FAQ module

Machinery safety refers to the measures and practices implemented to ensure the safe operation of machinery and equipment. It involves identifying and mitigating potential hazards, implementing safety features, and establishing procedures to protect workers and prevent accidents or injuries.

Machinery safety is crucial because it helps protect workers and operators from hazards associated with operating machinery, which is first priority within any work space. A workplace with a strong focus on machinery safety demonstrates a commitment to the well-being of its employees. This fosters a positive work environment and enhances employee morale

Common hazards associated with machinery include entanglement, crushing, shearing, impact, falling objects etc. It’s essential to conduct thorough risk assessments, implement appropriate engineering controls and safeguards, provide adequate training, and adhere to relevant safety standards and regulations to mitigate these hazards and ensure a safe working environment around machinery.

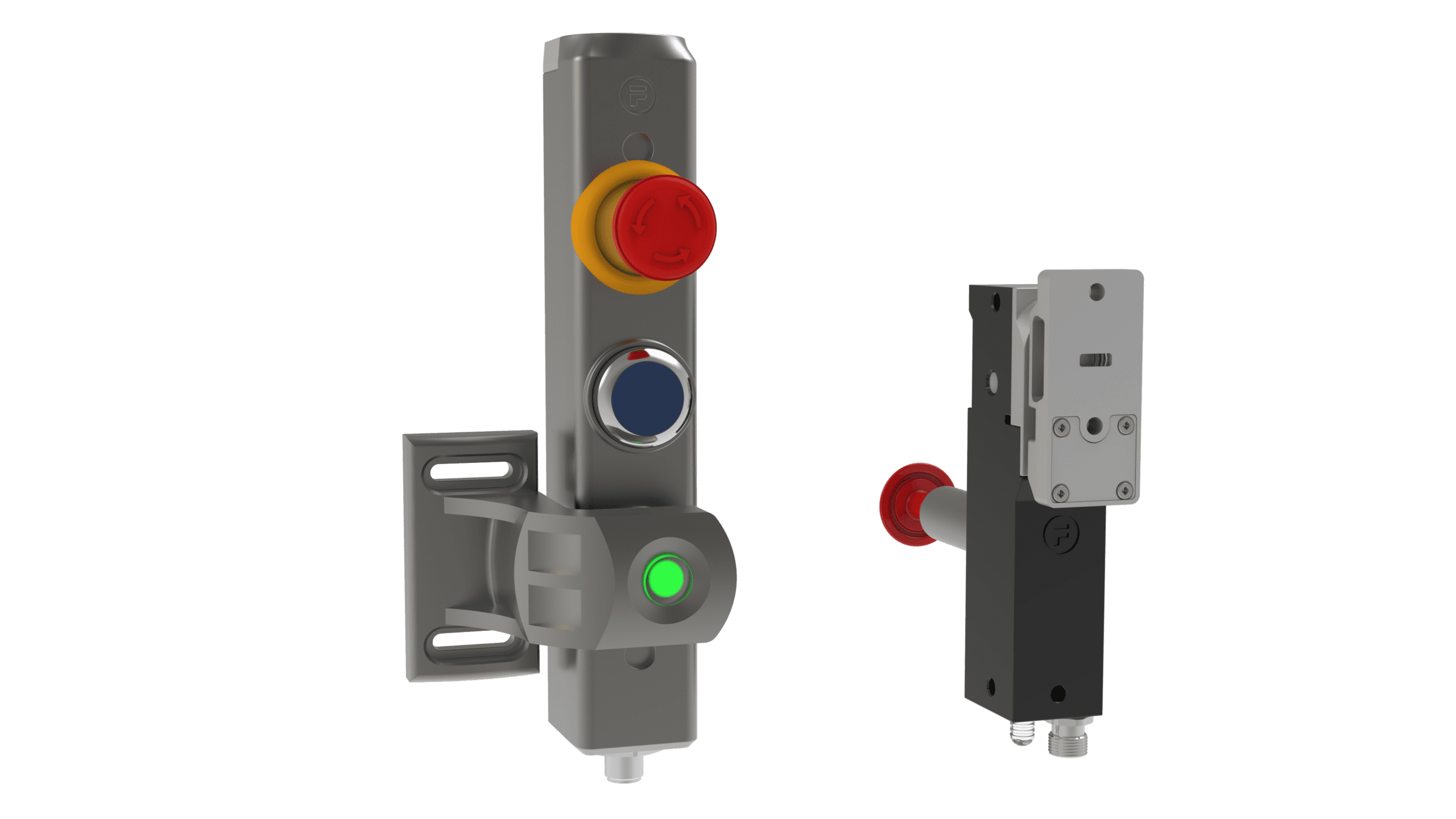

Here at Fortress, we design our products basing on the needs of the consumer. This involves designing out hazards where possible, implementing safeguarding measures like interlocks, guards, emergency stops, which provide clear and visible warning signs.

