How Presence Sensing Devices can Protect Employees when Collaborating with Robots

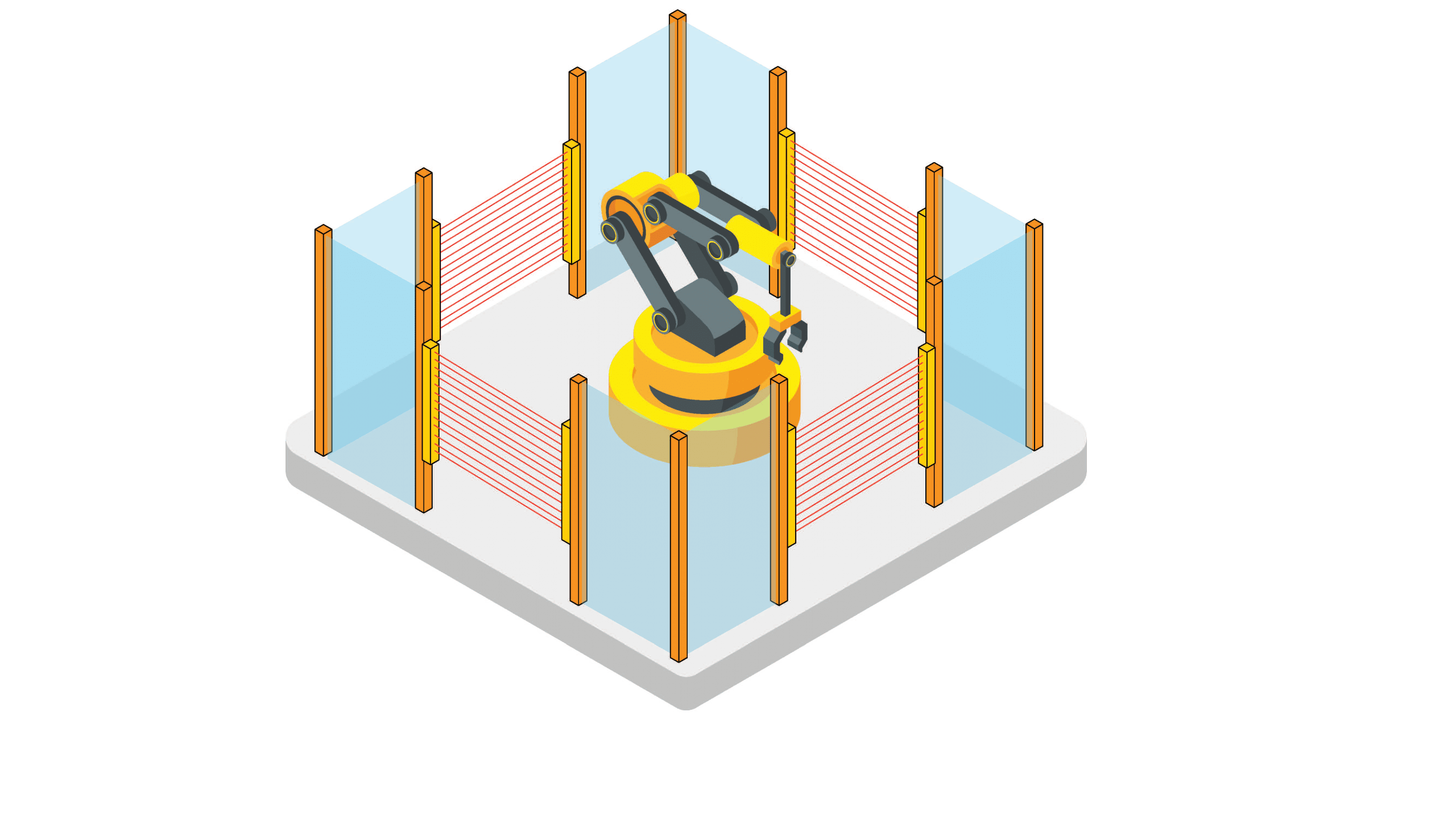

With the advent of the collaborative robot and the use of presence sensing safety devices the long-term future of fixed perimeter guarding is a hot topic in businesses seeing an opportunity to reduce its manufacturing space, but is all as it first appears?

ISO13855 (2010) Safety Machinery and Presence Sensing Devices

ISO13855 (2010) Safety of machinery — Positioning of safeguards with respect to the approach speeds of parts of the human body may an unwieldy title and might not be at the forefront of every safety engineer’s library of standards but it is critical when it comes to the design of safeguards for machinery. In practical terms the application of safeguards should take into account the time it takes for the machine to stop (overall system stopping performance) and the minimum distance to the hazard zone. Values for approach speeds (walking speeds and upper limb movement) are provided in ISO13855 and are proven in practical experience.

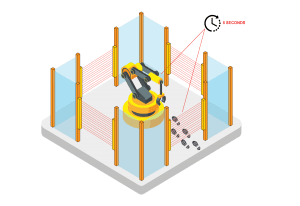

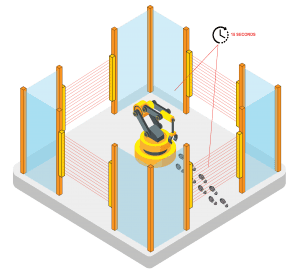

When fixed guarding is replaced by presence sensing safety devices (such as light curtains, pressure mats and laser scanners) it is critical that these devices are installed at a distance that ensures the operator cannot reach the hazard once a stop command has been generated. Even when it appears that a machine comes to an “instant” stop the designer of the safeguards must consider the response time of the presence sensing safety device and the safety relay (or other monitoring device). In cases where it is not possible to stop a machine mid cycle or predict the system stopping performance ISO13855 cannot be applied and logically presence sensing safety devices cannot be used as the primary means of safeguarding.

