About Wood, Paper and Pulp and processing:

Production facilities in the Wood, Paper, and Pulp sector tend to be harsh environments that can be extremely dangerous without the appropriate safeguarding and access control procedures.

Machines on the wet side of production are subject to a lot of residue that can cause blockages and damage to mechanical parts if routine maintenance is not carried out. This often means fast but safe access is critical to reduce downtime.

The dry side of production involves multiple access points and many hazardous moving parts, which can cause serious injury if the correct risk reduction measures are not implemented.

Why Fortress products are perfect in Paper, Pulp, and Saw applications:

The highest level of safety

Our interlocks meet the highest level of safety. Many of our interlocks are certified independently by TUV to PLe. Our amGardpro range is even rated to PLe for guard locking, so there is no need to fit two interlocks on gates as amGardpro is so strong that one is enough.

Our customisability ensures you can create an application which meets your exact safety requirements to ensure your people get the highest level of protection. Talk to our safety experts to help you navigate complex safety standards and ensure your people get the best possible protection.

Key Wood, Paper and Pulp Applications

The wet end of paper production can be very harsh on all equipment used in the area, using unsuitable equipment frequently cause downtime and, in the worst cases, unsafe conditions.

Fortress has IP69 rated, corrosion-resistant solutions for the harshest of environments allowing safe access and control of processes and peace of mind to operators.

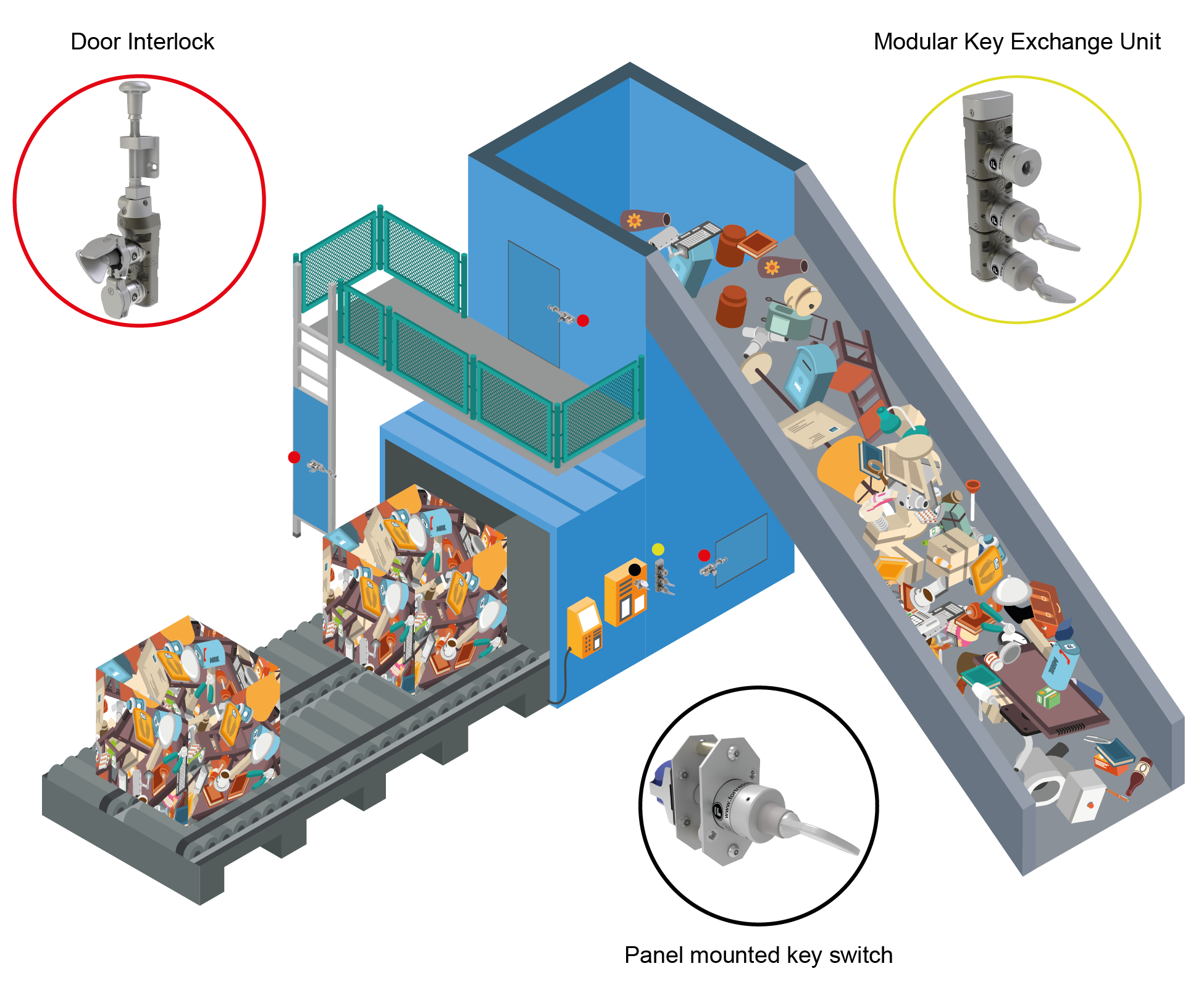

Baling presses are used in the recycling industry to compress and then bale paper and card for transportation. These machines are incredibly dangerous but access is sometimes required to clear jams and perform routine maintenance. EN 16500 and EN 16252 give safety requirements for Vertical and Horizontal Baling Presses respectively.

