When Completing A Risk Assessment – How Do I Prioritise Risk Reduction Measures?

ANSI B11.0 – 2015 Safety of Machinery. B11.0 from the American National Standards Institute provides the particularly useful ‘Hazard Control Hierarchy’ shown in the table below.

Risk Assessment

You will be performing risk assessments every day. As we go about our daily lives, we identify hazards and the risks associated. Without realising it, we complete a dynamic risk assessment every time we cross the street as we check whether cars are coming and make the decision to proceed or not.

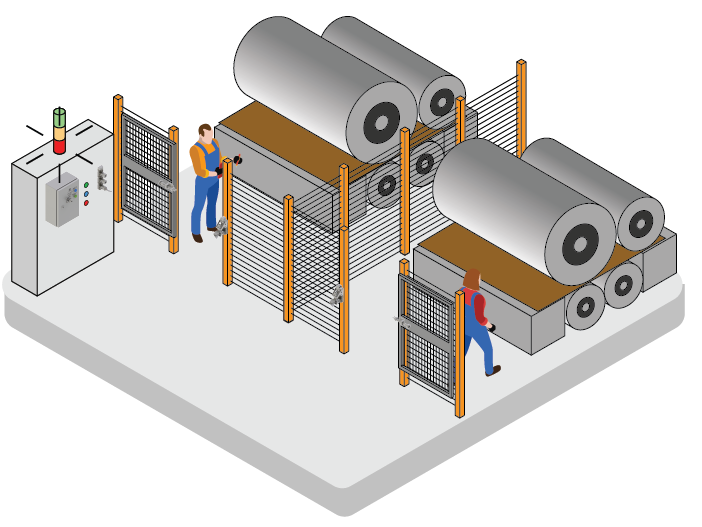

Stop lights are a welcome risk reduction measure. When it comes to the workplace, risk assessments suddenly appear to be more complex. However, useful risk assessment guidance is available for machinery safety via the use of available standards documentation.

