关于建筑材料制造:

建筑材料的制造很可能会产生一个极其肮脏、多尘和危险的环境。这种高浓度的灰尘和污垢可能会导致机械上的部件出现意外故障,从而导致停机时间 和危险情况。

Fortress 我们专注于提供一个强大的产品,在恶劣的环境中超过替代品,我们的大多数砖和混凝土制造的客户都让我们的设备持续超过10年。

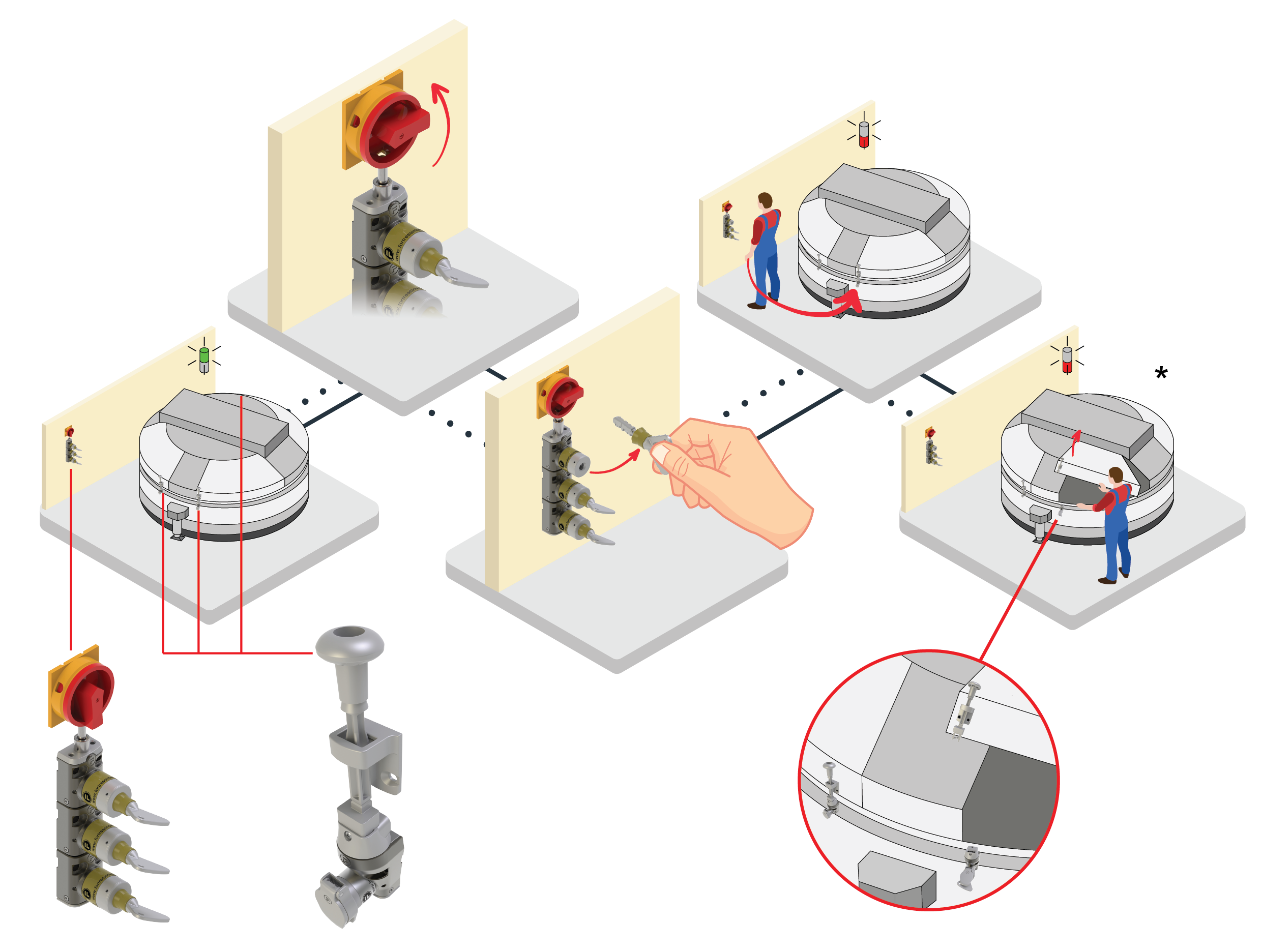

此外,大型烤箱和搅拌机呈现出保障性的空间,从机器 控制的角度来看,往往很少能看到。这意味着进入它们的人员不能被看到,使用人员的钥匙来防止重新启动是有利的。

为什么Fortress 是建筑材料生产环境的完美选择

砖和混凝土的主要应用

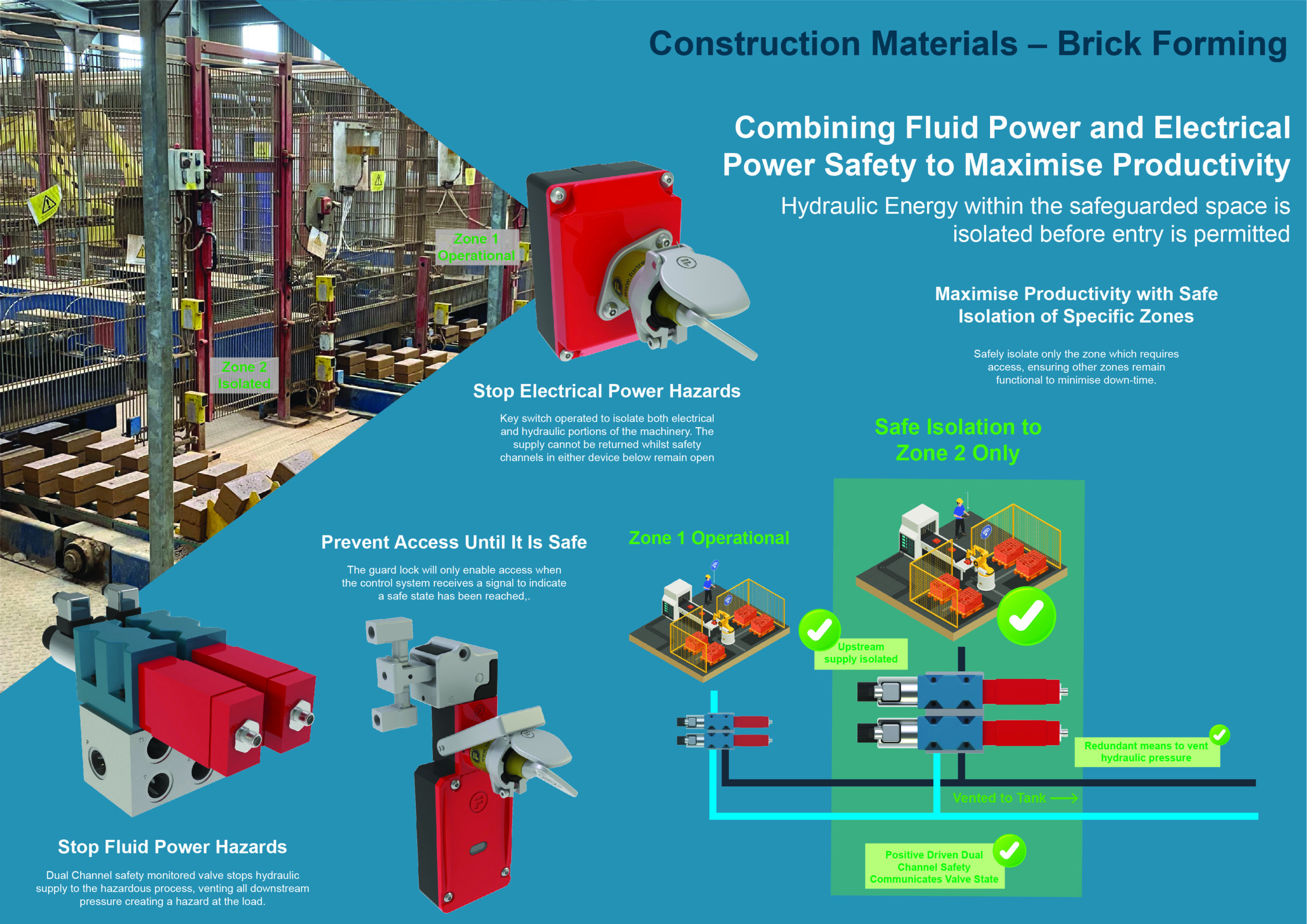

混凝土搅拌机是非常危险的机器,具有大型、高功率的叶片,在停机后有很长的停工时间。依靠操作人员来隔离电力,然后等待所需的时间,会导致偷工减料和不安全的情况。

Fortress 有坚固的解决方案,可以集成到现有的电源断路器中,以确保电源被隔离,在进入搅拌机之前,搅拌机已经完全停止。

如果多个入口都需要单独的安全和非安全 I/O ,那么在制砖设施中安装防护装置的工作就会很漫长。市场趋势已经开始转向与Ethernet/IP 和 的网络连接。 CIP 安全的网络连接,或用PROFINET 。 PROFIsafe 的网络连接,因此,安全防护解决方案提供了这一功能。

Fortress 为我们的重型产品系列提供网络通信,以使 CIP 安全 和 PROFIsafe 在恶劣的环境中。这些解决方案允许集成额外的I/O,如复位和输入请求,无需考虑额外的布线。

了解更多关于安全标准的信息,并观看Fortress 建筑材料部门的网络研讨会。

其他Fortress 建筑材料的应用

网络研讨会

网络研讨会