What Is Control Reliability In ANSI B11.19-2019?

ANSI B11.19-2019 Performance Requirements for Risk Reduction Measures: Safeguarding and other Means of Reducing Risk. Control reliability is an important concept introduced in the latest edition of B11.19 from the American National Standard Institute. Systems must conform but it can be confusing to understand how to achieve it and how performance levels and categories interact with control reliability.

It is first defined in 3.15 Control Reliability as:

“The capability of the [machine] control system, the engineering controls – devices, other control components and related interfacing to achieve a safe state in the event of a failure within the safety-related parts of the control system.”

However, in order to get wider understanding of what this means, it is important for anyone applying B11.19 to look for the explanatory note in E9.2.1.2

“While the requirements of control reliability are not directly comparable to the requirements of ISO 13849-1, for the purposes of this standard, complying with either of the following, at a minimum, will satisfy the requirements of control reliability:

• Category 3 or 4 according to ISO 13849-1 (1999);

• Performance Level “d” or “e”, according to ISO 13849-1 (2015).”

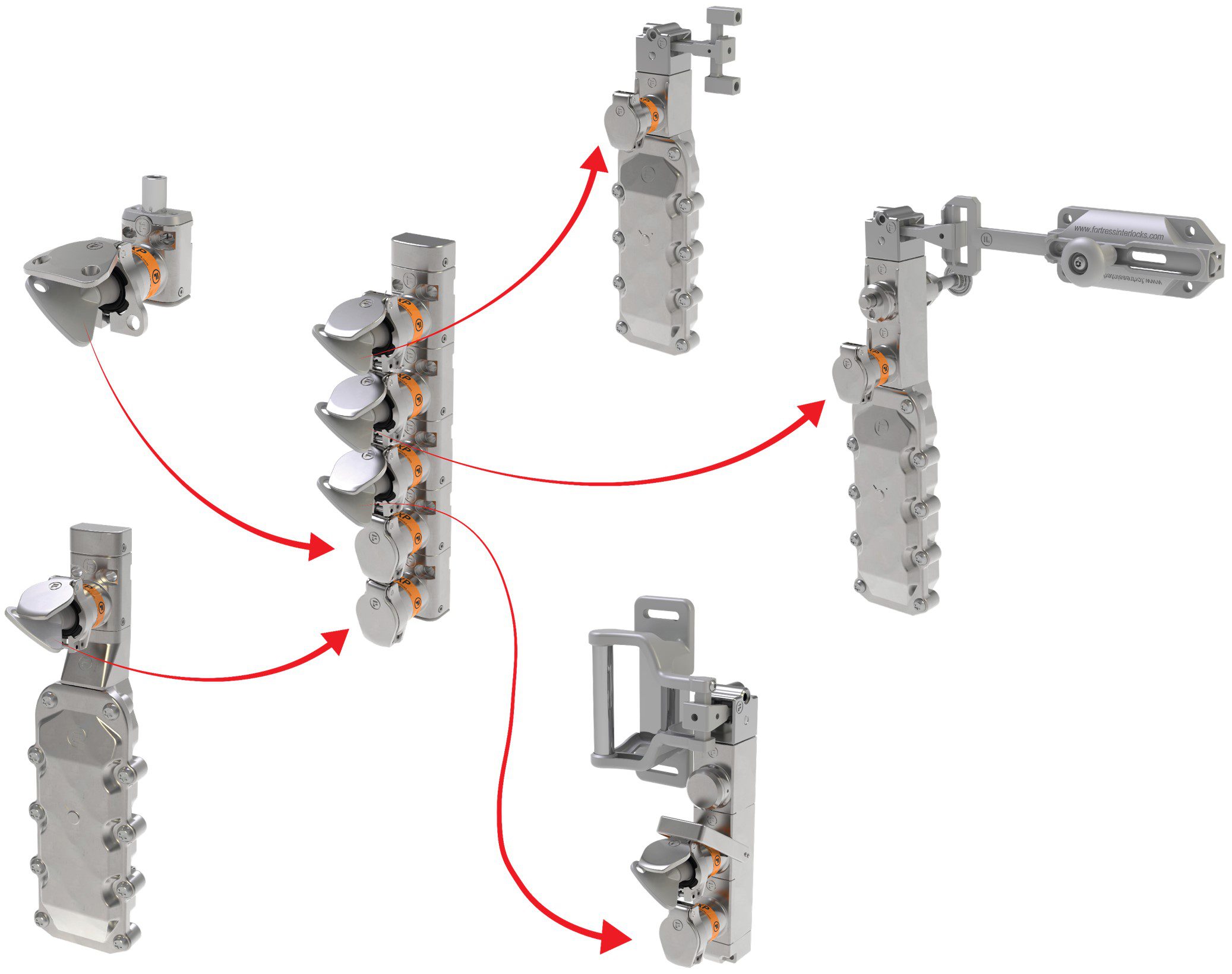

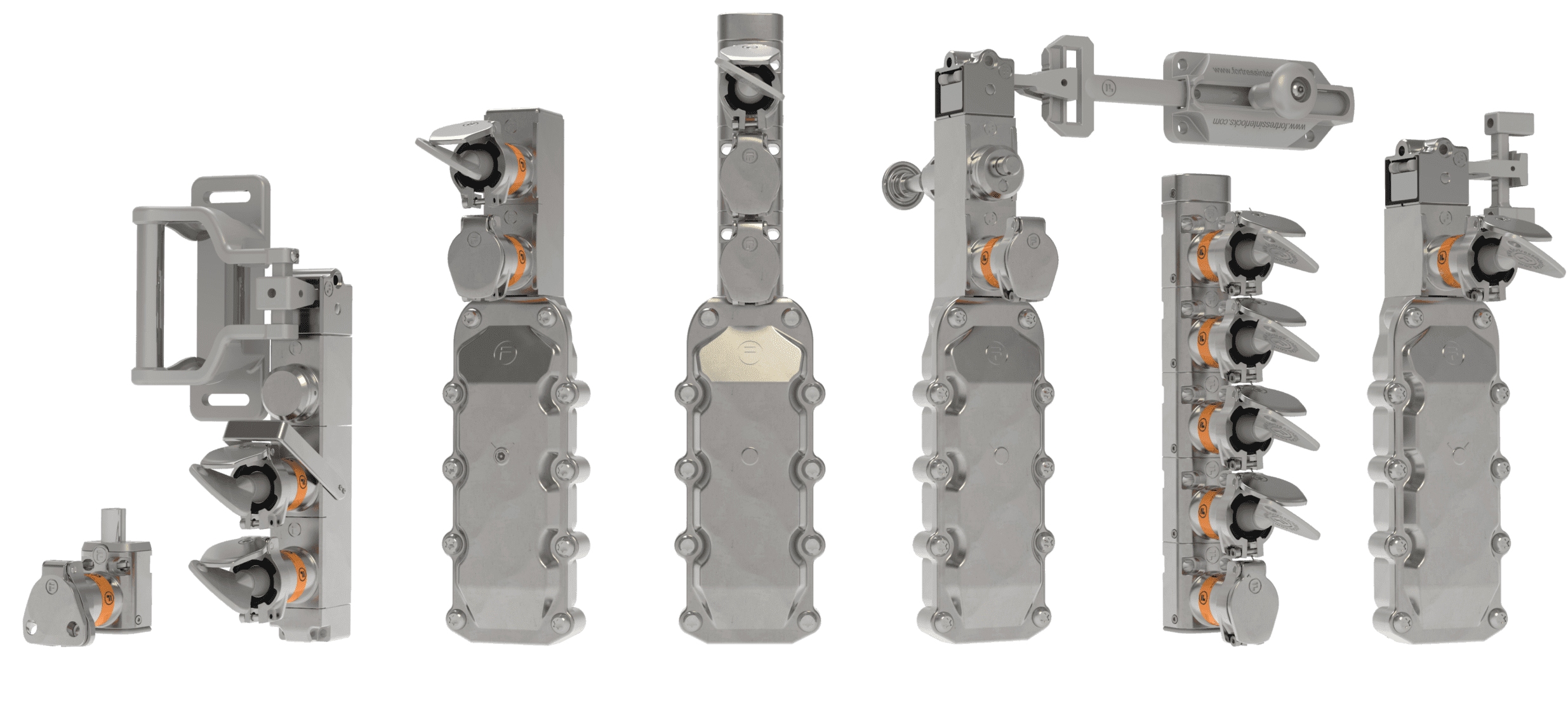

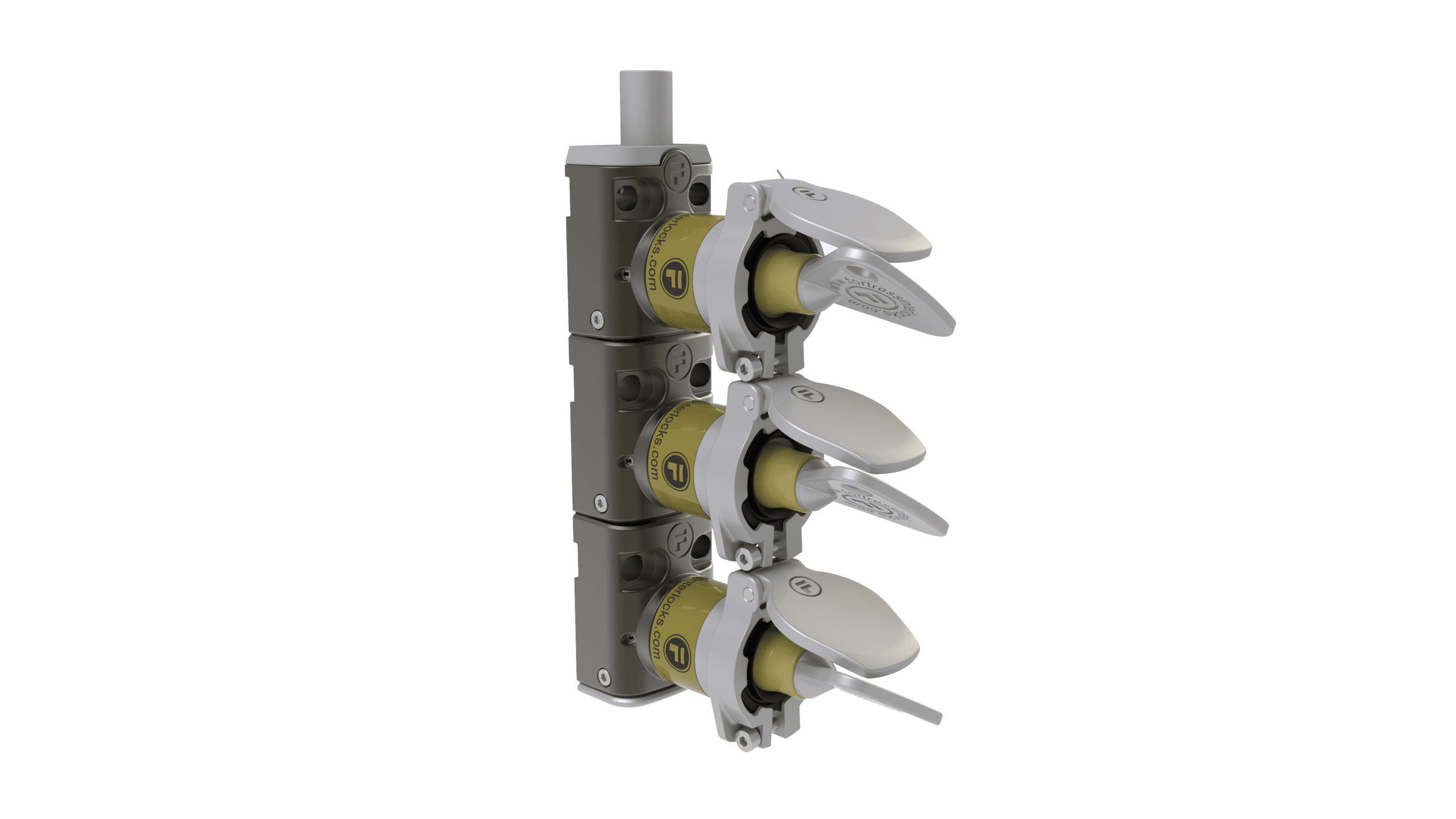

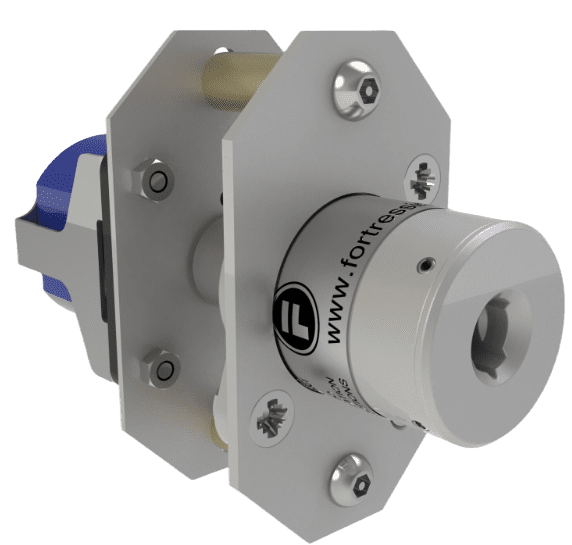

