ISO 14119 (2013) – Design to minimize defeat possibilities of interlocking

devices

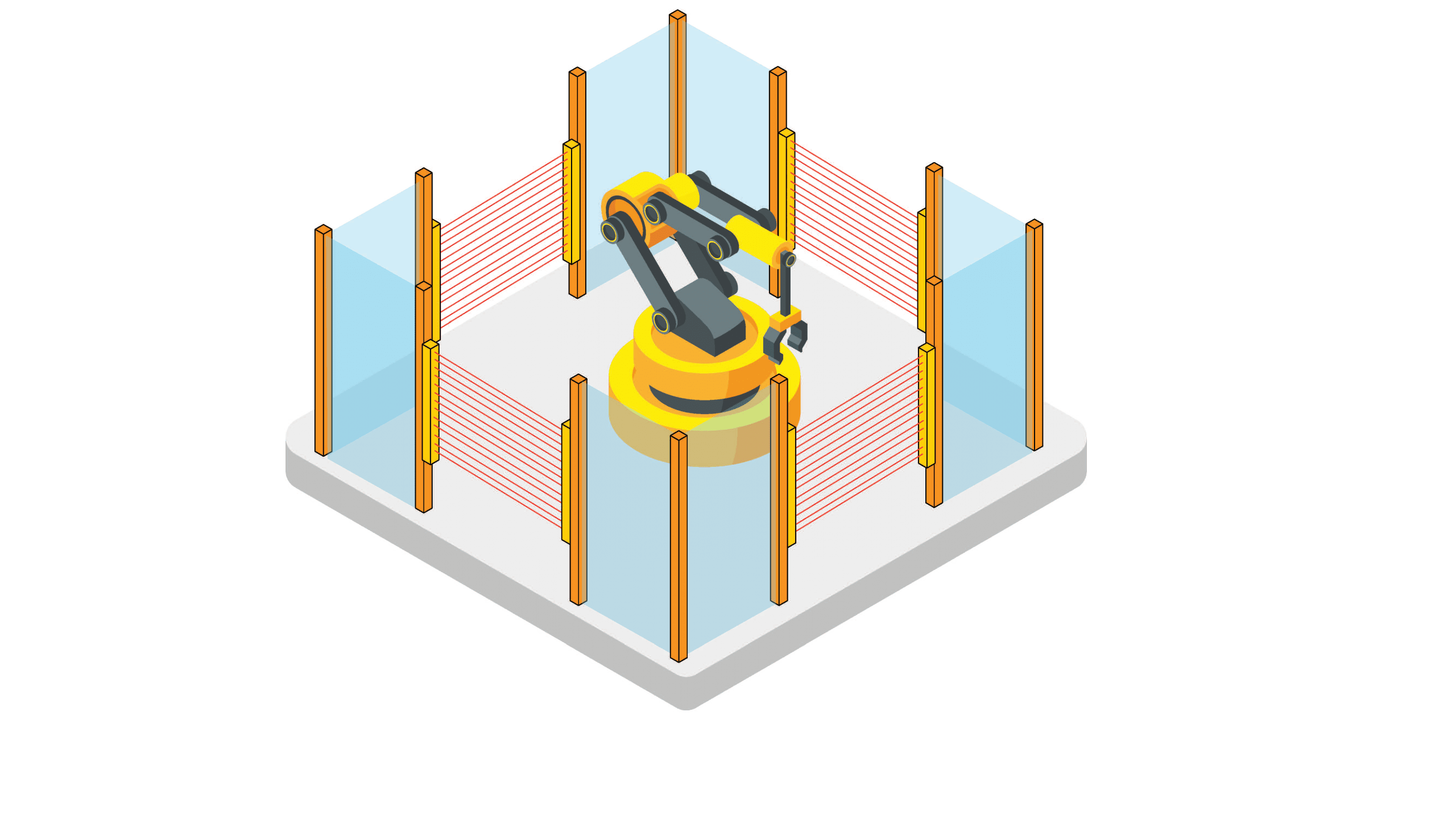

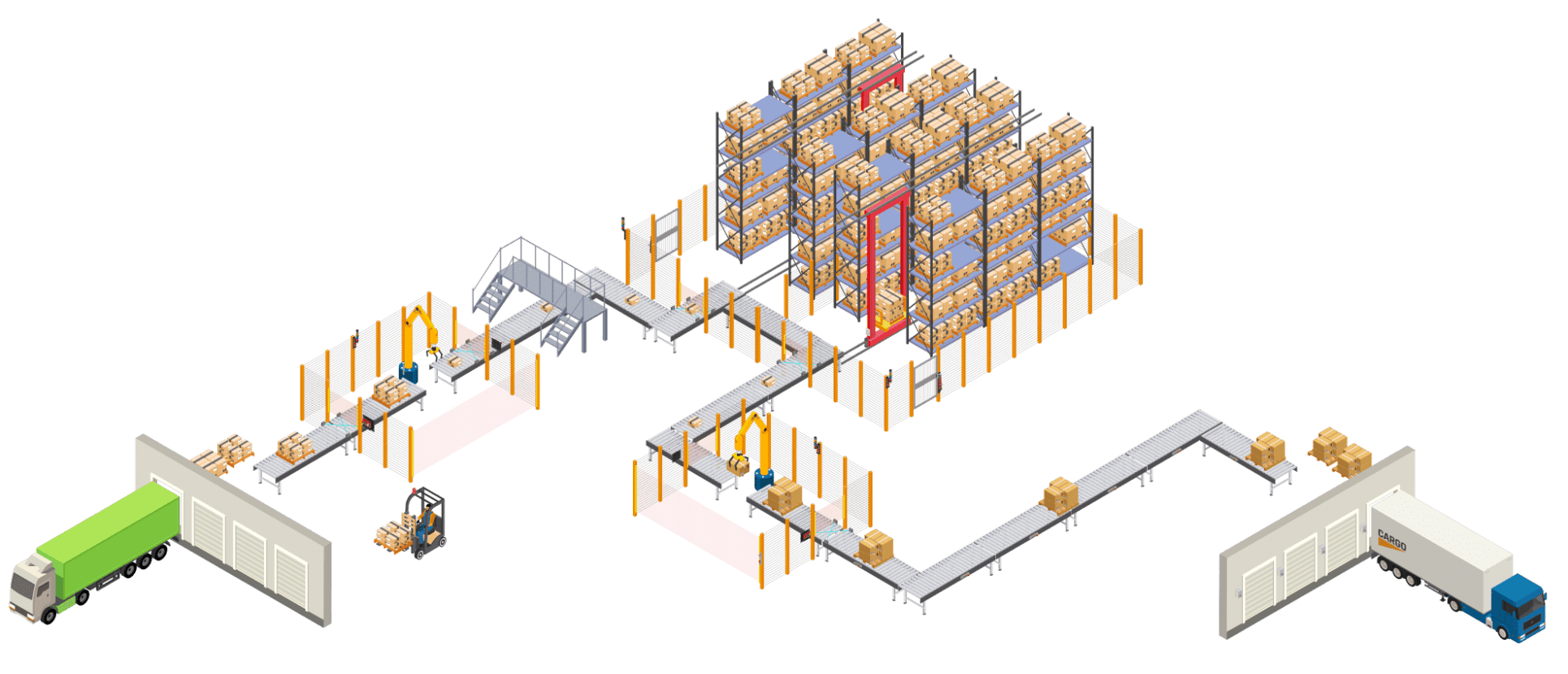

ISO 14119 requires machines to be designed to minimize the motivation for defeating the interlocking device, tying back to the requirement in ISO12100’s to take into account the possibility of defeating or circumventing protective measures during the risk estimation process.

