About Food and Beverage processing:

Harsh washdown procedures cause heavy wear on safety devices and eventual breakage. Such breakages cause costly amounts of downtime as the machine can no longer be safely accessed. Chemical and hot water washdown is the biggest challenge for industrial equipment so using heavy duty products is critical.

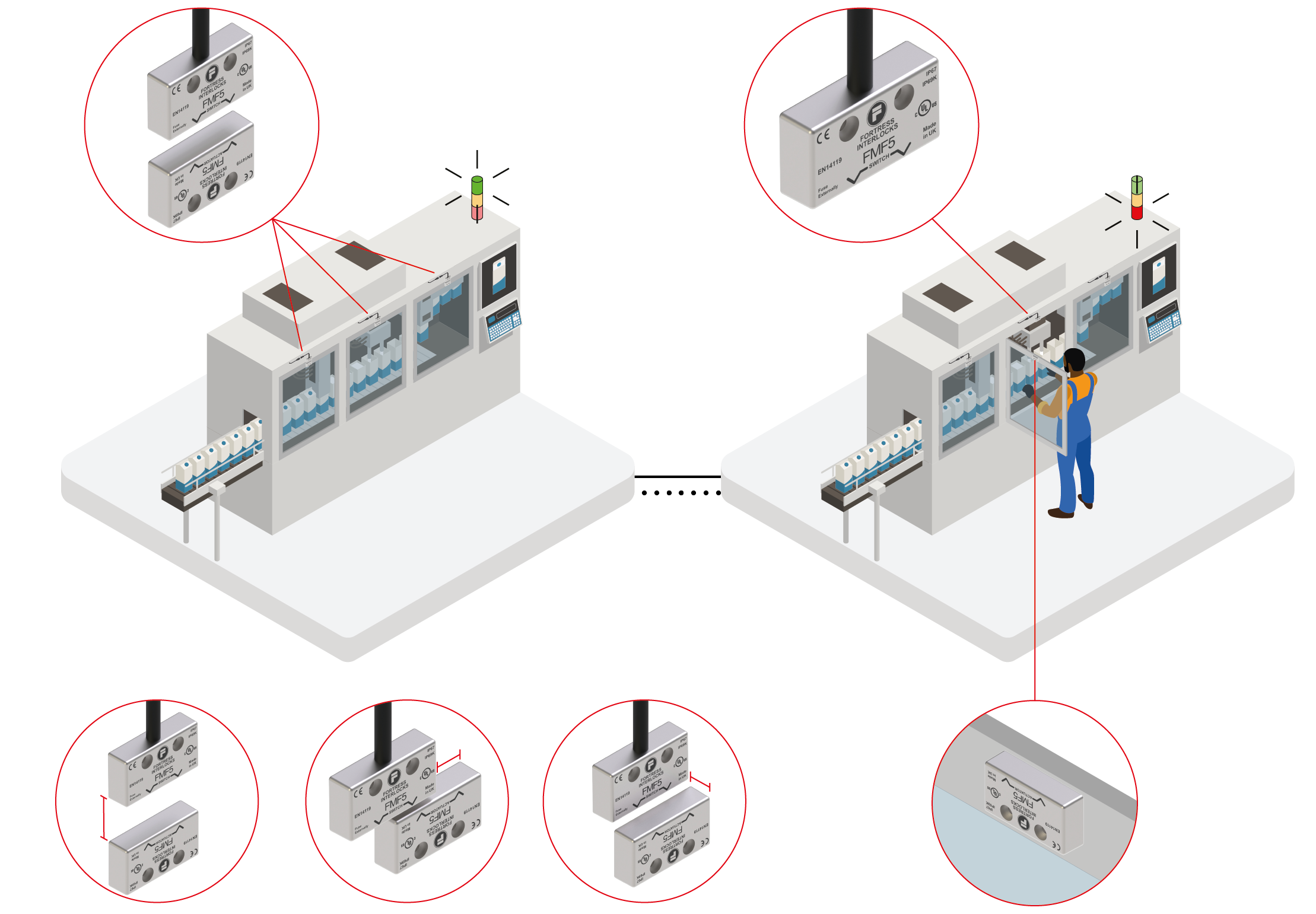

In the Food & Beverage industry, machines with dangerous moving parts can have long rundown times that could easily cause injury to personnel without the appropriate safeguarding and access control devices in place with devices approved for guard locking up to PLe.

