A common question that is asked when designing machinery safeguarding systems with supplementary release is “Do I need to allow operators to exit the safeguarded space through a locked access point?”

The functionalities that perform such a requirement are specified in ISO14119 (2013) Interlocking devices associated with guards — Principles for design and selection, but it is to the Risk Assessment and risk reduction standard ISO12100 we must turn to address the question of whether they are required.

ISO12100 (2010)

ISO12100 (2010) General principles for design — Risk assessment and risk reduction specify the basic terminology,

principles and methodology for achieving safety in the design of machinery. This standard is useful as it guides the

reader through the risk assessment process and the selection of safeguarding methods.

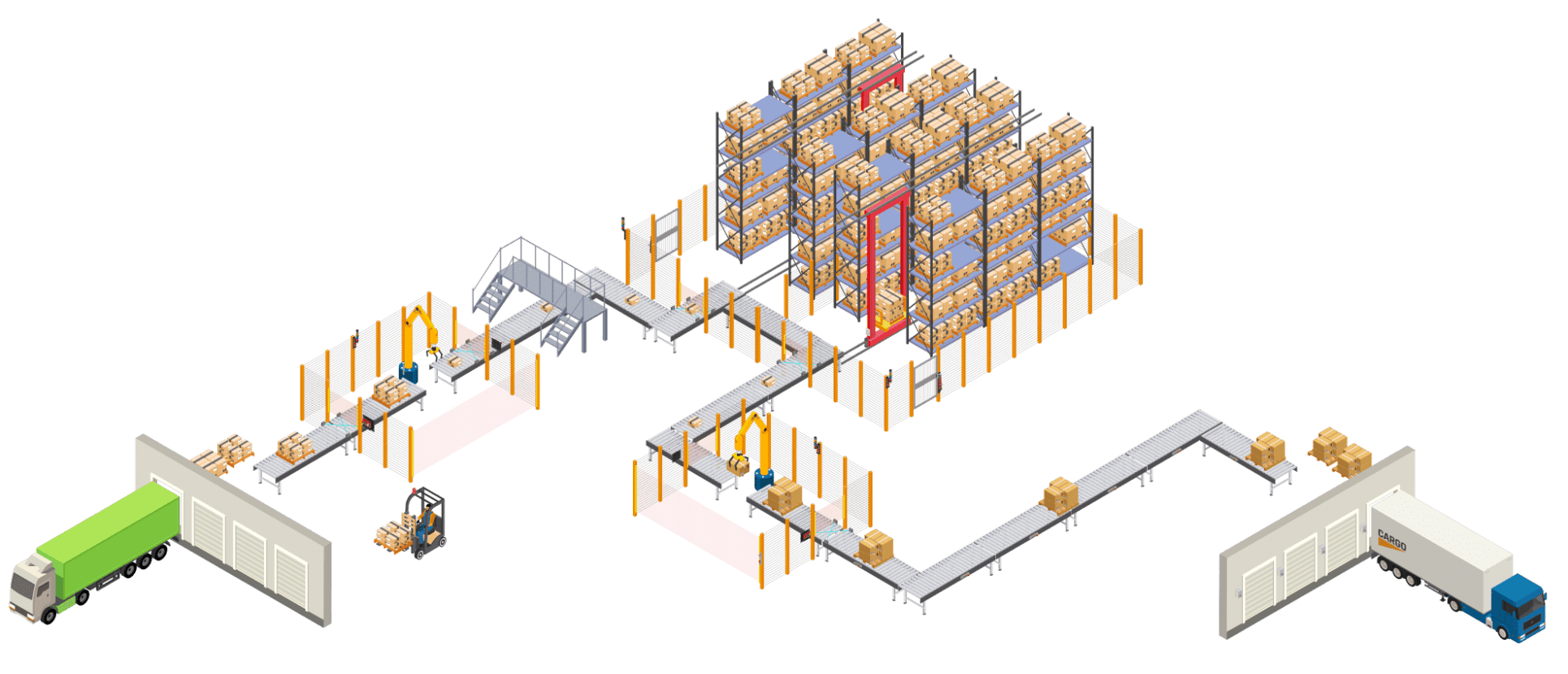

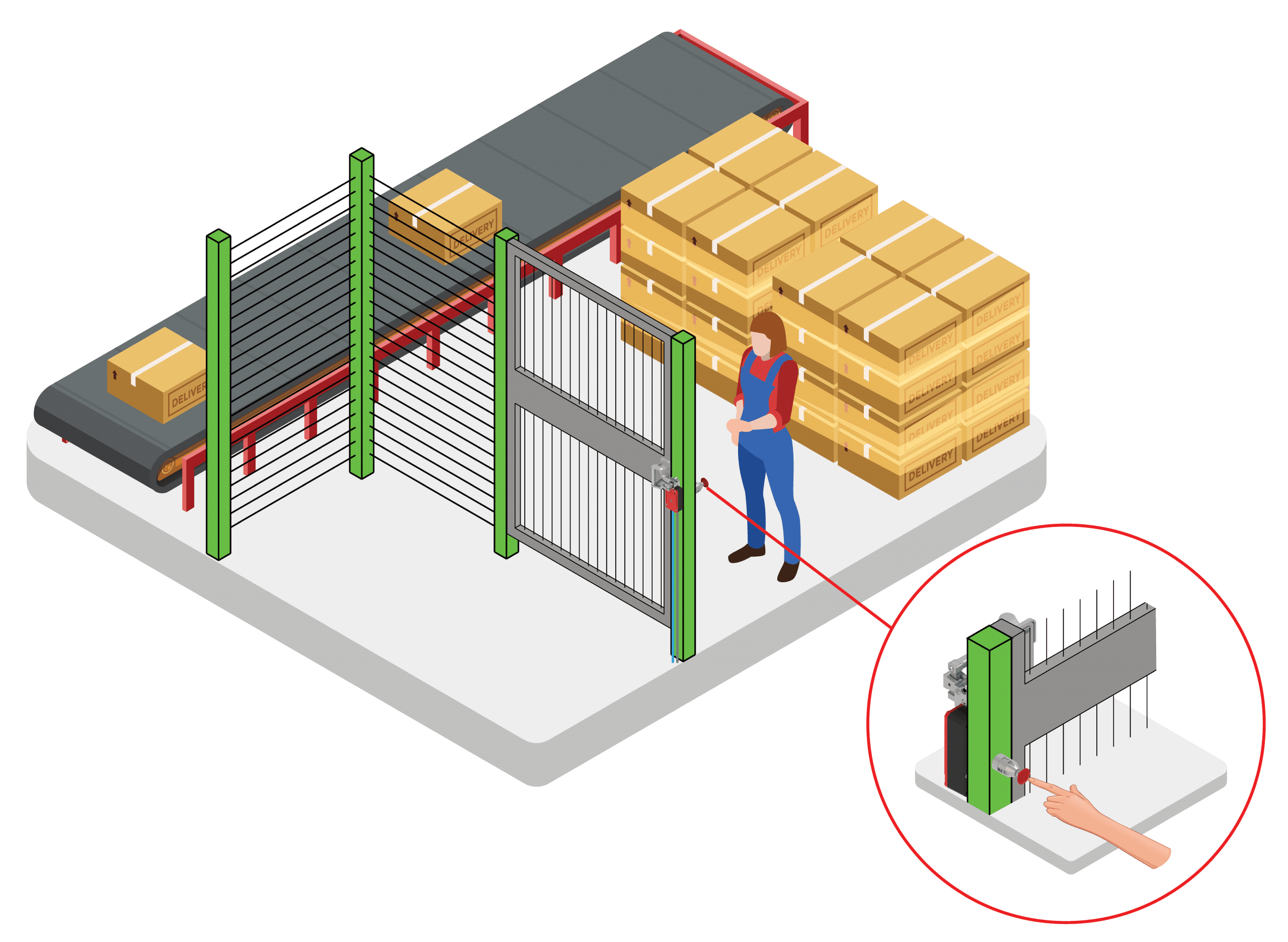

Paragraph 6.3.5.3 — Measures for the escape and rescue of trapped persons – will be the relevant section if the risk

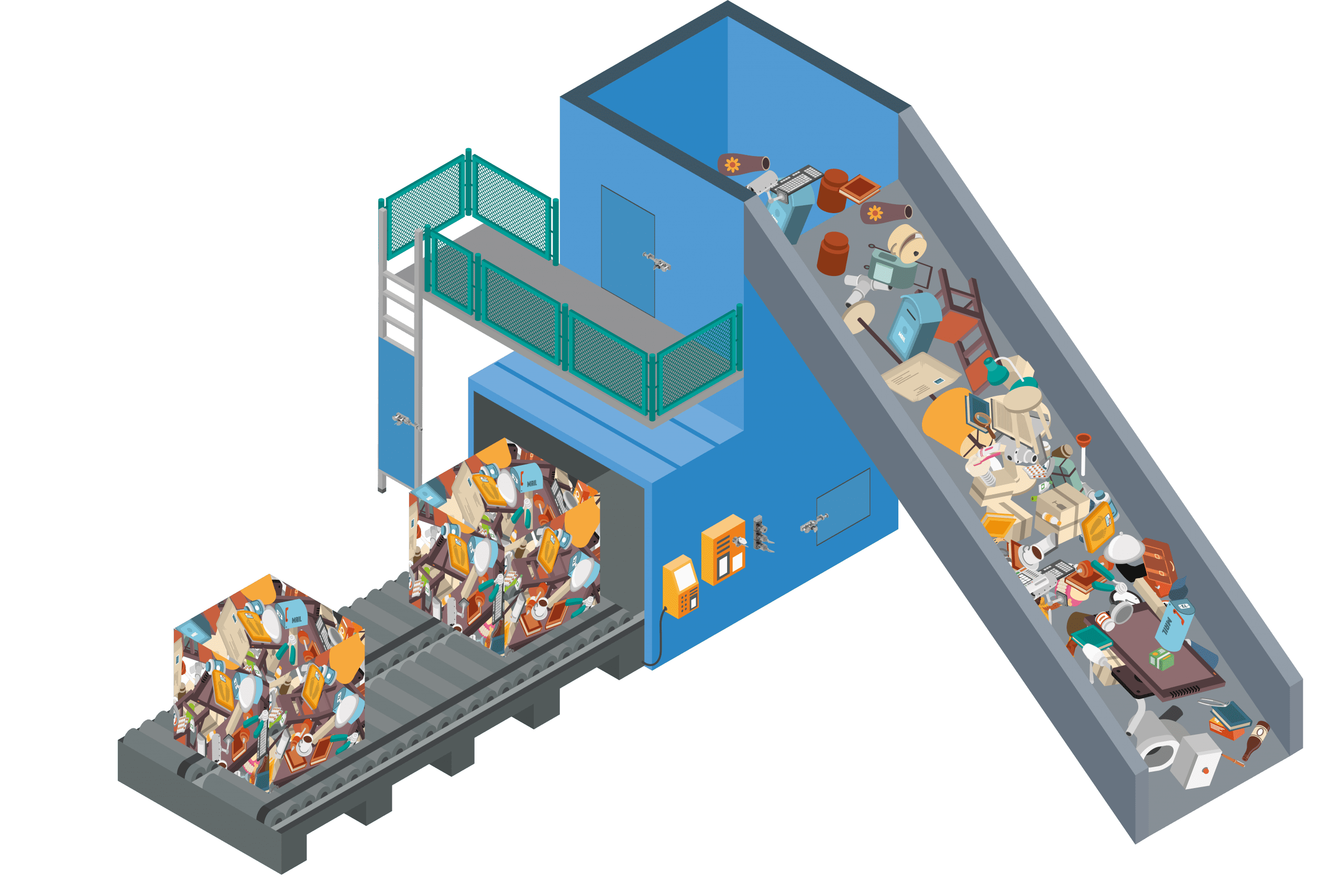

assessment identifies the risk of an operator becoming trapped within the safeguarded space when guard locking has been utilised. In this scenario the operator might need to exit the safeguarded space if a hazard occurs via the machine restarting for example. The operator may in turn be required to exit through a different interlocked guard to the one used for entry as hazards can occur preventing exit through the entry point.