Common hazards associated with machinery include entanglement, crushing, shearing, impact, falling objects etc. It’s essential to conduct thorough risk assessments, implement appropriate engineering controls and safeguards, provide adequate training, and adhere to relevant safety standards and regulations to mitigate these hazards and ensure a safe working environment around machinery.

Common hazards associated with machinery include entanglement, crushing, shearing, impact, falling objects etc. It’s essential to conduct thorough risk assessments, implement appropriate engineering controls and safeguards, provide adequate training, and adhere to relevant safety standards and regulations to mitigate these hazards and ensure a safe working environment around machinery.

Common hazards associated with machinery include entanglement, crushing, shearing, impact, falling objects etc. It’s essential to conduct thorough risk assessments, implement appropriate engineering controls and safeguards, provide adequate training, and adhere to relevant safety standards and regulations to mitigate these hazards and ensure a safe working environment around machinery.

Common hazards associated with machinery include entanglement, crushing, shearing, impact, falling objects etc. It’s essential to conduct thorough risk assessments, implement appropriate engineering controls and safeguards, provide adequate training, and adhere to relevant safety standards and regulations to mitigate these hazards and ensure a safe working environment around machinery.

Common hazards associated with machinery include entanglement, crushing, shearing, impact, falling objects etc. It’s essential to conduct thorough risk assessments, implement appropriate engineering controls and safeguards, provide adequate training, and adhere to relevant safety standards and regulations to mitigate these hazards and ensure a safe working environment around machinery.

Common hazards associated with machinery include entanglement, crushing, shearing, impact, falling objects etc. It’s essential to conduct thorough risk assessments, implement appropriate engineering controls and safeguards, provide adequate training, and adhere to relevant safety standards and regulations to mitigate these hazards and ensure a safe working environment around machinery.

Overview and key feature module

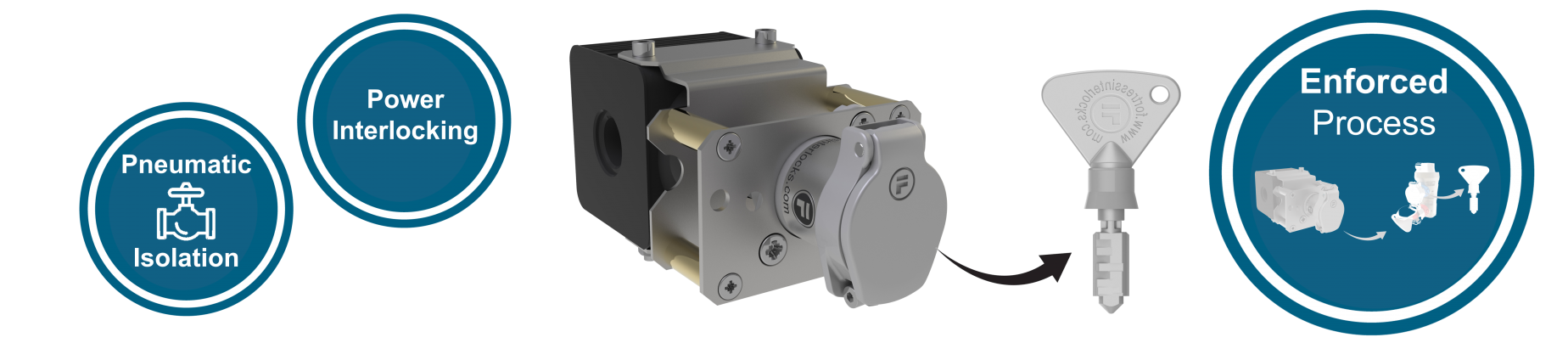

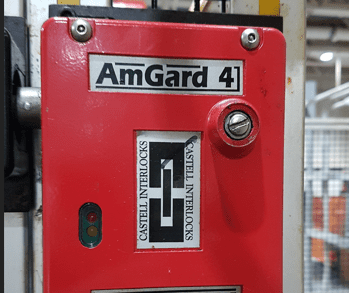

A trapped key interlock is a type of interlocking mechanism used to control access to hazardous areas or equipment. It assists in a variety of ways;

- Key Exchange: The trapped key interlock system involves a set of locks and keys. Each key is uniquely designed to fit into specific locks in a predetermined sequence.

