About Construction Materials Manufacturing:

The manufacturing of construction materials is very likely to create an extremely dirty, dusty and dangerous environment. Such high levels of dust and dirt can cause unexpected component failures on machinery resulting in downtime and dangerous situations.

Fortress focuses on providing a robust product to outlast alternatives in harsh environments, most of our customers in brick and concrete manufacturing have our equipment last well over 10 years.

Additionally, large ovens and mixers present safeguarded spaces often with little visibility from the perspective of the machine controls. This means personnel accessing them cannot be seen and using personnel to keys to prevent restart is favourable.

Why Fortress is perfect for construction material production environments

Key Brick and Concreate Applications

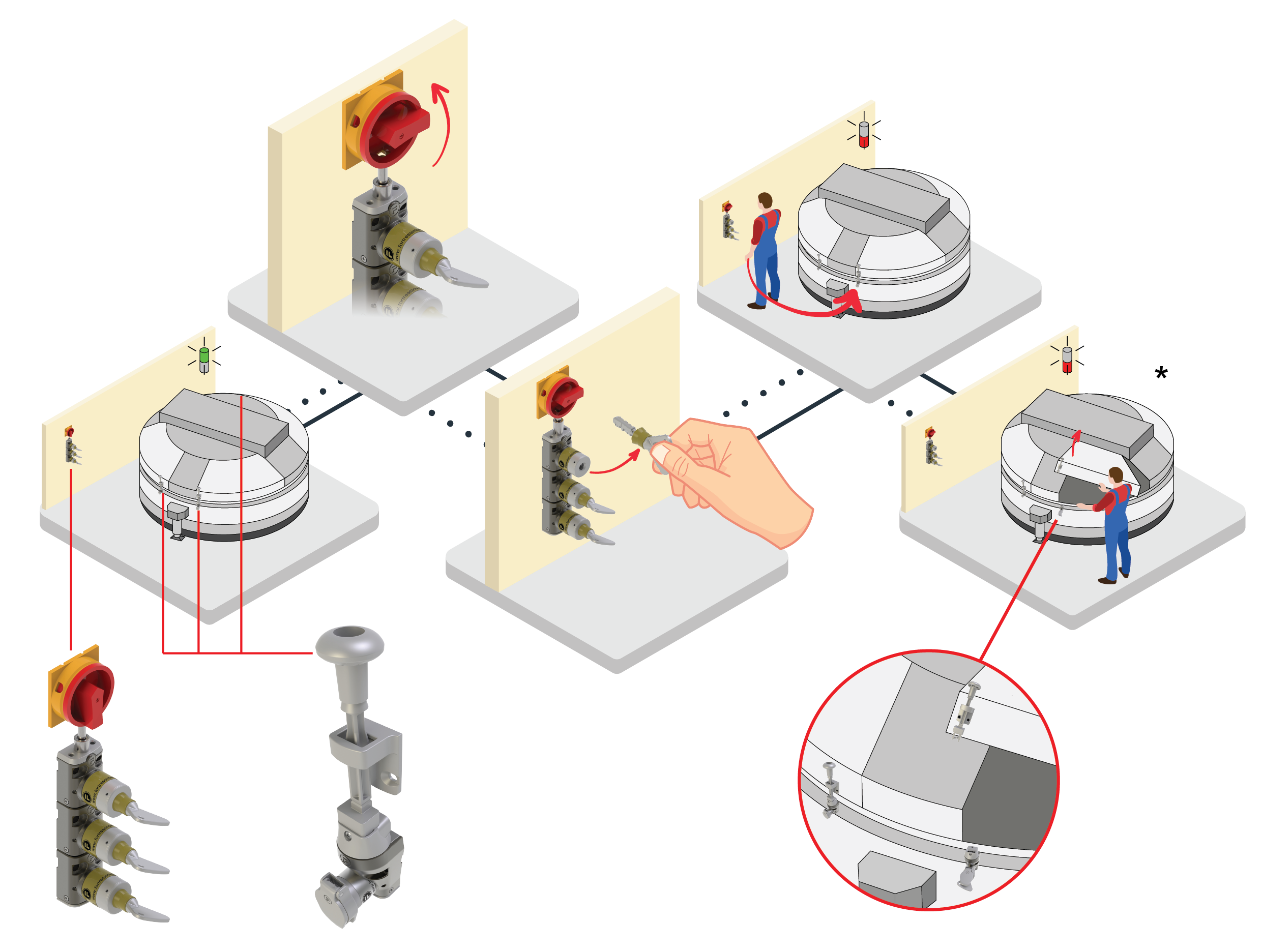

Concrete mixers are very hazardous machines with large, high power blades and long rundown times following shutdown. Reliance on operators to isolate the electrical power and then wait the required time can result in cut corners and unsafe situations.

Fortress has rugged solutions available to integrate into existing electrical supply breakers to ensure that power is isolated and the mixer has come to a complete stop before access to the mixer is possible.

