Hydraulic Monitored Safety Valves

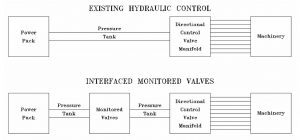

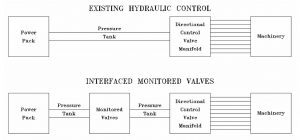

Hydraulic Monitored Safety Valves from Fortress Fluidsentry have become globally recognised as key components in safety related parts of fluid power control systems. Fortress’s monitored valve technology is designed as an interface between the fluid power operation & electrical safety circuits of machinery.

If an ⚡ Electrical powered system is designed for Cat. 4, SIL 3, PLe, why wouldn’t the 💧 Hydraulic powered system be designed to the same level?

Understanding Hydraulic Monitored Safety Valves

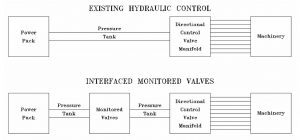

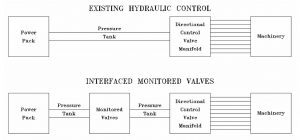

The Hydraulic Monitored Safety Valve (HSV) can be retrofitted to any hydraulic system to provide control system activated fluid isolation.

As shown in the video below, the downstream process (shown as a plunger at the top of the animation) is supplied with a hydraulic pump. The monitored safety valve is retro-fitted into this system between the upstream supply (pump) and downstream process. As part of the downstream process, a directional valve moves a linear actuator to perform hydraulic actuation.

The HSV is shown inside the dotted box. Using a 24V signal to energise the solenoid controlled valve, hydraulic energy is able to flow from the pump to the downstream process. When this is isolated, any residual energy in that downstream process is removed and returned to tank, and the input flow from the pump is isolated.

Great… but WHY use Fortress hydraulic monitored safety valves?

Fortress Fluidsentry products use patented technology to ensure hydraulic pressure is safety returned to tank through redundant means to protect against single point of failure.

There are lots of things that could go wrong in hydraulics…

❗ Broken or Non-moving Components ❗

🐌 Sluggish Response to energisation 🐌

❌ Pilot Seal Failure causing unexpected motion ❌

⏲️ Slow or Sticking Valve affecting Response Time ⏲️

💧 Leakage or Improper Sealing of Components 💧

🦠 Internal Wear and Contaminants 🦠

Therefore safety valves must be designed to fail safe.

ANSI B11.26-2018 Machines – Functional Safety For Equipment: General Principles For The Design Of Safety Control Systems Using ISO 13849-1 describes how hydraulic safety valves should be designed for use in Category 4 systems.

Here’s how hydraulic monitored safety valves prevent single point of failure.

✅ When the valve element is in the energised position, safety device contacts are positively driven open

(When the valve is energised (i.e. 24V is supplied to the solenoid), closed contacts are opened)

✅ When electrical signal is removed, fluid supply blocked and vented from hazardous motion

(When the 24V is removed, the valve blocks supply of fluid power through the valve and returns downstream energy back to tank)

✅ Mechanical Bias to exhaust downstream fluid power

(There is a bias of motion, such that removal of the 24V will guarantee incoming fluid power is isolated and downstream energy is removed)

✅ Safety rated device monitors position of the valve element in de-energised state

✅ Dual NC contacts are directly operated by the element in the transition to output state

(A highly reliable limit switch makes direct contact with the spool in the valve providing dependable feedback)

✅ The SRP/CS shall ensure both independent valve elements have transitioned by monitoring independent contacts

✅ Fault condition possible from non-synchronous motion of independent elements

(Independent switch contacts on each monitoring system detect motion of both vales, ensuring their synchronicity to identify faults)

How do they work?

Hydraulic monitored safety valves act as an output within the control system.

Input ➡️ – Logic 💻 – Output ➡️

Outputs directly enable or control the power to the machine actuators that produce hazardous motion e.g. contactors or fluid power valves.

In a Category 4 system, all components within the system must meet that same level of safety. If there is Hydraulic energy inside a safeguarded space, isolation of the energy (and removal of residual energy) must occur before the Logic in the system (the safety PLC) can unlock the Input (an interlock or access control device).

Let’s look at a Hydraulic system

When the valve is energised, the solenoids directly drive the switches to swap state. Redundancy in the switches provides synchronous and independent safety feedback to the logic control, identifying fault conditions such as contamination and sluggish response amongst others.