The minimum distance to the hazard is calculated using the equation:

S = (K x T) + C

Where:

S is the minimum distance in mm

K is the approach speed in mm/s of the body or parts of the body

T is the overall system stopping time in seconds

C is the intrusion distance in mm

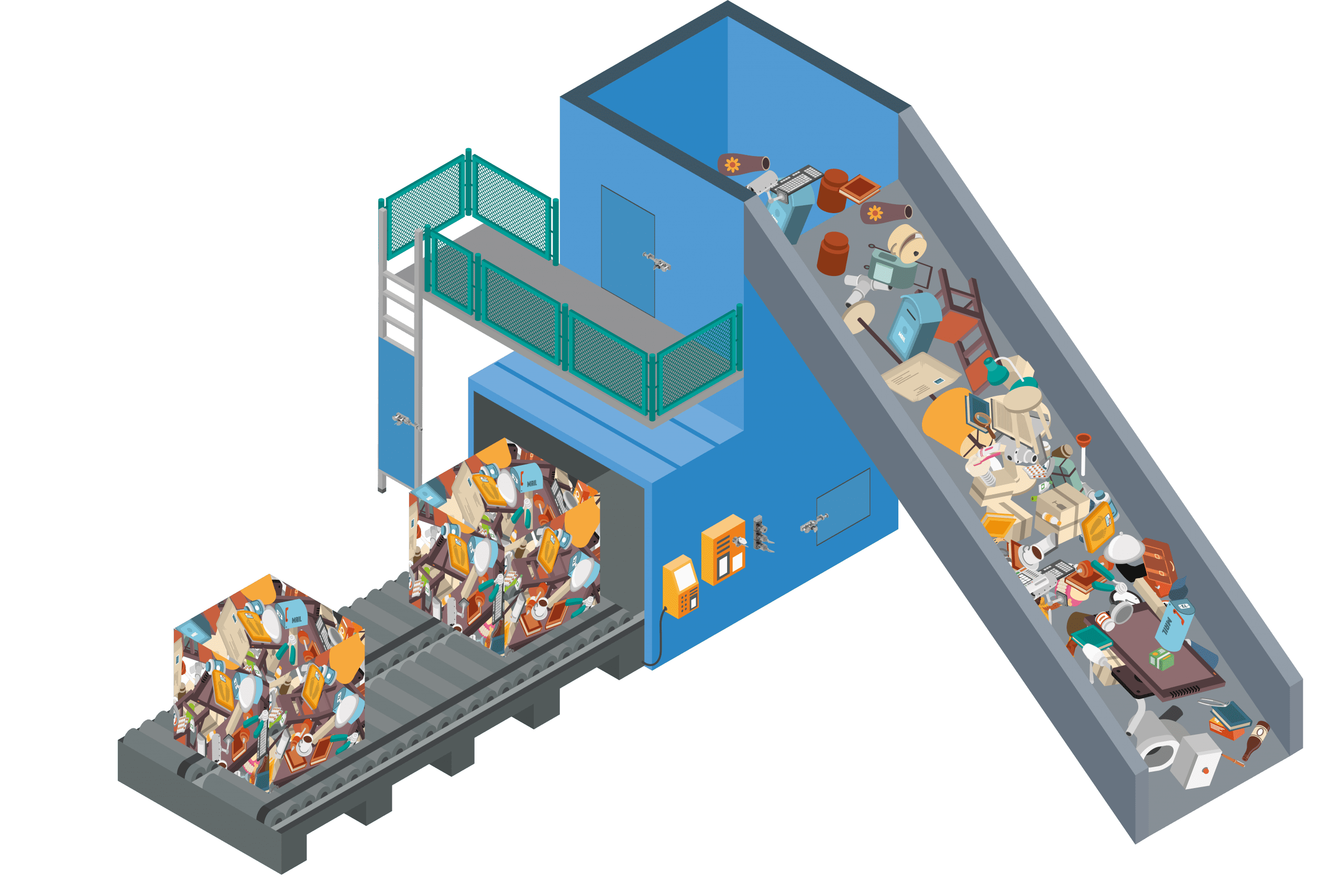

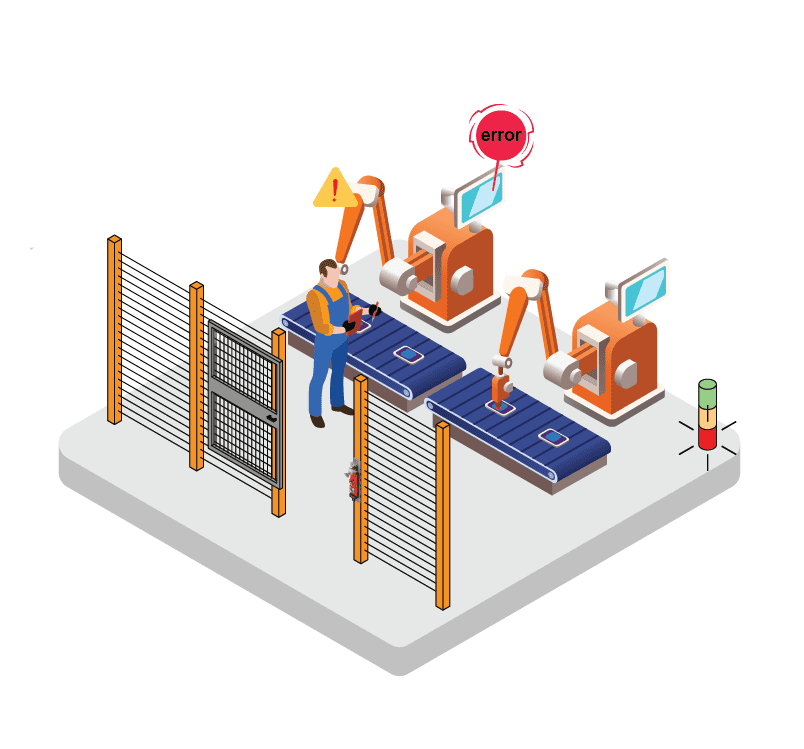

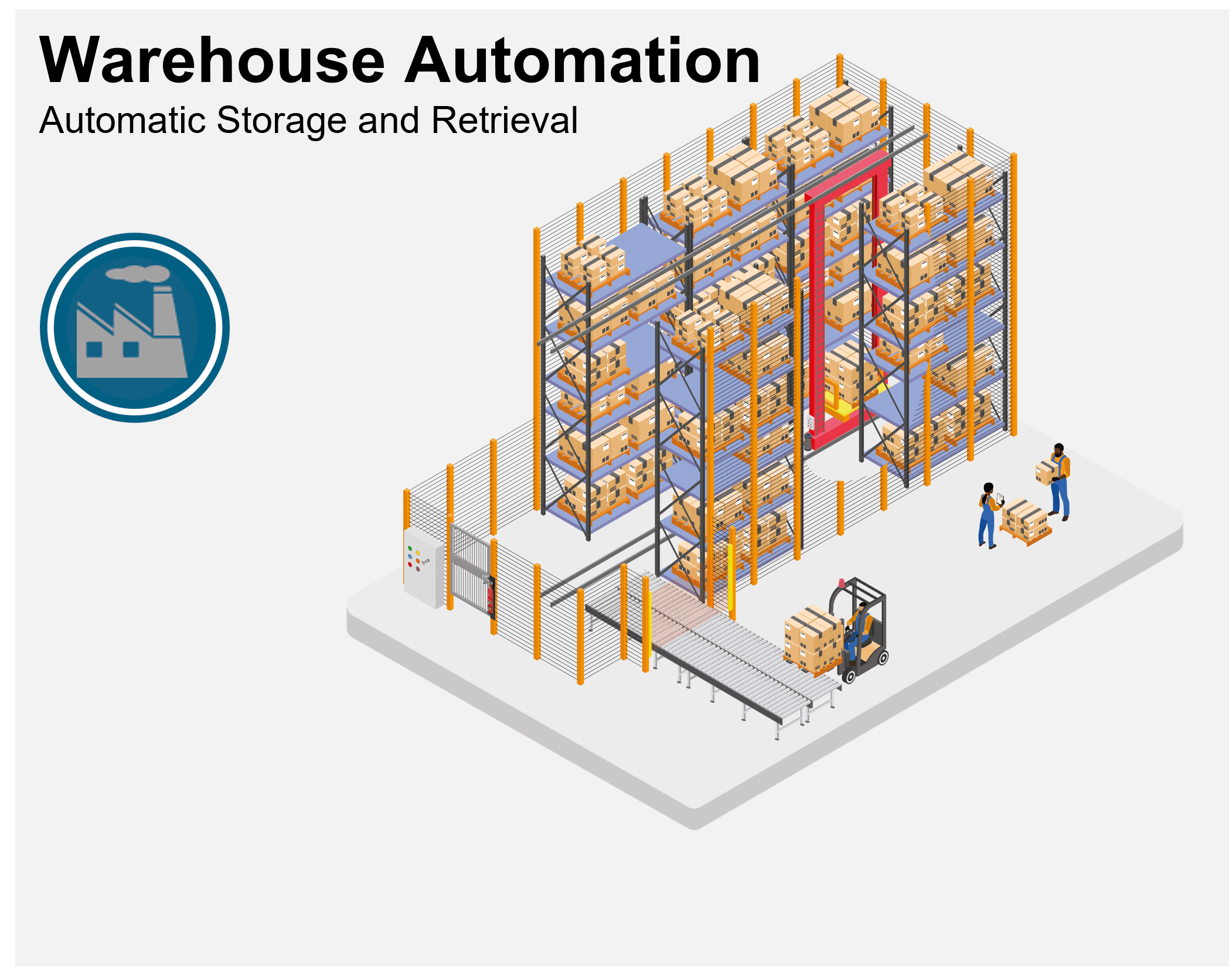

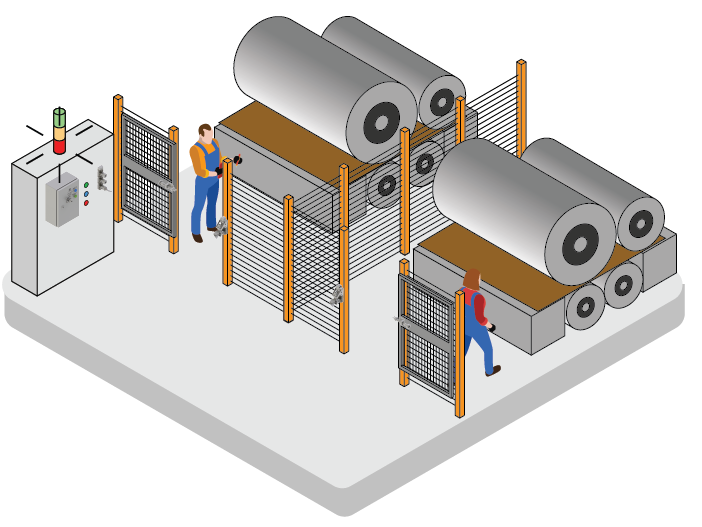

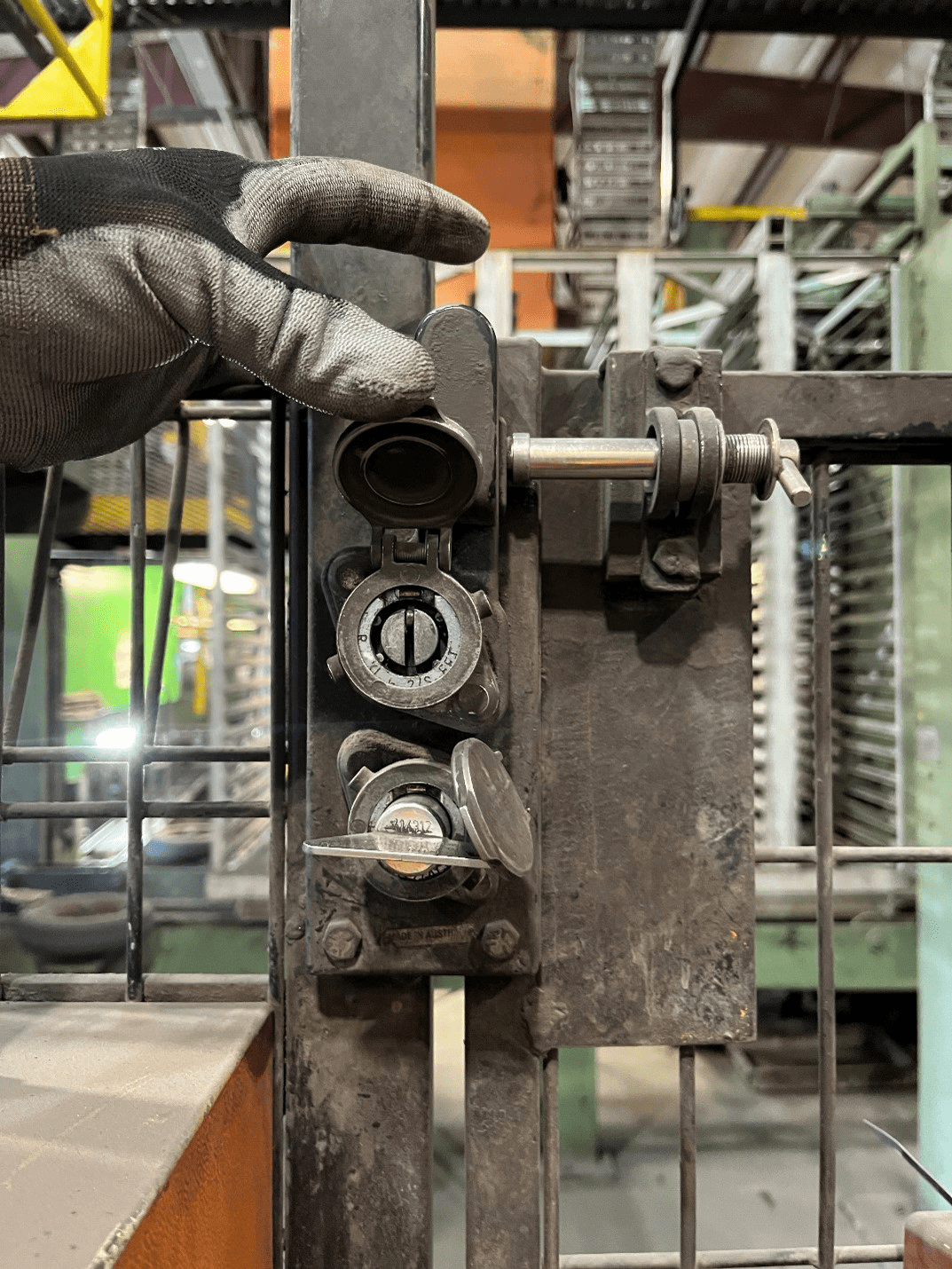

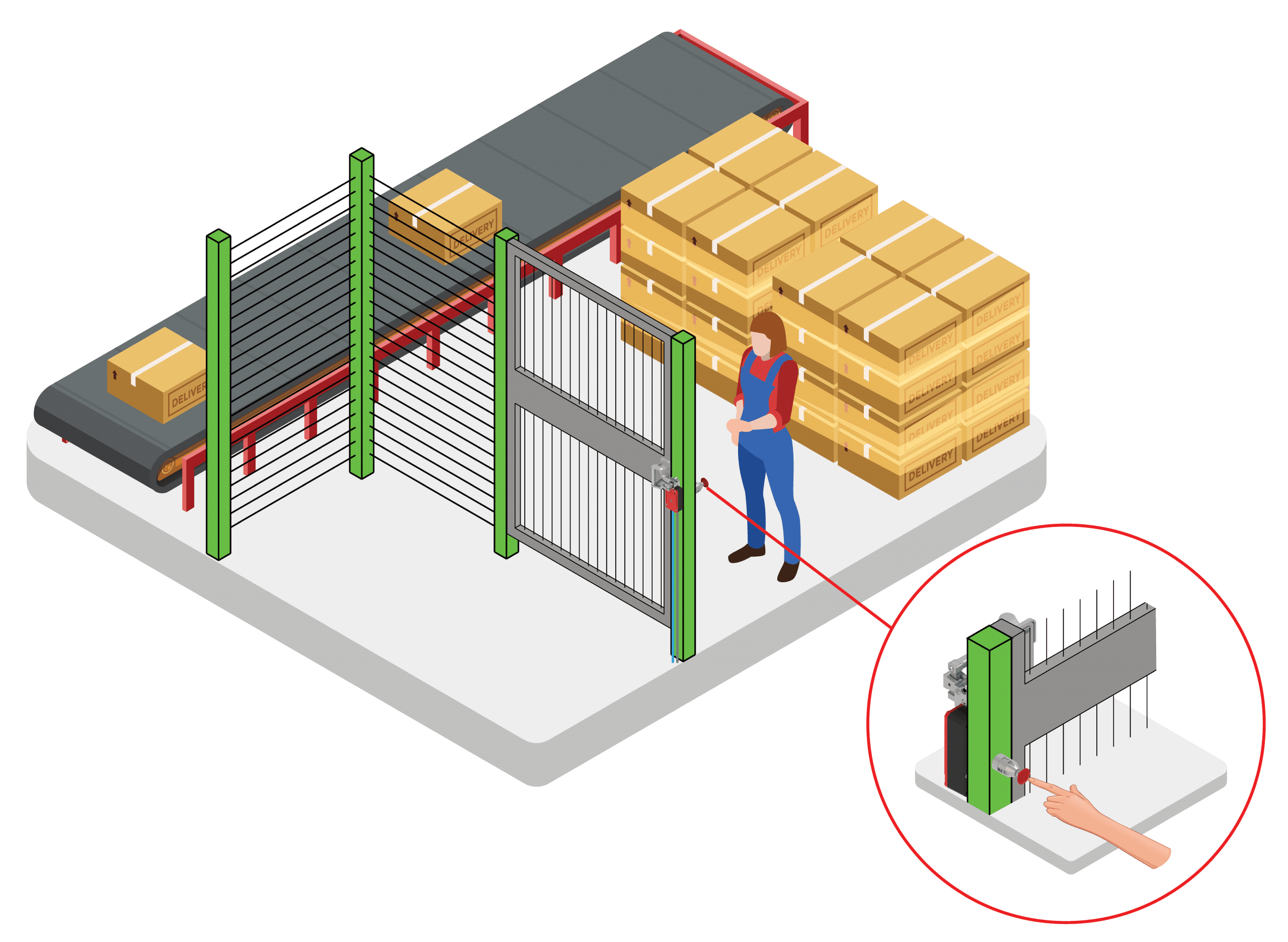

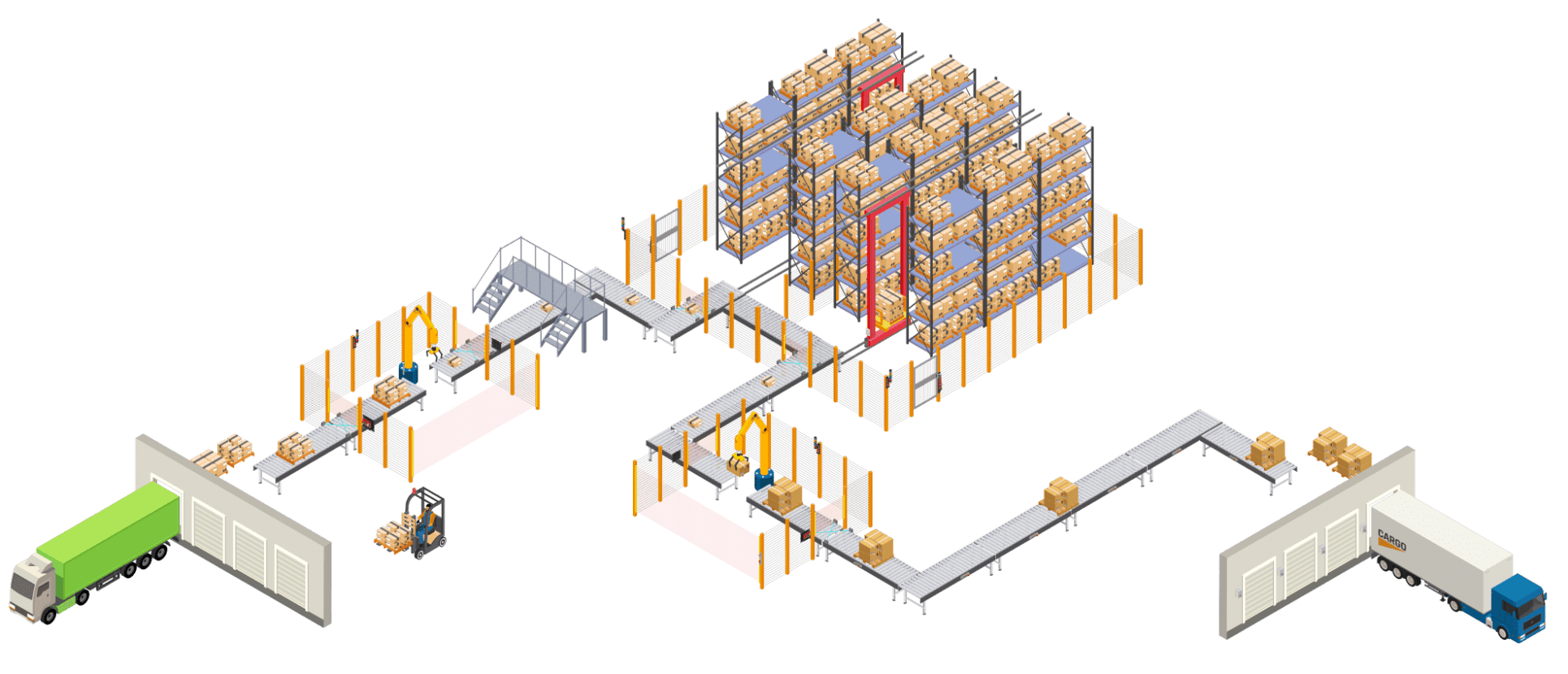