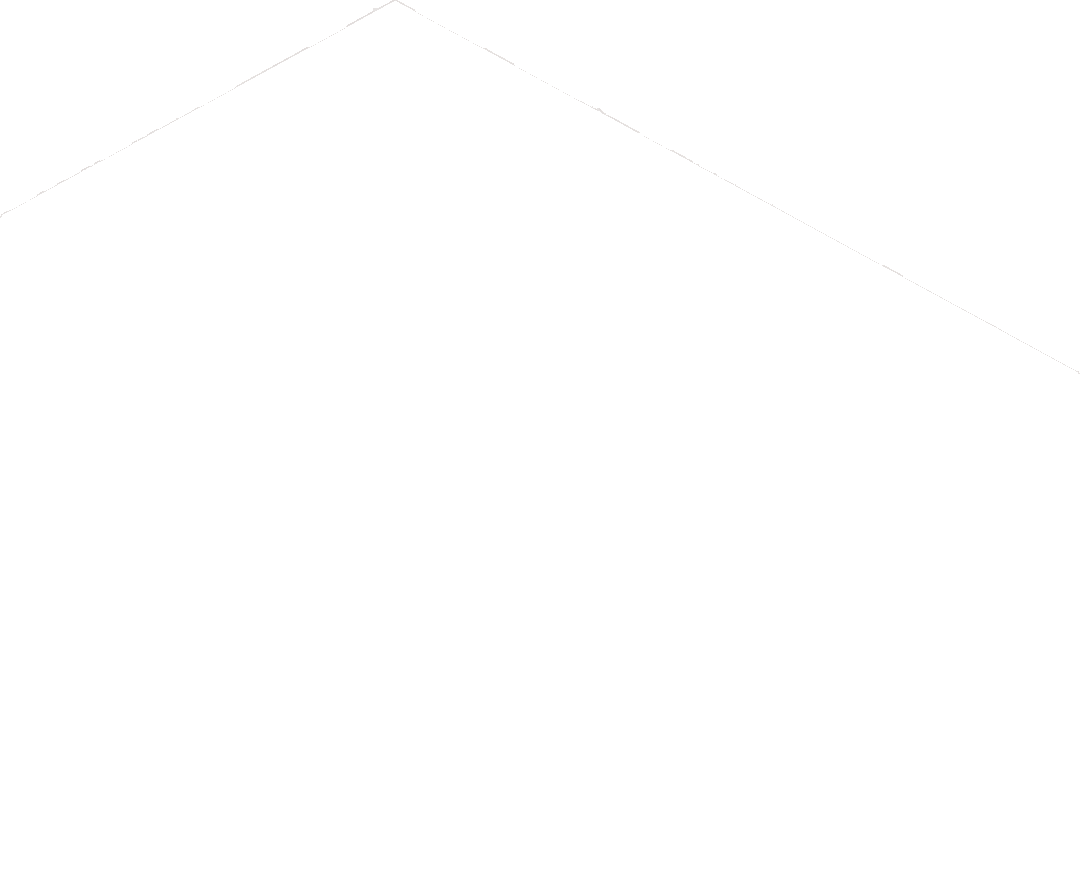

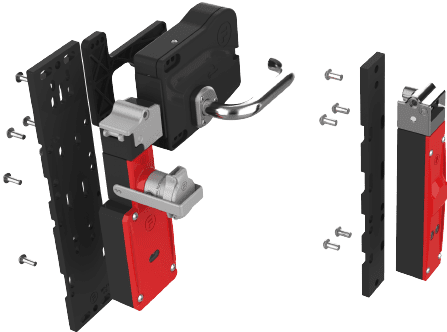

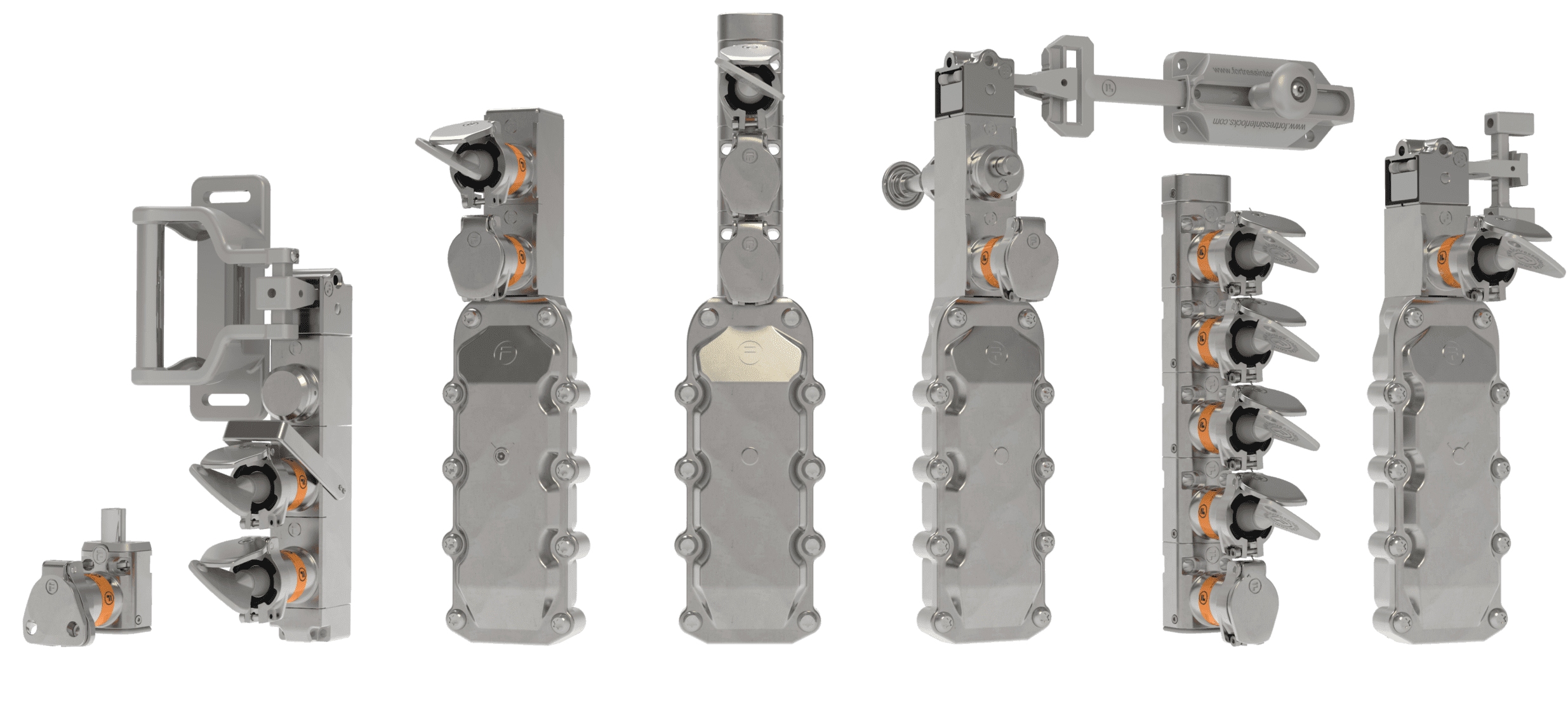

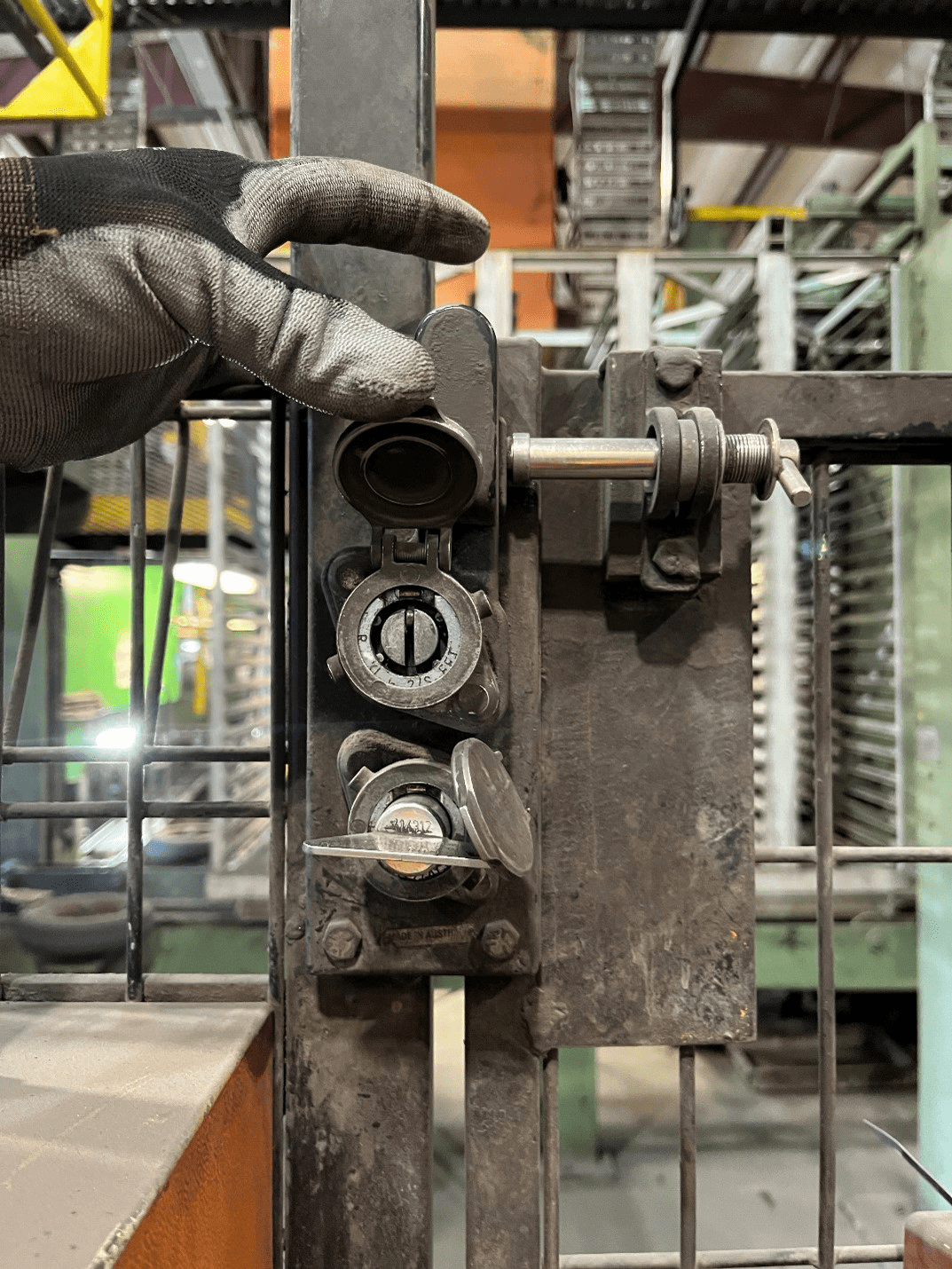