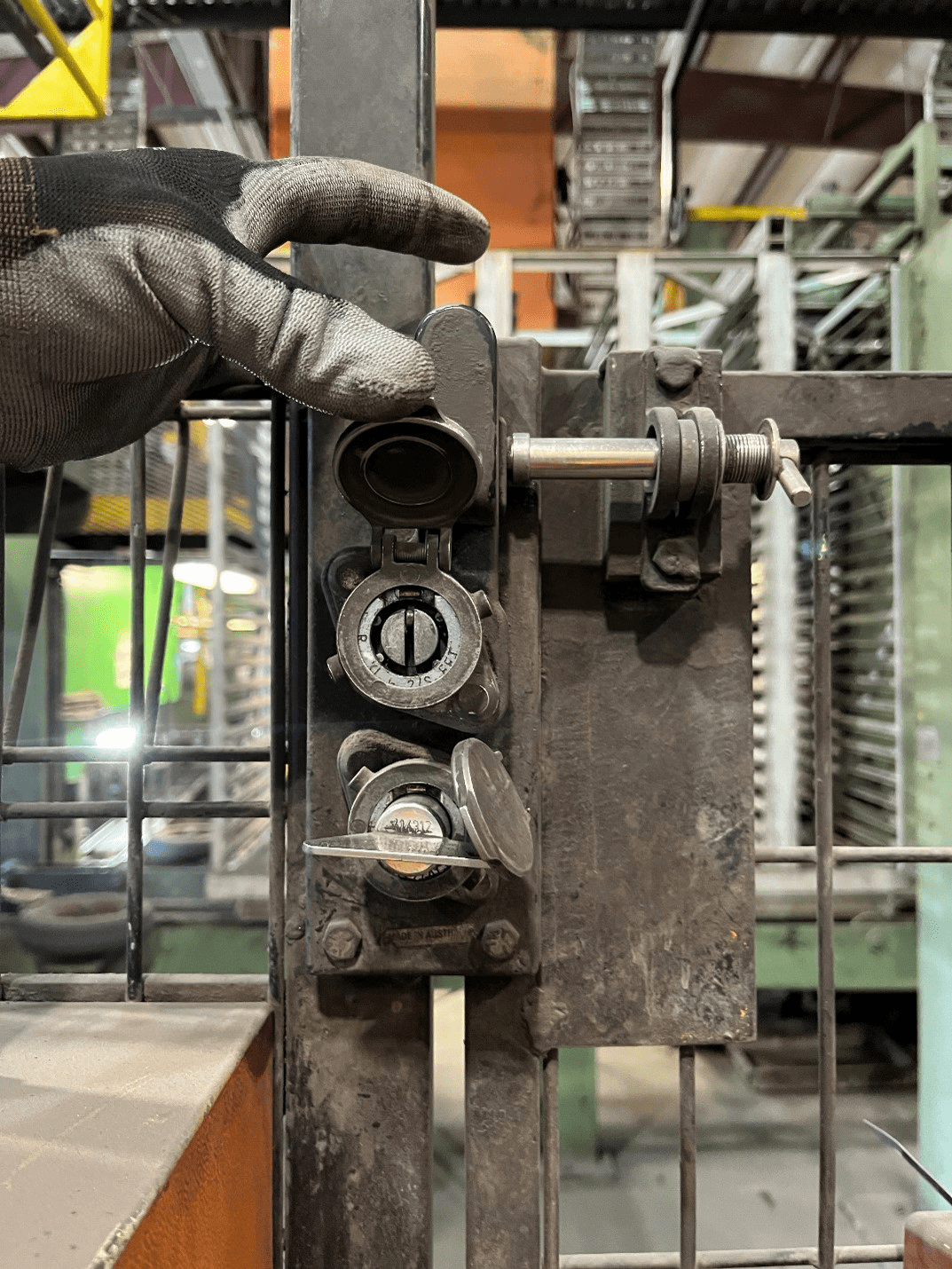

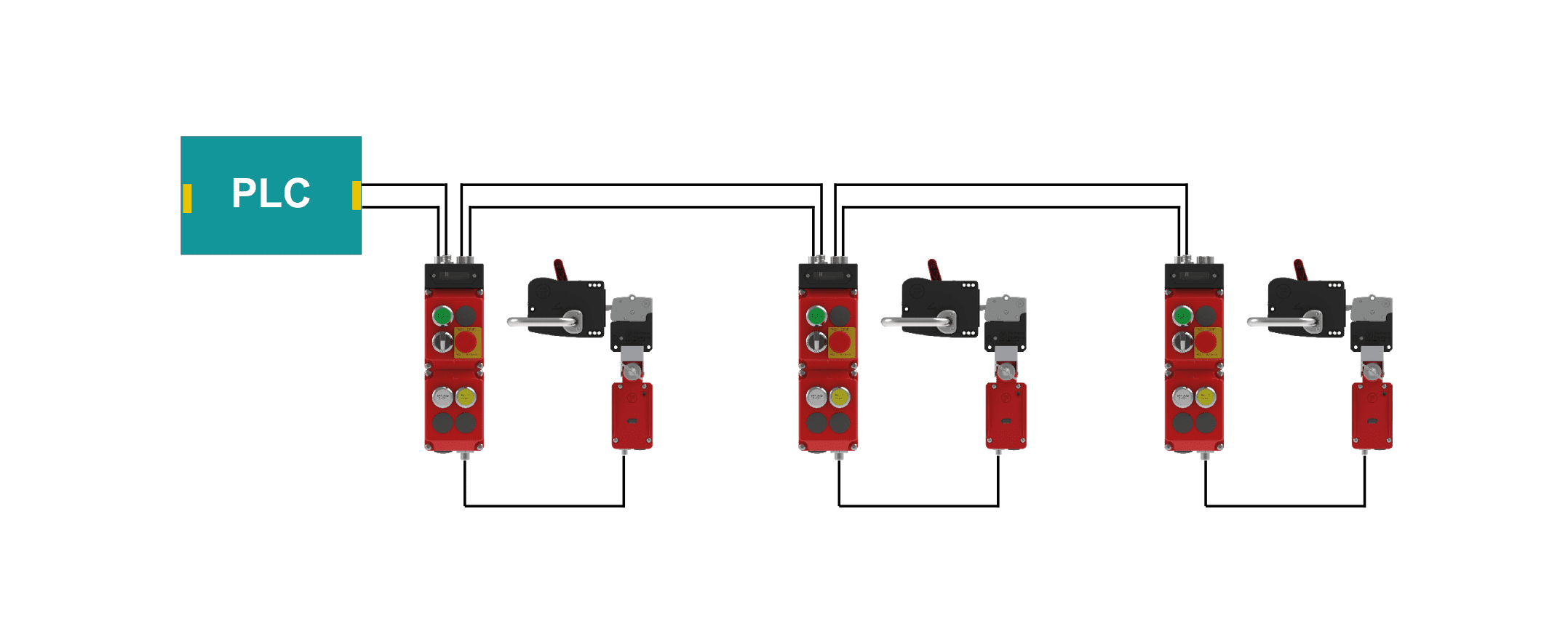

The use of “Personnel Keys” (keys released from trapped key interlocking devices) can be used to protect operators

entering the safeguarding space and thus substantially reduce the risk of an operator becoming trapped inside locked

guards. ISO/TS 19837 (2018) Trapped key interlocking devices — Principles for design and selection covers this

extensively and clarifies where personnel keys are not a substitute for all supplementary release functions. The

examples in the annex are particularly useful.

