Hazardous Locations and Explosive Atmospheres

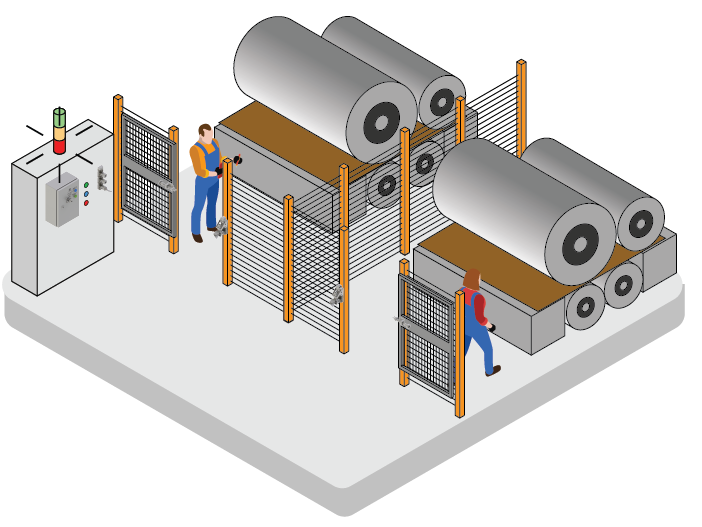

Industries such as wood manufacturing, chemical, pharmaceutical and food & beverage have areas that contain combustible dusts or flammable gases. Equipment put in these areas can heat up or cause a spark and become the ignition that, along with the oxygen in the air and the combustible material, causes an explosion.

Explosive Atmospheres

These explosions are very dangerous and, in the past, have done large amounts of damage, delayed production, injured and even killed employees. Whilst the safest way to mitigate this risk is to have no equipment in an explosive atmosphere at all, in many applications there is necessary equipment needed for manufacturing and/or safety that is required to be located within the explosive environment. In fact, an investigation into an explosion that happened in a factory in America concluded that the explosion could have been prevented with the use of interlocks to safeguard the correct process.

To mitigate the risk of explosion from the equipment manufacturers make products that are designed specifically to go in this environment. To prove that the equipment is safe it needs to be tested and certified to the level of risk in which it is being placed.

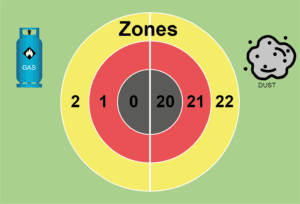

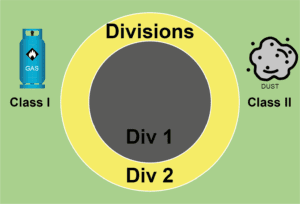

Different industries and plants that have combustible dust or flammable gasses, have areas with different risk levels. These risk levels are called Zones or Divisions depending which certification is being used. To understand the zones or divisions of an individual plant a risk assessment must be done.

Zones and Divisions

The current definitions of these Zones and Divisions are as follows:

Zone 0 (Gas) / Zone 20 (Dust) – Explosive atmosphere occurs continuously or frequently during normal operation

Zone 1 (Gas) / Zone 21 (Dust)- Explosive atmosphere is likely to occur occasionally during normal operation.

Zone 2 (Gas) / Zone 22 (Dust) – Explosive atmosphere is not likely to occur during normal operation.

Certificates

There are multiple certificates around the world to show that a product is safe to be used in this environment, the most common three are ATEX used in Europe, IECEx seen as the around the world certificate and the North American certificate used in the USA and Canada.