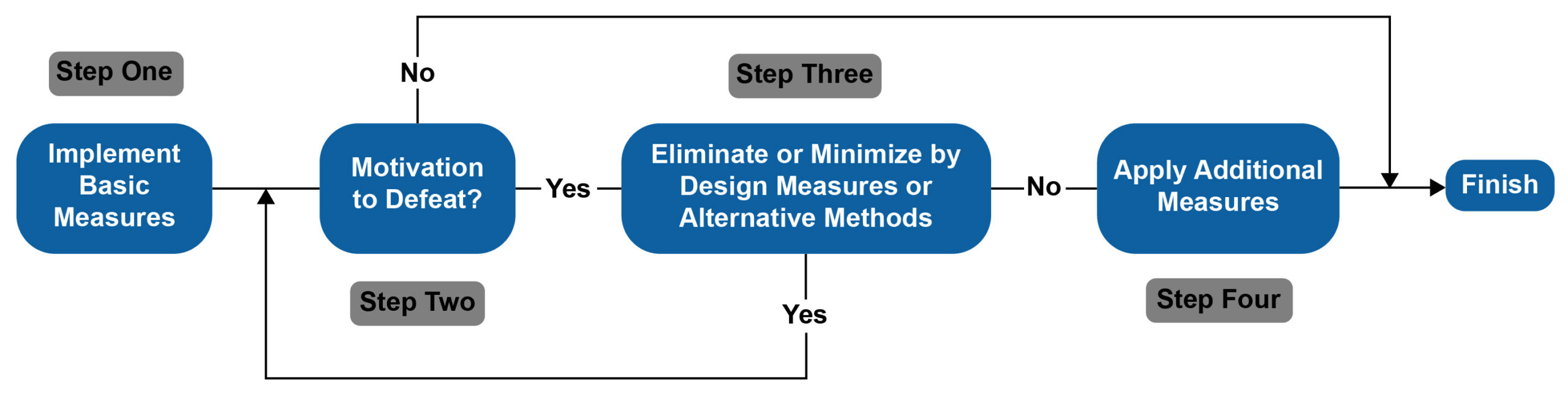

The Four-Step Process to Minimize the Motion to Defeat

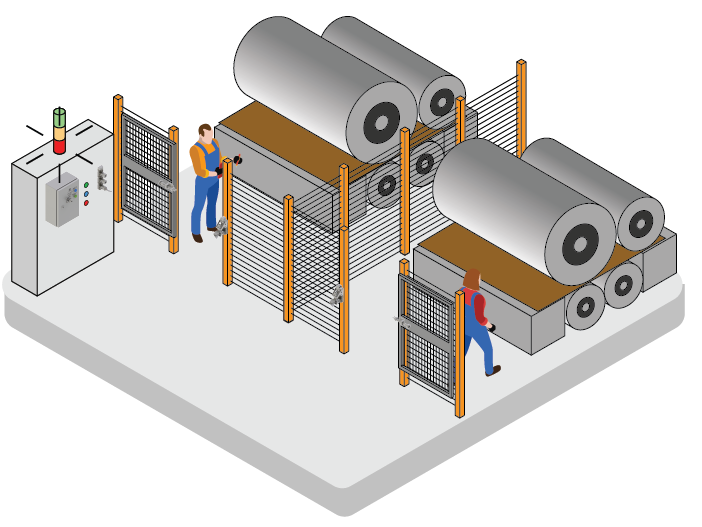

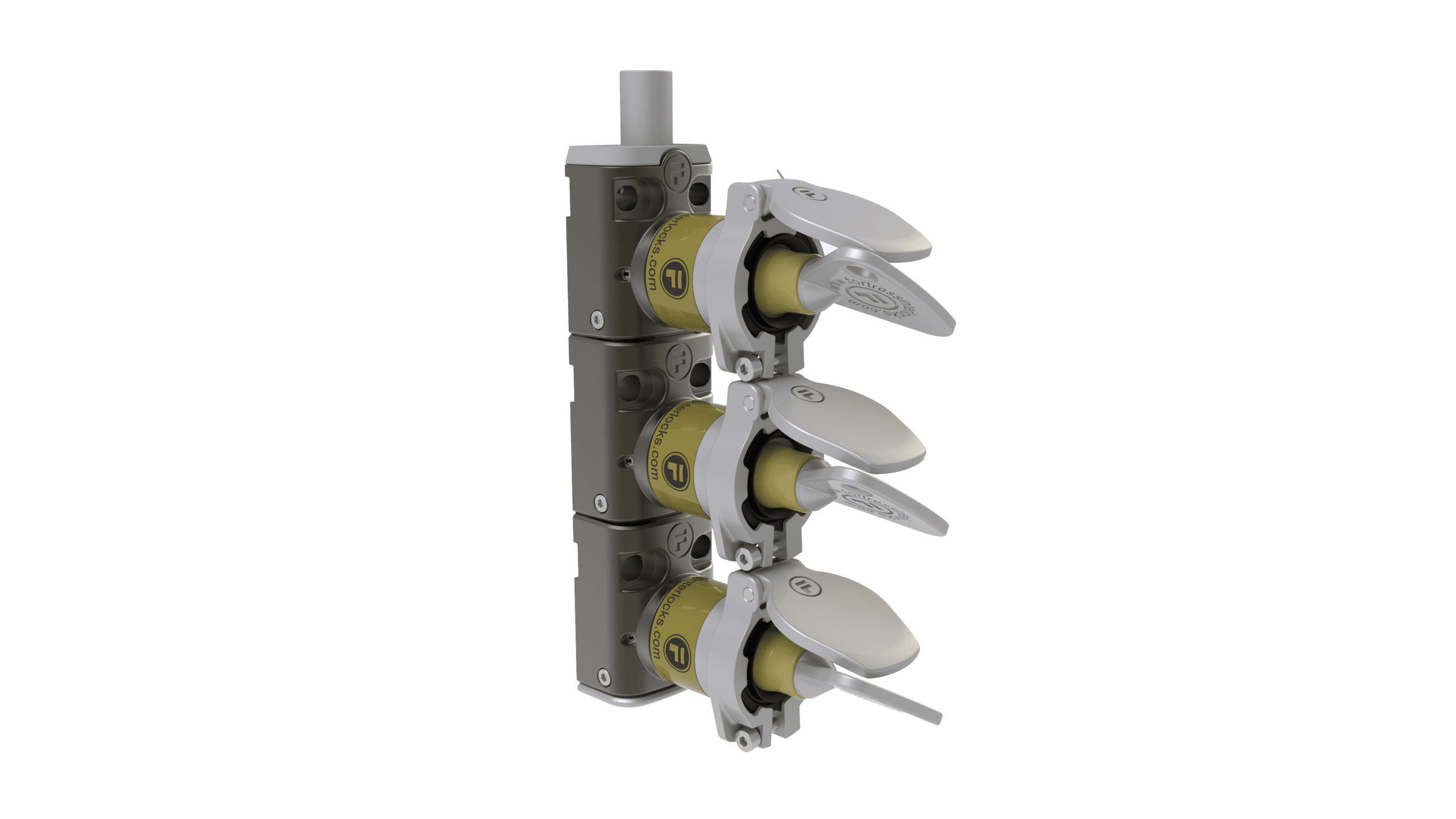

First on the list is implementing basic measures described in section 5 of ISO14119 – Requirements for the design and the installation of interlocking devices with and without guard locking. At this stage Type 3 Interlocking Devices (Uncoded non-contact switches) can only be used if it is reasonably foreseeable that they will not be defeated.