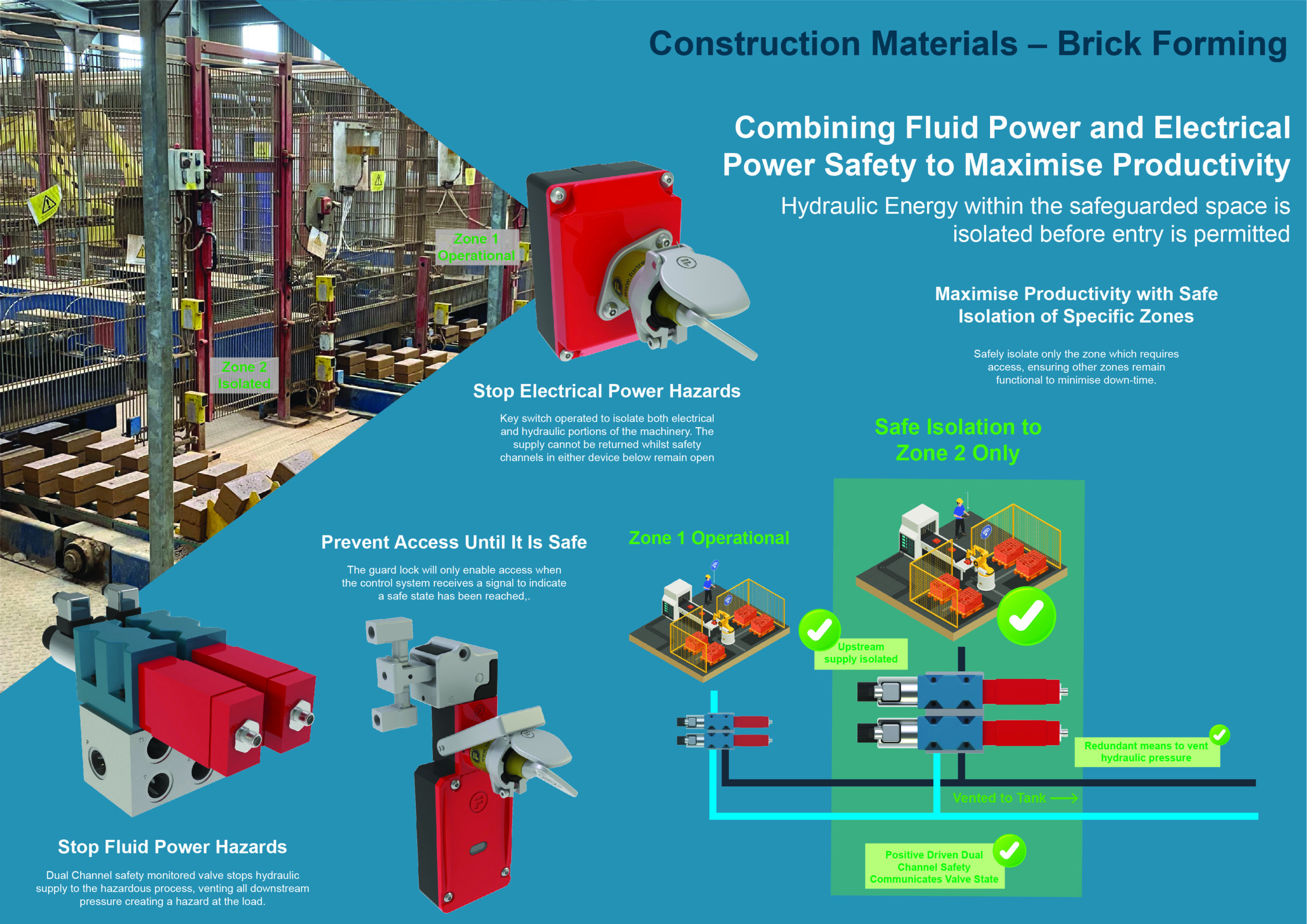

Hydraulic presses are used to form bricks, often in very large facilities. Where access is required for a maintenance or cleaning operation it can be costly to isolate the entire hydraulic supply and dangerous to leave it connected. Using the safety related part of the control system to ensure access is only possible when that zone has been made safe improves both safety and productivity.

Fortress has safety rated hydraulic power valves which can be used to safely block and bleed power from the required zone in response to a request to enter from a gate interlock.

Electrical and Mechanical Installation of safeguarding devices into brick making facilities can be lengthy when multiple entry points each require individual safe and non-safe I/O connection. The market trend has started to shift towards network connection with Ethernet/IP and CIP safety, or PROFINET with PROFIsafe and as a result safeguarding solutions offer this feature.

Fortress offer network communications for our heavy-duty range to enable CIP safety and PROFIsafe in harsh environments. These solutions allow additional I/O such as Reset and Enter Request to be integrated with no additional cabling considerations.

Safe access may not always require a run-down time, some hazards can be stopped instantaneously. Whilst inside the safeguarded space however, low visibility can lead to accidental machine restart. Mechanical features can be designed into solutions to prevent this unexpected restart and protect operators.

Fortress offers integrated mechanical measures to prevent unexpected restart. The Fortress safety key can be pocketed by operators when entering a safeguarded space.

Learn more about the safety standards, and watch the Fortress Webinar for the Construction Materials sector.

Other Fortress Construction Materials applications

We are experts in providing safety solutions for automation

Contact us for tailor guidance and solutions for your machinery safety applications

Webinar

Webinar