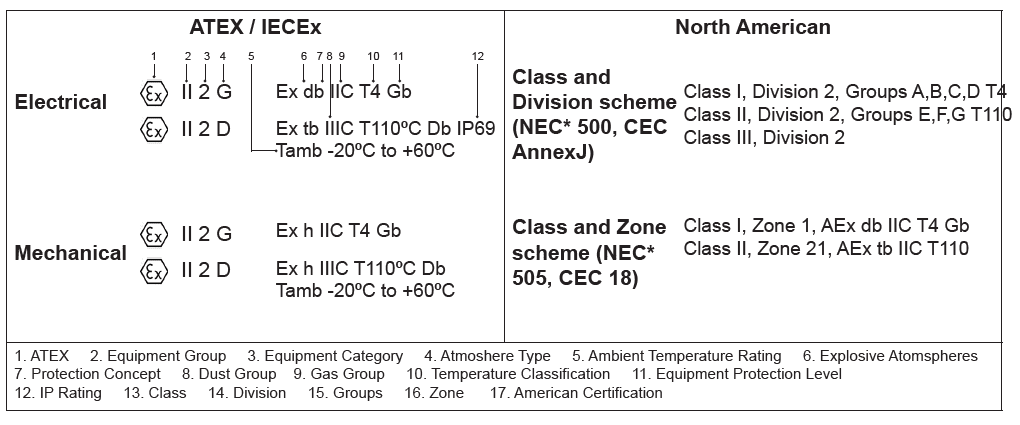

Looking at the markings on a piece of equipment allows you to see the highest risk level where the equipment can be used.

For example, if a risk assessment indicates the area the equipment is going into is zone 2 then equipment marked, zone 0, Zone 1 or Zone 2 can be used. (1), Ex (6), AEx (17) are all marks to show that the equipment is suitable to be used in an explosive atmosphere.

The Equipment Group (2) tells you the location of where you can put the equipment; I indicates the equipment can be used in undergrounding , II indicates that the equipment is for surface industries, not underground mining. The Atmosphere type (4) indicates the type of atmosphere that you can put the equipment in an ATEX environment, Gas or dust.

The equivalent for the North American certificate is Class (13), in contrast to ATEX and IECEx, North America has three types separating out fibers and flyings (Class III) from dust (Class II) as well as keeping Gas (Class I).

In the ATEX/ IECEx marking the zones are not explicitly stated however the equipment category(3) and the Equipment protection level (11) indicates which zone the equipment is suitable for. Equipment in category 1 is suitable for all zones, category 2 is for zone 1/21 and Zones 2/22 whilst category 3 is just for zone 2/22.

The first letter of the equipment protection level indicates if it is suitable fo G, Gas or D dust, whilst the second letter indicates if it has a, a very protection level for all zones, b, a high protection level suitable for zones 1/21 and zones 2/22 or c, a protection level suitable for just zone 2/22. In contrast the North American Certificate explicitly says what zone(16) or Division(14) the equipment is suitable for.

Dust Group (8), Gas group (9) indicate what type of Dust or Gas the equipment can go into. Group IIC is most easy to ignite gases and Group III C is conductive combustible dusts these are the highest level indicating the equipment is suitable in all dusts and gases. Groups (15) from the North American Certification uses letters, listing all letters A-G also shows the equipment is suitable in all dusts and gases.

The Ambient Temperature rating(5) indicates the temperature range that you can put the equipment into. Whereas the temperature classification shows the maximum surface temperature that the equipment can reach, the igniting point of the atmosphere must be higher than this temperature.

The IP rating (12) is on the Dust marking of the ATEX/ IECEx and NEC 505/ CEC 18. The first marking indicates the dust rating and the second number indicates the water rating. 69 is the highest possible rating and indicates that the product is dust tight and suitable for high pressure and temperature water jet.

As well as showing where the equipment can be used ATEX/ IECEx marking and NEC 505/ CEC 18 marking also indicates the protection concept(7). The protection concept indicates how the equipment will stop the ignition of the combustible material. db indicates the equipment protection is “flameproof enclosure”, any sparks/ flames are contained within the enclosure and will not cause ignition of the outside atmosphere. Tb indicates the equipment protection is Enclosures, this excludes dust from getting into the device and h indicates nonelectrical equipment suitable for use in potentially explosive environment.