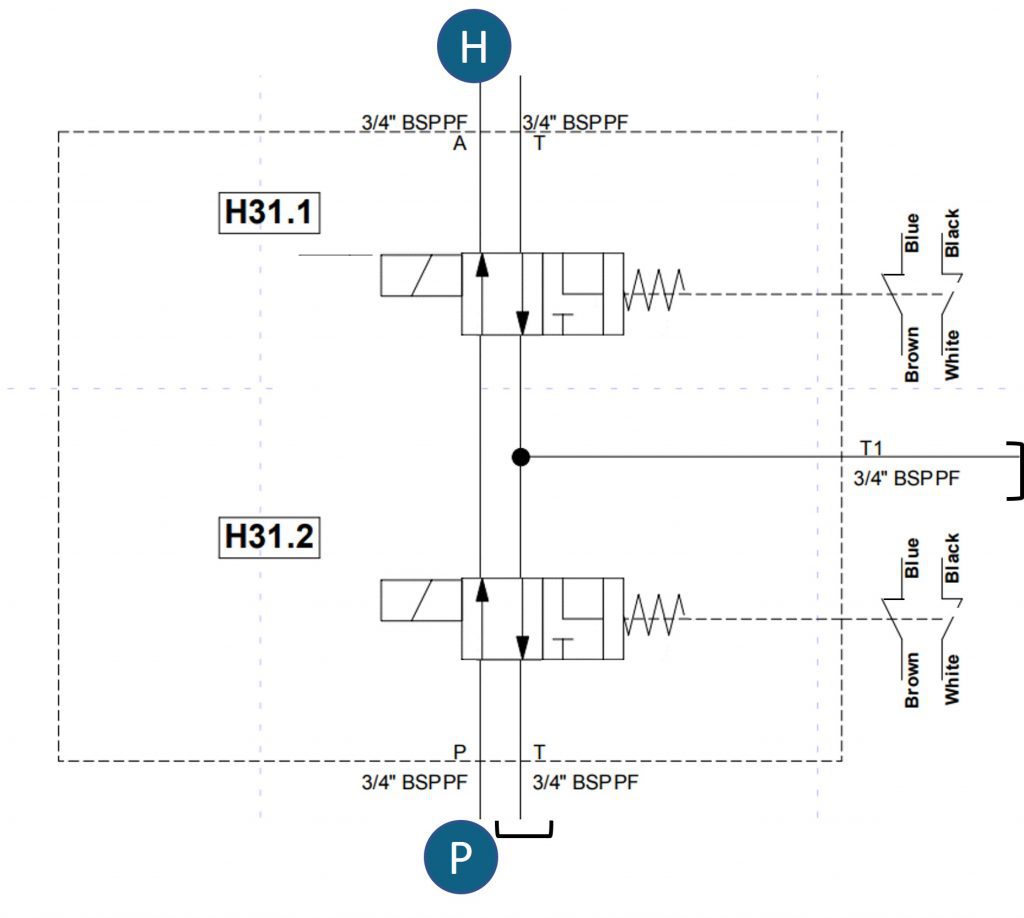

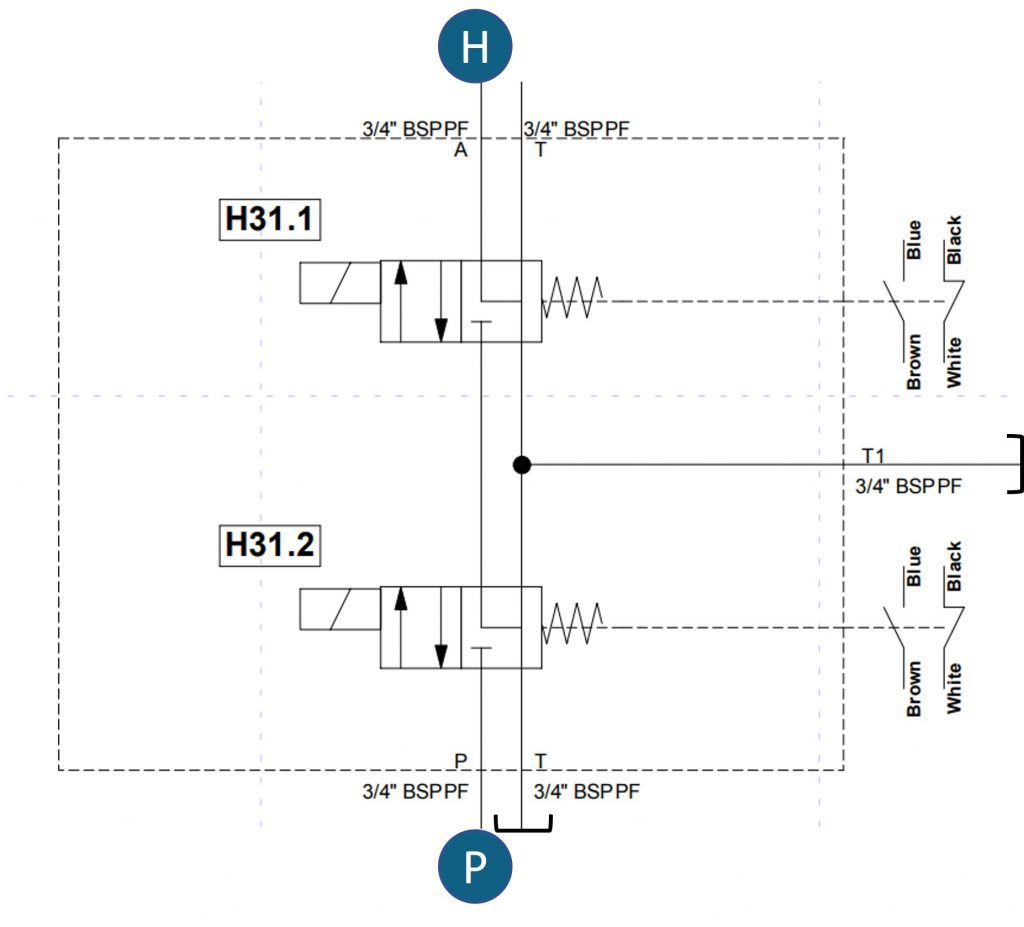

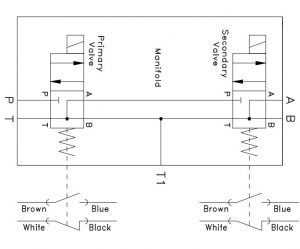

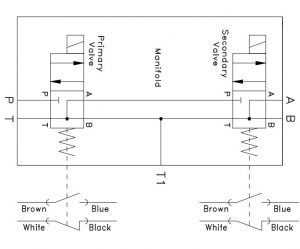

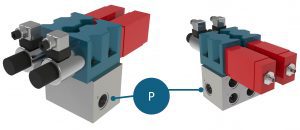

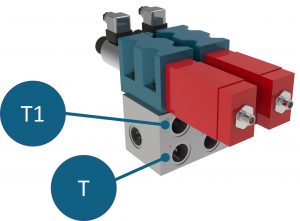

In the image below, the Hydraulic valve is de-energised (there is no supply to the solenoid) to return to its’ safe state. The the flow of energy from the pump (P) to the hazardous process (H) is isolated at port ‘P’. Residual energy at the Hazard is returned to the tank via port ‘T’ and port ‘T1’. In this state, the dual switches are directly operated by the element in the transition. A cross linked dual relief in the valve allows a redundant means to remove hazardous energy in the event one port is blocked.

In the return to isolated state, the closing of dual channel safety switches on hydraulic monitored safety valves is communicated to the safety PLC via M12 connection to signal to the input to (in the case of access control) allow access to a safeguarded space.