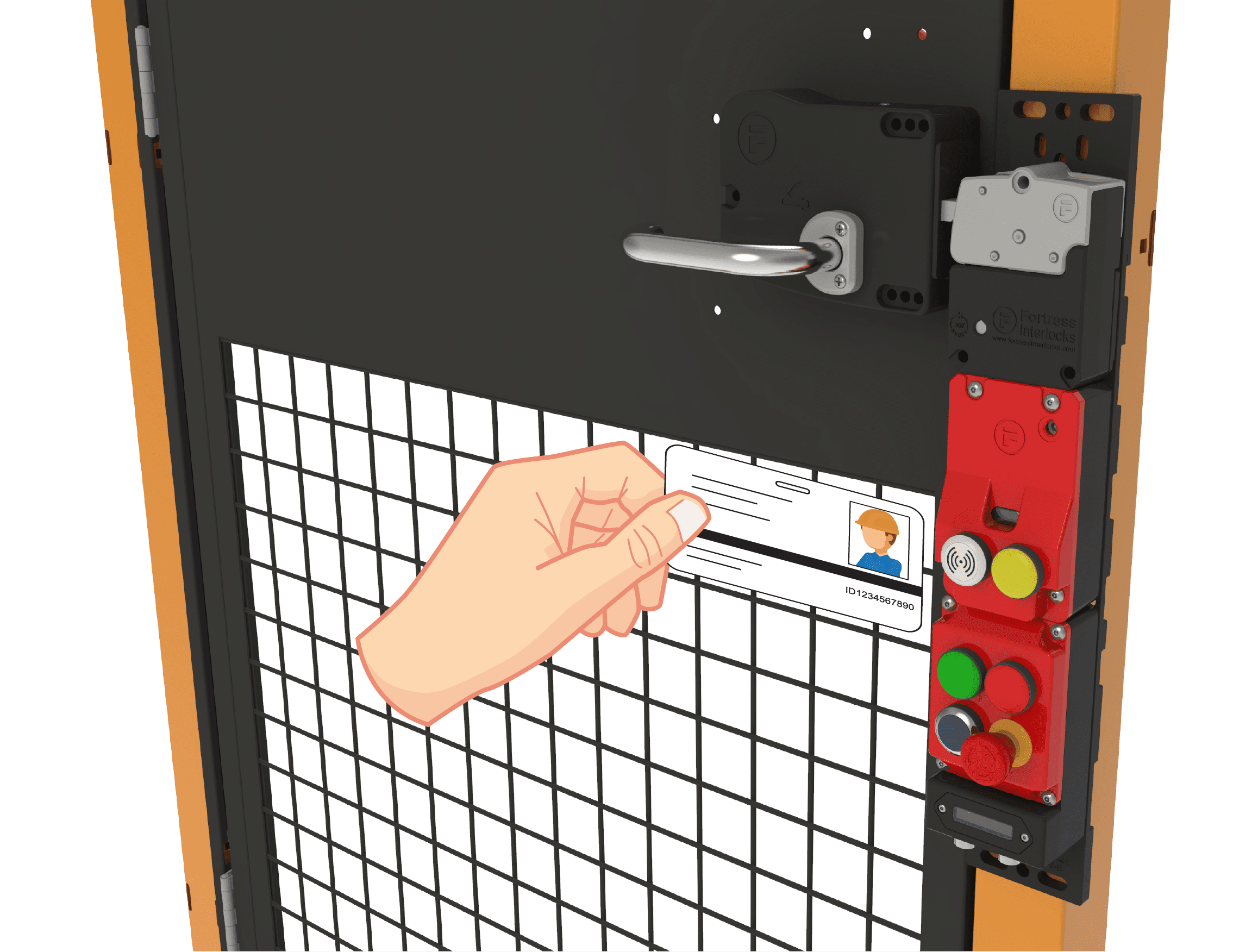

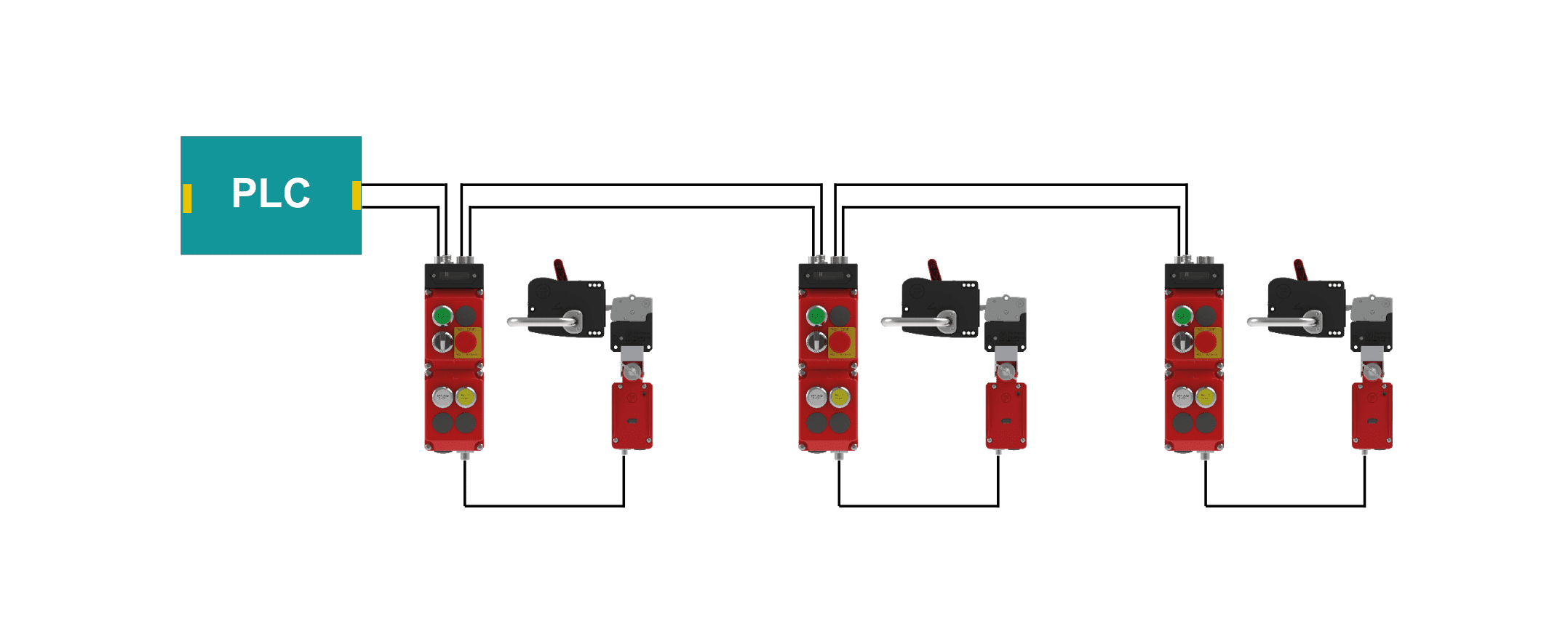

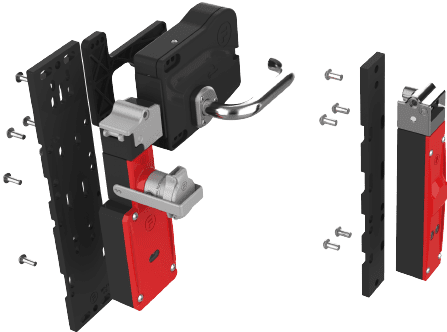

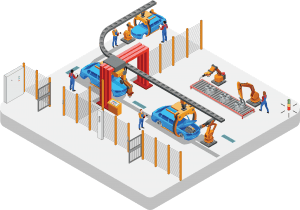

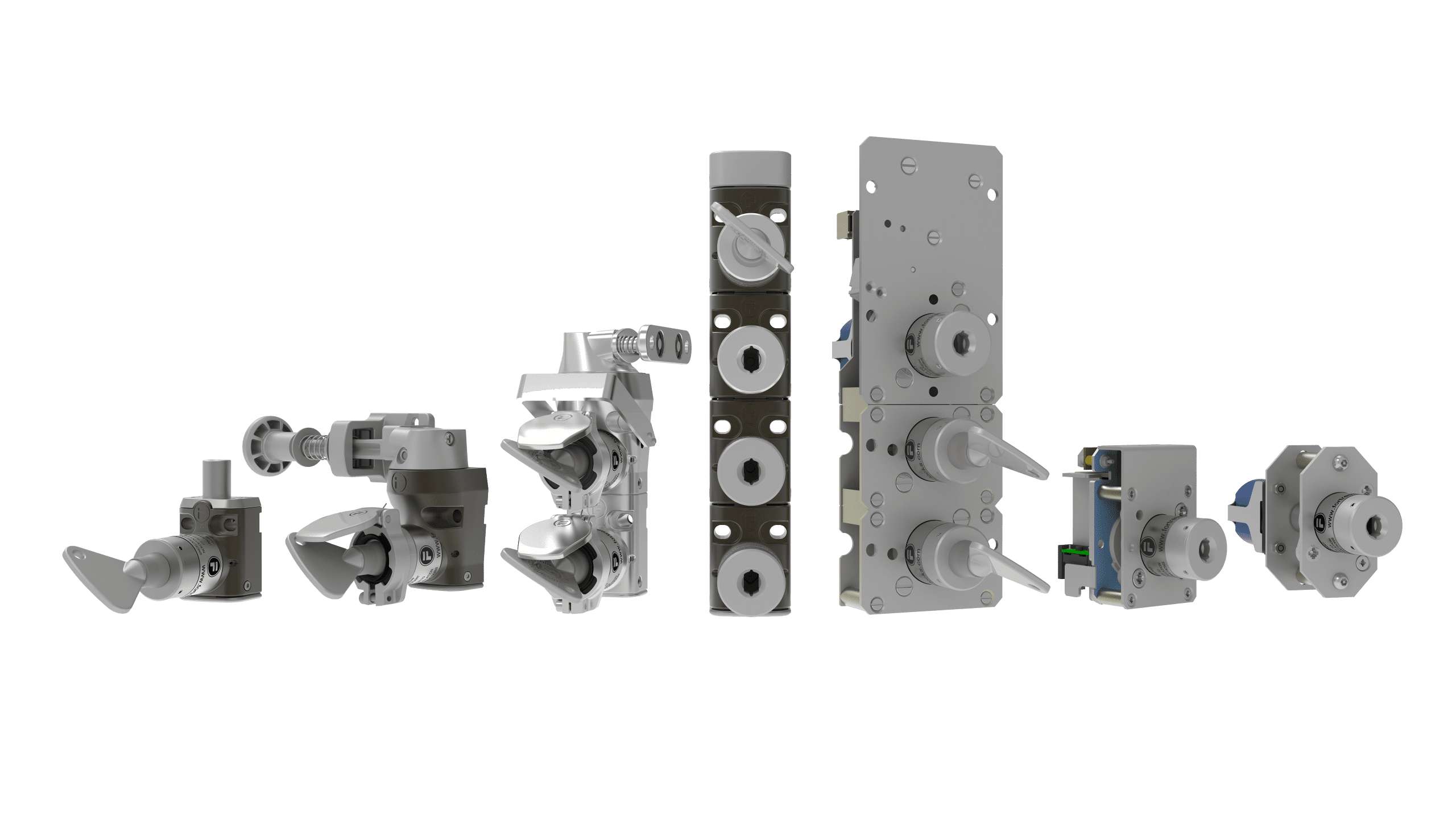

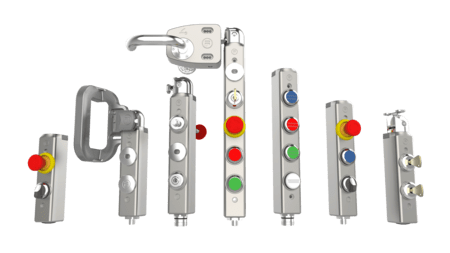

Whilst more and more collaborative robots are being used in the manufacturing environment, we are also seeing the rise of the “integrated manufacturing system” where two or more machines work in combination. This creates a challenge for the designer of safeguards where the span of control of a single safeguarding device might be extensive and complex. It is in this scenario where fixed perimeter physical guarding provides an excellent option, particularly in conjunction with safety guard locking devices and personnel keys to protect operators entering the safeguarded space.

