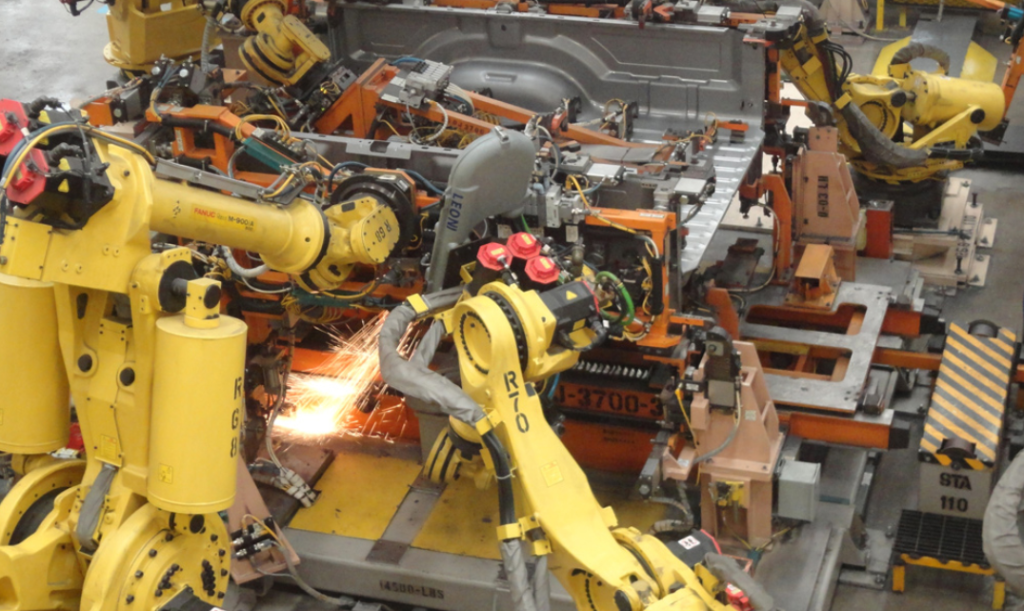

About the application

During car manufacturing, automated robot welding cells are used to accurately and efficiently spot weld automobile frames. Multiple robots spot weld on the frames at any given time in each cell.

The challenge

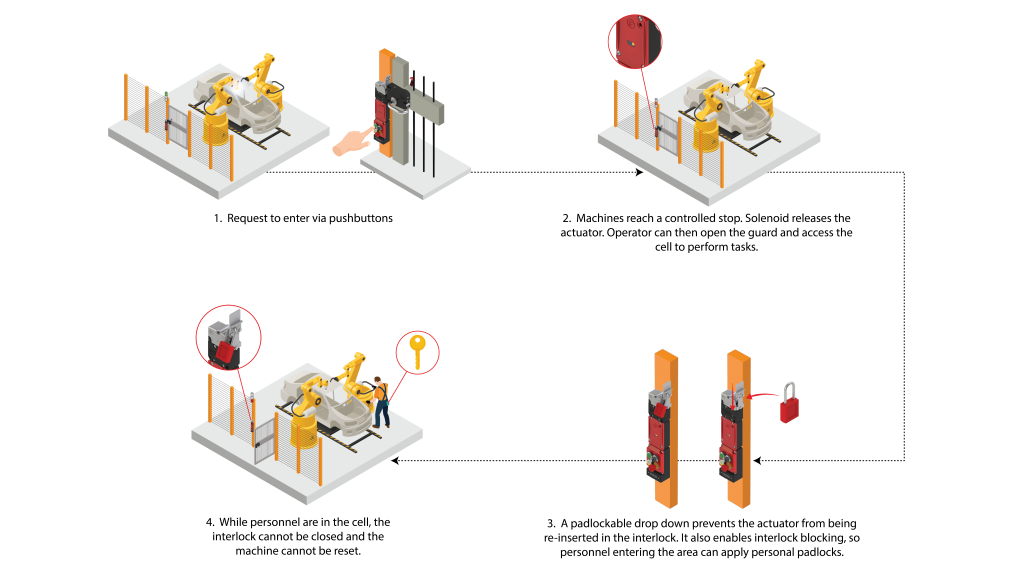

Personnel may need to gain access to the welding cell for maintenance or troubleshooting. In these circumstances, access should only be permitted once machinery has come to a controlled stop. There is also a risk of personnel becoming trapped.

The solution

Fortress recommended an amGardpro interlock with guard locking function and proNet option pod (with pushbuttons and emergency stop) that communicates over EtherNet/IP. A request to enter via the pushbuttons sends a signal to the welding cell’s control system, bringing the cell to a controlled stop. Subsequently, the solenoid is energized, and the actuator is released.

A padlockable drop down on the head of the interlock can be used to perform interlock blocking and prevent unexpected start-up. There is also a single handle escape release to allow personnel to escape should they become trapped.

Step by step

Why amGardpro?

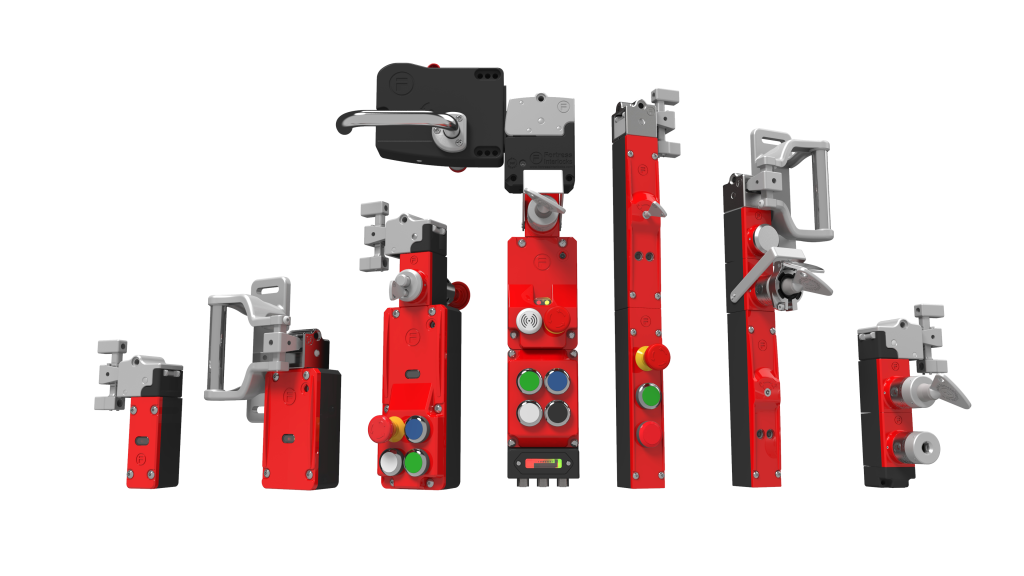

A completely configurable solution to meet the exact requirements of each application.

• Easy integration within the existing network thanks to the proNet module

• Unexpected start-up prevention with the padlockable drop down for interlock blocking

• Escape release as reactive inhibit function

In addition, integrated pushbuttons contribute to increased operational efficiency.

Alternative solutions

This solution successfully resolved a challenge for a specific customer. Fortress can accommodate alternative setups and/or multi-range options. Share your application details with us so we can design a bespoke solution to meet your needs.