What’s your approval process for selecting Hygienic equipment close to your food production?

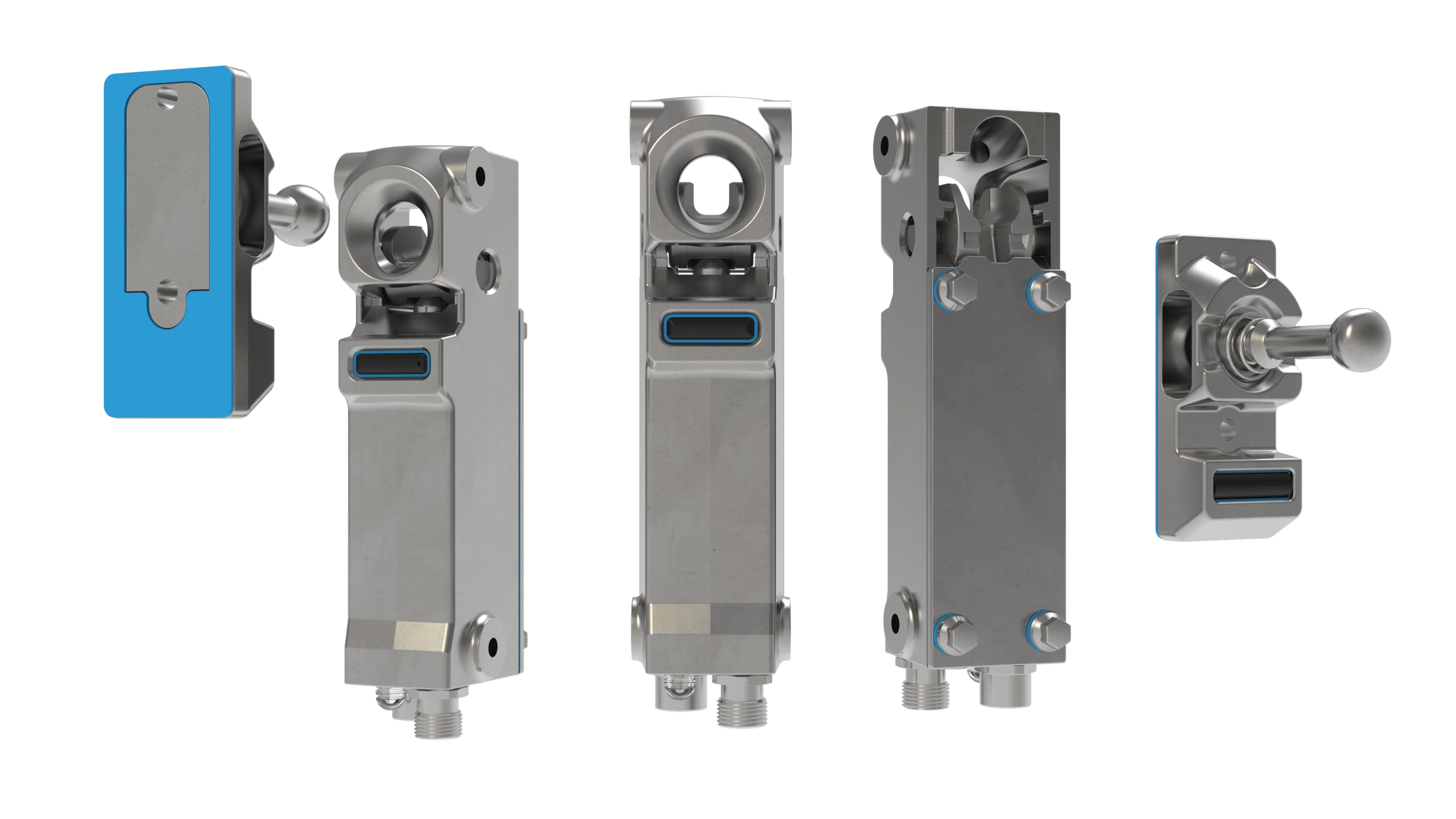

The HGL has gotten 3-A RPSCQC approval so its design is safe for use in certain zones of your food factory.

Save time by not having to get corporate approval for the use of the interlock in a hygienic environment – The HGL is the first and currently only interlock with approval of this kind to help you make sure you’re keeping your customers safe from contamination.

How often does broken equipment cause shutdowns on your production lines?

We know that machine shutdowns due to broken safety equipment can be extremely costly and annoying, that’s why ours are designed to last as long as possible. Designed with a stainless steel enclosure and FDA approved gaskets the HGL is IP69 third-party tested and approved to offer the highest level of ingress protection.

Our actuator mechanism is rated to have an 8,000N retention force because we know production is full of surprises.