If, after implementing basic measures, motivation to defeat isn’t foreseeable then additional measures aren’t needed.

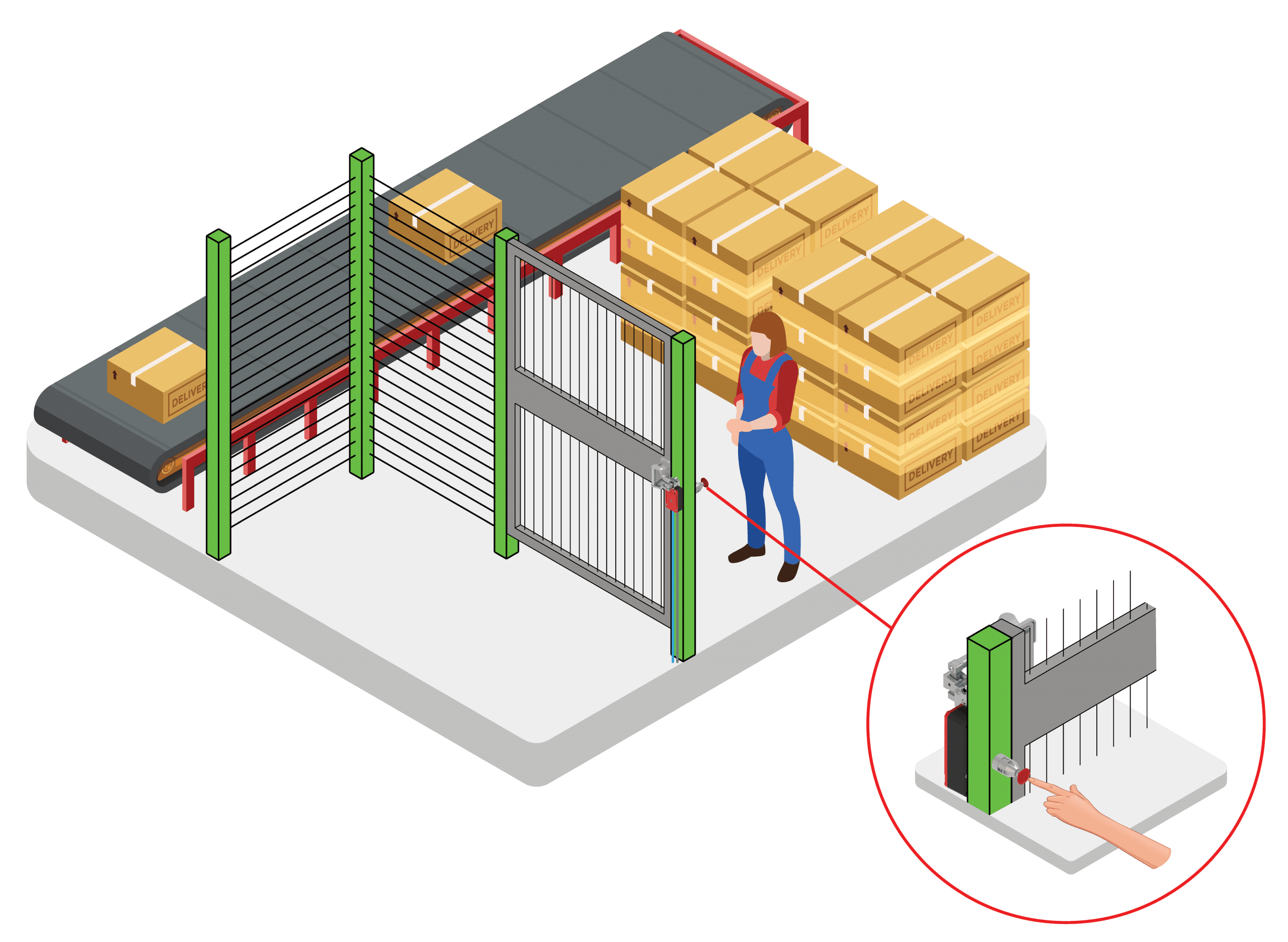

If motivation remains foreseeable, the next step is to identify whether it can eliminate or minimize defeat by design measures or alternative methods. In the case of the latter this may include special modes for setting, tool changing, fault finding, maintenance or process observation.

If the motivation can be eliminated or minimized additional measures are not required.

Finally, if motivation for defeat is still foreseeable, additional measures are required.

This four-step process is important, and worth reviewing again, this time as a flow chart.