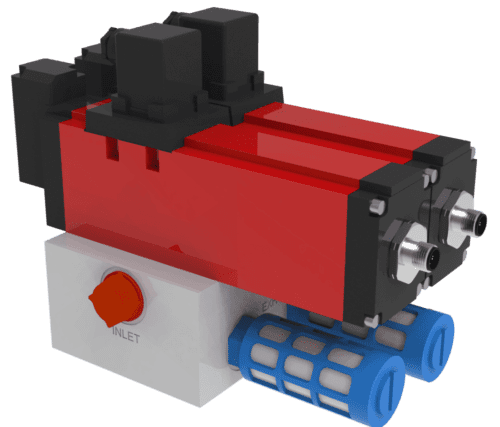

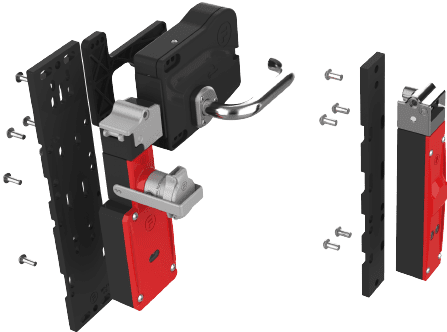

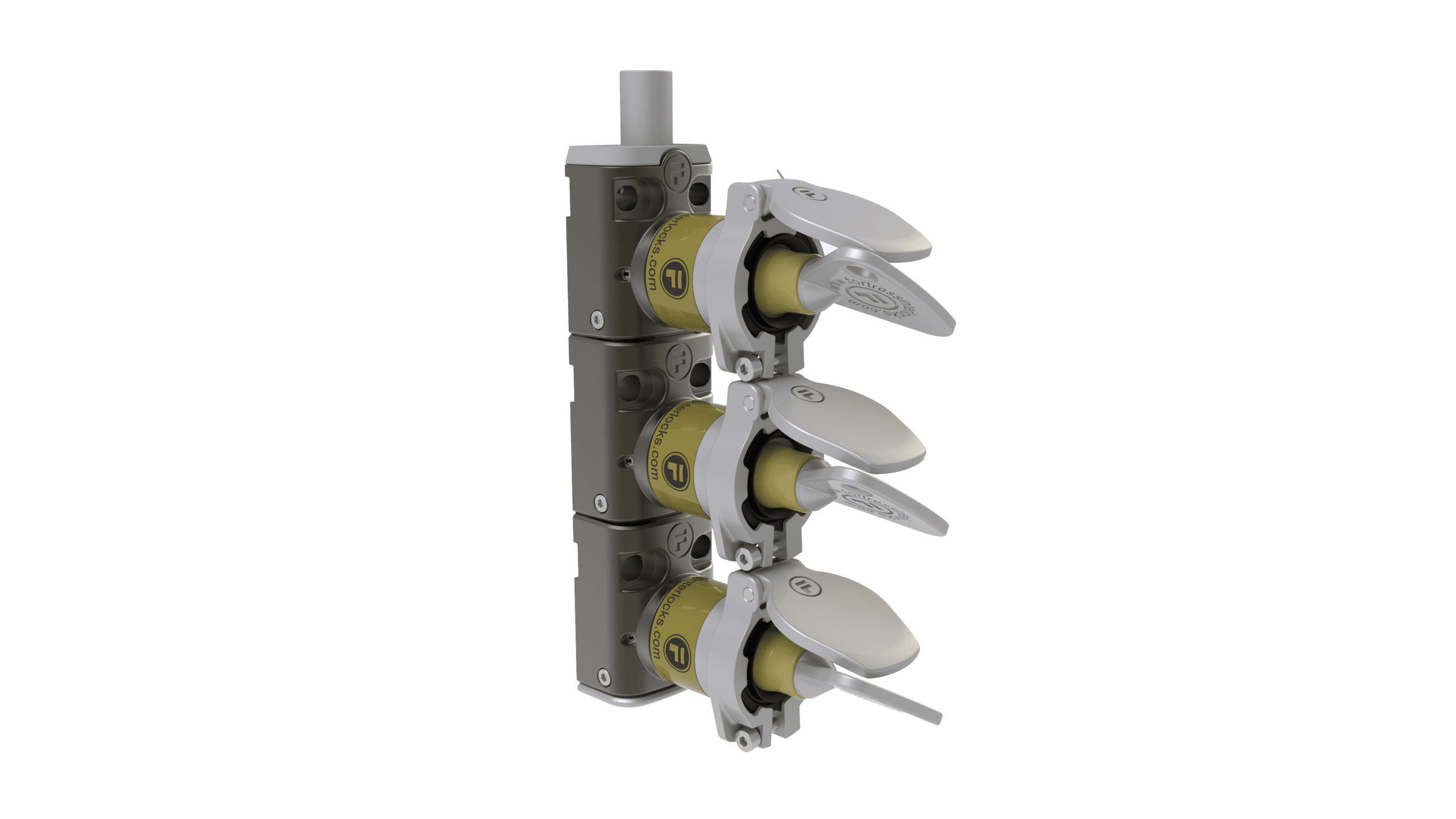

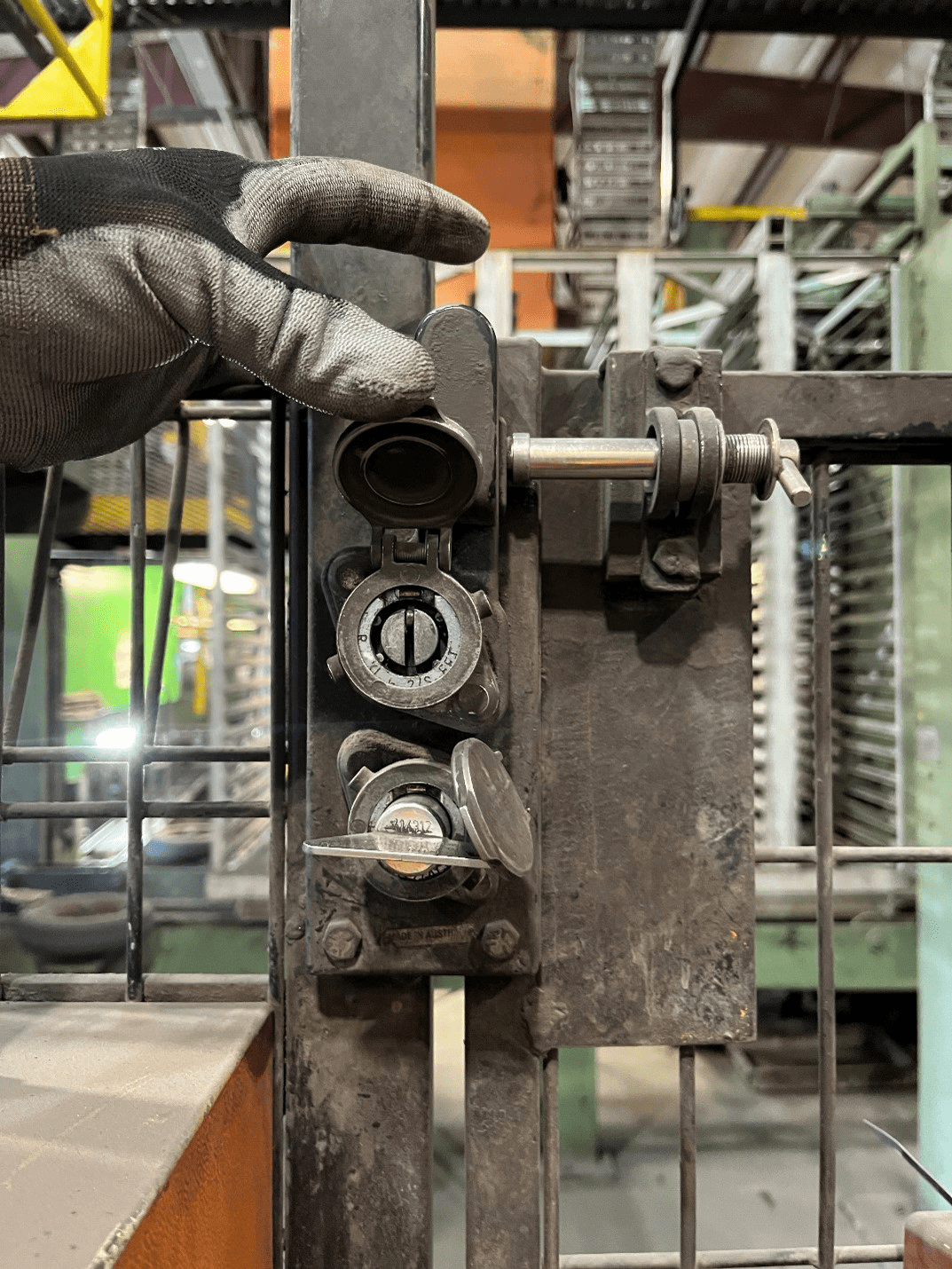

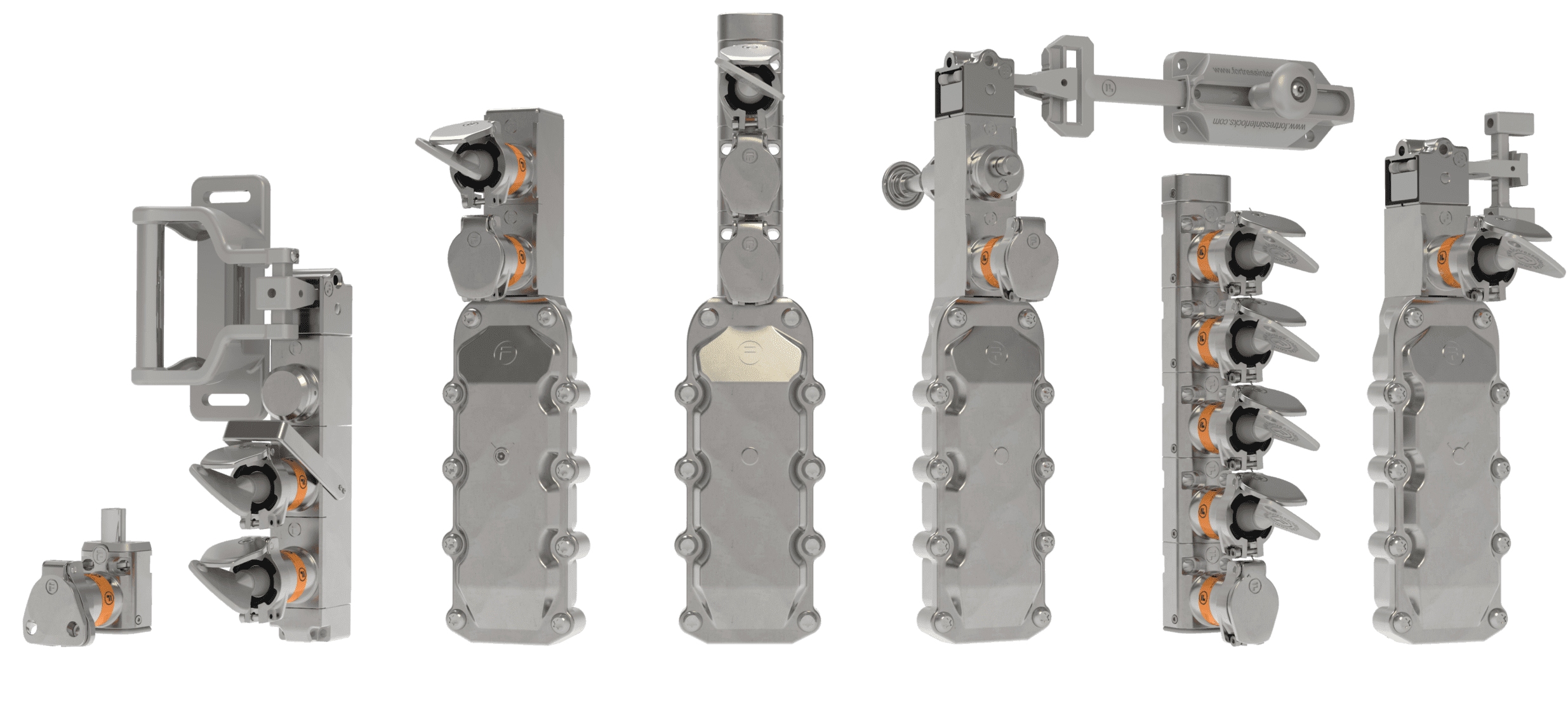

A risk assessment and selecting the right equipment for the hazardous area is important. If you put non-certified equipment, or equipment with too low a protection level into potentially explosive environments you risk an explosion, fines and in some locations jail time. However, putting certified equipment such as Fortress’ Alfred range allows you to maintain the important role this equipment plays whilst protecting you, your business, and your employees.

