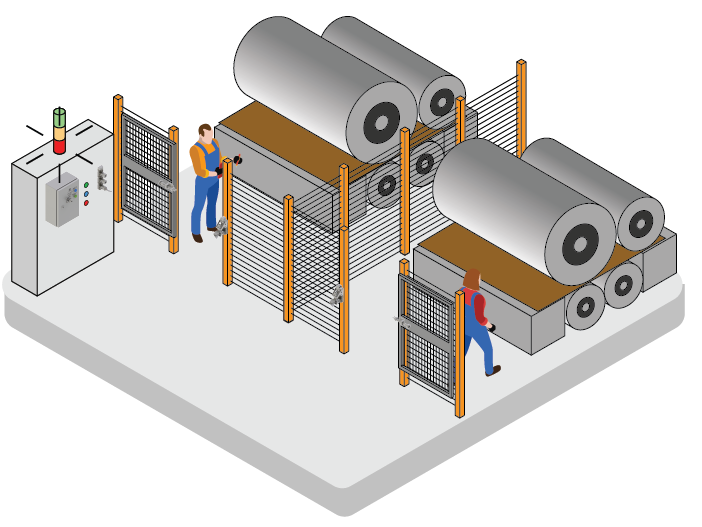

If My Machine Has a Run Down Time – How Do I Allow Safe Access After Lockout Tagout?