Our Solutions

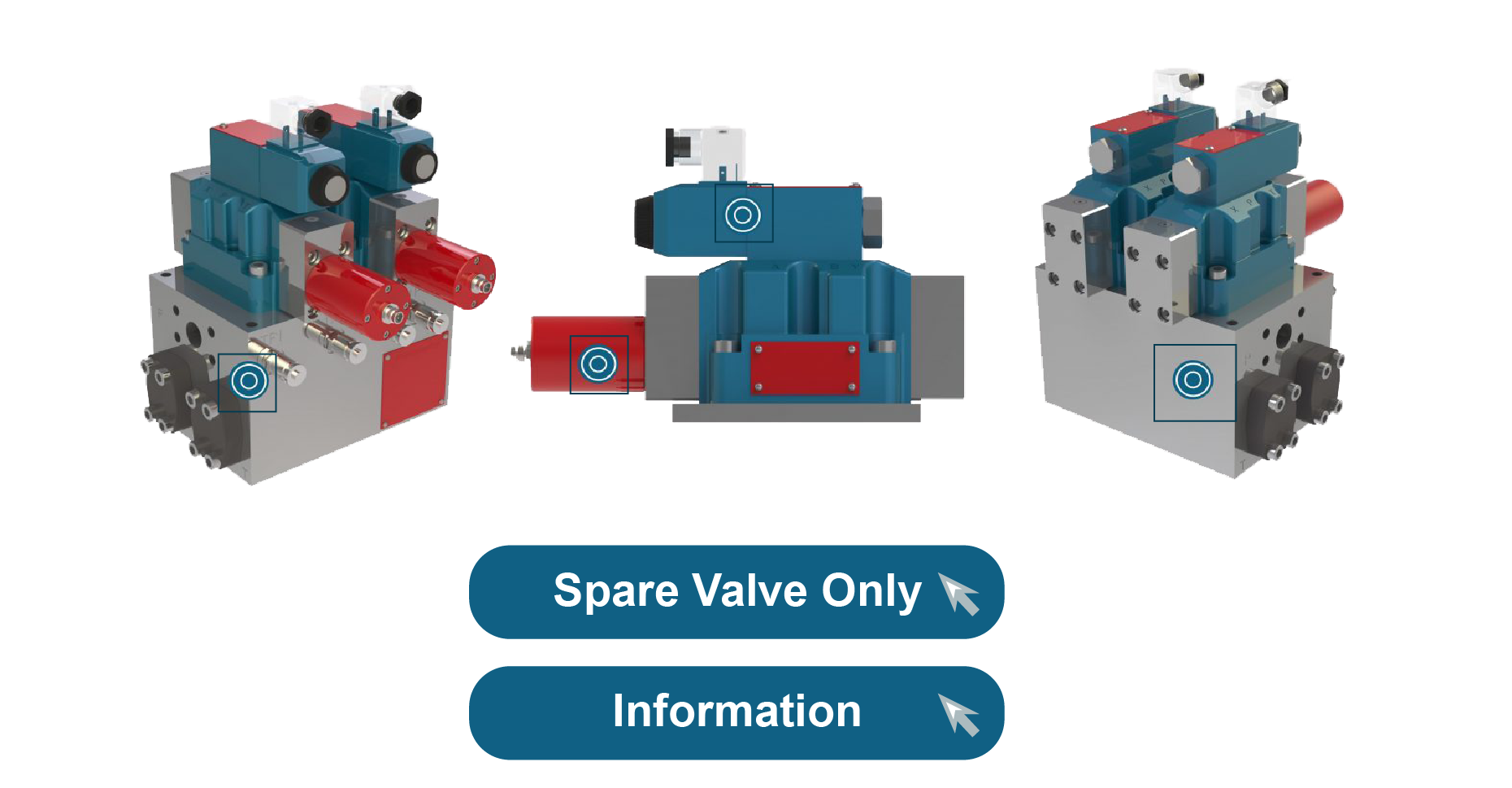

Selecting your Hydraulic Monitored Safety Valves

Select from the types below for more information on each product.

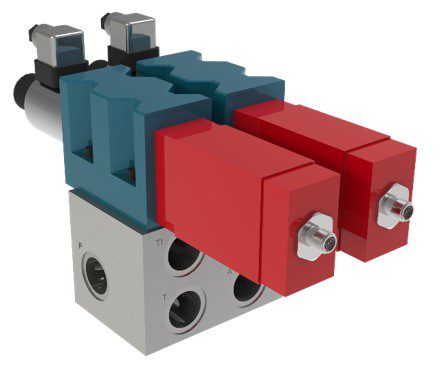

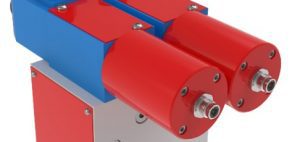

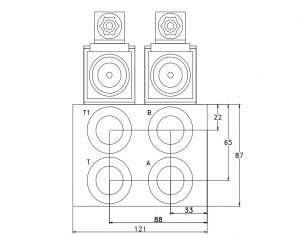

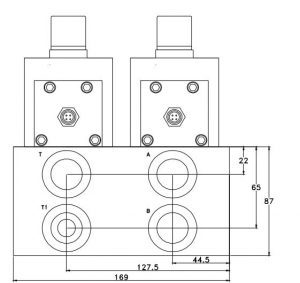

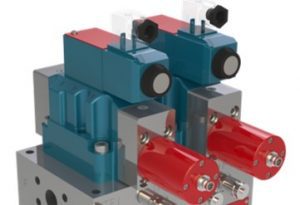

HSV-03AD-2-G075-MP0

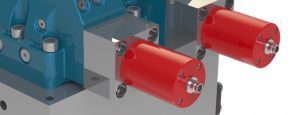

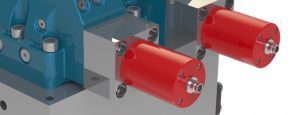

HSV (Hydraulic Monitored Safety Valve) – 03AD (Block and Bleed, Cetop 3 40LPM flow rate, M12 connection) – 2 (Dual Valve) – G075 (3/4″ BSP Port Size) – MP0 (standard manifold mounting from rear)

Performance

🔵 Valve working pressure range: 0 - 350 Bar

🔵 Solenoid: Direct Acting

🔵 Port connection: P, T, T1, A, B

🔵 Medium: 3/4" PBS Parallel Hydraulic Oil ISO 32 to 68

🔵 Oil operating temperature range: -20 C TO +70 C (Mineral Oil)

