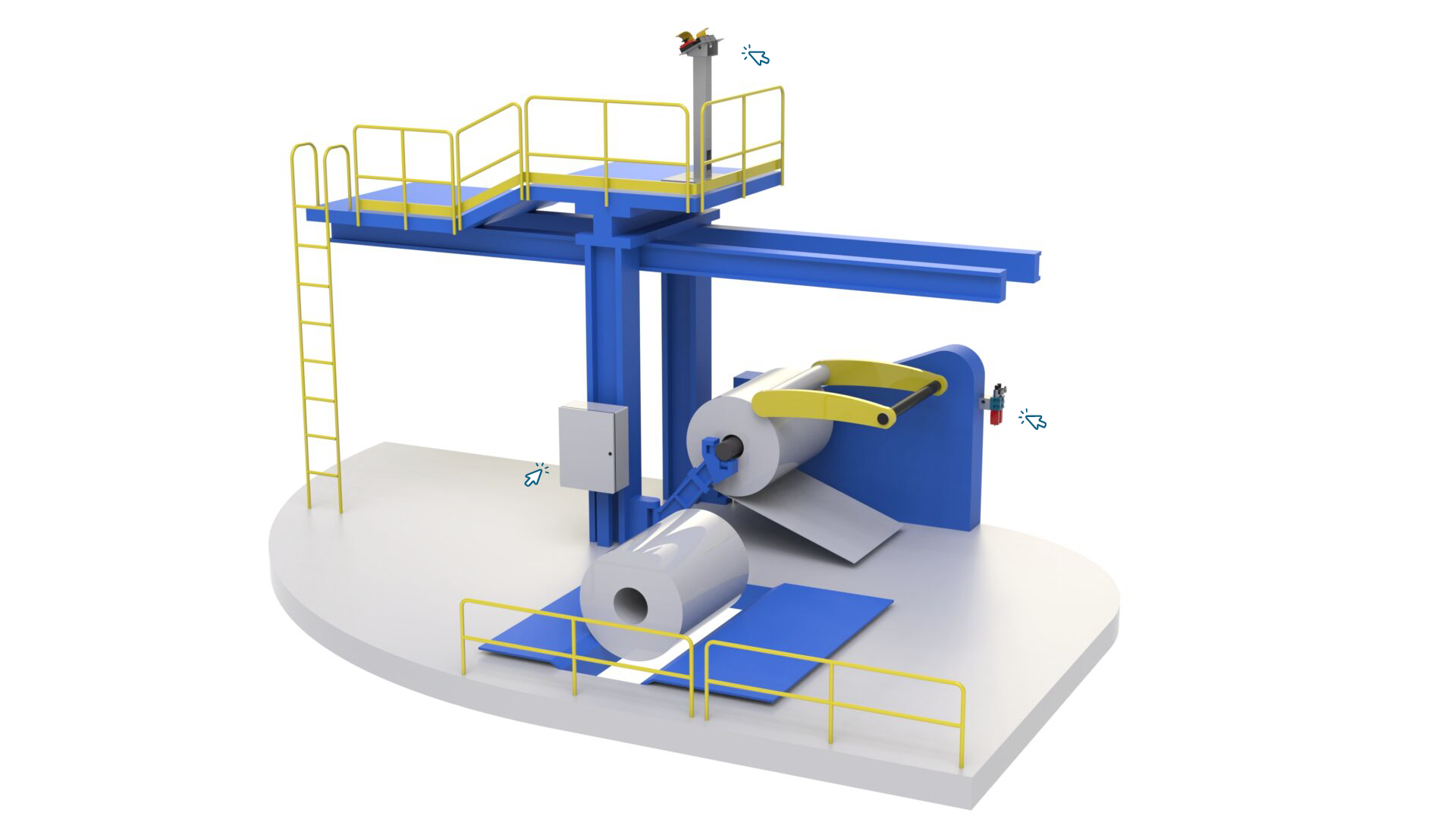

Sheet Metal Coiling in Steel Processing

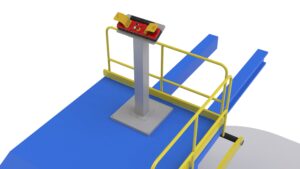

Click on the highlighted areas below to learn more about safeguarding a sheet metal coiling machine and how our push button control devices may benefit you.

Push Button Control Devices can be configured into a multitude of designs, from vertical stacks which sit inline with upright guarding, or in a configured array which can be installed at a convenient location. Fortress mounting solutions provide the flexibility to install against any flat surface. Push Button Control devices are offered with either PROFINET or EtherNet/IP protocols for non-safe communication and with PROFIsafe and CIP safety available for safety applications.

For the highest levels of risk, pneumatic and hydraulic systems require the same dual channel architecture and high diagnostic coverage as an electrical system would to achieve functional safety up to Category 4, SIL 3 or PLe.

In this coiling application, Fluidsentry will bleed the system after receiving a request to enter signal from the push button control device, removing hazardous energy and preventing injury to personnel upon accessing the safeguarded space.

The Safety I/O Module acts as a field device to connect a wide range of inputs and outputs via short, more cost-effective cable connection. Modules can be custom designed to integrate standard and safety inputs and outputs into a single device, eliminating the need for additional panel-based controls. Devices are compatible with both EtherNet/IP with CIP safety or PROFINET with PROFIsafe based systems.

In this coiling machine application, there are a number of ways in which Fortress products can improve upon personnel safety, line productivity and installation costs.

Our RFID access system can be used to manage access to control panel systems based on permission levels, whilst also collecting data on all instances of machine access and any resulting downtime. This means that only authorised personnel can enter the safeguarded space, and you can also monitor and improve productivity based on the data provided.

As with all of our heavy duty products, I/O control modules can be fully customised to your requirements and can include personnel safety keys to act as a proactive inhibit function. This is especially important in a sheet metal coiling machine application due to the poor visibility into the safeguarded area, allowing personnel to take control of their own safety and prevent injury.

Do you have custom built I/O cabinets with lengthy installation times and high costs? Fortress’ distributed I/O modules completely replace the need for manually built I/O and panel real estate and can be configured with EtherNet/IP or PROFINET protocols, making installation easy at a reduced cost.