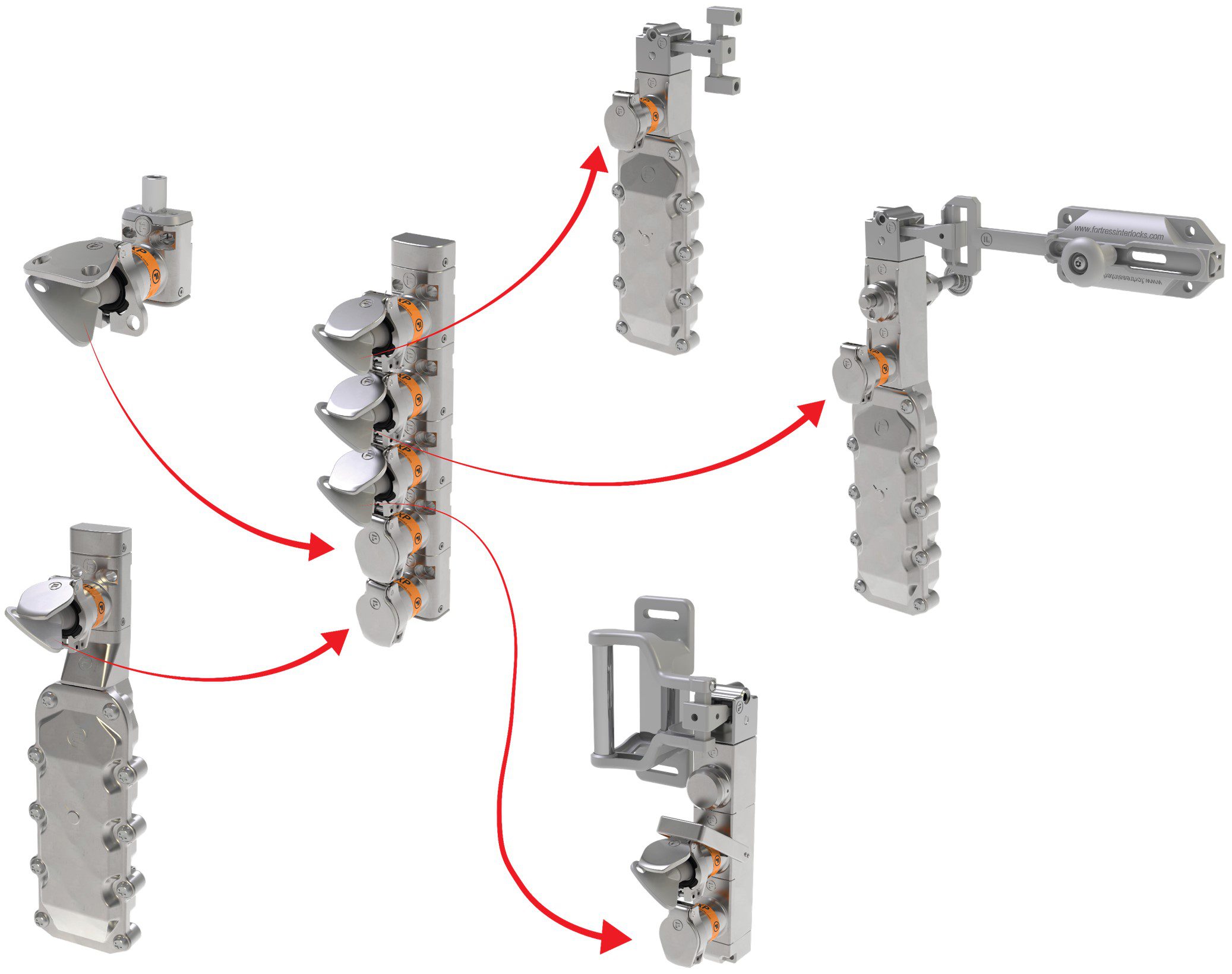

Product Mentioned in this Article

Click Here to Download Article

Click Here to Download Article