About metal production and processing

From pouring molten metal to huge rolling machines metal plants are very dangerous places. These facilities require extremely heavy-duty equipment which can resist the hot, oily, acidic and galvanic environment. Huge machines mean that safety systems are complex and difficult to manage on sites which span over several miles so wiring costs can be high.

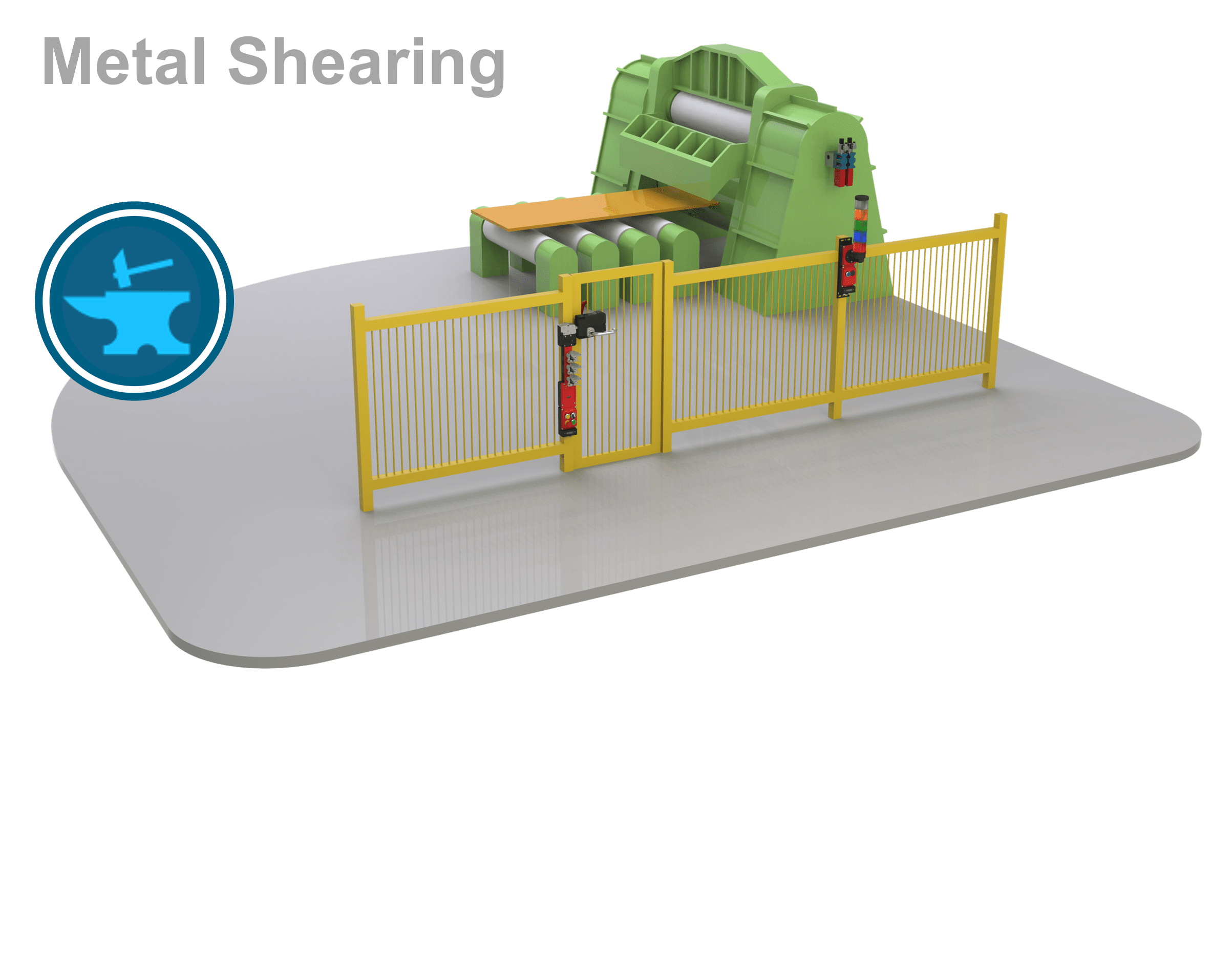

Highly automated forming machines cause huge safeguarded spaces where presence sensing is complex to install, putting personnel in danger unless specialist access control devices are installed.