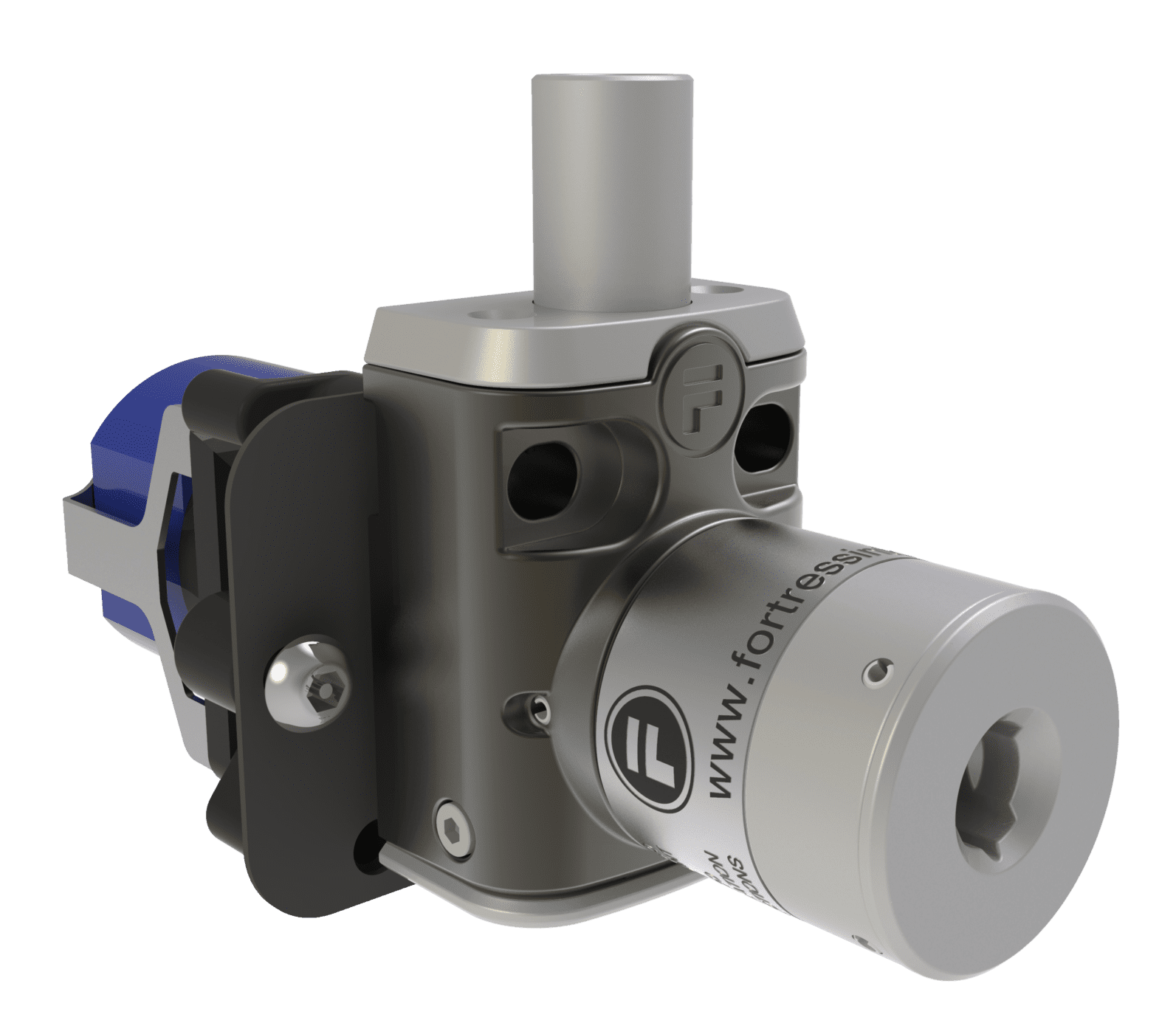

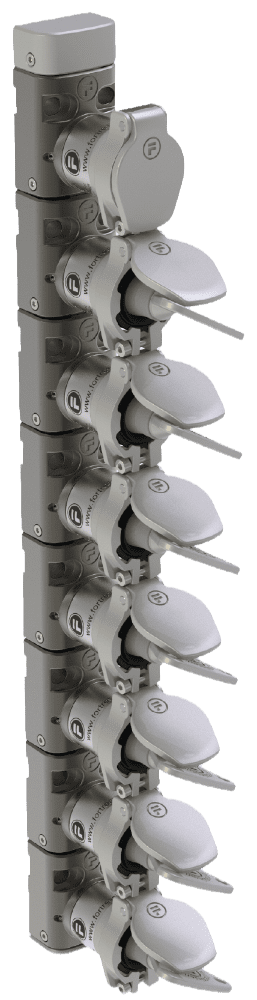

The only range of mechanical interlocks independently certified to PLe

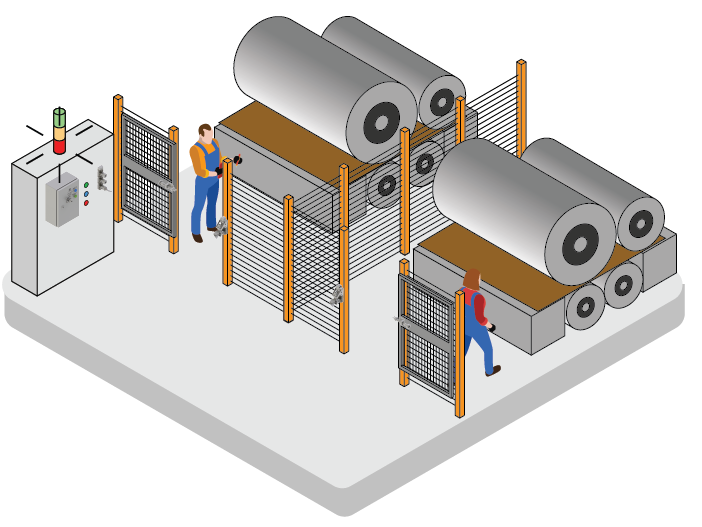

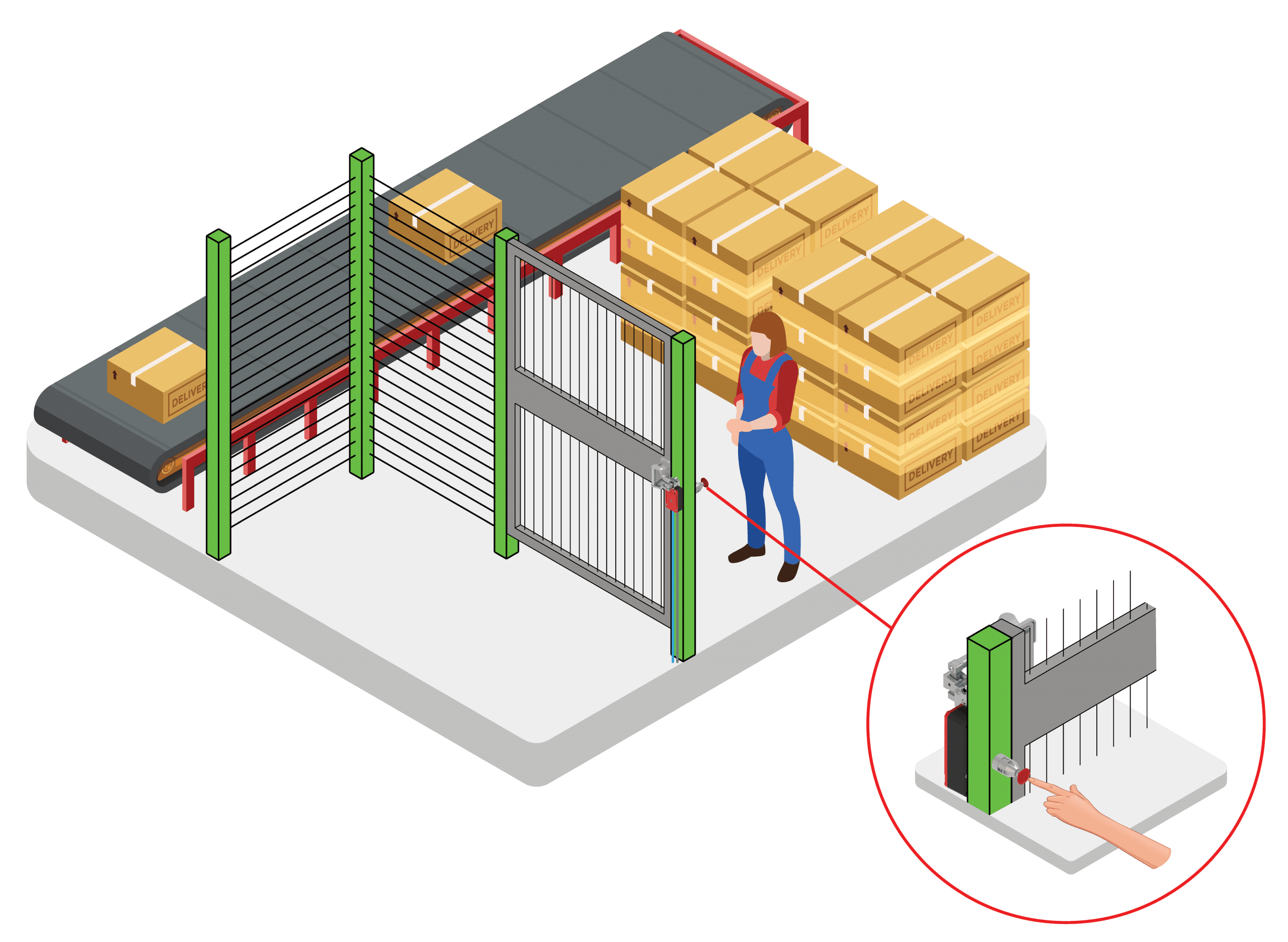

All Fortress product ranges therefore meet the requirements of control reliability with independent certification from TUV across all the ranges. Fortress’ mGard is the only range of mechanical interlocks independently certified to PLe applications.

Products Mentioned in this Article

mGard - Control Interlocking

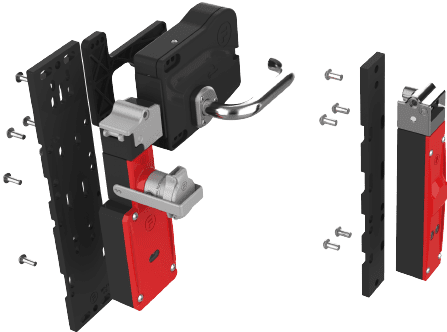

mGard - Interlocking with a mechanical bolt

Click Here to Download Article

Click Here to Download Article