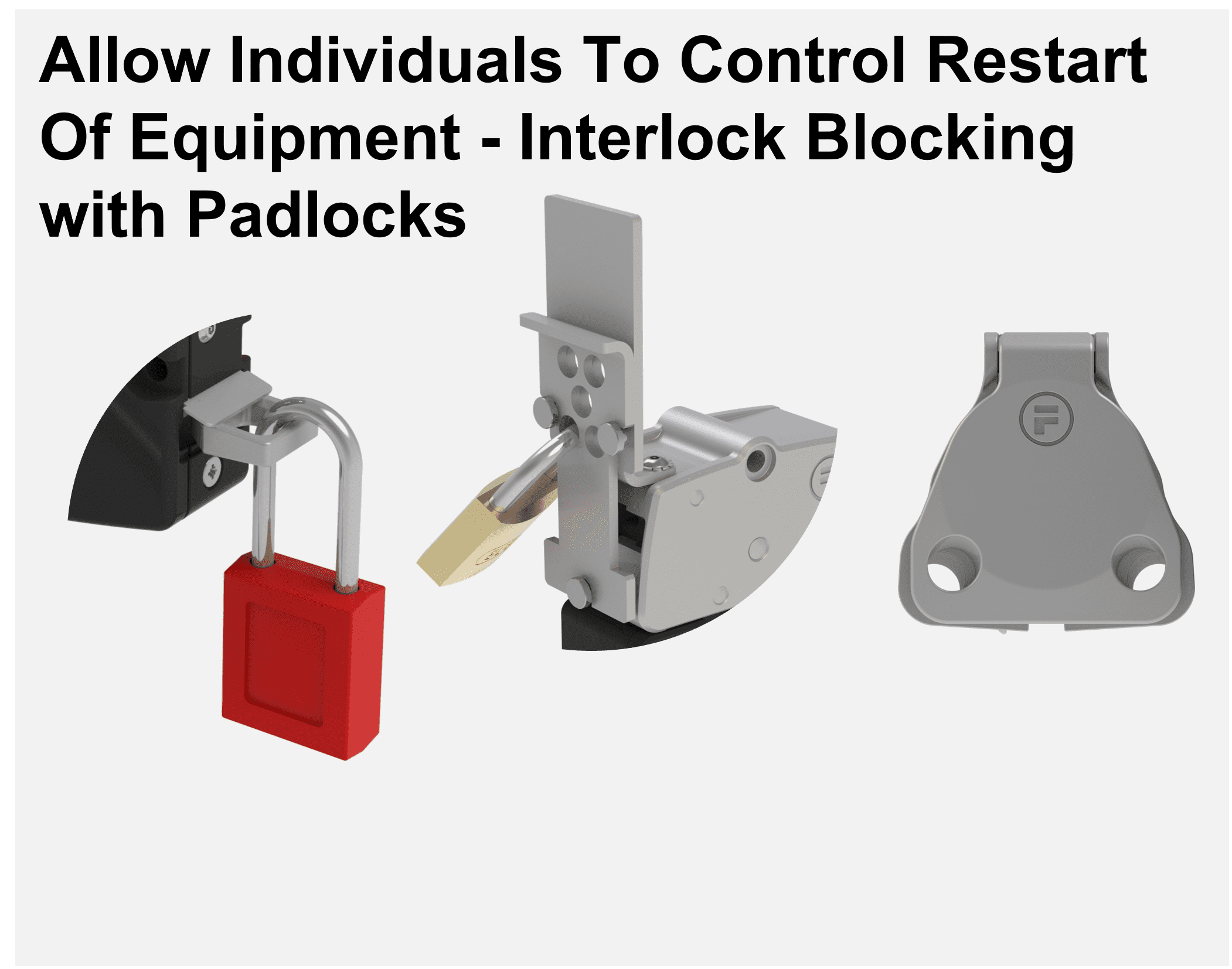

Fixed perimeter guarding has the potential to reduce the manufacturing footprint, it has the added advantage of preventing the egress of parts or material from the safeguarded space, and when interlocks with guard locking are used the operator cannot gain access to the machine until it is in a safe state.

Presence sensing safety devices will work hand in hand with fixed guarding and it has its place, but the reality is that fixed guarding is here to stay in the modern manufacturing environment and will also help machine designers reduce their manufacturing footprint.