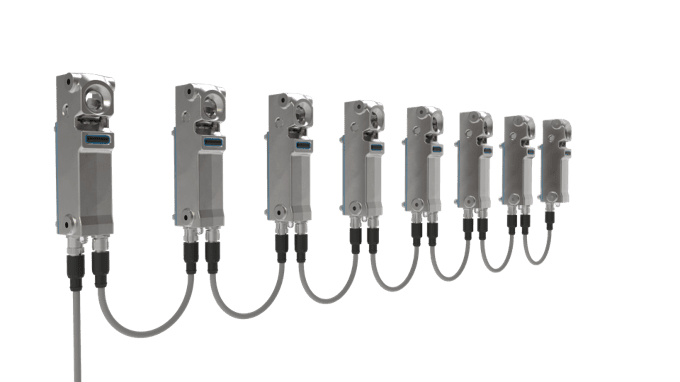

Do you have multiple access points on your machine?

OOSD communication allows for fewer cores in your wiring and daisy-chaining without fault-masking significantly reducing your wiring and safety relay costs espechilly on machines with several access points.

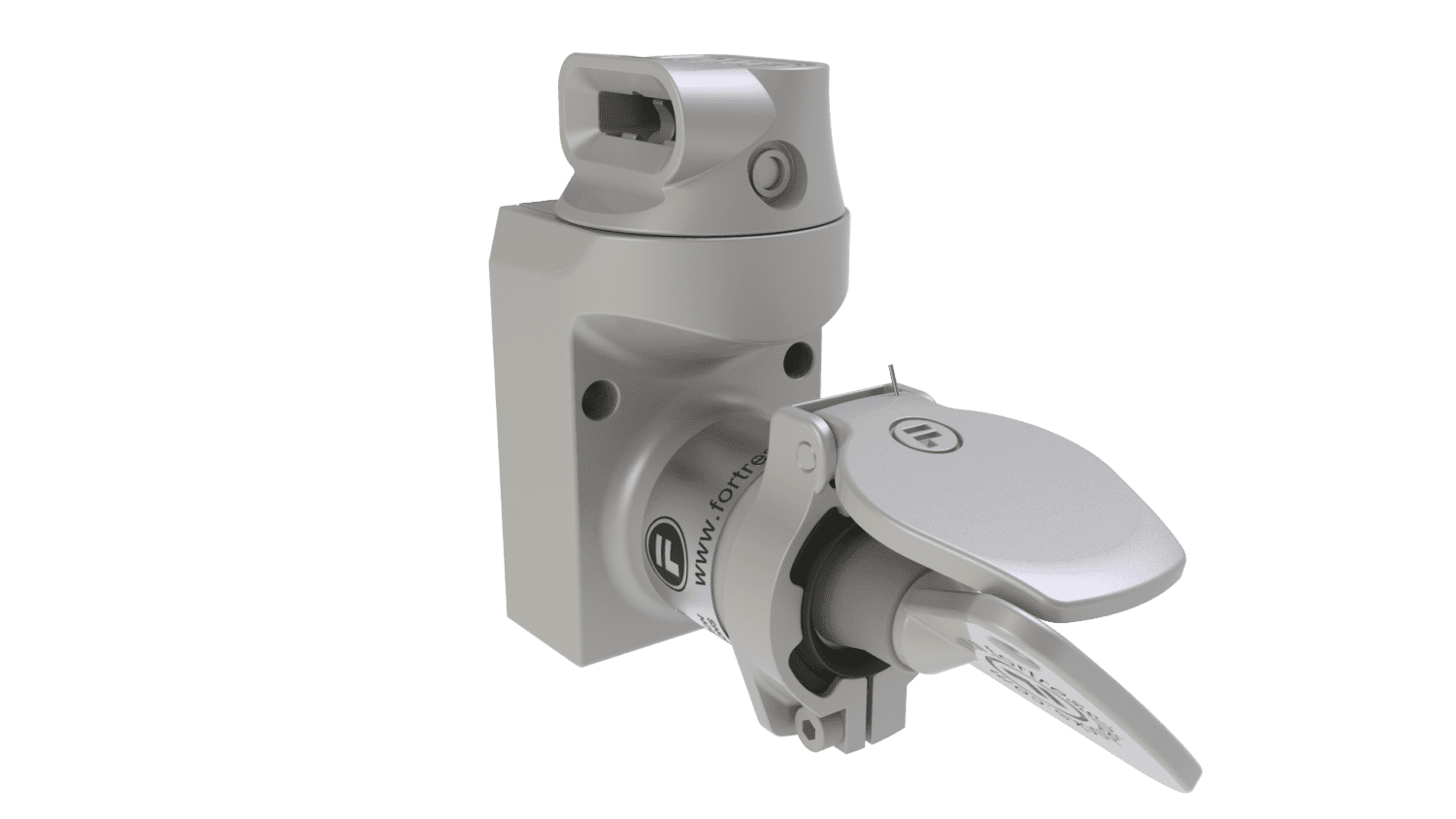

Saws cutting bread and blenders making smoothies usually carry on spinning after they are powered off…

If you have a dangerous rundown time the HGL can stay locked until the machine is safe. Make sure the ends of people’s fingers are kept safe from blades and blenders which carry on spinning for a few seconds after shutdown!

Learn more about Guard Locking

Do you have a high motivation to defeat and lots of interlocks on-site?

Our RFID actuators are high coded to ensure no spare actuators can be used to defeat the interlocks where you might have a high motivation to defeat.