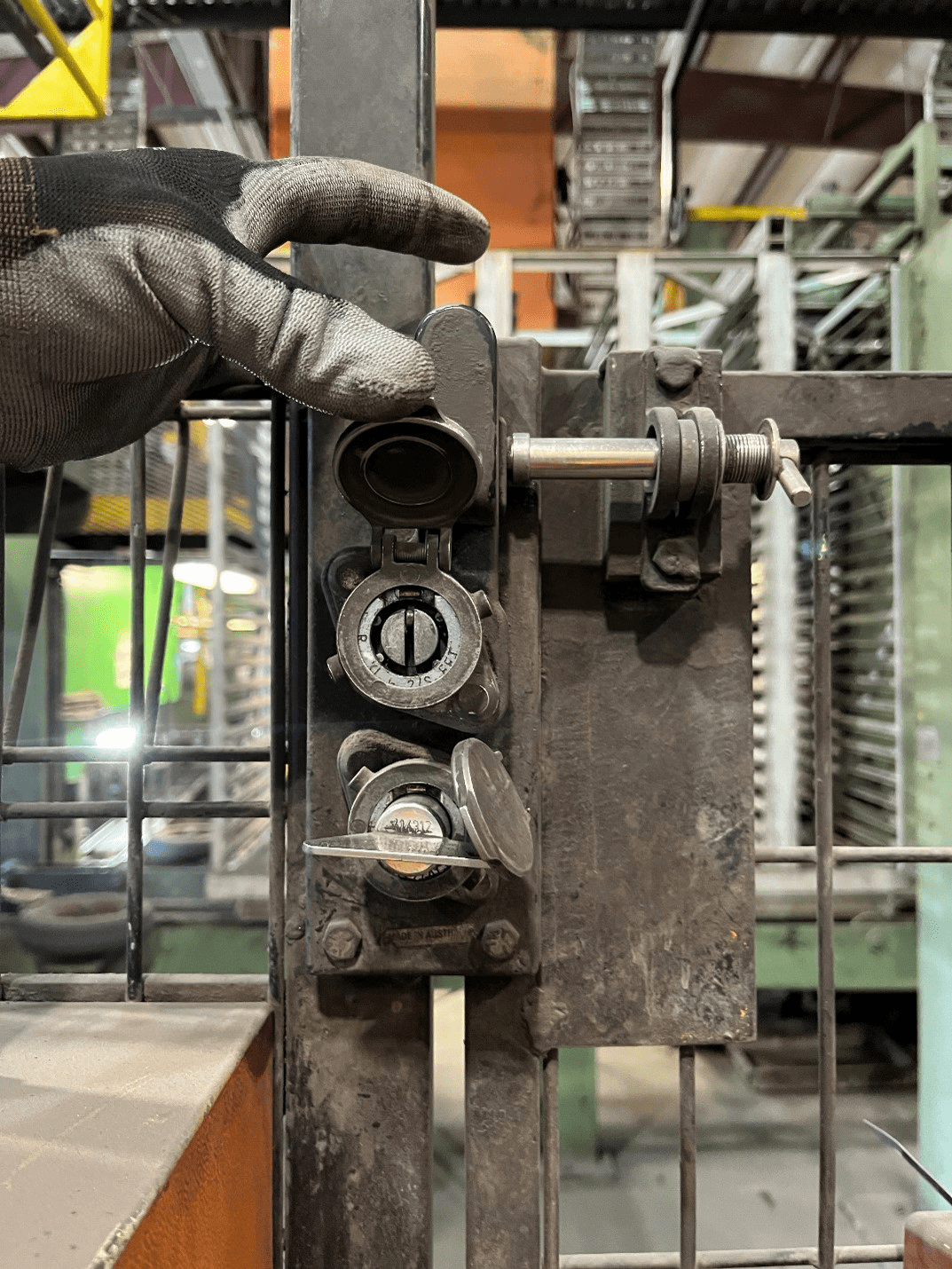

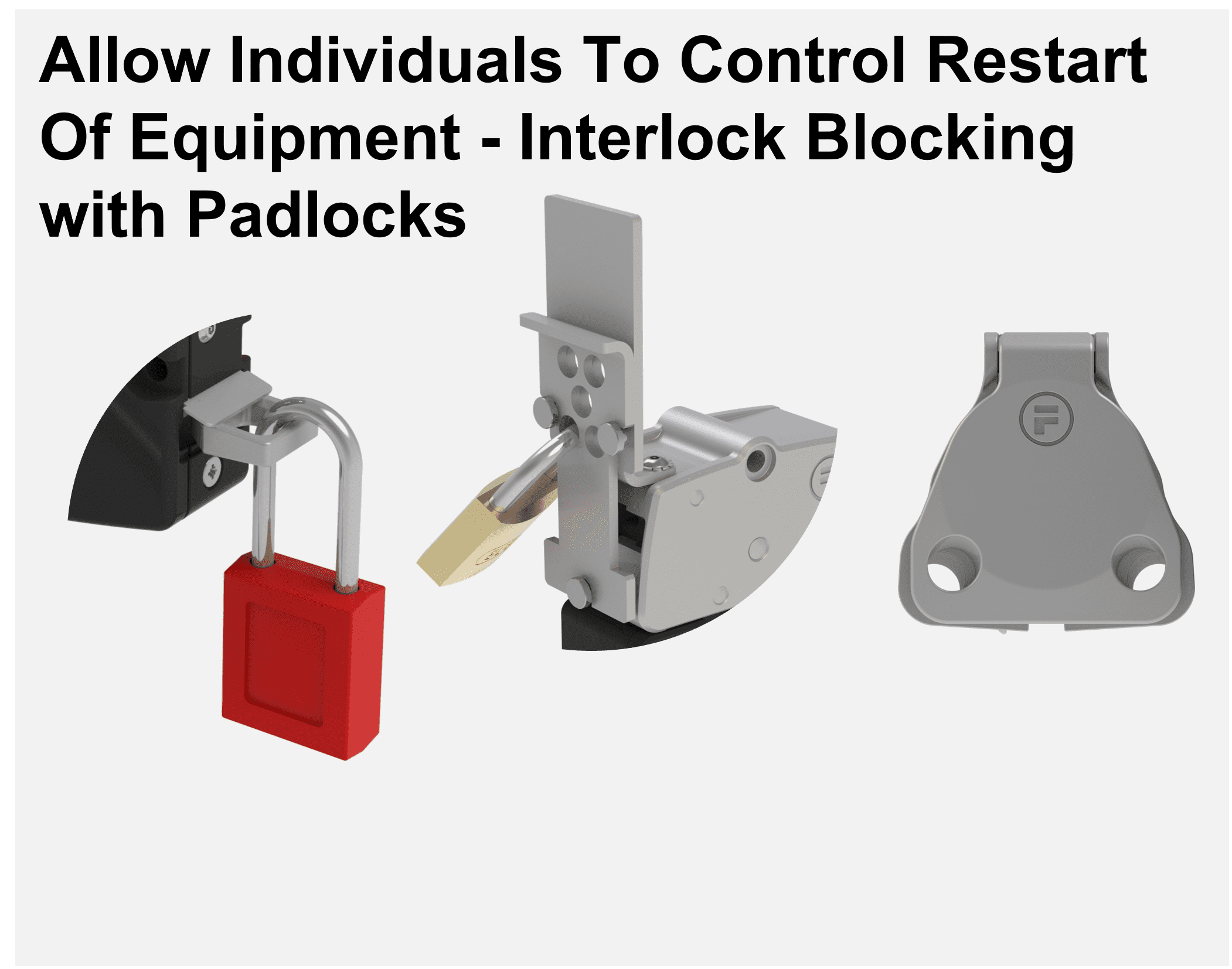

If the motivation to defeat cannot be eliminated, then ISO14119 requires additional measures to be taken to minimize the defeat possibilities of interlocking devices. This is broken down into four areas:

If the motivation to defeat cannot be eliminated, then ISO14119 requires additional measures to be taken to minimize the defeat possibilities of interlocking devices. This is broken down into four areas:

Motivation to defeat is a major topic in the project to redraft ISO14119 with significant emphasis on additional measures to prevent defeat. The current draft defines non detachable and rules out the use of security screws. Considerable effort has been made to improve the existing table of requirements, but the emphasis remains on additional measures rather than addressing the underlying problem – why would an operator want to defeat an interlock.

When considering additional measures, it is essential to take the four step approach, with the critical question that must be asked – “Does motivation to defeat exist?” If it does not exist or can be eliminated, then there is no need for any additional methods.

The reality is that motivation to defeat should be eliminated during the risk assessment process and may not only provide a safer working environment but also lead to productivity gains. When emphasis is placed on making it harder to defeat interlocking devices the problem does not go away it just moves elsewhere.