🔵 Flow rate: 40LPM

🔵 Activation time: 32 Milliseconds

🔵 Deactivation time: 50 Milliseconds

40 LPM for Risk Category 4

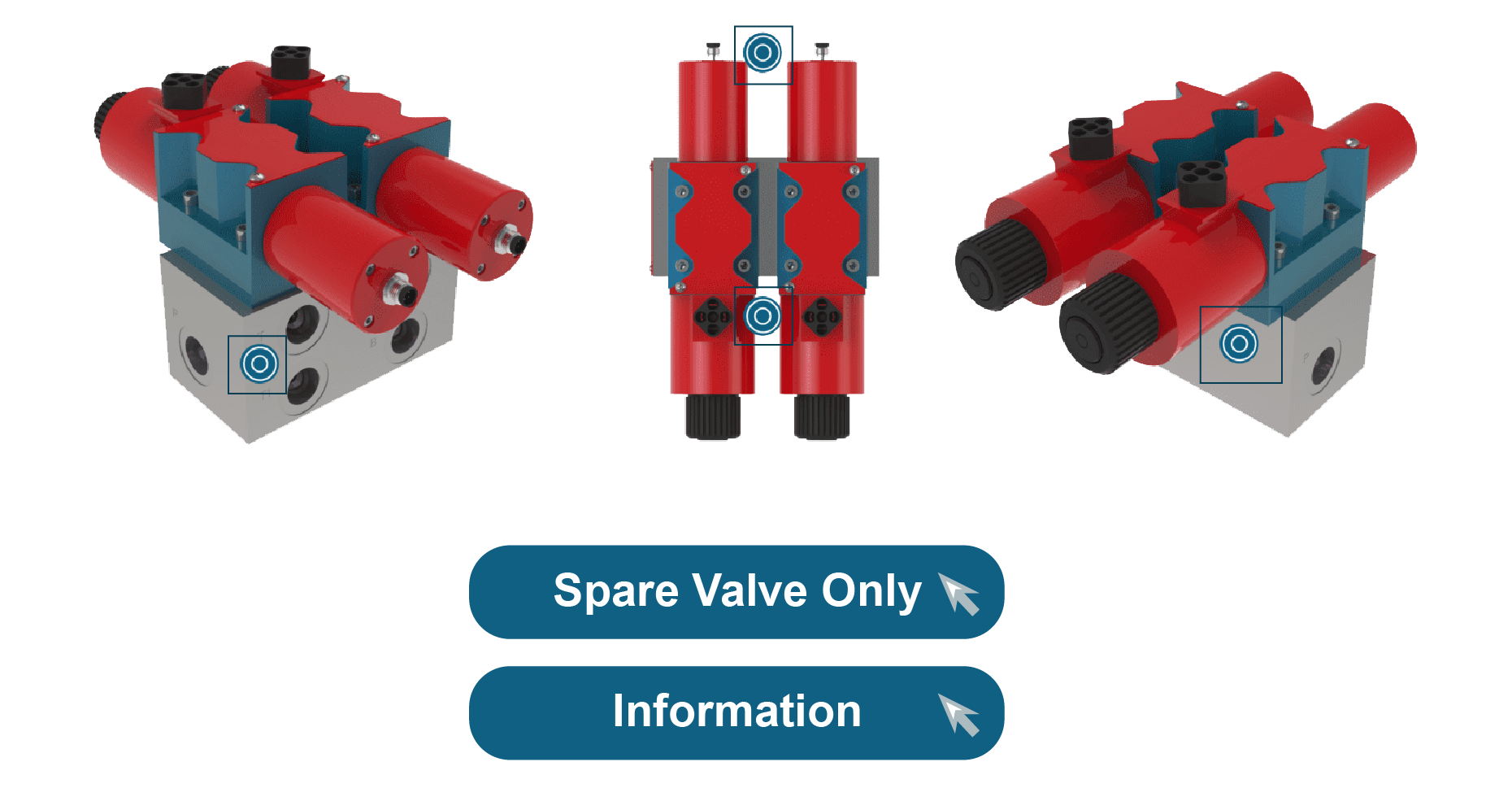

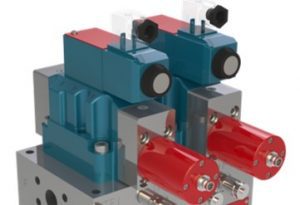

Dual directional control valves mounted on a specially manufactured manifold for hydraulic safety applications in Cetop 3 sizes.

Supplied in a four port two-position single solenoid format.

The valve incorporates a two pole precision positive driven plunger type limit switch pre-approved to category 4 safety applications.