- Sequential Operation: To access a hazardous area or enable a particular machine function, the operator must follow a predetermined sequence of operations using the trapped key system. For example, the operator may need to remove a key from one lock, insert it into another lock, and then rotate that key to release another key.

- Key Trapping: As the operator progresses through the sequence, keys become trapped or locked in certain positions. This prevents them from being removed until specific conditions are met or actions are completed, ensuring that operations are carried out in the correct order.

Key features Right Block

WYSISYG

A trapped key system is a safety mechanism used in industrial settings to control access to hazardous areas or equipment. It involves the use of interlocking devices and keys to ensure that certain operations can only be performed in a predetermined sequence, preventing accidents and injuries.

Trapped key systems are commonly used in industries such as manufacturing, energy, mining, and transportation, where safety is a critical concern. They are designed to enforce strict control over access to potentially dangerous machinery or areas, reducing the risk of injury to workers and preventing damage to equipment.

A trapped key system is a safety mechanism used in industrial settings to control access to hazardous areas or equipment. It involves the use of interlocking devices and keys to ensure that certain operations can only be performed in a predetermined sequence, preventing accidents and injuries.

Trapped key systems are commonly used in industries such as manufacturing, energy, mining, and transportation, where safety is a critical concern. They are designed to enforce strict control over access to potentially dangerous machinery or areas, reducing the risk of injury to workers and preventing damage to equipment.

A trapped key system is a safety mechanism used in industrial settings to control access to hazardous areas or equipment. It involves the use of interlocking devices and keys to ensure that certain operations can only be performed in a predetermined sequence, preventing accidents and injuries.

Trapped key systems are commonly used in industries such as manufacturing, energy, mining, and transportation, where safety is a critical concern. They are designed to enforce strict control over access to potentially dangerous machinery or areas, reducing the risk of injury to workers and preventing damage to equipment.

A trapped key system is a safety mechanism used in industrial settings to control access to hazardous areas or equipment. It involves the use of interlocking devices and keys to ensure that certain operations can only be performed in a predetermined sequence, preventing accidents and injuries.

Trapped key systems are commonly used in industries such as manufacturing, energy, mining, and transportation, where safety is a critical concern. They are designed to enforce strict control over access to potentially dangerous machinery or areas, reducing the risk of injury to workers and preventing damage to equipment.

Check out video Module

What is Trapped key interlocking

trapped key interlocks provide a reliable and visible method of controlling access and ensuring safe operations in industrial environments. They offer a robust and effective solution for preventing unauthorized access to hazardous areas and maintaining proper machinery sequencing.

Products benefits module for key features

Products benefits module for key features

Featured article module

Webinar exploring and explaining trapped key interlocking

Explore our solution module

Safety and Access Key

Automated Storage

EtherCAT (Ethernet for Control Automation Technology) is an industrial Ethernet-based communication protocol used in automation systems. EtherCAT is designed to enable real-time communication between various devices in an industrial control system, such as programmable logic controllers (PLCs), sensors, actuators, and other industrial automation devices. It provides a high-speed, deterministic communication network, allowing for precise and synchronized control of distributed devices.

The key feature of EtherCAT is its ability to achieve real-time performance by using a distributed clock mechanism. Unlike traditional Ethernet-based protocols, EtherCAT does not require each device to process the entire data frame. Instead, each device reads and processes only its relevant data from the frame, allowing for fast and efficient communication.