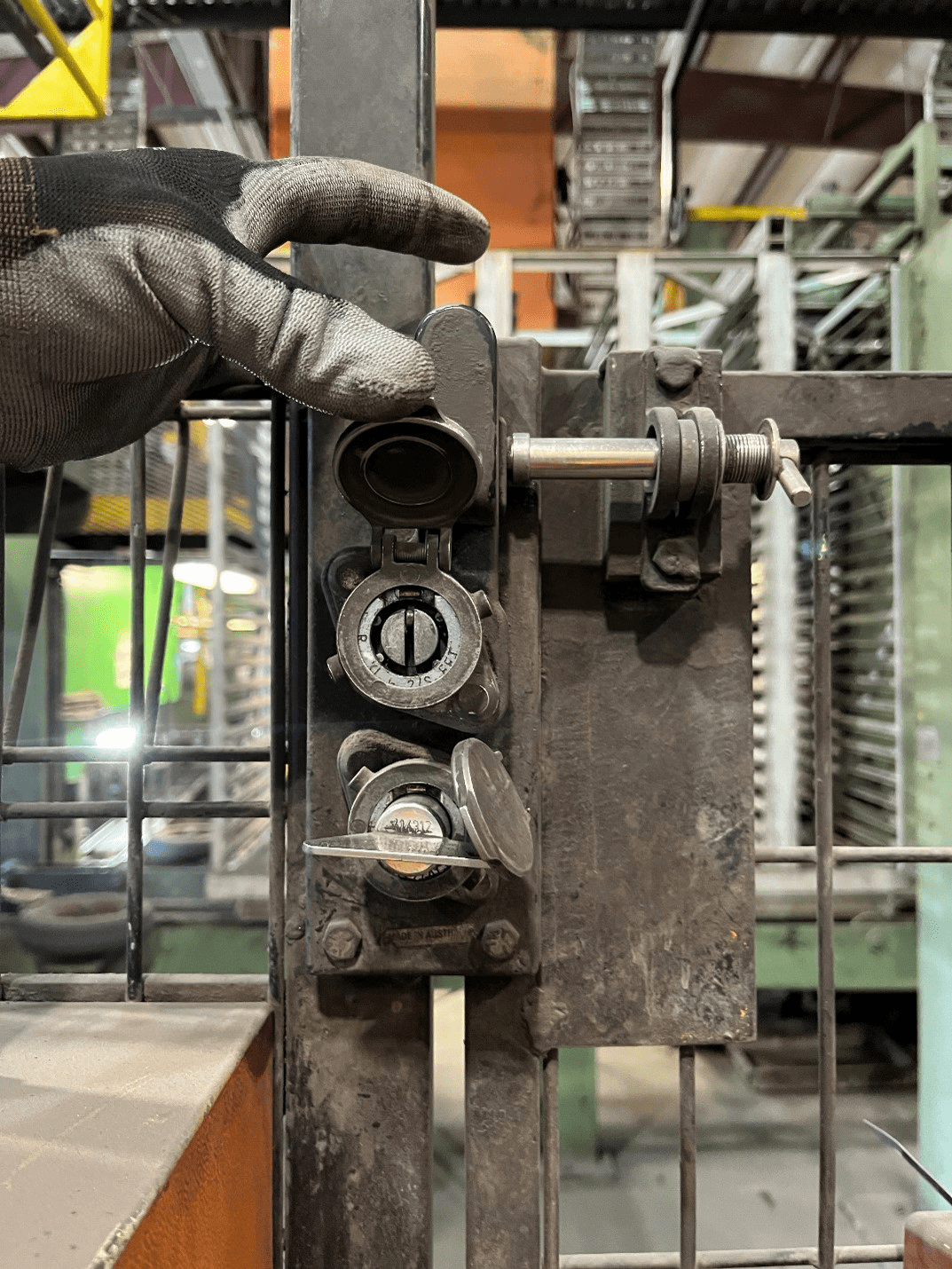

Many machines still pose a hazard even after energy sources are isolated. Any moving components with significant inertia such as flywheels on stamping presses or blades within mixers take time to cease motion. Traditional Lock-Out / Tag-Out (LOTO) approaches require employees to remove power sources to machines. Often supported by a documented procedure and padlockable elements. This procedural approach cannot always be applied to machines with a high risk of a danger still existing immediately after the power is ‘locked out’.

The American National Standard Institute included examples of alternative risk reductions when writing the 2016 edition of the Z244.1 standard, this document discusses Example 1 that relates to machines with run down times.

Example 1:

Alternative Risk Reduction Measures of Control for Machines / Equipment with Run Down Time within ANSI/ASSE Z244.1 includes the following paragraph:

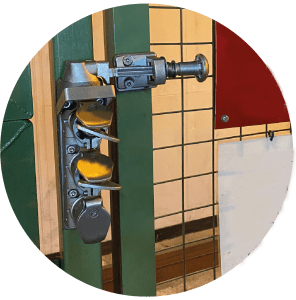

“A trapped key safety interlocking system incorporating a time delay feature will reduce the risk of this hazard. It can be used to prohibit entry until all residual motion is either eliminated or at a significantly reduced level”

Types of Time Delay Units

Depending upon the application there are several types of time delay units that could be incorporated, these are:

Mechanical Time Delay

Where a mechanical timer (often a spring mechanism) is used to control the release of a key(s). Typically seen on older systems, mechanical timers offer the advantage of requiring no electrical connection but require regular inspection to ensure the mechanism continues to time correctly. Adjustment of time duration is then not often possible.

Electronic Time Delay

Where the key used for access is released upon a signal from an electronic timer device after the set time since isolation has elapsed. This type of system has some great advantages including very consistent timing control, timers are often programmable so during installation the length of time required can be set based on the observed parameters. Also applied to curing ovens and heating chambers that require a time delay between shutting down the heating elements and access.

Voltage Sensing Unit

Where the key for access is released upon detection of zero movement in the moving components via a back emf unit monitoring the voltage of the motor’s windings. When the motion of rotating elements has stopped the voltage being produced by the motor will be zero based on the principle of electricity generation.

Voltage sensing units tend to be the engineer’s choice when the rotating object is of unknown or changing mass as this leads to a variable run down time for the rotating components. Sensing zero speed allows access as soon as it is safe to do so, minimising any lost time in a timer arrangement. Can only be fitted to machinery or re-equipment that has motor windings accessible for monitoring.

