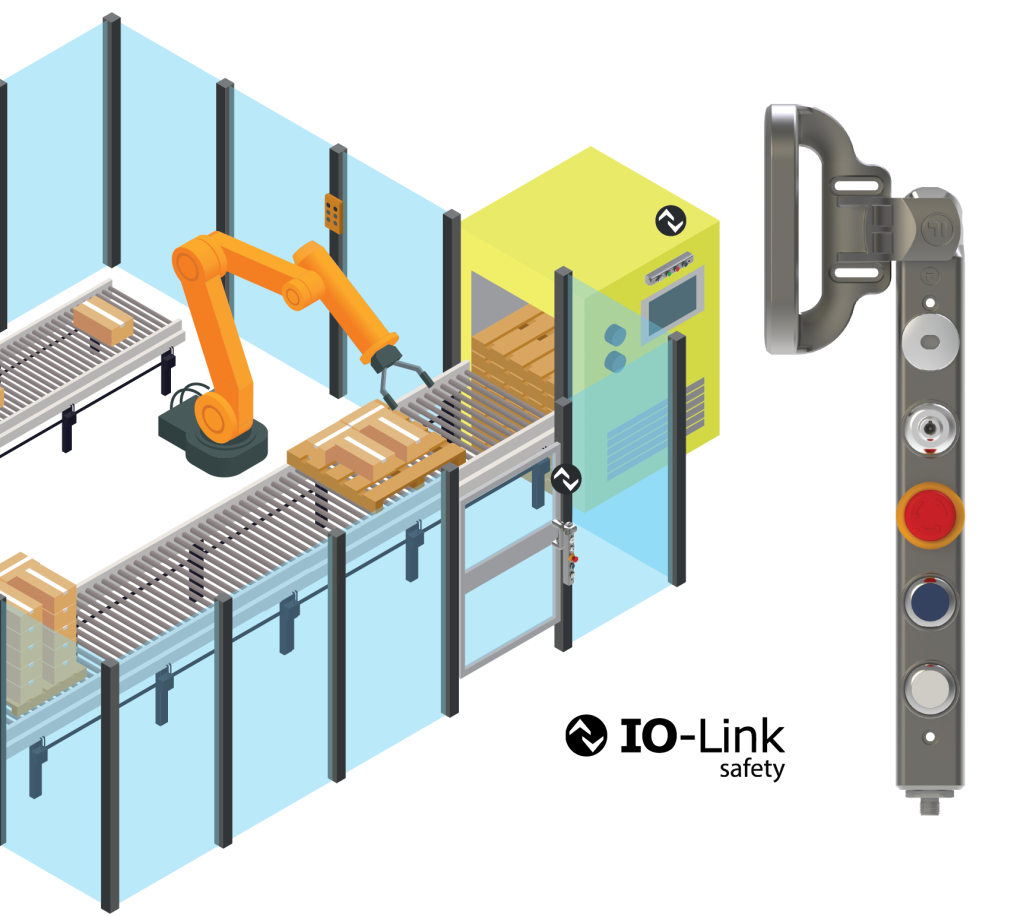

We are excited to announce a significant upgrade to the connectivity capabilities of our popular tGard range of configurable access and control solutions, which is now compatible with IO-Link Safety.

This development offers enhanced connectivity, faster integration, and even more versatility in industrial applications, and brings new possibilities for those seeking efficient, cost-effective safety solutions while maintaining the high standards of safety and reliability that tGard is known for.

Key Benefits of tGard with IO-Link Safety

IO-Link is a globally standardised communication technology (IEC 61131-9) that enables point-to-point communication between sensors and actuators at the field level and the control system. IO-Link Safety (standardised worldwide in IEC 61139-2) adds a safety communication layer, allowing the incorporation of functional safety devices such emergency stops and interlocks.

By choosing tGard with IO-Link Safety, customers can benefit from:

• Reduced Cabling and Installation Cost: A single M12 connector, for both data and power, results in fewer cables and faster setup, making it easier to integrate tGard devices into both new and existing systems.

• Increased Data Availability and Accuracy: IO-Link provides real-time access to process data, diagnostic data, and device information. This capability now built into tGard allows users to monitor their systems more efficiently, gaining valuable insights into device performance, operating times, and potential issues. Users can access device parameters, operating data, and diagnostic information from the PLC level, facilitating the quick identification of faulty devices.

• Reduced Downtime: If a replacement is needed, the new device is immediately recognised, and the previous configuration is restored. This plug-and-play feature reduces downtime and ensures the system is back up and running as quickly as possible.