Products Mentioned in this Article

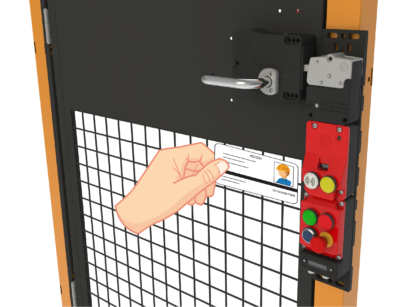

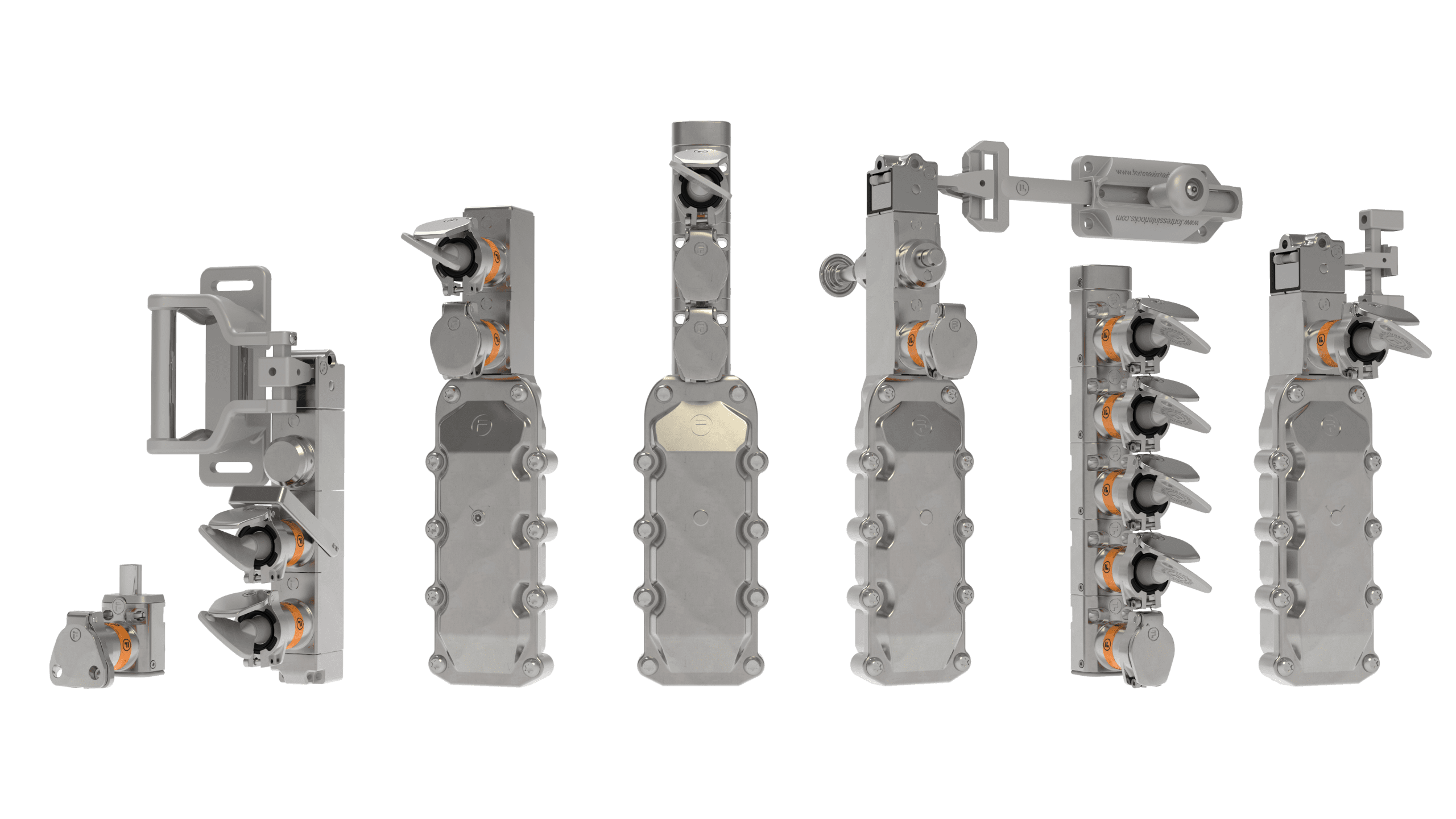

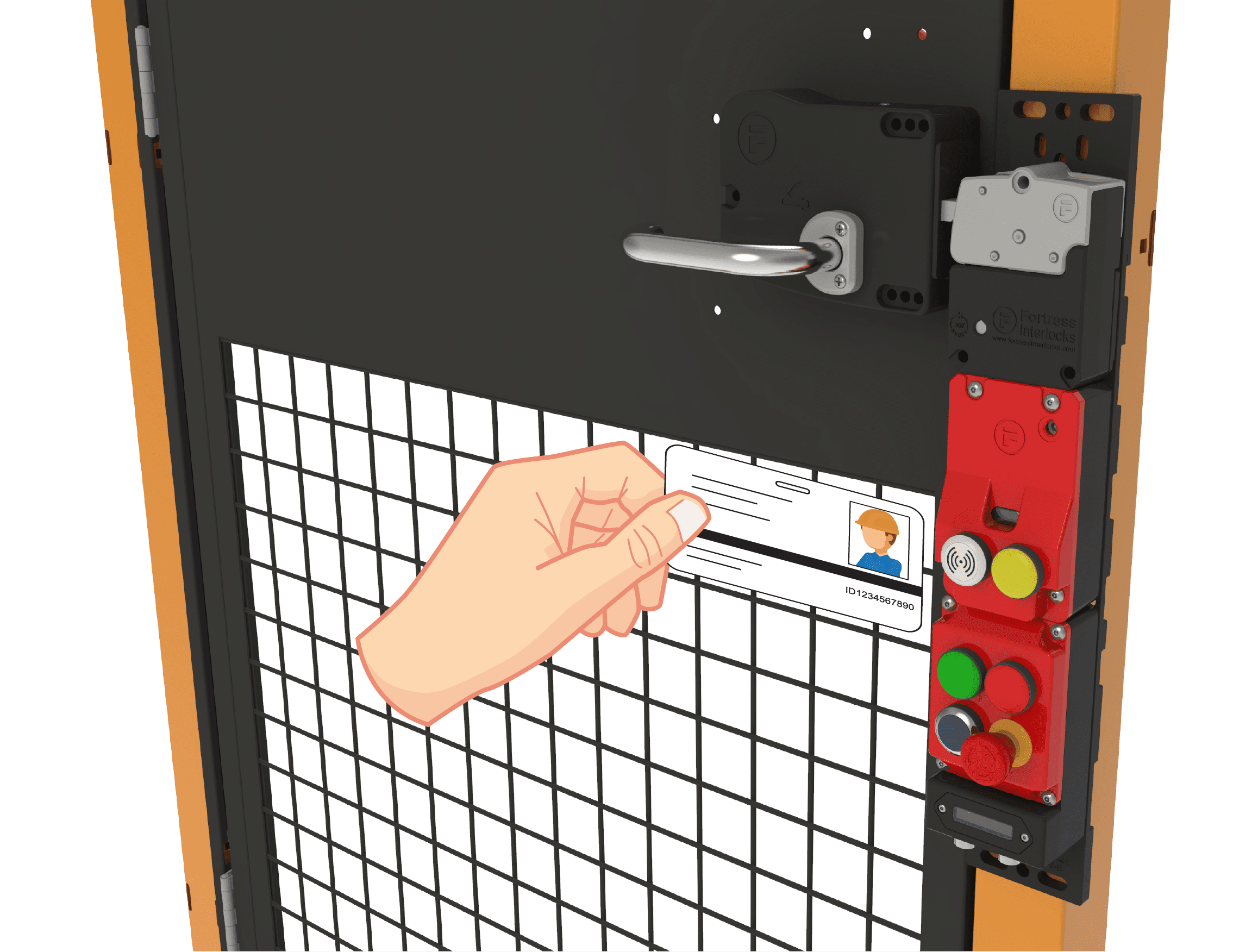

