什么是amGardpro?

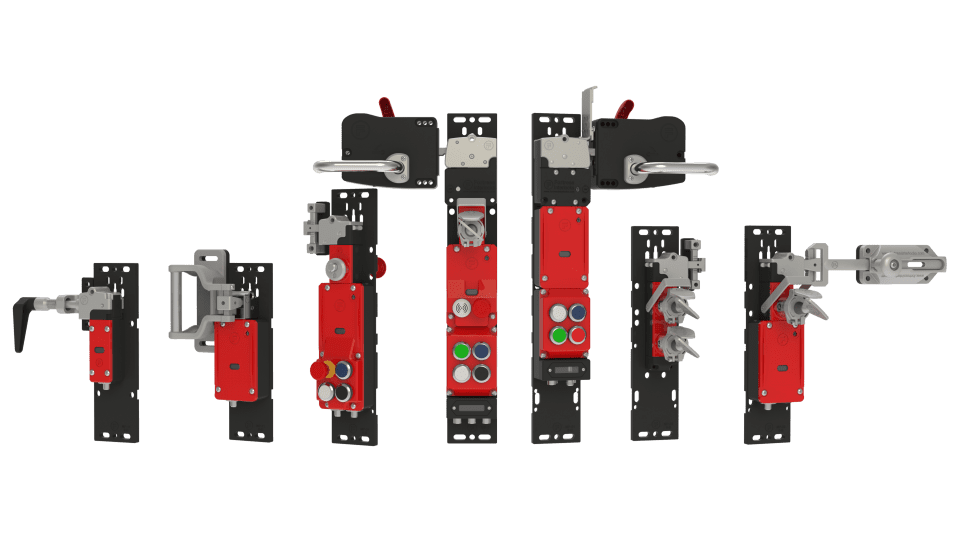

一个完全可配置的安全解决方案,旨在满足您应用的确切要求。

设计、测试和第三方认证,最高可用于PLe/Cat.适用于安全和风险管理至关重要的各种行业,包括但不限于制造业、汽车、餐饮业和仓库自动化 。

按钮控制和截留钥匙 ,都可以组合成一个单元,提供一个具有成本效益的解决方案。

网络连接通过proNet实现,proNet是由Fortress 开发的附加模块,允许amGardpro与主要工业网络协议进行通信:EtherNet/IP,PROFINET 和EtherCAT。

主要优势

适用于苛刻的环境

网络连接选项

可配置的设计

为什么选择amGardpro?

为什么选择amGardpro?

探索amGardpro系列

由于有各种组件和功能可供选择,你可以灵活地创建你自己的个性化安全解决方案。

amGardpro 最受欢迎的功能是proNet,这是我们的网络通信模块,可与主要的工业网络协议进行通信。

请浏览以下部分,了解更多 了解amGardpro系列的可配置性。

你是否想从重型 范围内建立一个解决方案?