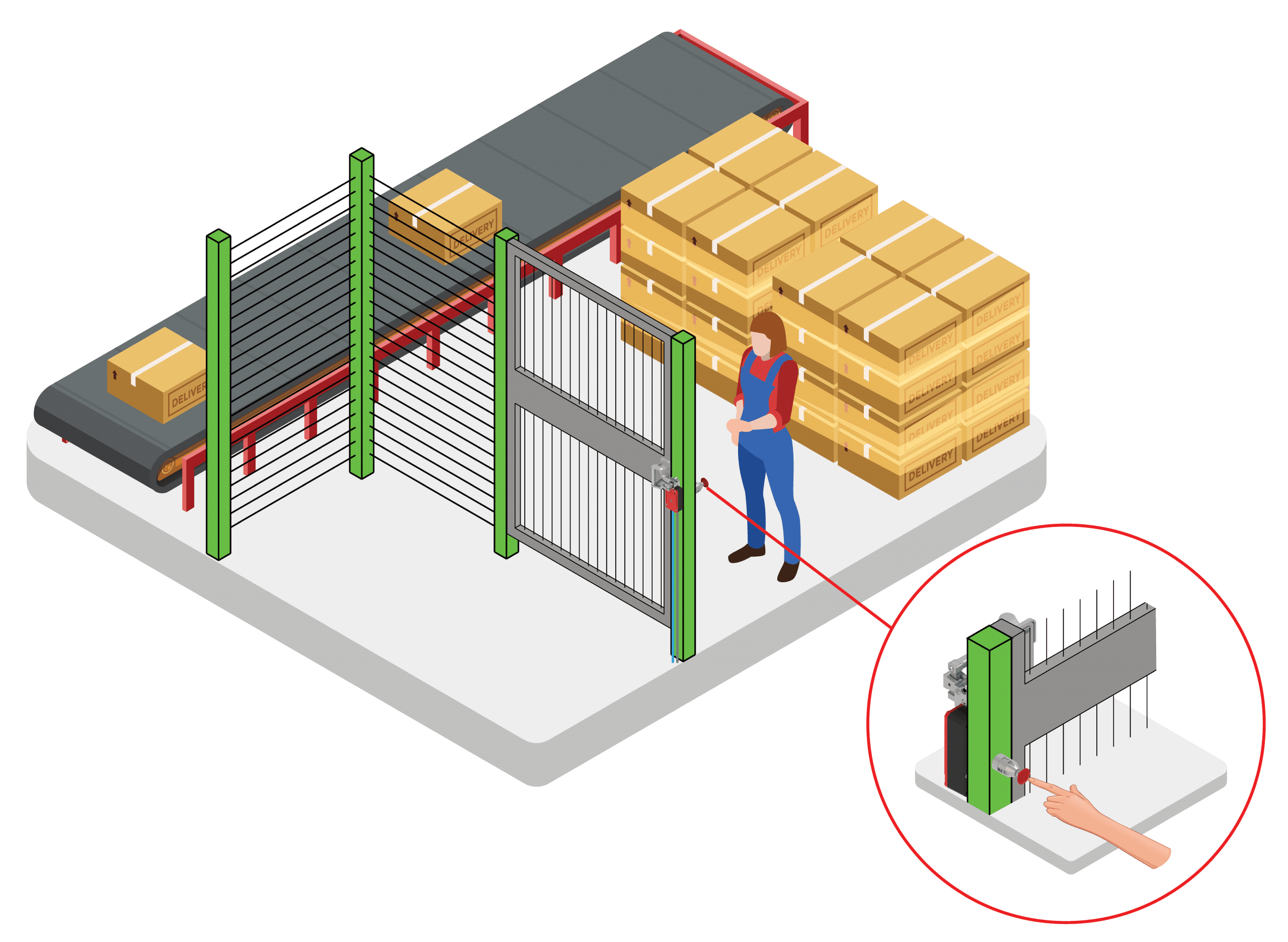

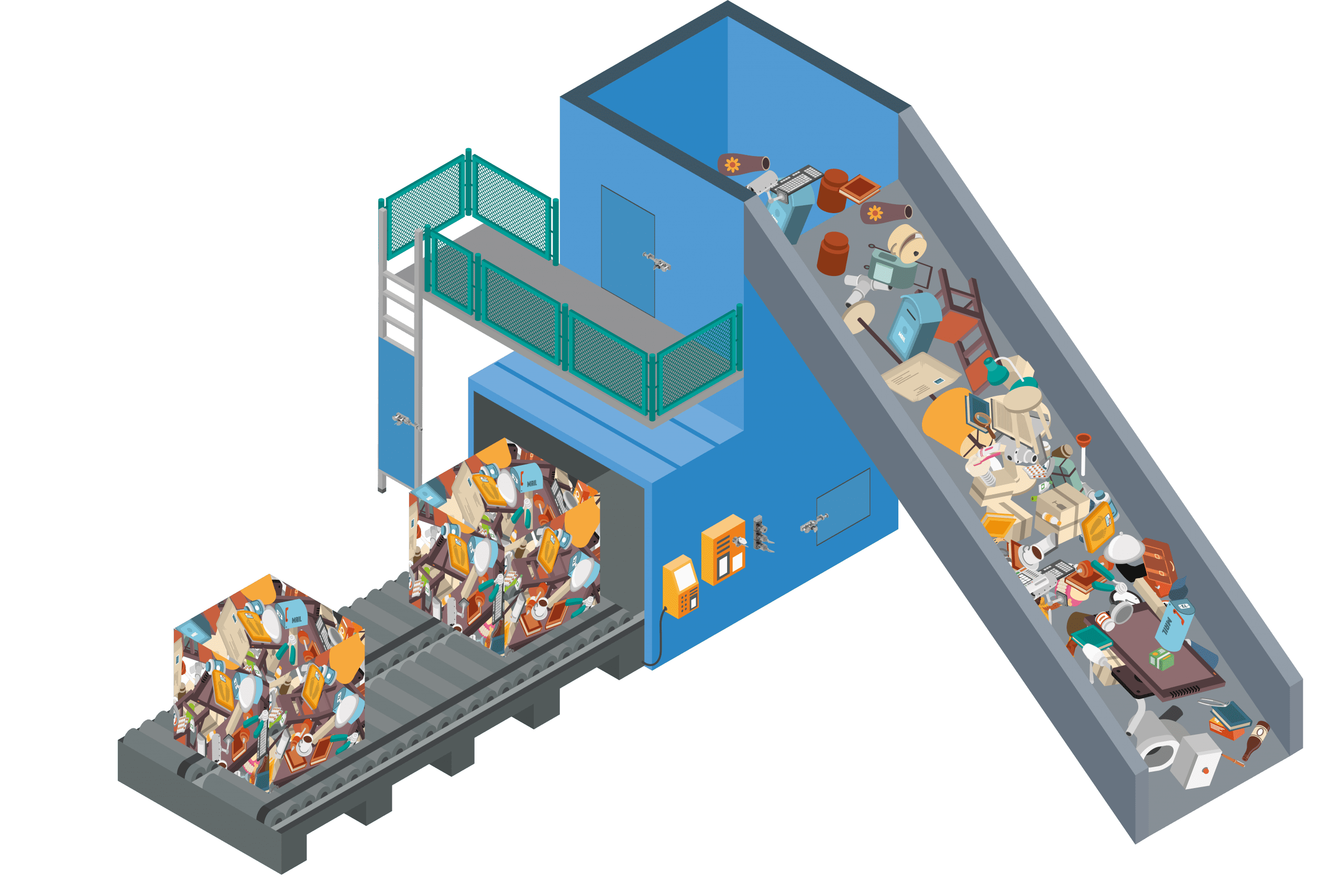

It’s worth remembering that when it is not possible to eliminate risk through design, Engineering Controls including interlocks become the “preferred” method of risk reduction as they can greatly reduce the probability of harm occurring. Training, Lockout Tagout (LOTO), and Personal Protective Equipment (PPE) are lower in the hierarchy as they rely on people remembering and following procedures.

Fortress offers training on machinery safety standards specific to the United States which can be delivered at a customer’s facility.

