If you operate machinery in your facility, you know the importance of ensuring the safety of your workers. One way to do this is by preventing unexpected start-ups or restarts of the machinery, which can cause accidents and injuries.

But what is an unexpected start-up and how is it addressed in machinery safety standards?

What is an Unexpected Start-Up?

An unexpected start-up is the unintentional activation of machinery or a process control system. It can occur when a machinery is restarted after being shut off, or when a machinery that was not in operation is turned on. Unexpected start-ups can be caused by a variety of factors, including human error, electrical malfunctions, and mechanical failures.

The ISO and B11 Standards

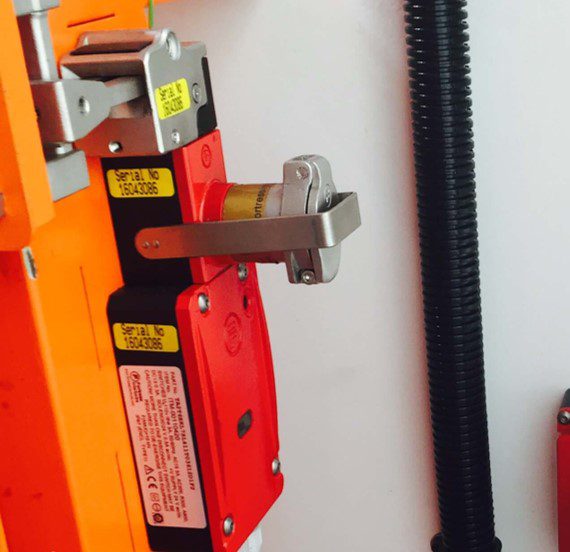

The ISO and B11 standards are two of the most widely recognized machinery safety standards that address unexpected start-ups. The ISO standard, ISO 14119, Safety of machinery – Interlocking devices associated with guards – Principles for design and selection, specifies the minimum requirements for interlocking devices that are used to prevent unexpected start-ups or restarts of machinery. The B11 standard, B11.19, Safety of Machinery – Human Body Access to Machinery – Principles for Design, provides guidelines for the design of machinery to prevent injuries caused by unexpected start-ups or restarts of the machinery.

Preventing Unexpected Start-Ups

There are several ways to prevent unexpected start-ups or restarts of machinery, including the use of presance detection equipment and personnel keys. Personnel keys are keys that are retained by a worker who needs to access the machinery. If the key is not present, the machinery will not start or will shut off if it is already in operation. This helps to prevent accidents caused by unexpected start-ups or restarts of the machinery.

Talk to an Personnel Key Expert

Fortress Safety has experts who can help you ensure the safety of your workers in machinery applications.