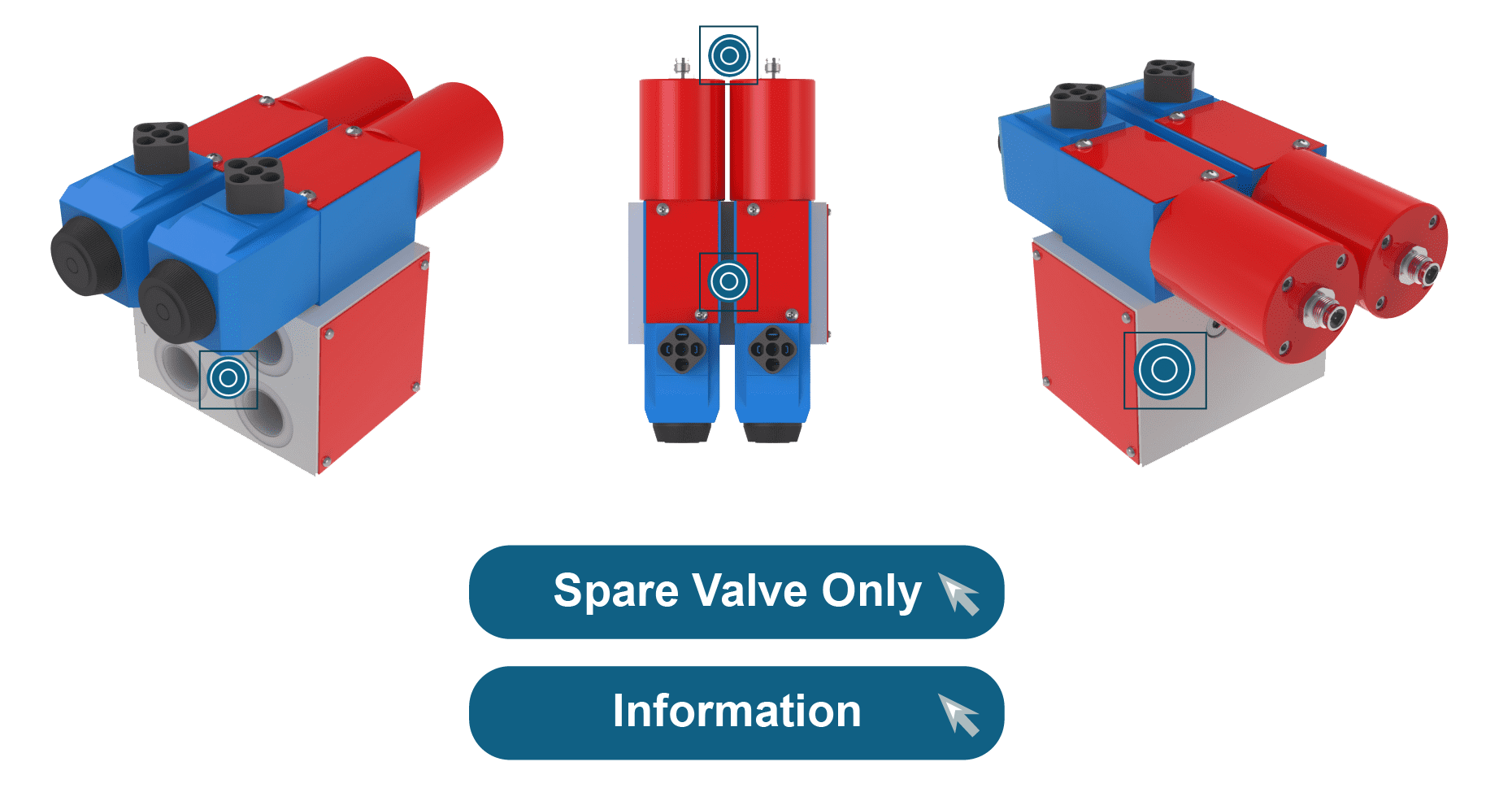

HSV-03AD-S

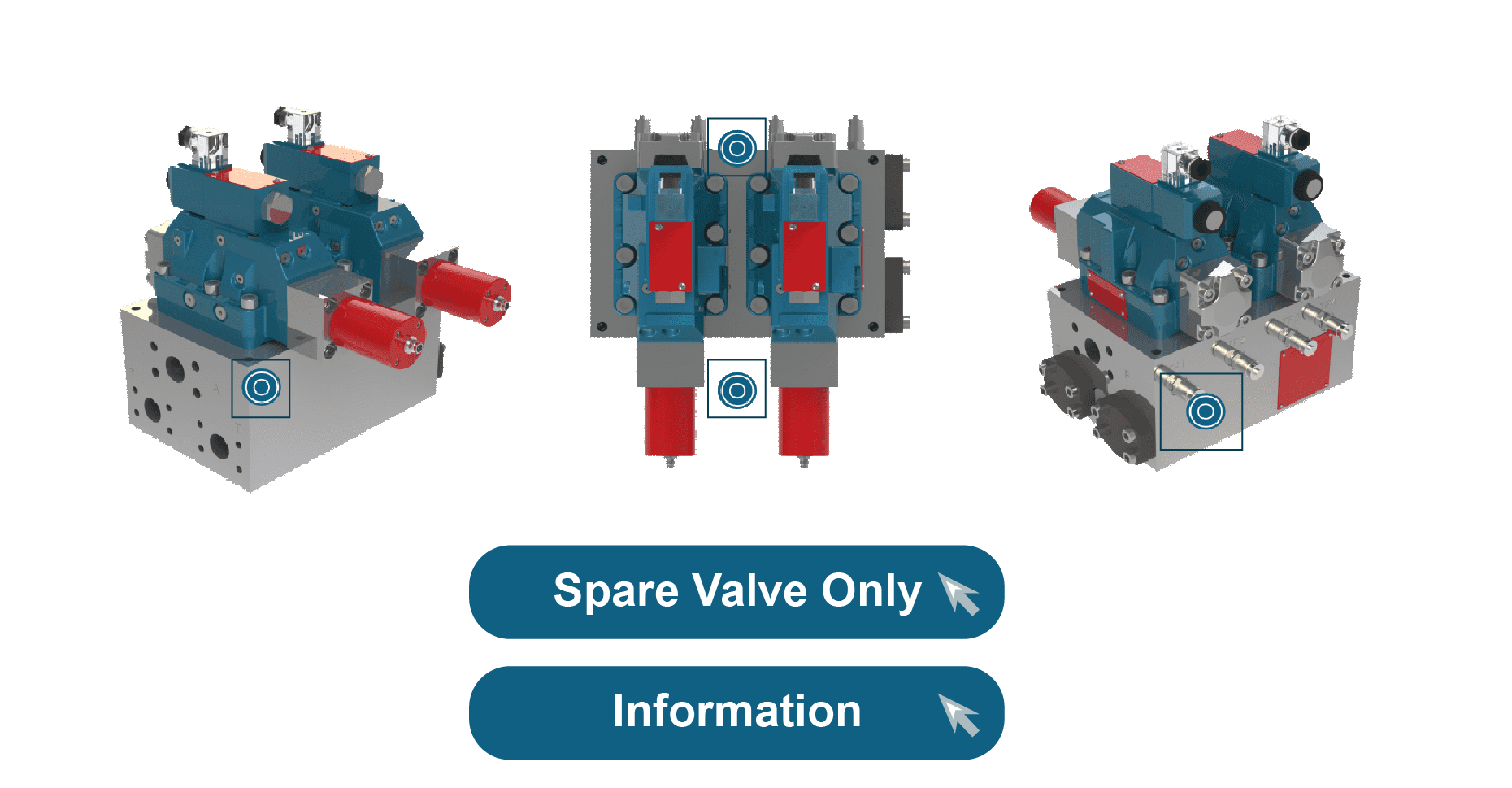

Fortress Fluidsentry valves are designed for easy maintenance with the understanding that urgent situations require urgent attention. Where a valve is not operating as expected, a spare can be swapped in within minutes to minimise the impact of downtime.

Each Fluidsentry monitored valve provides a normally closed mechanically linked positive opening high precision switch for the safety function (de-energised state). To prevent undetected faults the monitoring contacts should not be series connected in a feedback circuit.

Dual directional control valves mounted on a specially manufactured manifold for hydraulic safety applications in Cetop 3 size supplied in a four port two position single solenoid format.

P, T, T1, A, B Ports - ¾” BSP Parallel

HSV-05AD-2-G075-MP0

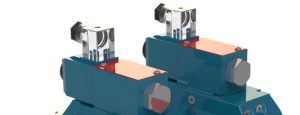

HSV (Hydraulic Monitored Safety Valve) – 05AD (Block and Bleed, Cetop 5 110LPM flow rate, M12 connection) – 2 (Dual Valve) – G075 (3/4″ BSP Port Size) – MP0 (standard manifold mounting from rear)

Performance

🔵 Valve working pressure range: 0 - 315 Bar

🔵 Solenoid: Direct Acting

🔵 Port connection: P, T, T1, A, B

🔵 Medium: 3/4" PBS Parallel Hydraulic Oil ISO 32 to 68

🔵 Oil operating temperature range: -20 C TO +70 C (Mineral Oil)

🔵 Flow rate: 110LPM

🔵 Activation time: 50 Milliseconds

🔵 Deactivation time: 130 Milliseconds

110 LPM for Risk Category 4

Dual directional control valves mounted on a specially manufactured manifold for hydraulic safety applications in Cetop 5 sizes.

Supplied in a four port two-position single solenoid format.