Why Fortress products are perfect in metallurgy:

Key Metal Industry Applications

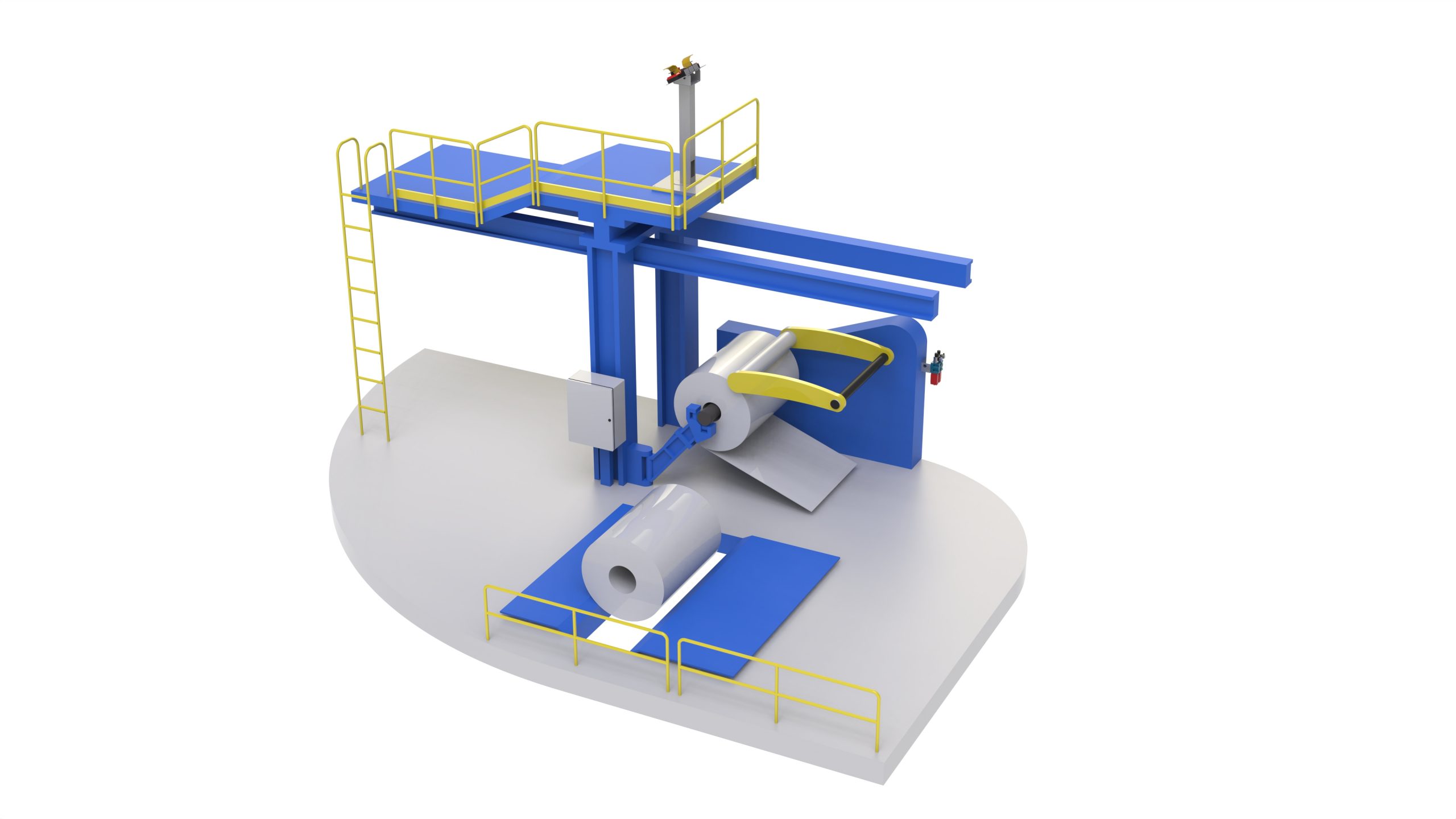

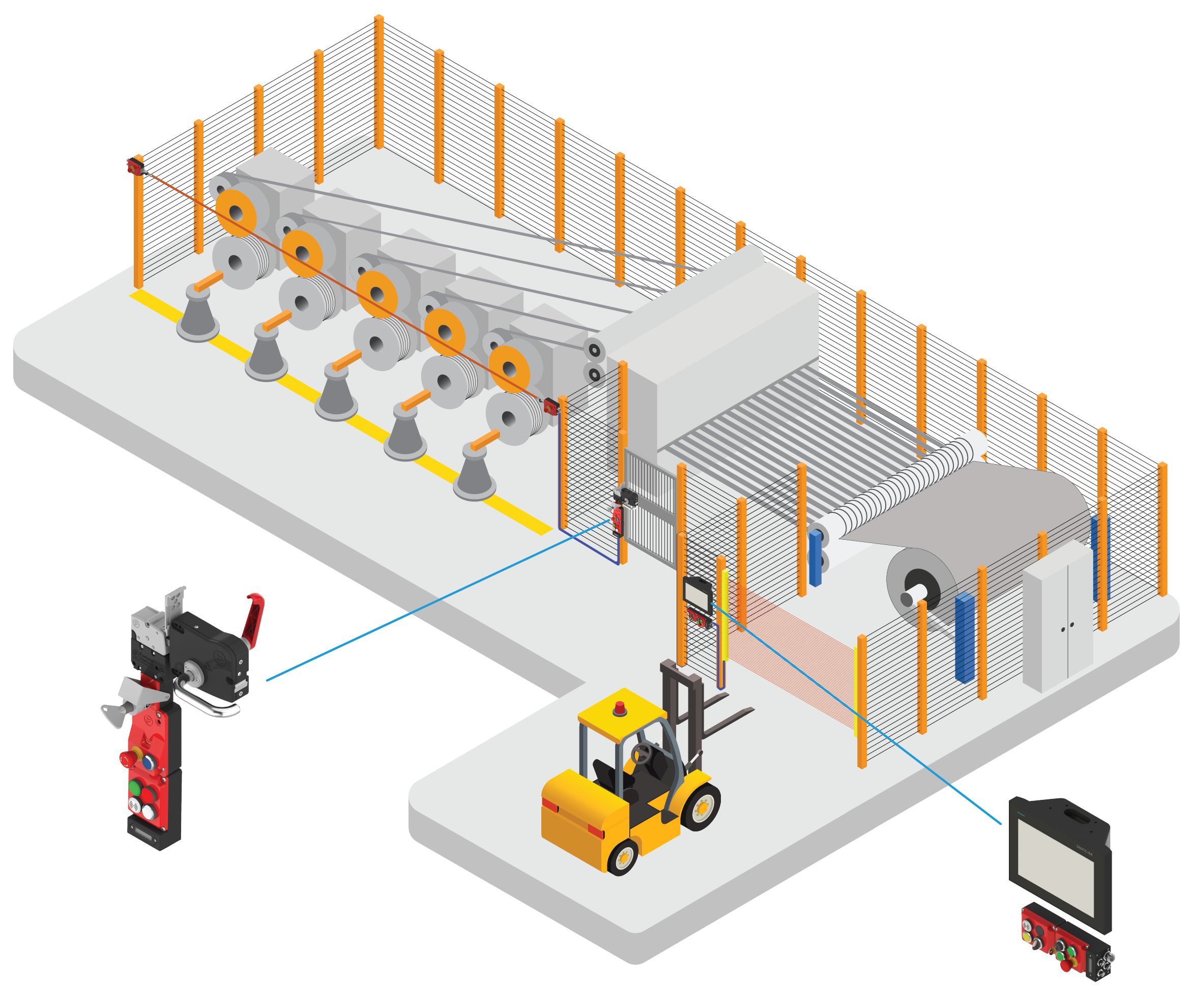

Metal processing lines often cover vast spaces with long distances between control panels and access doors. This can lead to prohibitively high costs of wiring and reduction in control functionality at each access point.

Fortress offers tailored solutions for control and safe access with minimal electrical installation by having over a single industrial ethernet connection.

Slitting lines can be highly dangerous pieces of machinery, however operators may require whole body access into the safeguarded space to carry out maintenance, troubleshooting or cleaning operations. While anyone is inside it’s essential that the machine is not able to be restarted, on large machinery it may not be possible to see operators from the reset location so a proactive inhibit function will give them personal control.

Fortress has the option to add a forced extraction safety key to our range of robust gate interlocks, the operator must take this key to gain entry and the machine is prevented from reset and restart until it is returned, giving individual control and peace of mind to the operator.