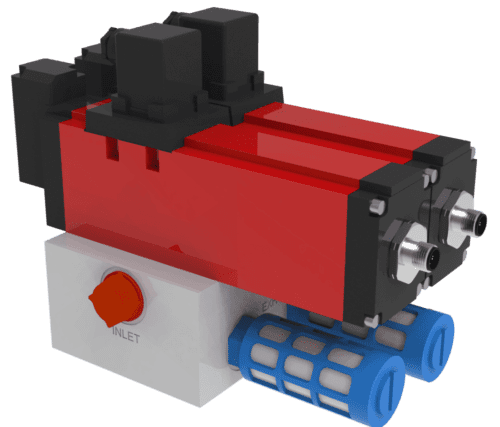

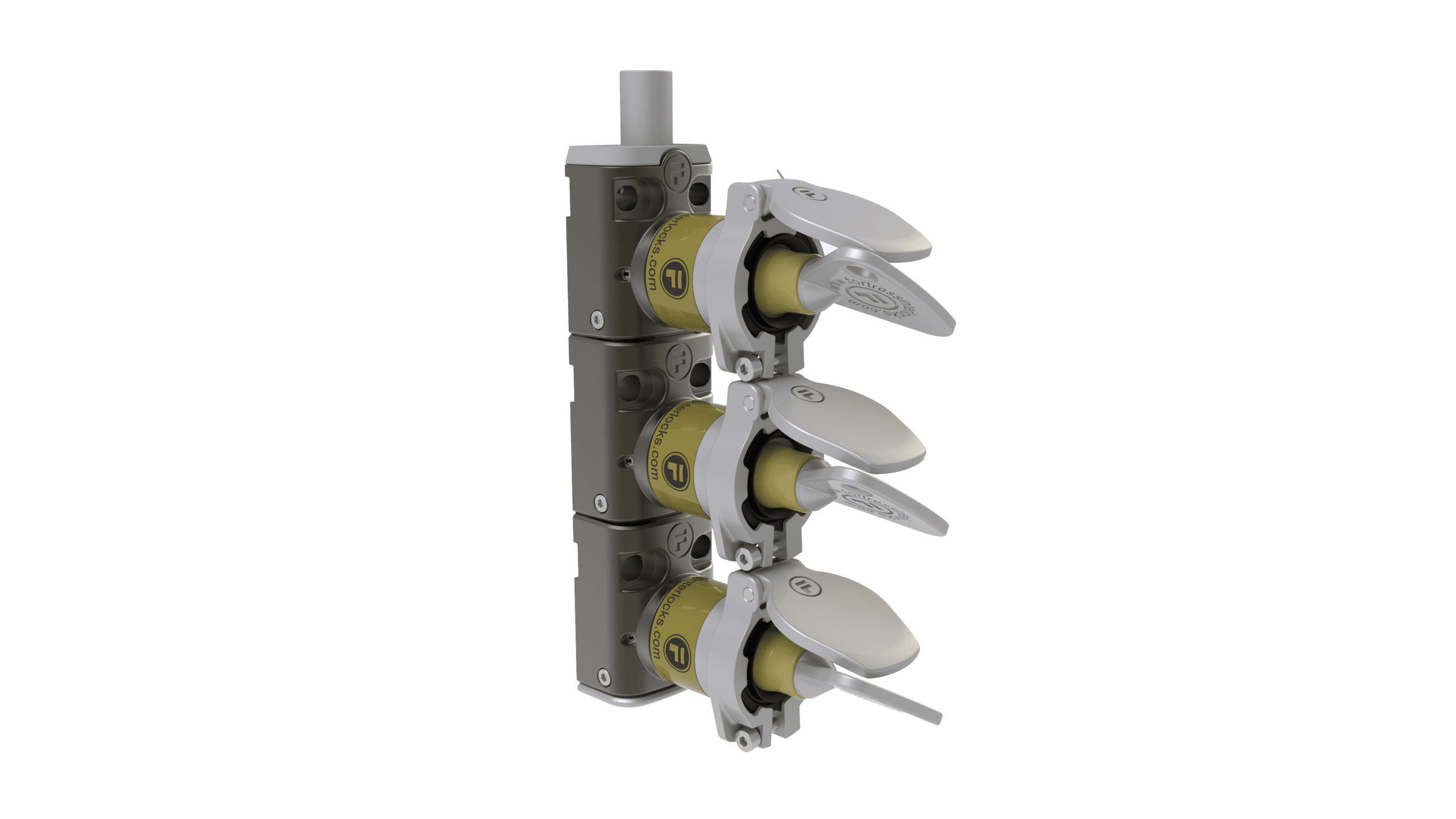

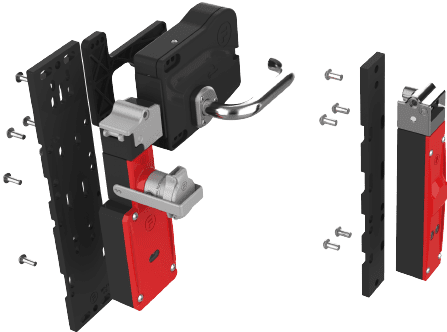

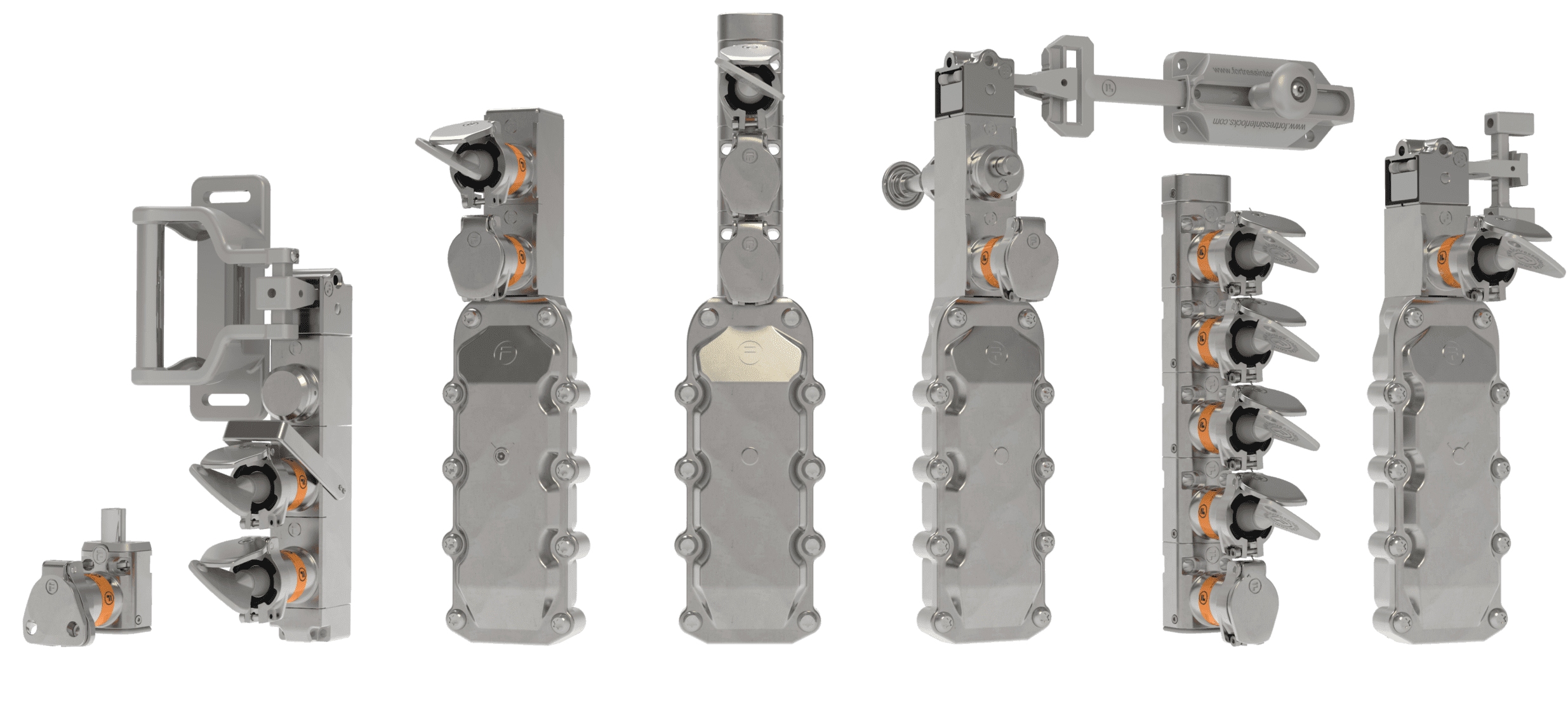

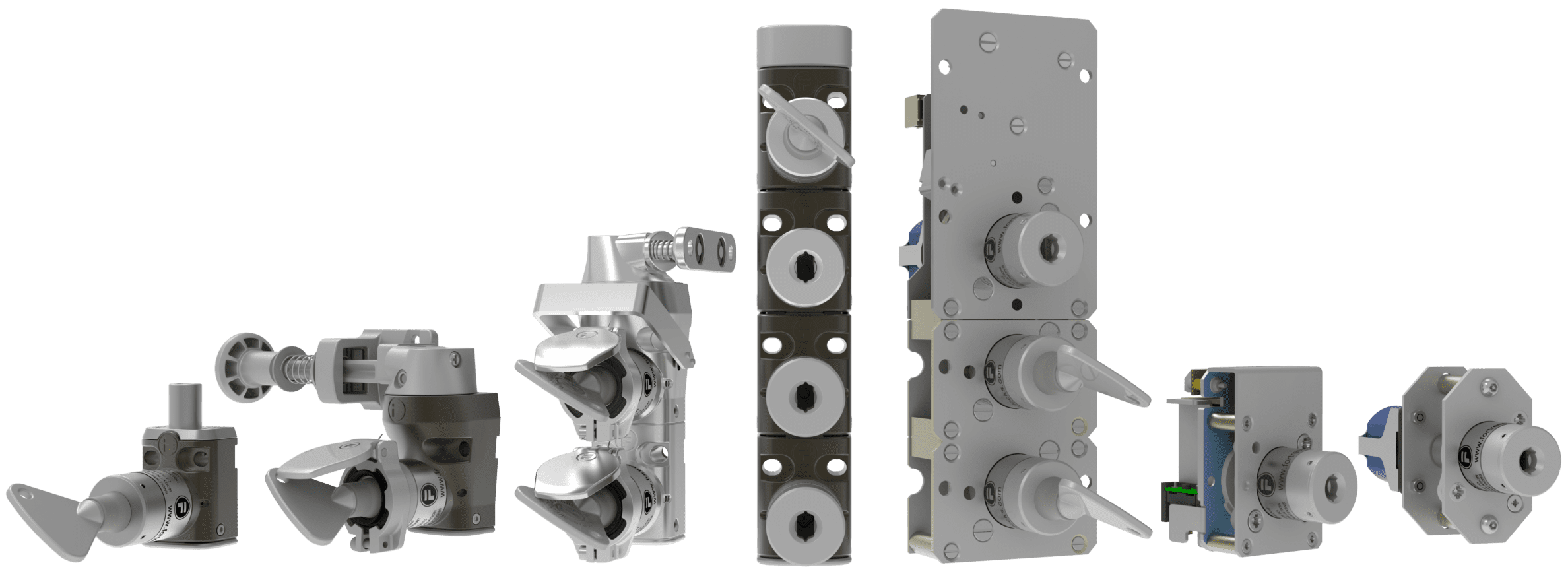

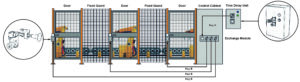

Fortress prides itself on offering a wide arrangement of time delay and voltage sensing units to customers within the mGard portfolio of products. ‘VS’ units are our Voltage Sensing offering while our Electronic Time Delay unit are available in three options:

Fortress prides itself on offering a wide arrangement of time delay and voltage sensing units to customers within the mGard portfolio of products. ‘VS’ units are our Voltage Sensing offering while our Electronic Time Delay unit are available in three options:

All options are supplied pre-wired in an IP66 stainless steel enclosure for mounting upon machinery. Lock elements can be alloy construction or full stainless steel for outdoor or corrosive environments.

Products Mentioned in this Article

mGard

Click Here to Download Article

Click Here to Download Article