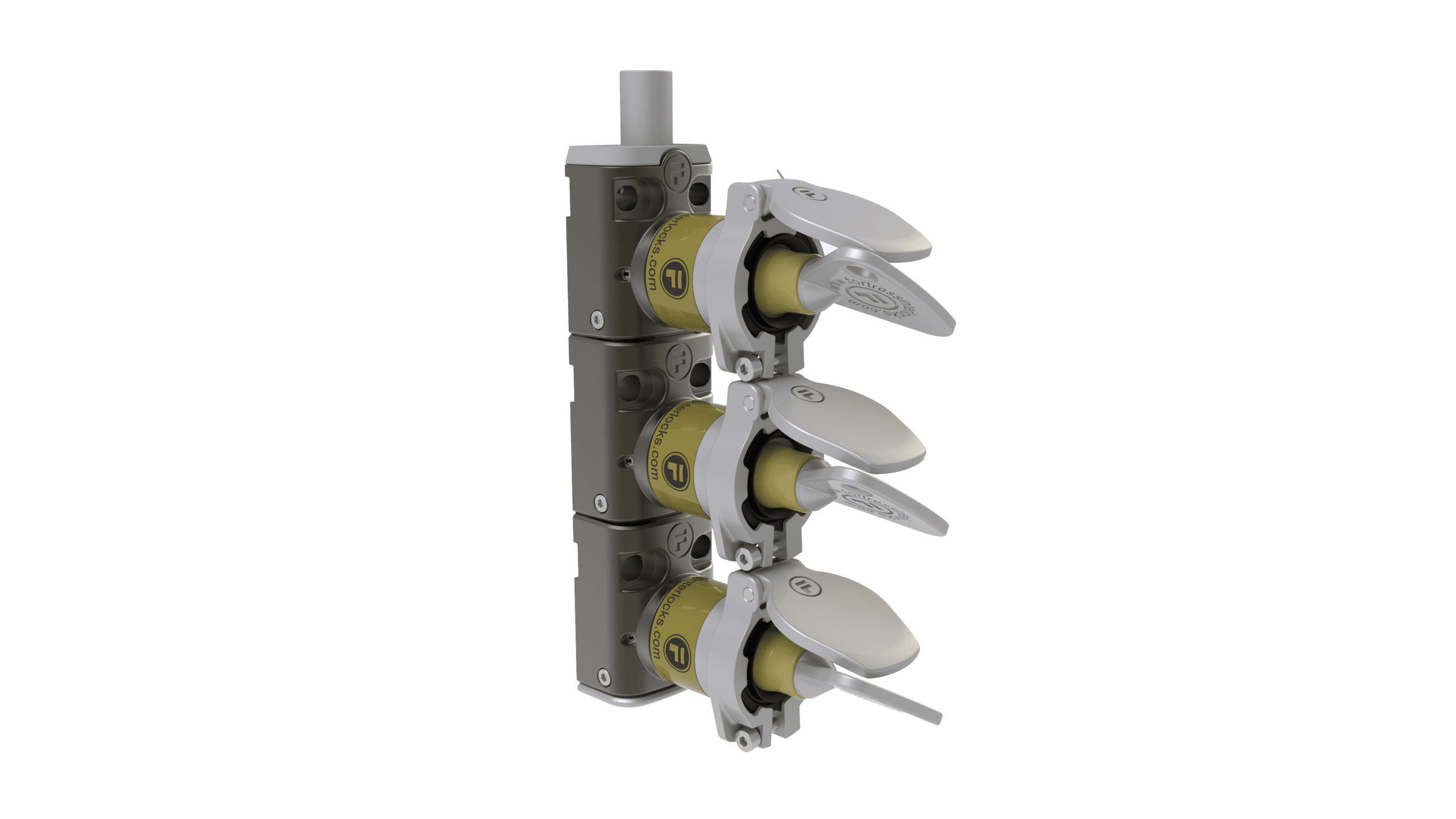

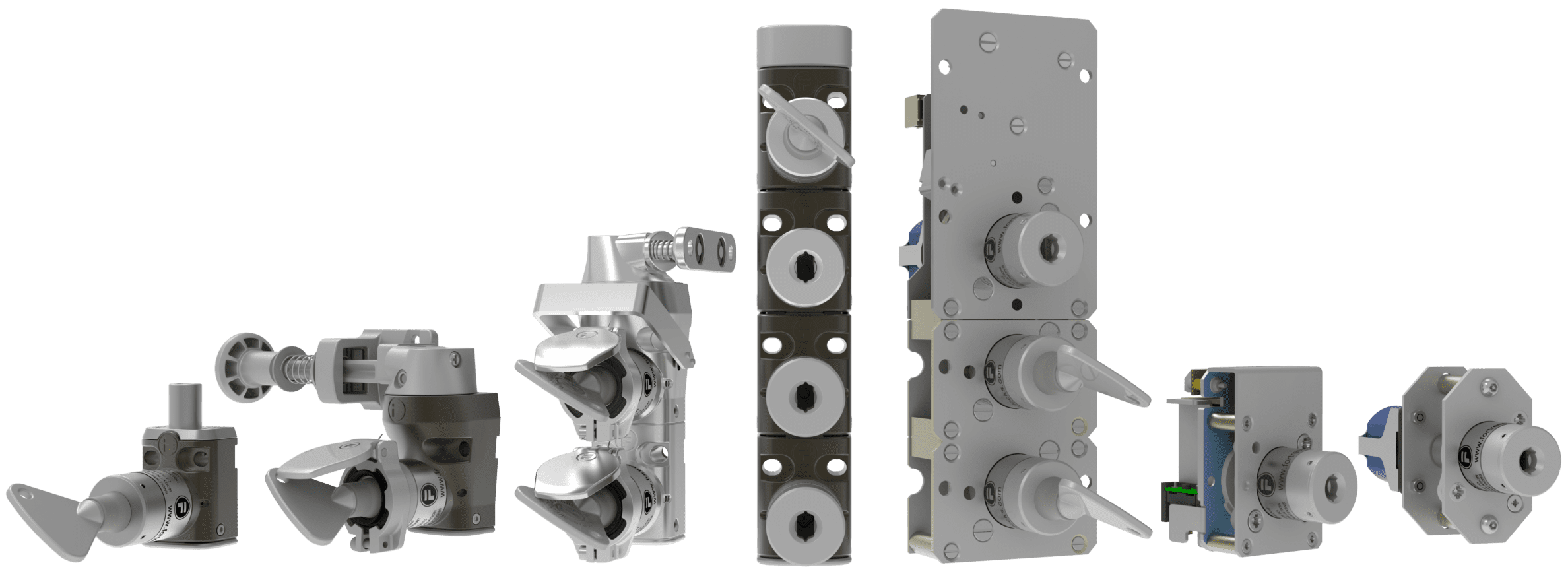

Products Mentioned in this Article

amGardpro

Click Here to Download Article

Click Here to Download Article