The valve incorporates a two pole precision positive driven plunger type limit switch pre-approved to category 4 safety applications.

HSV-05AD-S

Fortress Fluidsentry valves are designed for easy maintenance with the understanding that urgent situations require urgent attention. Where a valve is not operating as expected, a spare can be swapped in within minutes to minimise the impact of downtime.

Each Fluidsentry monitored valve provides a normally closed mechanically linked positive opening high precision switch for the safety function (de-energised state). To prevent undetected faults the monitoring contacts should not be series connected in a feedback circuit.

Dual directional control valves mounted on a specially manufactured manifold for hydraulic safety applications in Cetop 5 size supplied in a four port two position single solenoid format.

P, T, T1, A, B Ports - ¾” BSP Parallel

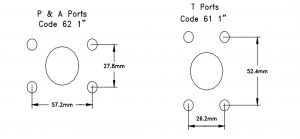

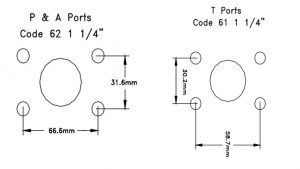

HSV-07AD-2-C100-MP0

HSV (Hydraulic Monitored Safety Valve) – 07AD (Block and Bleed, Cetop 7 250LPM flow rate, M12 connection) – 2 (Dual Valve) – C100 (Code 62 Ports A & P 1″, Code 61 Ports T 1″) – MP0 (standard manifold mounting from rear)

Performance

🔵 Valve working pressure range: 0 - 350 Bar

🔵 Solenoid: Direct Acting

🔵 Port connection: P, T, A

🔵 Ports - P & A Code 62 1"; T Code 61 1"

🔵 Medium: Hydraulic Oil ISO 32 to 68

🔵 Oil operating temperature range: -20 C TO +70 C (Mineral Oil)

🔵 Flow rate: 250LPM

🔵 Activation time: 32 Milliseconds

🔵 Deactivation time: 67 Milliseconds

250 LPM for Risk Category 4

Dual directional control valves mounted on a specially manufactured manifold for hydraulic safety applications in Cetop 7 sizes.

