What is proNet?

A network communication module developed by Fortress that allows amGardpro to communicate with the main industrial network protocols: EtherNet/IP, PROFINET and EtherCAT.

A proNet option pod can be configured as part of an amGardpro interlock, but also as standalone control station and connected to external devices.

Standard and safety I/O are communicated through a chosen protocol via a cable connected to the Fortress proNet device. Safety I/O is exchanged using PROFIsafe, CIP safety, or Safety over EtherCAT.

Main features of the network-enabled range

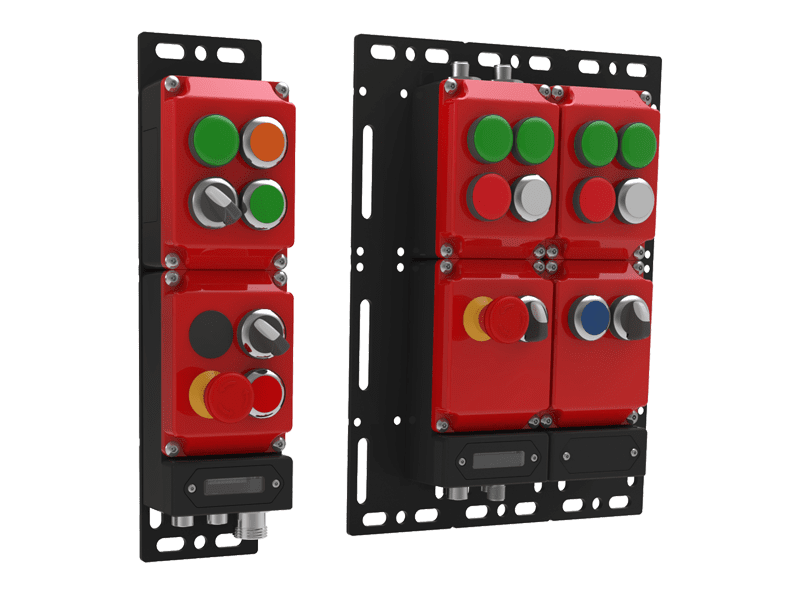

The highly configurable design of the networked product range allows you to piece together various elements. Pushbutton controls, integrated safety I/O (such as emergency stops, guard locking, and key monitoring), as well as connectors for external and distributed I/O, can be incorporated in a cost-efficient solution.

proNet also features:

✅ 3 Dual Channel Safety Inputs

✅ Up to 40 standard I/O per configuration (depending on the type of network protocol)

✅ An integrated network switch to facilitate ‘daisy-chain’ bus topologies with no additional hardware