点击我们的 "产品工具 "按钮,今天就可以设计你的产品。如果你需要帮助或指导,请访问我们的 "如何购买 amGardpro"页面。

通过一些应用实例查看amGardpro的运行情况

与安装在防护罩上的proNet模块联锁。该设备与以太网供电(PoE)连接。

amGardpro联锁,带强制拔出的钥匙,逃避释放 ,和独立的控制舱,用于木材、造纸和纸浆行业

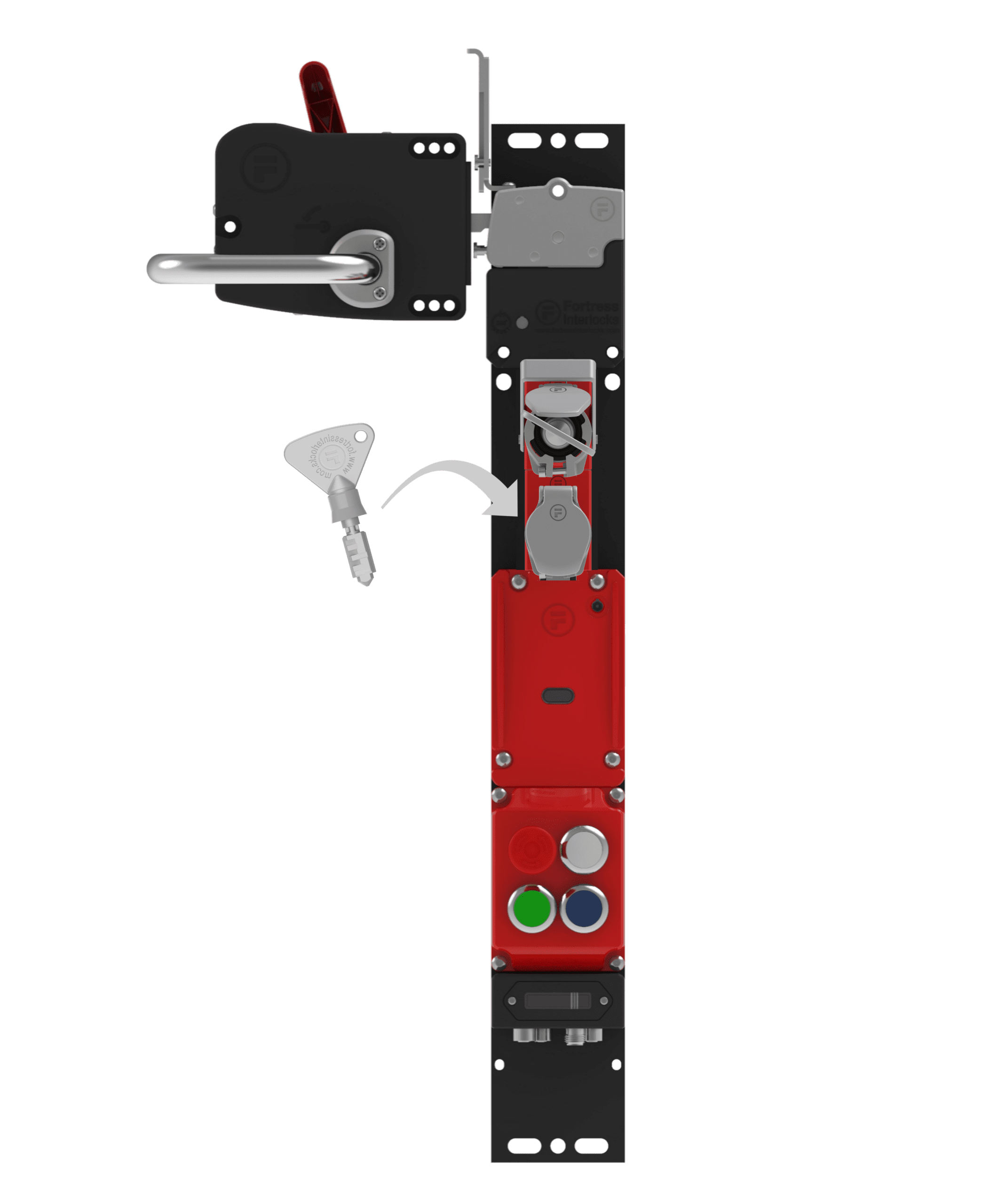

安装板上的联锁,带有强制提取的钥匙,带有紧急停止 按钮的控制舱,以及用于砖厂的RFID 阅读器

访问这些页面以了解更多

- 在这里,创建一个独特的重型联锁,在一个精简的设备中实现所有的控制功能。

- 使用我们的技术样本/图纸生成工具为所选产品生成技术文件、技术样本和CAD文件。

- 将您唯一的物料编码转换成福帝斯的型号,使用我们的参考工具

- 计算您系统的安全性能等级,使用我们的SISTEMA库

- 点击此处了解福帝斯产品工具详情

所有可供下载的资料

要获取amGardpro 技术资料,请登录

EN - amGardpro 手册

1份文件 13 MB

DE - amGardpro 手册

1份文件 13 MB

EN -RFID 安全钥匙手册

1份文件 0.00 键盘

EN -Frank 手册

1份文件 0.00 键盘

FRANK 下载

(  请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

不锈钢amGardpro 下载 - S40

(  请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

PROFINET 和标准GSDML下载

(  请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

非标准的GSDML

(  请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

EtherNet/IP 和标准EDS下载

(  请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

非标准的EDS

(  请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

EtherCAT下载

(  请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

证书和认证

(  请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

应用说明

(  请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)图纸和3D CAD文件

- 在这里,创建一个独特的重型联锁,在一个精简的设备中实现所有的控制功能。

- 使用我们的技术样本/图纸生成工具为所选产品生成技术文件、技术样本和CAD文件。

- 将您唯一的物料编码转换成福帝斯的型号,使用我们的参考工具

- 计算您系统的安全性能等级,使用我们的SISTEMA库

- 点击此处了解福帝斯产品工具详情

下载和技术资料

样册

EN - amGardpro 手册

1份文件 13 MB

DE - amGardpro 手册

1份文件 13 MB

EN -RFID 安全钥匙手册

1份文件 0.00 键盘

EN -Frank 手册

1份文件 0.00 键盘

操作说明

(  请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

FRANK 下载

(  请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

不锈钢amGardpro 下载 - S40

(  请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

PROFINET 和标准GSDML下载

(  请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

非标准的GSDML

(  请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

EtherNet/IP 和标准EDS下载

(  请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

非标准的EDS

(  请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

EtherCAT下载

(  请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

证书和认证

(  请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

应用说明

(  请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)

请登录或注册以获取文件)