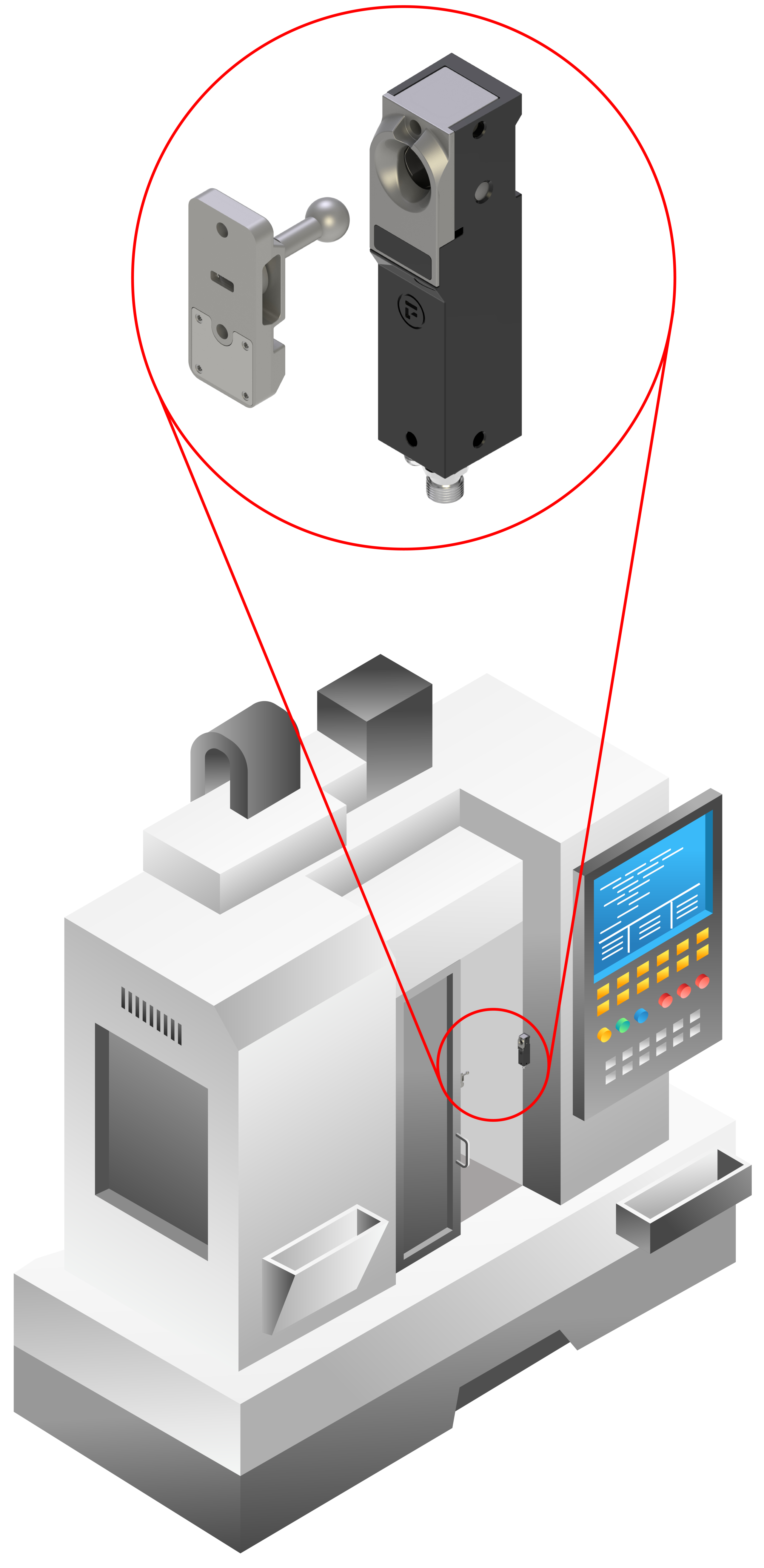

CNC machine centres have guarding in place to protect operators during operation, however for placing of parts and changing tooling access is required. Small doors and tight spaces can make it difficult to fit sufficiently robust interlocks with guard locking functionality. Operators often try to defeat interlocks to increase productivity but in doing so risk their own safety.

Fortress has compact guard locking devices, holding the guard locked during operation and allowing access after the cycle has completed and the machine is in a safe state. RFID actuator coding prevents defeat of the interlock.

