Paper Machine Safety and Preventing Machine Restart – Roller / Winder

In Paper making facilities, frequent Whole Body Access is required by staff during normal operation and production.

Whole Body Access is a situation where a person can be completely inside the safeguarded space of a machine.

It is possible that a person may be trapped inside this space if risk reduction measures are not applied to protect them. There also may be a situation where multiple people enter a safeguarded space to carry out work and one or more person(s) are not seen by others as they finish their task and leave the space.

If the machine could be inadvertently reset and restarted while they are still inside the area, this is known as an “unexpected restart”. There are several ways of reducing this risk which may be more or less practical, depending on the particular application:

1) 👀 Give a clear view of the area from the manual reset

2) ❗ Use presence sensing to detect if anyone is inside the area

3) ⚙ Use other protective measures such as interlock blocking or safety keys (see below)

4) 📢 Use an audio-visual pre-start warning

In the scenario we look at below, visibility was poor and there was no clear location for manual reset where the entire safeguarded space was visible. Presence sensing devices were similarly not practicable at this location where operation was dirty, dusty, and wet. Frequently up to two operators were entering the safeguarded space and a risk reduction measure was needed to prevent unexpected restart during their access.

“How can you protect up to two individuals performing Whole Body Access in harsh environments?”

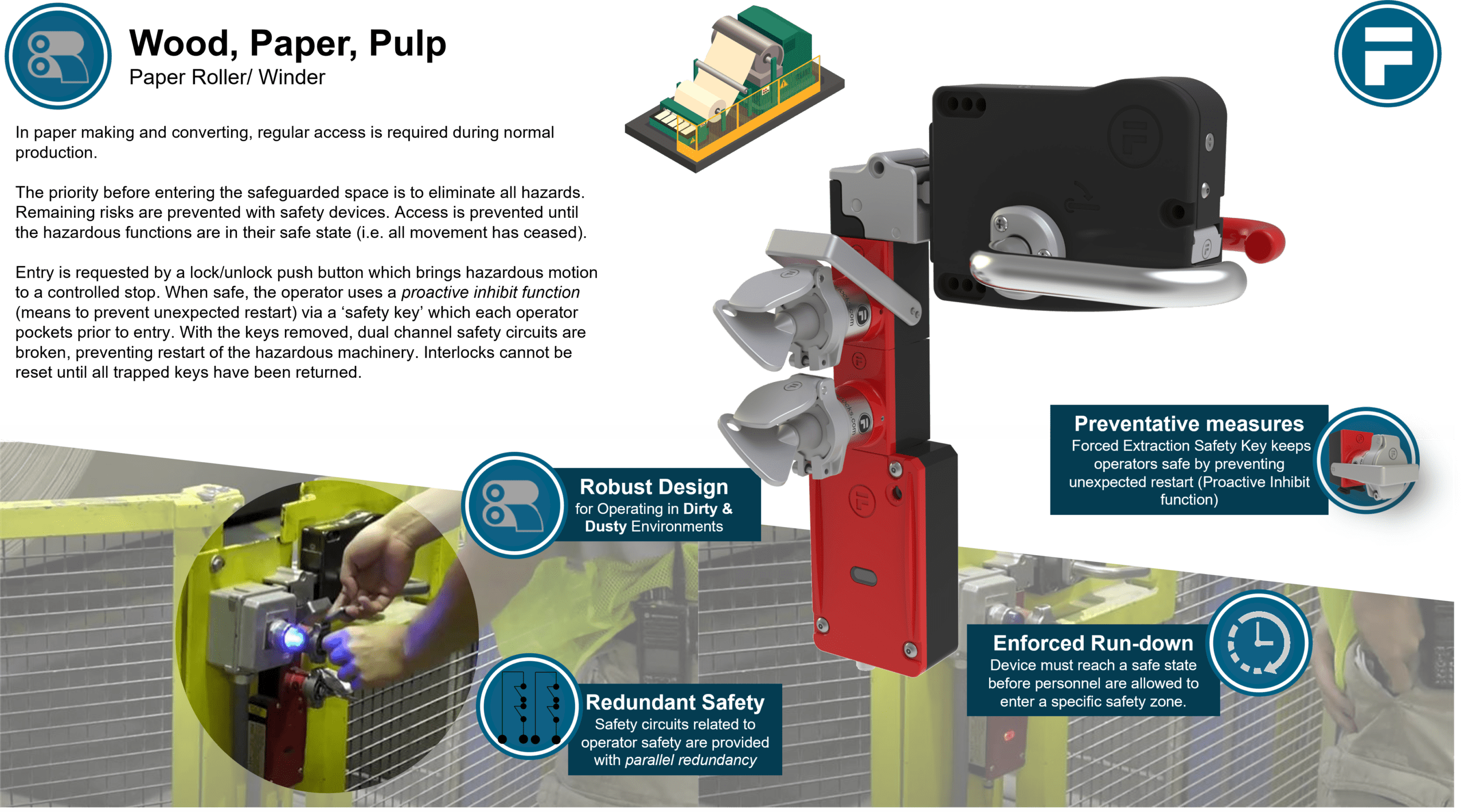

In paper making and converting, regular access is required during normal production.

The priority before entering the safeguarded space is to eliminate all hazards. Remaining risks are prevented with safety devices. Access is prevented until the hazardous functions are in their safe state (i.e. all movement has ceased).

Entry is requested by a lock/unlock push button which brings hazardous motion to a controlled stop. When safe, the operator uses a proactive inhibit function (means to prevent unexpected restart) via a ‘safety key’ which each operator pockets prior to entry. With the keys removed, dual channel safety circuits are broken, preventing restart of the hazardous machinery. Interlocks cannot be reset until all trapped keys have been returned.

Key Features of a Safeguarding Solution

- Robust Design – to protect again harsh environments which can be both wet, and dirty/dusty.

- Integrated Preventative Measures – to protect operators against unexpected restart.

- Enforced Run-Down – through a Guard Interlock with Guard Locking to prevent access until it is safe to do so

- Redundant Safety – to achieve up to a Cat. 4, SIL 3, Performance Level e Solution.