Selecting your Heavy Duty Escape Release

An Escape Release requires the following conditions to be met

Why use the Heavy Duty Escape Release?

Where operators are performing Whole Body Access, measures should be provided in the event of unexpected start up or restart of hazardous machinery to egress from the hazardous space. Manual reset to restart hazardous machinery is typically done from a location with a good view of the safeguarded space.

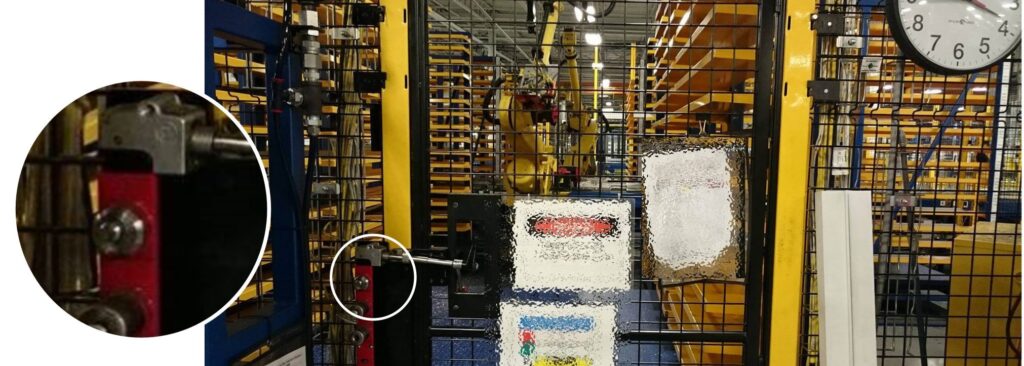

In the application pictured below, low visibility makes it almost impossible for anyone performing this reset to guarantee if users are inside behind obstacles. If the machinery restarts and someone is inside the safeguarded space, they need the means to escape to safety.

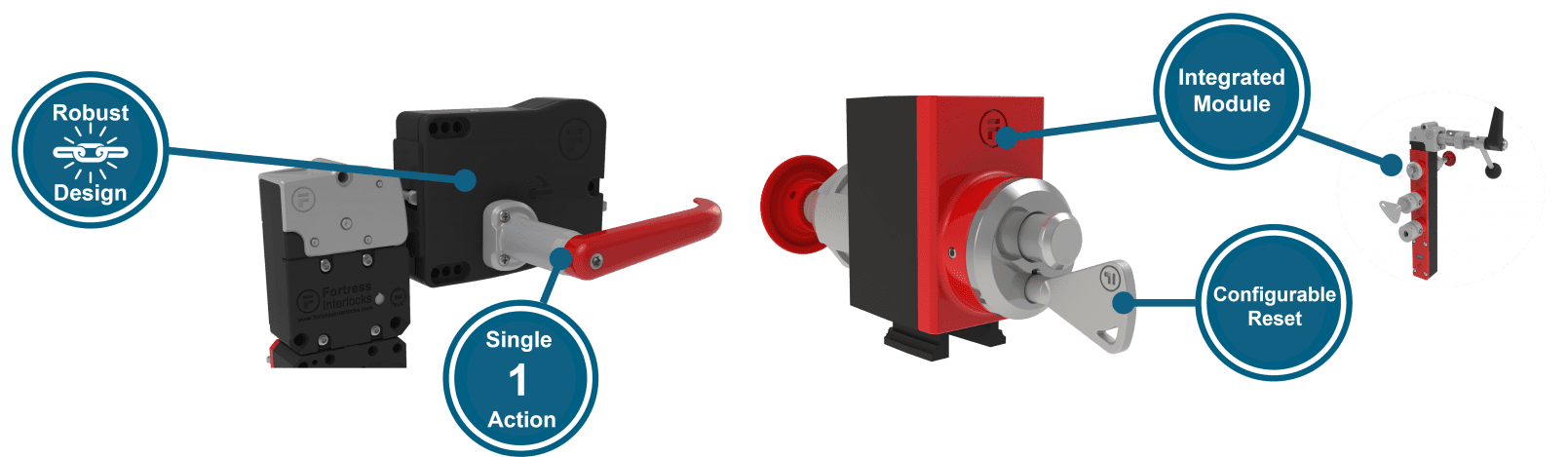

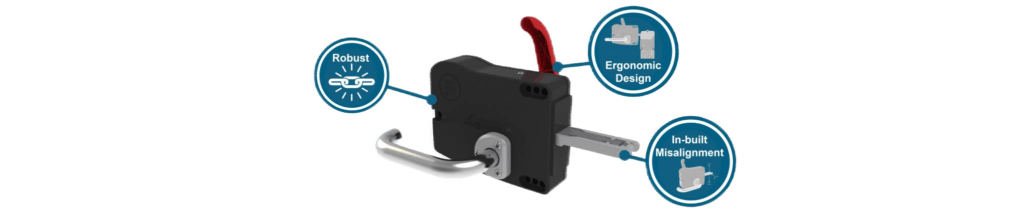

The Heavy Duty Escape Release from Fortress is designed to survive harsh manufacturing and industrial processing conditions.

In the application pictured below, the device is installed at a paper recycling facility. The device continues to perform to the highest level of safety despite the wet conditions & paper debris its operates alongside.

Heavy Duty Escape Release Reset Options

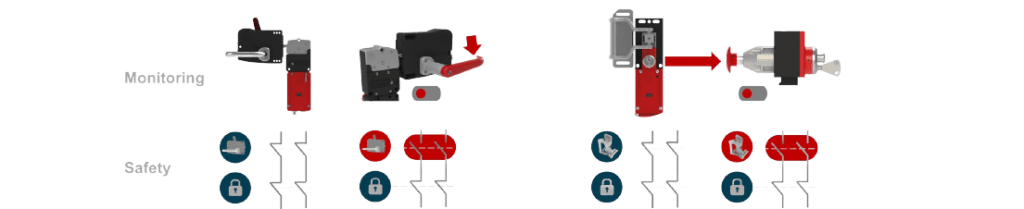

Automatic Reset

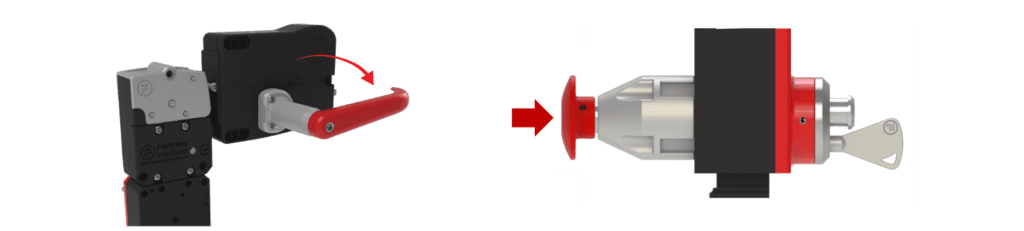

Automatic reset occurs as soon as the handle of the escape release is pulled back to it’s ‘un-actuated‘ position; i.e. returned to its original position.

Push Reset

Instant reset of an escape release can be achieved but pressing the button on the front of the escape release module from outside the protected area.

Auxiliary Reset

Effective monitoring of escape release use can be achieved with an auxiliary reset (in this case via a key). The key forces a procedure to occur in order for the reset to take place. The key must be inserted into the mechanism in order to reset the escape release.