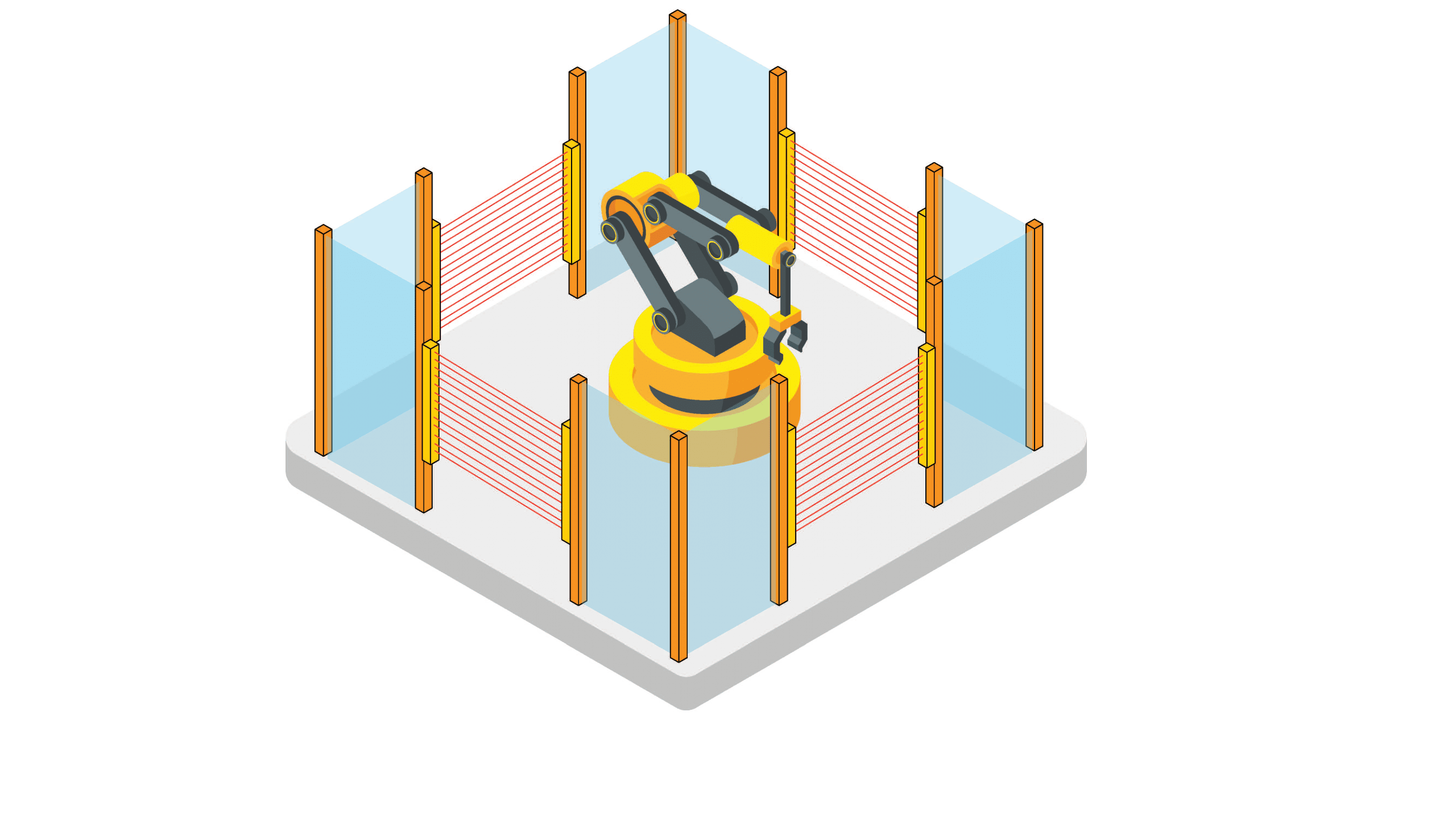

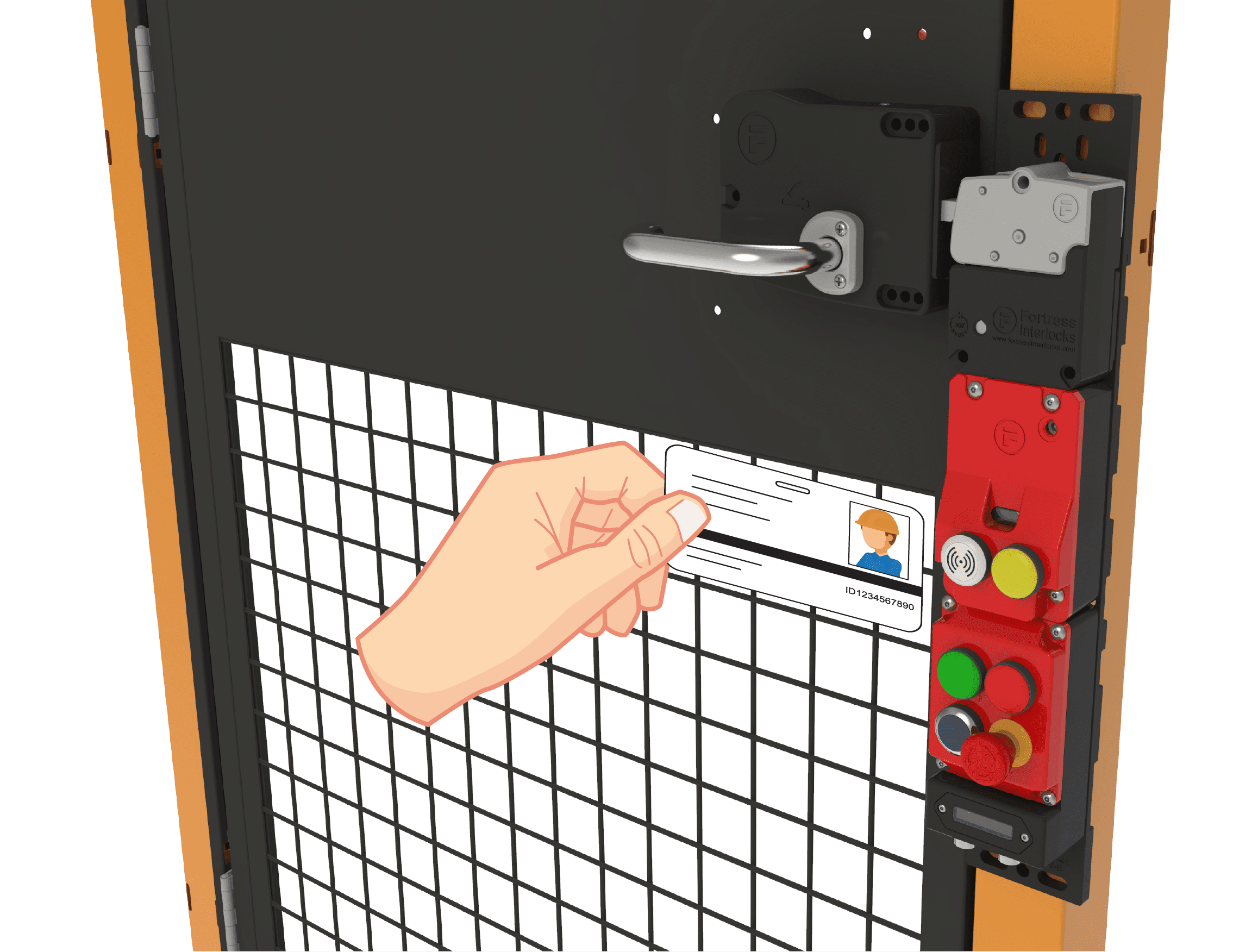

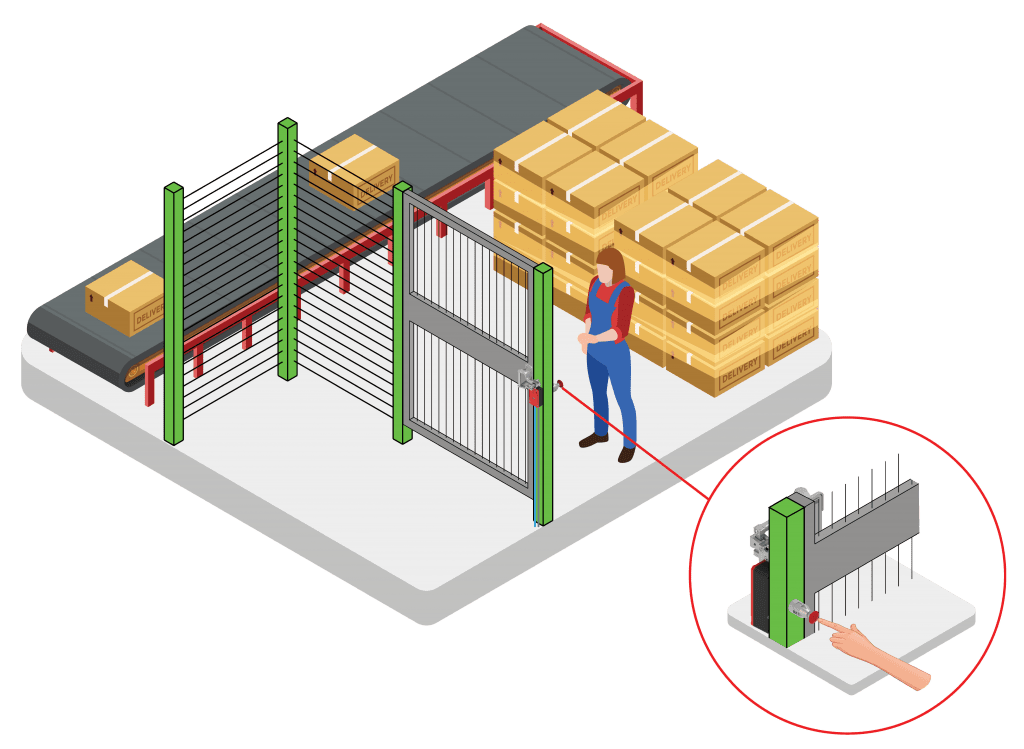

If the need for exit is established, it is ISO14119 (2013) that provides the specific guidance on the type and implementation of exit. In section 5.7.5 Supplementary release of guard locking there are three types of exit:

If the need for exit is established, it is ISO14119 (2013) that provides the specific guidance on the type and implementation of exit. In section 5.7.5 Supplementary release of guard locking there are three types of exit:

In all cases actuation initiates a stop command. The full requirements are laid out in the paragraphs within section 5.7.5. It is important to note that the unlocking means is manually operated and acts directly on the principle of the locking mechanism in the cases of emergency and escape release.