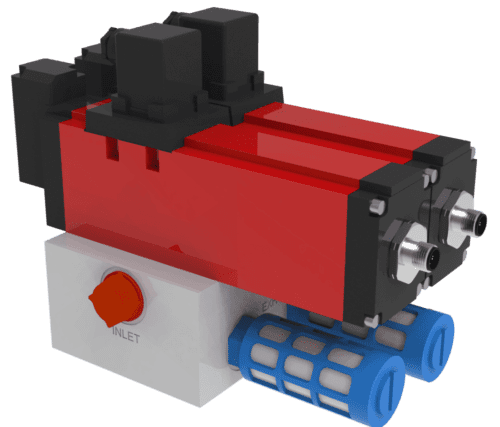

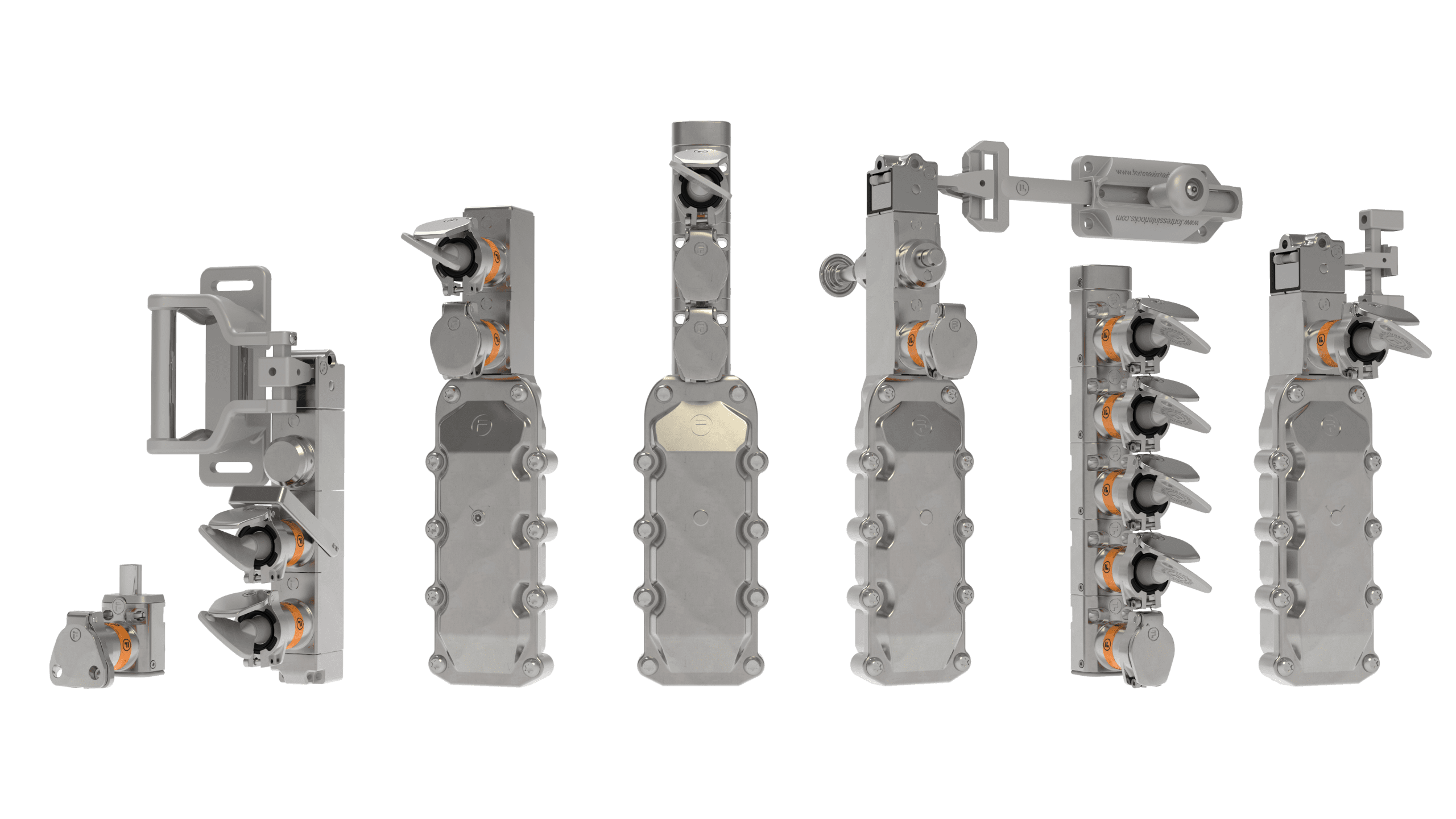

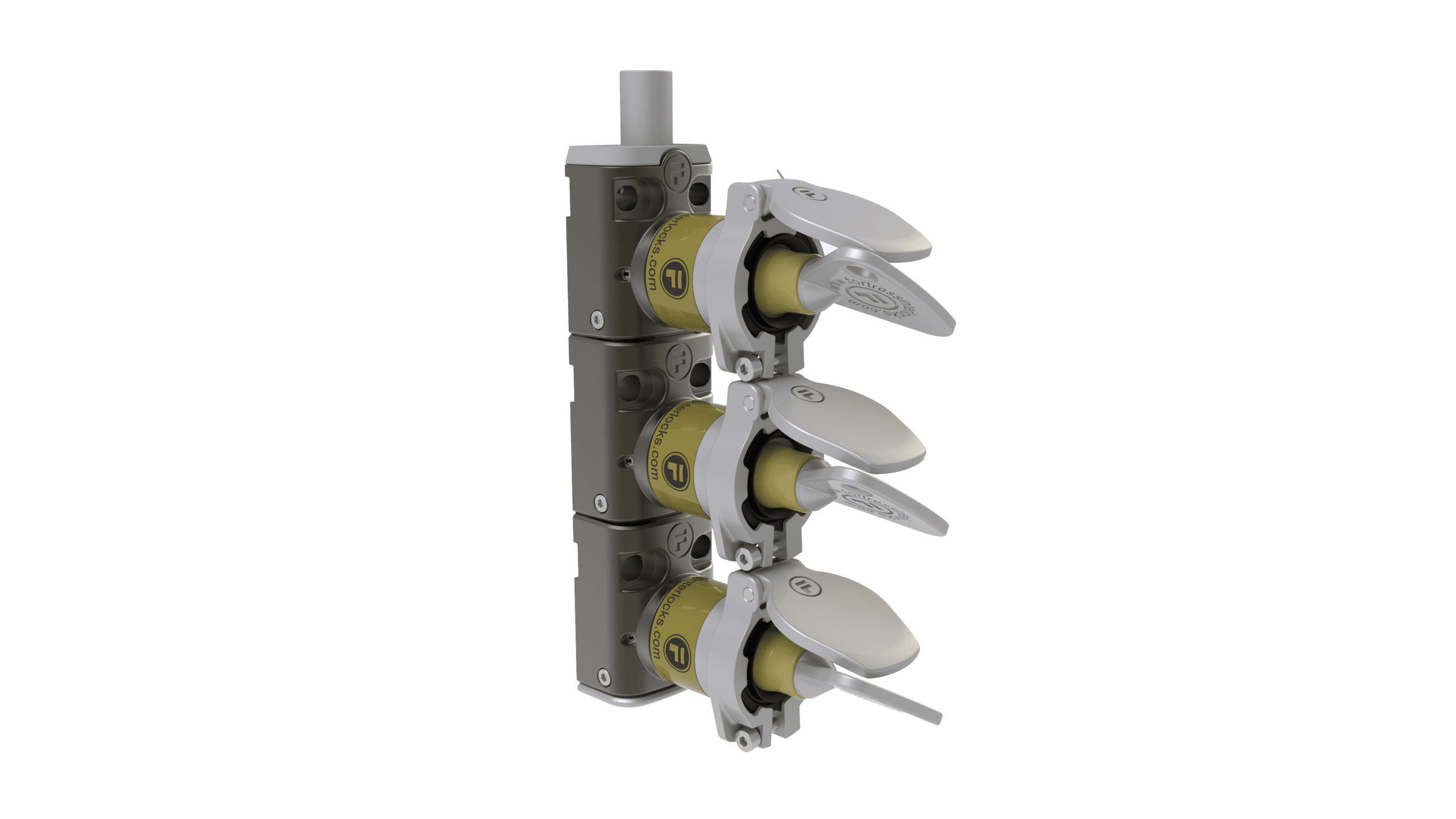

Products Mentioned in this Article

mGard

Click Here to Download the Article

Click Here to Download the Article