![]()

• Integration of Safety Devices on IO-Link: Functional safety devices like tGard communicate directly with the IO-Link Safety Master.

Why Choose tGard from Fortress Safety?

tGard interlocks and control stations from Fortress Safety have long been a go-to answer for industries requiring configurable safety and control systems, allowing the design of tailored solutions to suit various applications requirements.

tGard’s adaptability makes it ideal for use across a range of industries, including manufacturing, automation, and heavy machinery, where the safety of personnel and productivity are top priorities.

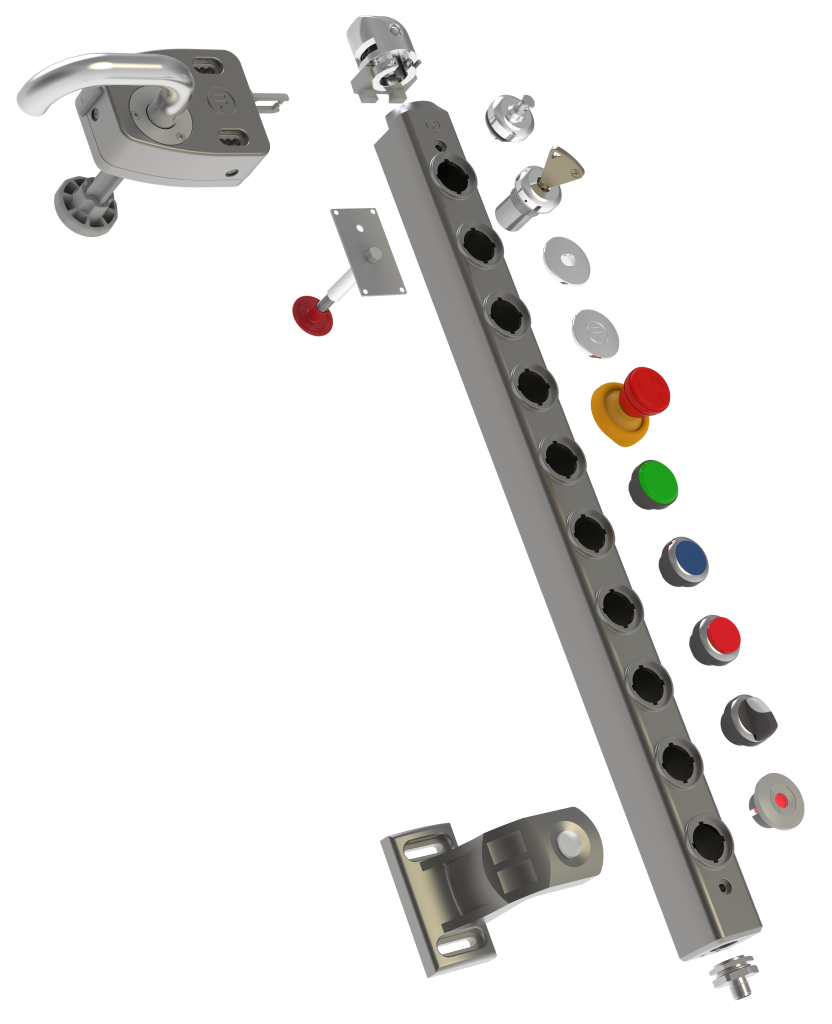

Key features of tGard include:

• Compact Metal Body: The compact design and aluminium body ensure durability even in demanding environments.

• Easy Installation: Just two mounting points for quick installation.

• High Configurability: tGard units can accommodate up to 10 modules. Users can configure interlocks with or without guard locking, access or personnel keys, and operator controls, providing maximum flexibility. Escape release, emergency stops, and different actuator types make tGard suitable for many different applications.

• Simplified Connectivity: Pre-wired units come with a variety of quick disconnect options, further simplifying the installation process. IO-Link enabled devices are fitted with a 5-pin M12 connector.

By expanding the connectivity capabilities of the tGard range, Fortress Safety is offering a future-proof solution that can meet the evolving demands of modern industries, helping customers optimise processes, improve predictive maintenance, and reduce unplanned service interventions. Particularly, tGard with IO-Link Safety is perfect for companies looking to enhance their safety systems while also improving installation speed, reducing downtime, and gaining better control over system data.

Contact us

Get in touch with our team to find out how the new connectivity capabilities of tGard can help optimise your safety systems and support your operational goals.