Additionally, large machines require many access points where maintenance personnel cannot be seen, posing the risk of unexpected restart. Similarly, confined spaces such as vats and mixing silos can pose a risk to any personnel attempting to enter them.

Why Fortress products are perfect for the Food and Beverage industry:

The highest level of safety

Our interlocks meet the highest level of safety. Many of our interlocks are certified independently by TUV to PLe. Our amGardpro range is even rated to PLe for guard locking, so there is no need to fit two interlocks on gates as amGardpro is so strong that one is enough.

Our customisability ensures you can create an application which meets your exact safety requirements to ensure your people get the highest level of protection. Talk to our safety experts to help you navigate complex safety standards and ensure your people get the best possible protection.

Key Food and Beverage Applications

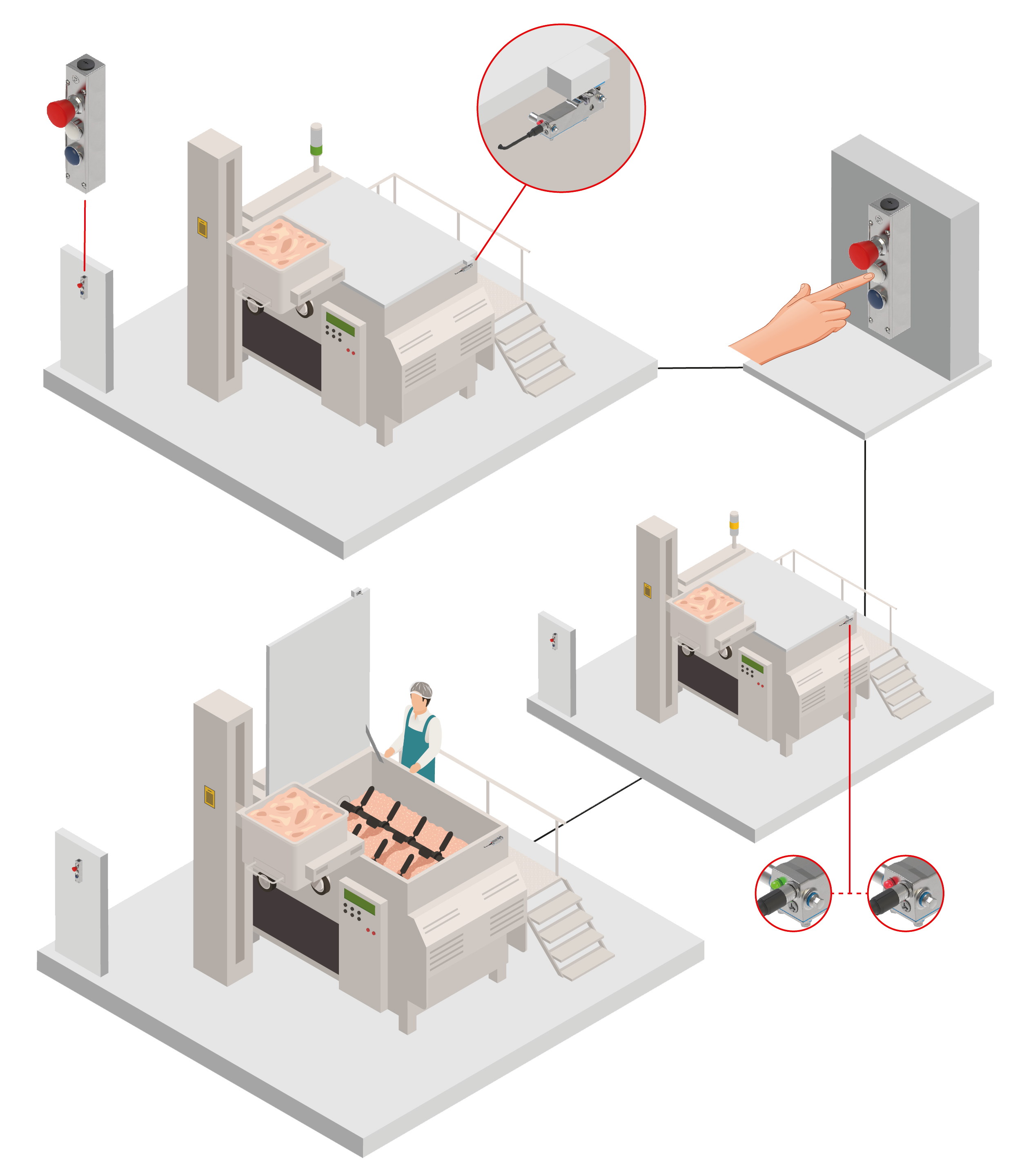

Food mixers must be frequently cleaned to meet rigorous food hygiene requirements but their rotating paddles or blades which may not stop immediately on powering down meaning they remain dangerous for some time.

Fortress has an IP69 rated, A3 approved guard locking solution designed to be used in a washdown environment, keeping the mixer locked closed until it is safe to open.

It is common to place machine control outside of the washdown area to prevent failures caused by frequent contact with water and cleaning agents. This can lead to inefficiencies and even dangerous situations in the case of emergency stop buttons not being available close to the hazard.

Fortress has stainless steel IP69 rated, configurable control stations suitable to be used in a washdown environment available with a variety of buttons, lamps and emergency stop devices.

Non-contact interlocks are often preferred in food and beverage applications due to ease of cleaning, but hygeinic washing equipment can have high levels of vibration which is known to cause nuisance trips in these devices.

Fortress has stainless steel non-contact interlocks with industry leading misalignment to prevent nuisance trips during the machine process while still keeping operators safe when the doors are opened.