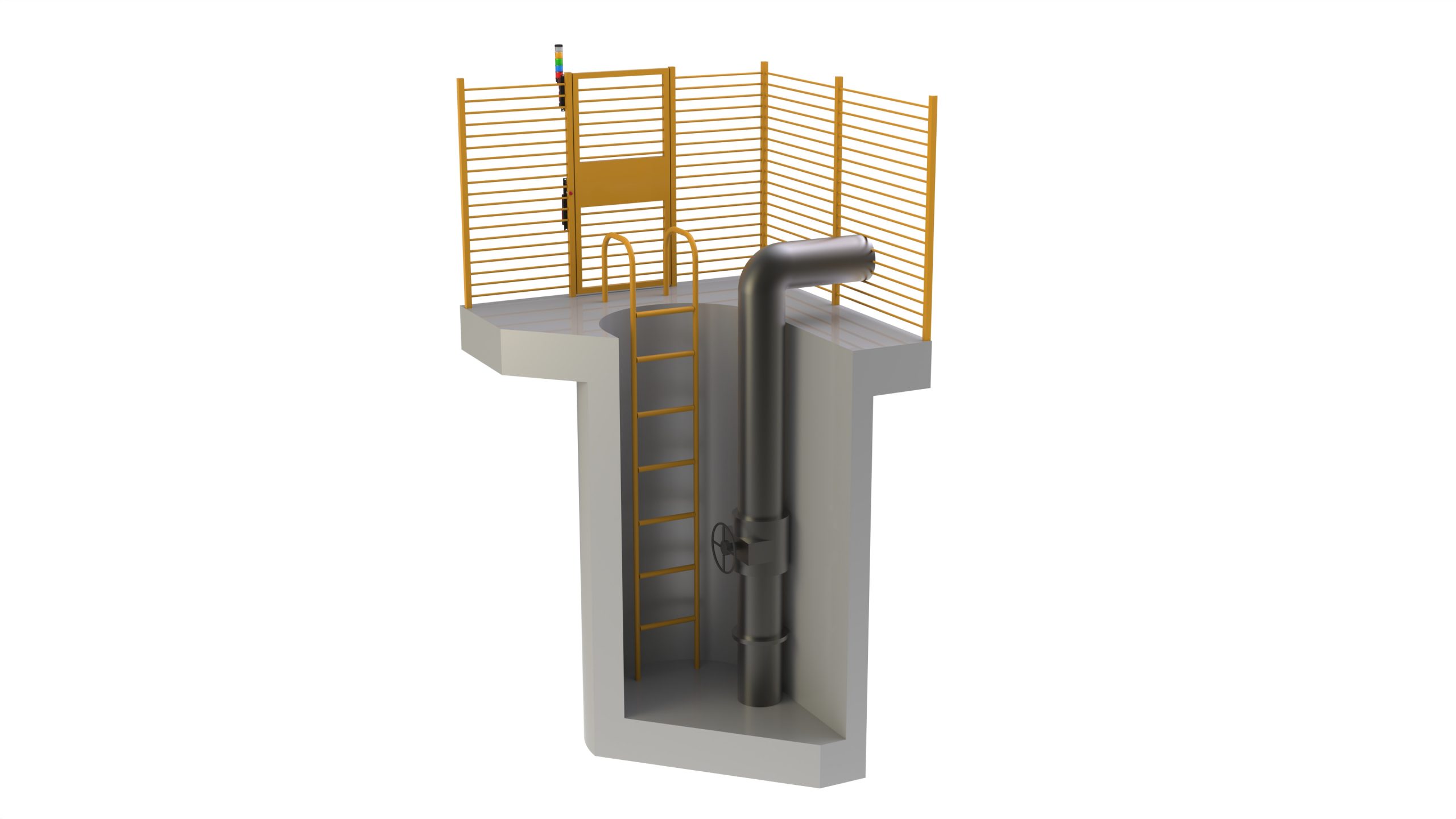

Hydraulic rams are often used to move material between functions on steel production lines, when access is required for maintenance the hydraulic power needs to be isolated. Full isolation of the hydraulic power results in unnecessary downtime in neighbouring zones, to maximise productivity safe access is required to individual zones.

Fortress has a hydraulic safety valves which are suitable for use in the highest risk applications (PLe, Category 4 and SIL3) to allow safe access to machinery powered by fluid power.

Learn more about the safety standards, and watch the Fortress Webinar for the Metals Production sector.

Other Fortress metal applications

We are experts in providing safety solutions for automation

Contact us for tailor guidance and solutions for your machinery safety applications.

Webinar

Webinar