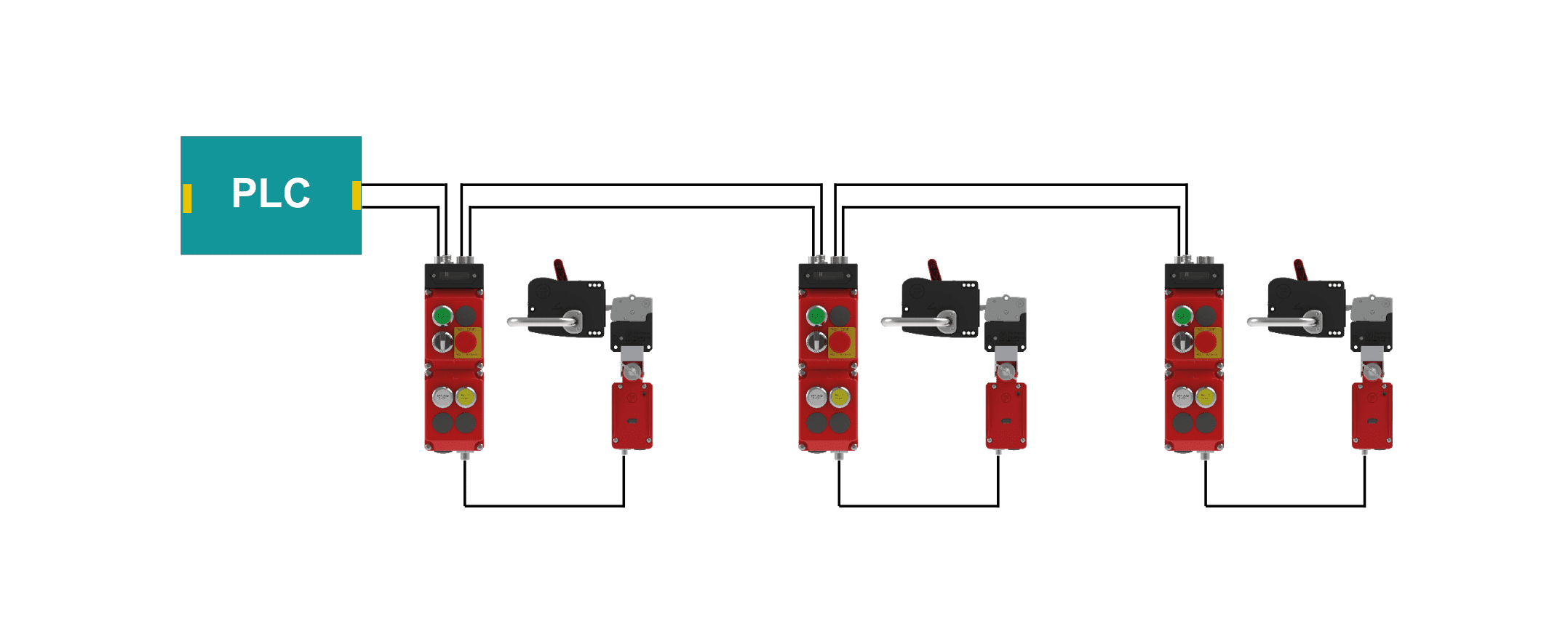

amGard pro

Click Here to Download the Full Article

Click Here to Download the Full Article