There is some confusion in the market place, particularly about emergency and escape release. Escape release is the most widely used function but there are clear cases where emergency release might be required. An example might be in an integrated manufacturing system where an operator is incapacitated some distance away from an open entry point to a safeguarded space and entry must be gained through another interlocked guard. This emergency release functionality can take the form of a knob override on an interlock in these cases.

Another critical issue sometimes forgotten when considering supplementary release guard locking is the system stopping time. The operation of Escape, Emergency or Auxiliary release will allow access to the hazard regardless of any machine run down time and this must be taken into account during the risk assessment process as hazards may exist for some time after the release of the locked entry point.

Products Mentioned in this Article

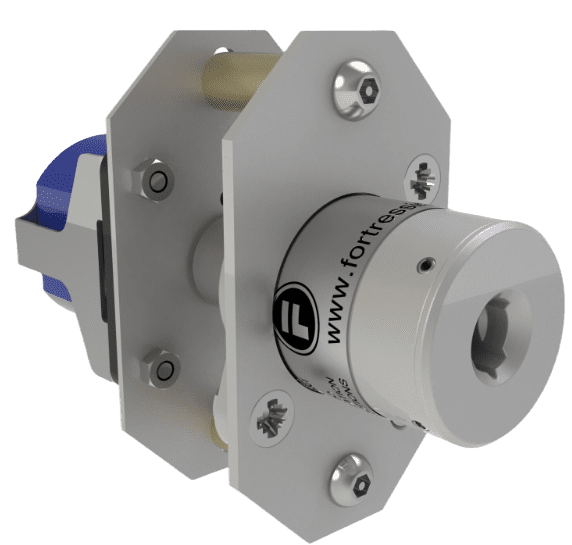

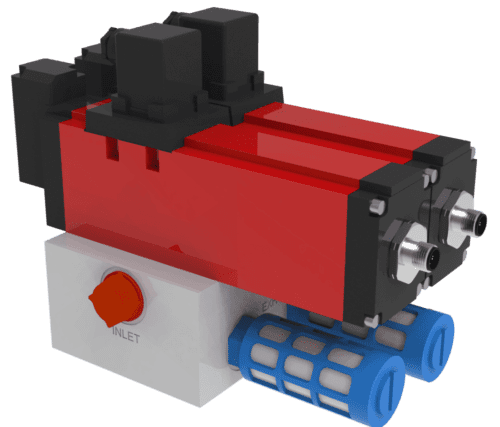

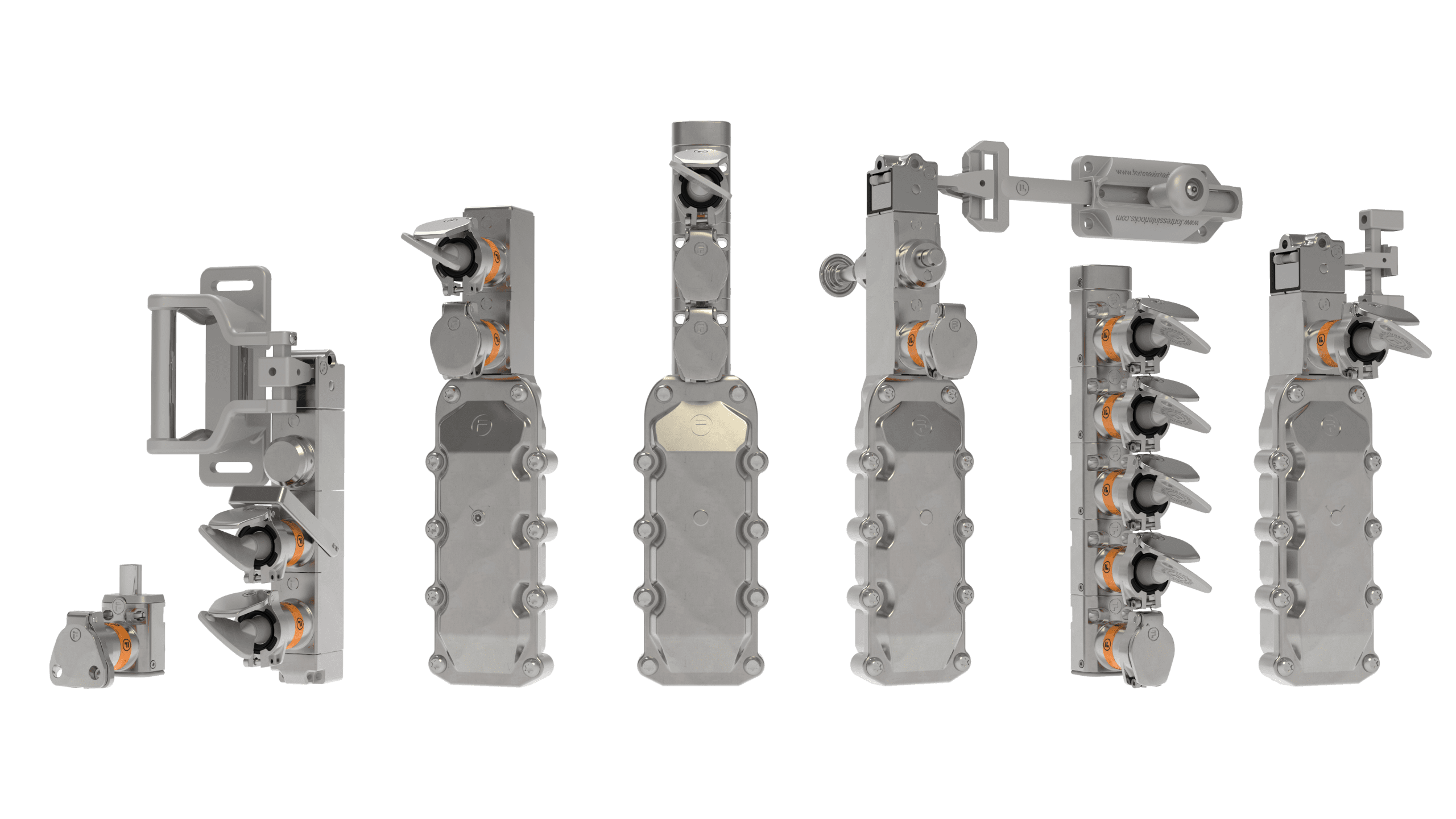

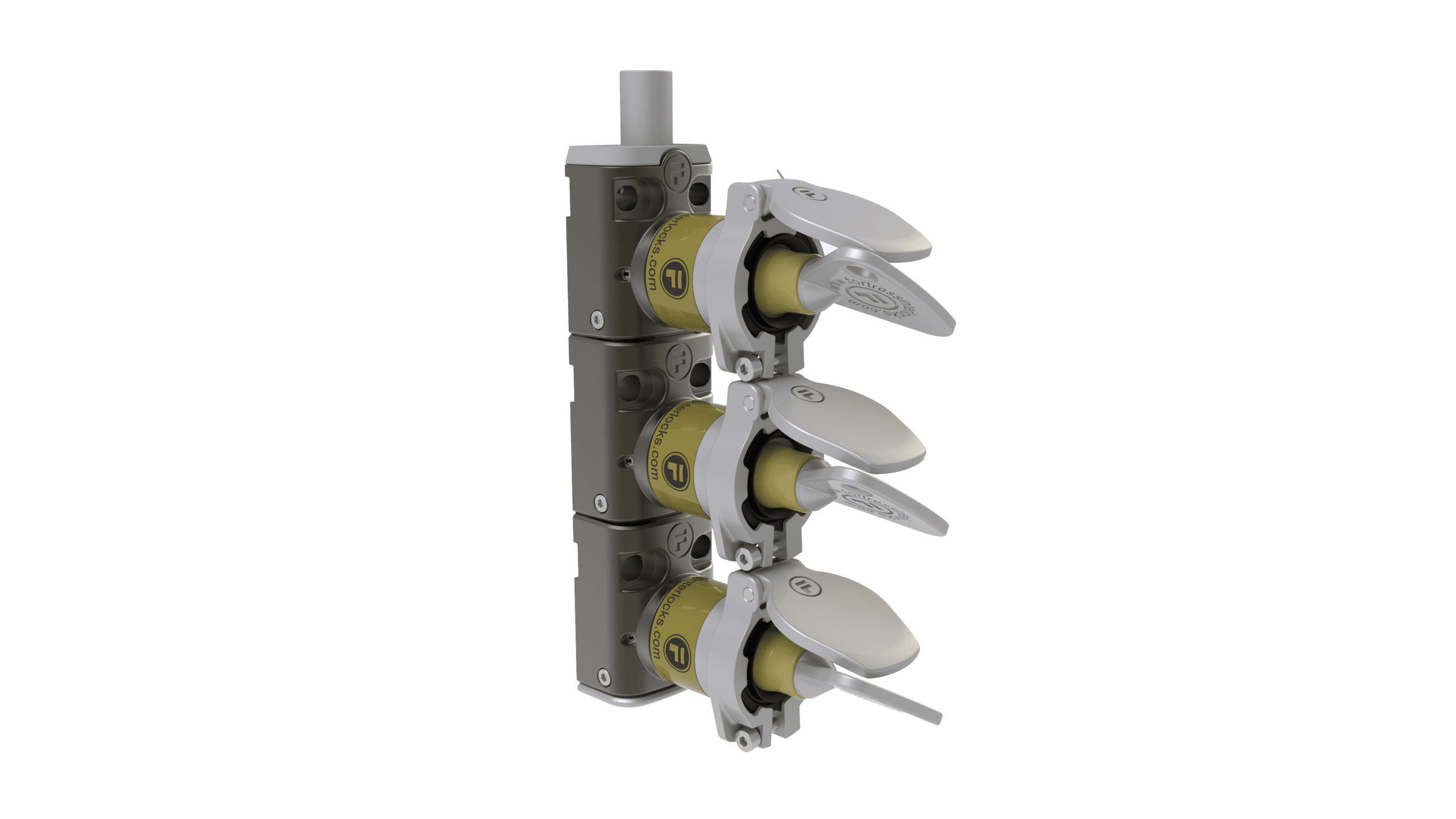

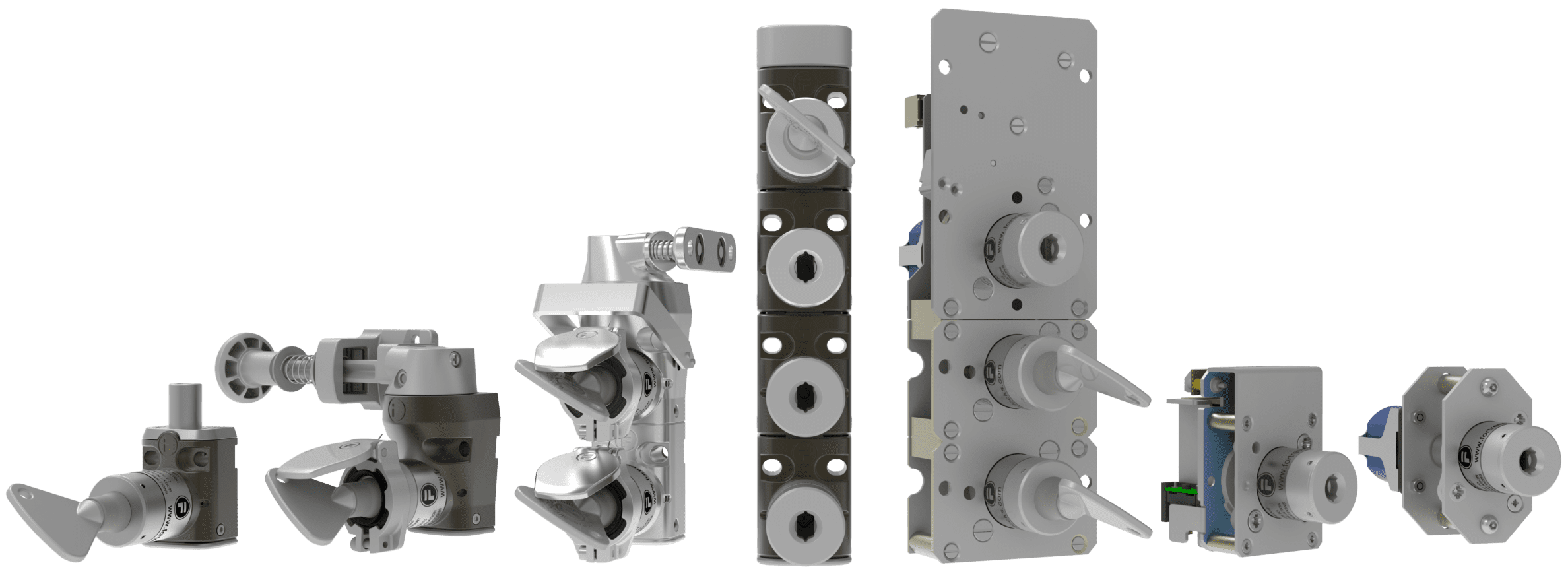

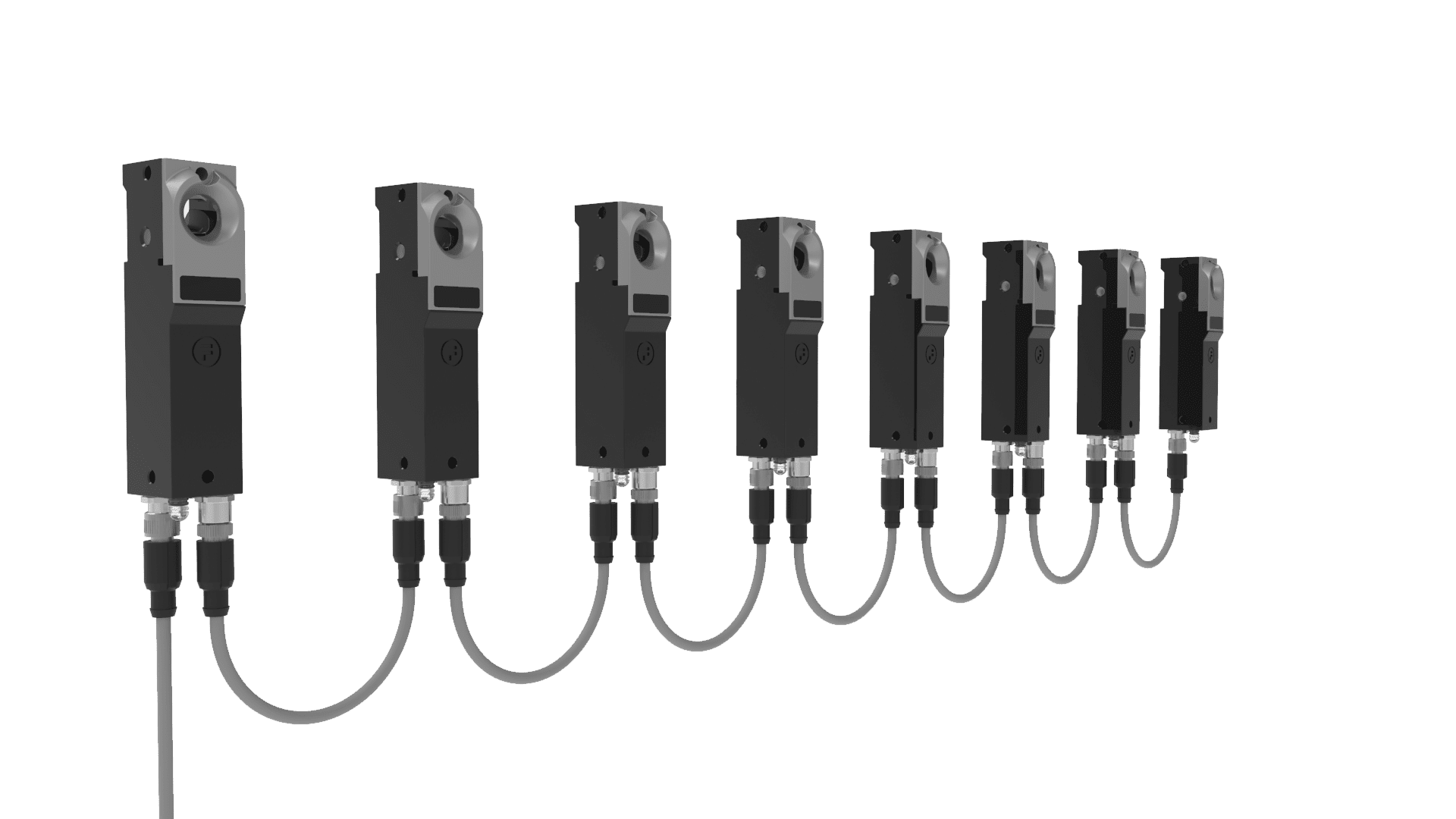

amGard pro

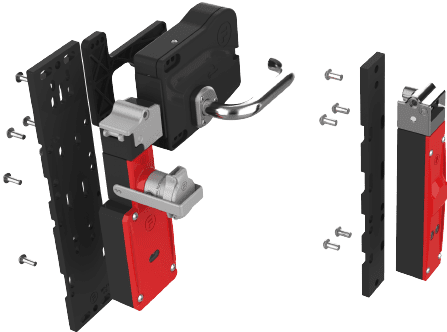

mGard

Click Here to Download the Article

Click Here to Download the Article