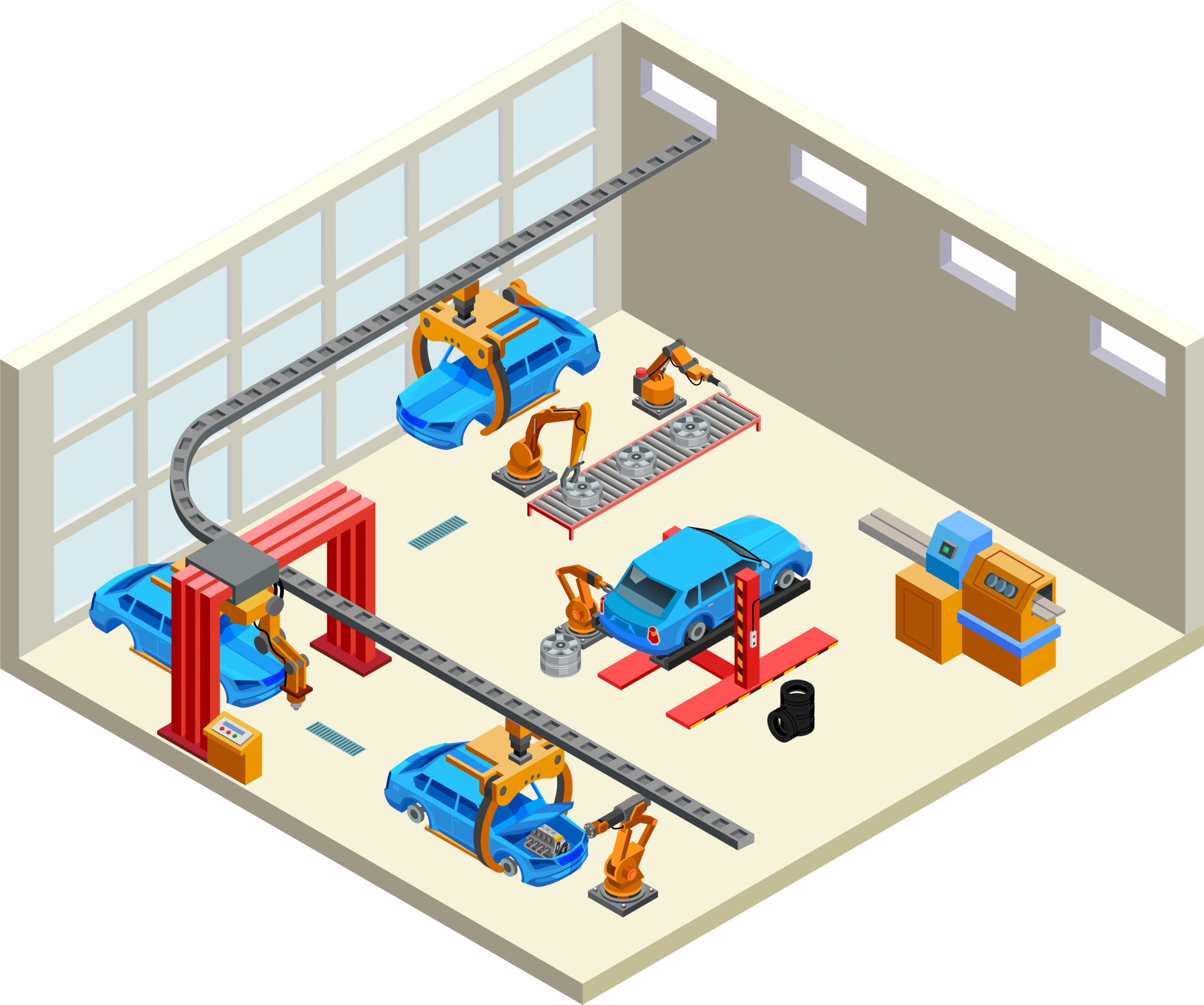

关于汽车制造

最大限度地减少停机时间 ,这在汽车制造业中是至关重要的,因此,快速、正确、安全地进行维护是至关重要的。确保由正确的、经过正确培训的人员来执行,可以最大限度地提高效率,减少生产线停机时间 。由于有这么多人与自动化工具、生产线和机器人单元紧密合作,出现了独特的挑战。

Fortress 可以制定最终用户的规格,以确保所有生产基地都有一致的高水平的安全,这些规格涵盖了所有机器- 安装的 I/O要求,以提供一个降低成本的集成,同时也使人员免受事故和伤害。

为什么Fortress 是汽车制造业的完美选择。

关键的汽车应用

汽车厂按照严格的时间表运行,任何停机时间 ,都会造成很大损失。限制那些经过正确培训和授权的人进入生产线,可以减少不必要的停机时间 ,跟踪这种访问提供有价值的数据,以了解和改进工厂流程。

Fortress 有访问控制 解决方案,与你现有的现场识别程序一起工作,限制未经授权的访问,防止停机时间 ,并提高生产力。

汽车零件喷漆中使用的溶剂常常导致喷漆车间被列为潜在的爆炸环境。为了确保在那里工作的操作人员和整个工厂的安全,所有部件都必须被正确评定为可在爆炸性环境中使用。

Fortress 有一系列强大的解决方案,可提供安全进入危险环境和在危险环境中使用,被评为IECEX、ATEX和CCCEX的1/21区和2/22区。

工业6轴机器人技术为迅速提高复杂任务的效率、速度和准确性提供了灵活性。如果这些机器在错误的时刻被接入,其效果可能是非常危险的。

Fortress 坚固的解决方案,以防止进入,直到危险的运动可以被控制停止。执行器的设计可以防止高达10kN的强力冲击,同时提供高达+/-12mm的错位公差。

了解更多关于安全标准的信息,并观看Fortress 汽车制造部门的网络研讨会。

其他Fortress 汽车和一级应用

网络研讨会

网络研讨会