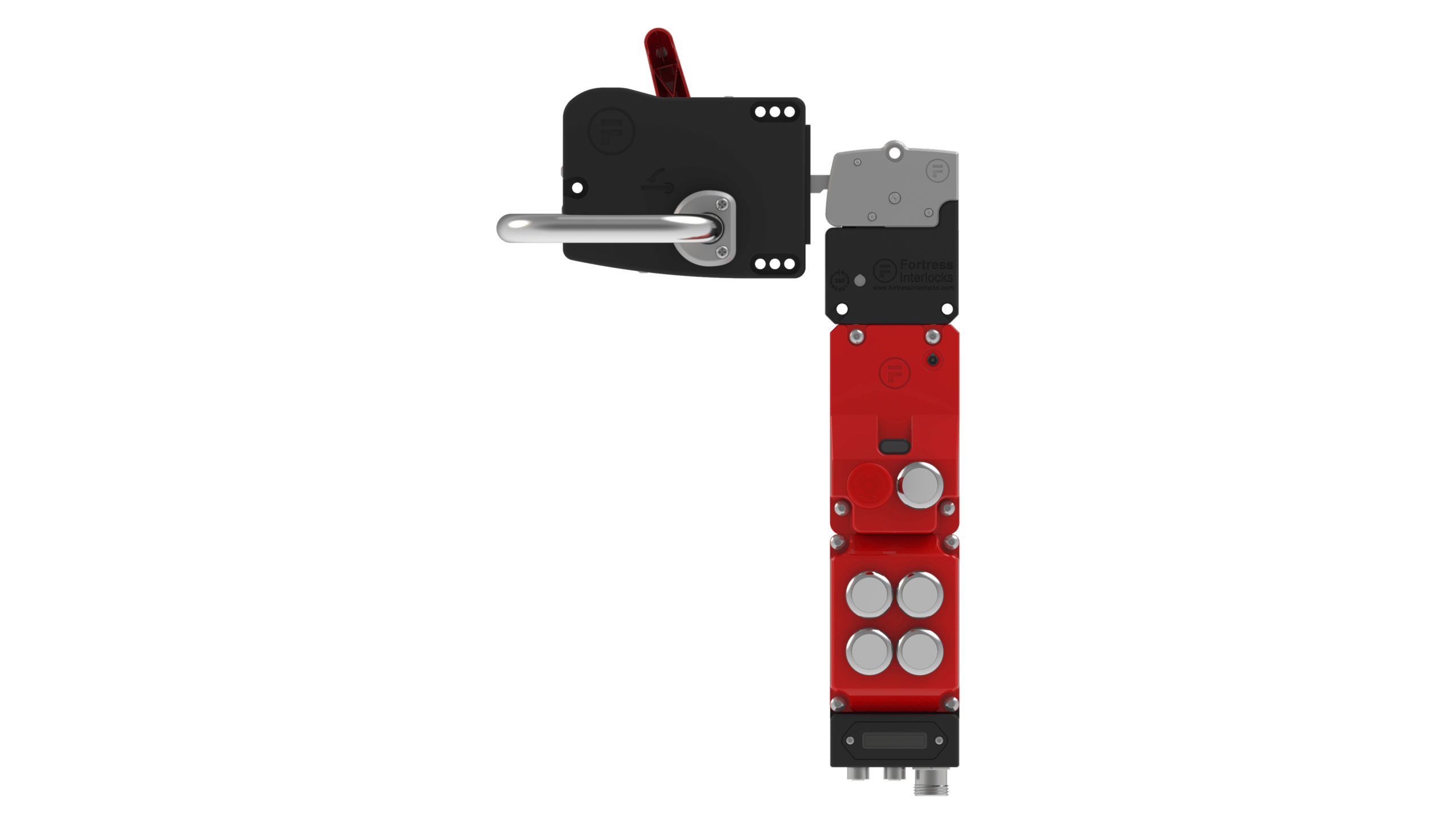

Fortress utilises a complex part numbering system that allows you to configure our amGardPro units to meet your exact requirements in almost any application.

To get the most out of our products and utilise the wide range of amGardPro features that we offer, it is a great idea to familiarise yourself with our part numbering system.

Assets module

EtherCAT (Ethernet for Control Automation Technology) is an industrial Ethernet-based communication protocol used in automation systems. EtherCAT is designed to enable real-time communication between various devices in an industrial control system, such as programmable logic controllers (PLCs), sensors, actuators, and other industrial automation devices. It provides a high-speed, deterministic communication network, allowing for precise and synchronized control of distributed devices.

The key feature of EtherCAT is its ability to achieve real-time performance by using a distributed clock mechanism. Unlike traditional Ethernet-based protocols, EtherCAT does not require each device to process the entire data frame. Instead, each device reads and processes only its relevant data from the frame, allowing for fast and efficient communication.

amGard pro

Fortress utilises a complex part numbering system that allows you to configure our amGardPro units to meet your exact requirements in almost any application.

To get the most out of our products and utilise the wide range of amGardPro features that we offer, it is a great idea to familiarise yourself with our part numbering system.

Related Sectors (Only For Sectors)

Sectors