Fortress’ robust trapped key interlocks are an ideal and well used solution to meet the requirements of these standards and ensure the safety of operators working on these machines.

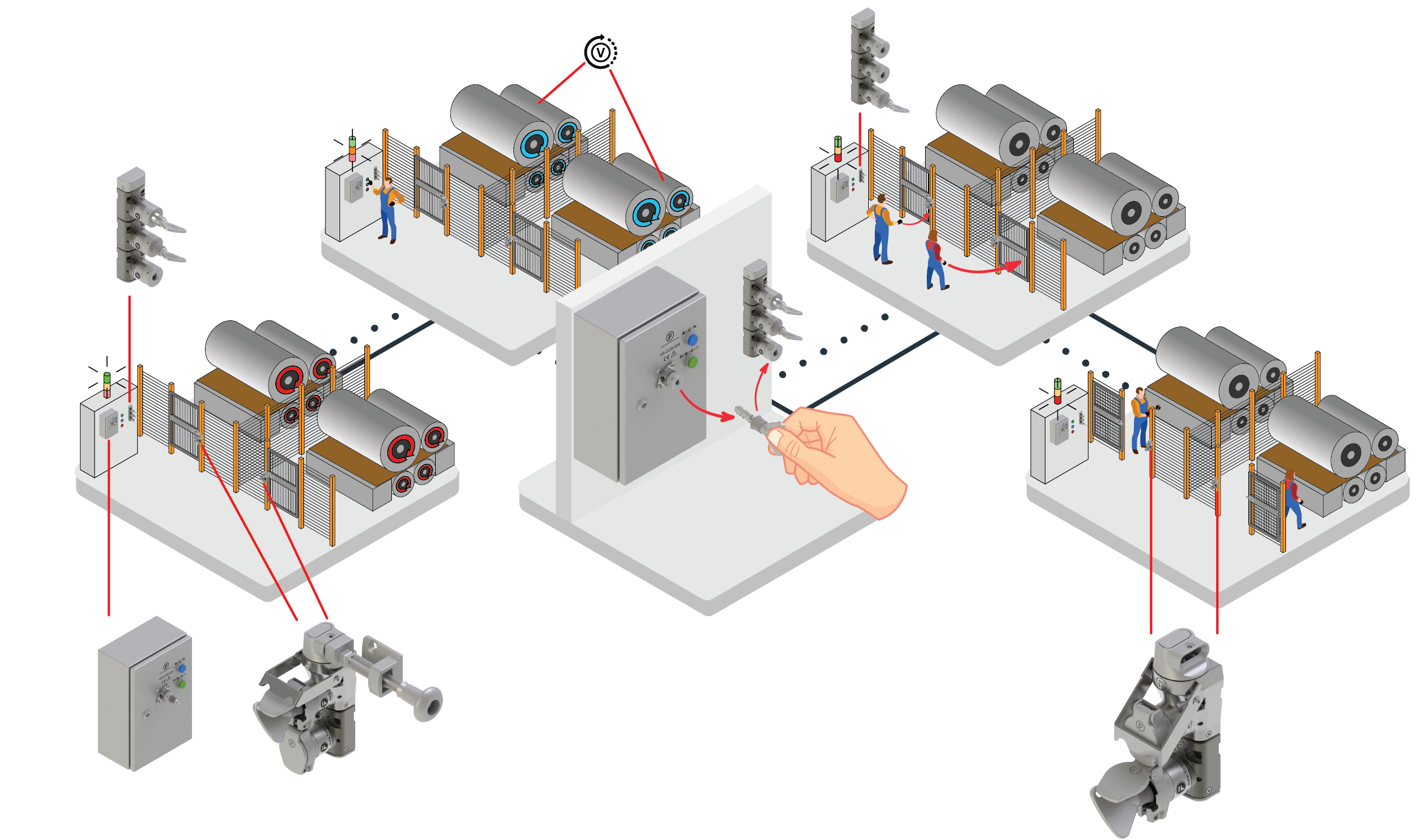

Paper manufacturing lines often cover vast spaces with long distances between control panels and access doors. This can lead to prohibitively high costs of wiring and reduction in control functionality at each access point.

Fortress offers tailored solutions for control and safe access with minimal electrical installation by having over a single industrial ethernet connection.

Frequent access to machinery in paper making is crucial during normal operation. The size of machinery and visible obstacles present inside safeguarded spaces mean operators can be hidden at times whilst performing whole body access. Inhibit functions are needed to ensure restart of machinery is not successful until operators safely leave this area.

Fortress offers tailored solutions to integrate proactive inhibit functions to prevent unexpected restart whilst performing whole body access. The Fortress safety key can be designed into all heavy duty solutions. Read the case study below to learn more.

Learn more about the safety standards, and watch the Fortress Webinar for the Wood, Paper and Pulp sector.

Other Fortress Wood, Paper and Pulp Applications

We are experts in providing safety solutions for automation

Contact us for tailor guidance and solutions for your machinery safety applications.

🔒 Webinar

🔒 Webinar