Supplied in a four port two-position single solenoid format.

The valve incorporates a two pole precision positive driven plunger type limit switch pre-approved to category 4 safety applications.

HSV-07AD-S

Fortress Fluidsentry valves are designed for easy maintenance with the understanding that urgent situations require urgent attention. Where a valve is not operating as expected, a spare can be swapped in within minutes to minimise the impact of downtime.

Each Fluidsentry monitored valve provides a normally closed mechanically linked positive opening high precision switch for the safety function (de-energised state). To prevent undetected faults the monitoring contacts should not be series connected in a feedback circuit.

Dual directional control valves mounted on a specially manufactured manifold for hydraulic safety applications in Cetop 7 size supplied in a four port two position single solenoid format.

P & A Ports - Code 62 1"

T Ports - Code 61 1"

HSV-08AD-2-C125-MP0

HSV (Hydraulic Monitored Safety Valve) – 08AD (Block and Bleed, Cetop 8 550LPM flow rate, M12 connection) – 2 (Dual Valve) – C125 (Code 62 Ports A & P 1.25″, Code 61 Ports T 1.25″) – MP0 (standard manifold mounting from rear)

Performance

🔵 Valve working pressure range: 0 - 350 Bar

🔵 Solenoid: Direct Acting

🔵 Port connection: P, T, A

🔵 Ports - P & A Code 62 1.25"; T Code 61 1.25"

🔵 Medium: Hydraulic Oil ISO 32 to 68

🔵 Oil operating temperature range: -20 C TO +70 C (Mineral Oil)

🔵 Flow rate: 550LPM

🔵 Activation time: 32 Milliseconds

🔵 Deactivation time: 67 Milliseconds

550 LPM for Risk Category 4

Dual directional control valves mounted on a specially manufactured manifold for hydraulic safety applications in Cetop 8 sizes.

Supplied in a four port two-position single solenoid format.

The valve incorporates a two pole precision positive driven plunger type limit switch pre-approved to category 4 safety applications.

HSV-08AD-S

Fortress Fluidsentry valves are designed for easy maintenance with the understanding that urgent situations require urgent attention. Where a valve is not operating as expected, a spare can be swapped in within minutes to minimise the impact of downtime.

Each Fluidsentry monitored valve provides a normally closed mechanically linked positive opening high precision switch for the safety function (de-energised state). To prevent undetected faults the monitoring contacts should not be series connected in a feedback circuit.

Dual directional control valves mounted on a specially manufactured manifold for hydraulic safety applications in Cetop 8 size supplied in a four port two position single solenoid format.

P & A Ports - Code 62 1.25"

T Ports - Code 61 1.25"

What are the Port Connections?

Inlet ‘P’ Port

The supply port or ‘P Port’ supplies the valve from the upstream energy source. When the hydraulic safety valve (HSV) is activated, the P port enables the flow of fluid through the valve to the downstream process. When the HSV is deactivated, the P port is blocked.

Outlet ‘A’ and ‘B’ Ports

In the energised state, the A port receives the input of fluid from the P port enabling the flow of energy to the downstream process. The B port returns the fluid from the downstream process back to tank (via the T and T1 ports). In the de-energised state, the A port is redirected straight to the T and T1 ports to return downstream energy to tank.

Tank Ports ‘T’ and ‘T1’

The T and T1 ports (or tank ports), complete the loop of energy flow from the downstream process to the upstream tank.

(Ports are measured in BSP – British Standard Pipe (as defined in ISO 228) except CETOP 7/8)

What is Activation and Deactivation Time?

Activation time is the time to activate the switches from the solenoid energised state to the solenoid isolated state (i.e. time to transition from energy transfer from P to A enabled to P port blocked, A to tank).

Deactivation time – time to deactivate the switches from the isolated state and return the valve to the solenoid energised state (i.e unblock the P port and enable P to A flow).

What is the Valve Working Pressure Range

Maximum allowable working pressure (MAWP) of a monitored safety valve is the highest level of pressure (Bar) that can flow through the valve. Above this level, components may fail such as springs, seals, or the main body.

What is Flow Rate?

Flow Rate (LPM) – the volume of oil in litres that flows through the defined surface area per minute.

CETOP 3 – HSV-03AD-2-G075-MP0

CETOP 5 – HSV-05AD-2-G075-MP0

CETOP 7 – HSV-07AD-2-C100-MP0

CETOP 8 – HSV-08AD-2-C125-MP0

CETOP 3 – HSV-03AD-2-G075-MP0

CETOP 5 – HSV-05AD-2-G075-MP0

CETOP 7 – HSV-07AD-2-C100-MP0

CETOP 8 – HSV-08AD-2-C125-MP0