✅ Diagnostic functions available via a web interface

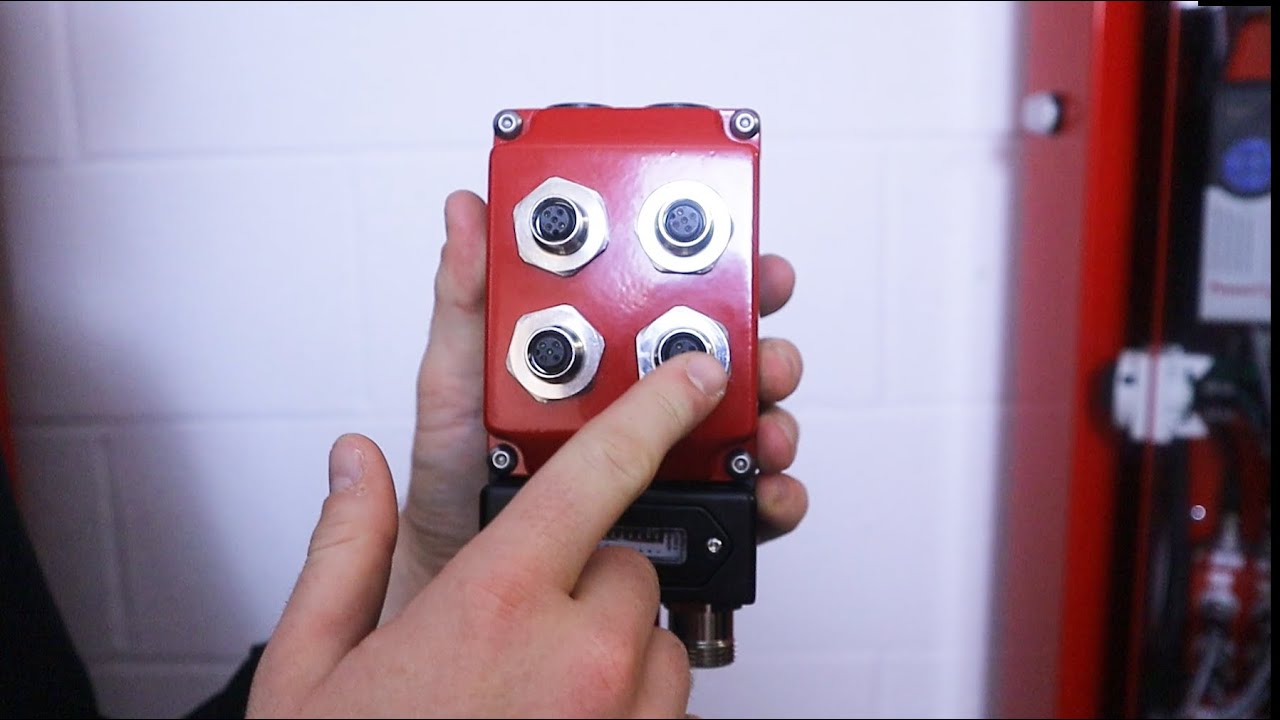

With multiple connector configurations available, units can be ordered with the respective mating cables in a variety of lengths.

Installation and validation can be performed at reduced time and cost compared to hardwired connections.

The three types of amGardpro products capable of network connectivity are interlocks, control stations, and I/O blocks modules.

Supplying Power and Data to the Networked Devices – Cabling Topologies

Fortress offers a variety of connector sets for network connection at no additional cost. Our application experts are always happy to help select the right solution for your application.

The connector set options available from Fortress are designed to suit line, ring, star, or tree topologies. See some examples below.

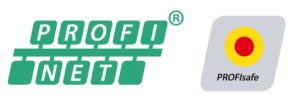

PLC – Programmable Logic Controller | PSU – Power Supply

Star or Tree Topology

The PF07 connector set is for standalone devices and utilises M12 connectors to link nodes via 4-pin D-coded Industrial Ethernet for Data Communication and 5-pin A-coded Male for Power.

(also available in 7/8″ connectors)

The PF17 connector set offer a 4-pin D-coded M12 Industrial Ethernet for Data Communication and 5-pin 7/8″ Male for Power, with a single internal power connection (pin 2 for 24V and pin 3 for 0V) (with earthing connection).

The PF13 connector set offer a 4-pin D-coded M12 Industrial Ethernet for Data Communication and 4-pin 7/8″ Male for Power, with a single internal power connection (Pin 2 for 24V and Pin 3 for 0V) (no earth).

Line or Ring Topology

The PF10 connector set utilises M12 connectors to link multiple devices via daisy-chain. The set includes two M12 D-coded Industrial Ethernet connectors for Data Communication and two 5-pin A-coded Male and Female connectors for Power.

(also available in 7/8″ connectors)

The PF11 connector set utilises 7/8″ 5-pin connectors to link multiple devices via daisy-chain. The set includes two M12 D-coded Industrial Ethernet connectors for Data Communication and Male and Female 5-pin 7/8″ connectors for Power (with earthing connection).

The PF14 connector set utilises 7/8″ 4-pin connectors to link multiple devices via daisy-chain. The set includes two M12 D-coded Industrial Ethernet connectors for Data Communication and Male and Female 4-pin 7/8″ connectors for Power (no earth).

Power over Ethernet

With Power over Ethernet (PoE) the power to the device is passed alongside data on Ethernet cabling via a single connector, with further reduction in cabling, setup complexity, and associated hardware costs.

Why choose Power over Ethernet (PoE)?

✅ No junction boxes. No dependency on local plug sockets for powering devices

✅ Reduced installation costs with a single cable connecting the networked solution to the logic controller

✅ Data communication and device power delivered simultaneously on a single cable

✅ Stable source of power from a single outlet to protect against power outages, potential equipment damage and electrical overload

✅ Flexibility to add and remove devices and adapt to changing environments without interruption

FRANK – Managing Permissions over Industrial Networks

Fortress has developed Fortress RFID Access Network Keys (FRANK). Using the employees’ existing RFID cards, the FRANK system allows the assignment of employee permissions, which can then be used to enforce conditions for machine operation or access.

Designed to work with amGardpro proNet devices, FRANK can be integrated into automation systems using network protocols to manage access control permissions. Click on the button below to find out more.

Explore our product videos

Hardwired vs Network Connection

What are the benefits of networked communication to the time and cost of installing your safety system?

Explore our product videos

What is FRANK?

This video showcases FRANK, our Industrial Access Control Solution.

Explore our product videos

On Machine I/O Blocks

Fortress’ I/O Blocks allow you to connect your hardwired safe and non-safe devices to an ethernet network and back to your PLC with minimal cabling.

Visit these pages to learn more

Need help?

Our team of experts is always available. Simply click on the button below to get in touch.