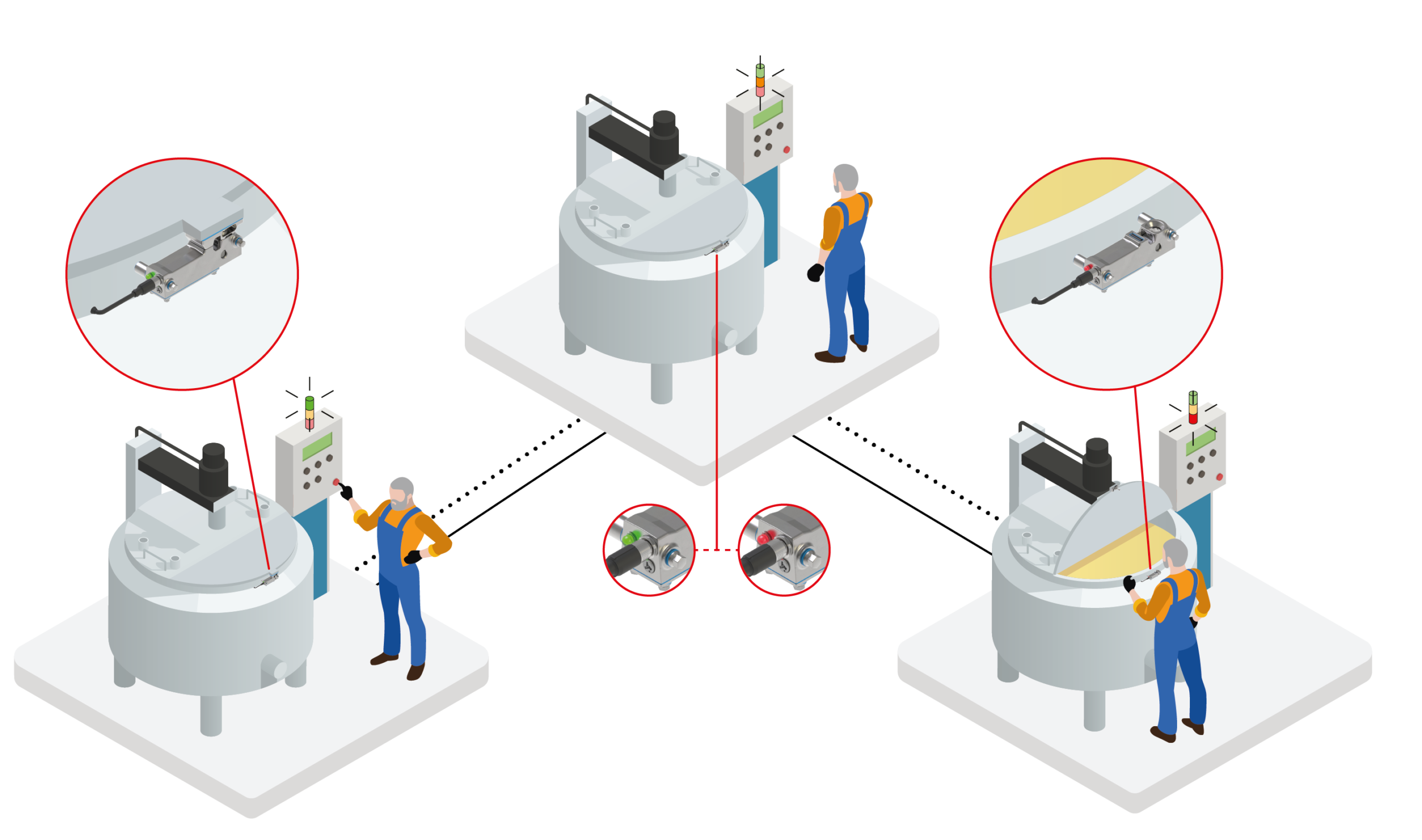

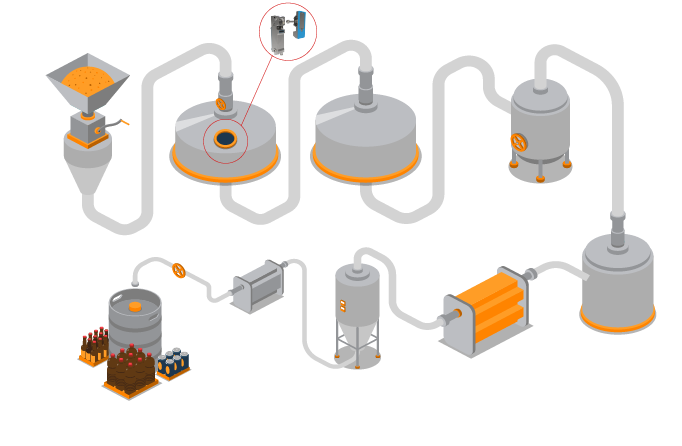

In distilling and brewing there are a number of different power sources to be considered before safe access to the mash tun is possible. Not only does the electrical power and pneumatic power need to be isolated but access also needs to be restricted until the temperature has reached a safe level.

Fortress has isolation devices for electrical, pneumatic and hydraulic power which can then be incorporated in a trapped key system to prevent access until all power sources are isolated and a safe monitor or timer indicates it is safe to enter the area.

Learn more about the safety standards, and watch the Fortress Webinar for the Food & Beverage sector.

Other Hygienic and washdown applications

We are experts in providing safety solutions for automation

Contact us for tailor guidance and solutions for your machinery safety applications

Login to Watch the Food & Beverage Sector Here

Login to Watch the Food & Beverage Sector Here